Ingersoll Rand D-Series Non-Cycling Refrigerated Air Dryer

INTRODUCTION

This manual is an integral part of the dryer you bought, and must remain with the machine even if this will be resold. It is highly recommended that the qualified*personnel for installation, maintenance and/or control will fully comply with the contents of this manual and the prevention and safety rules in force in the country where the system will be used. In this way, not only the usage of the machine will be rational, but also the service will result cost effective. In case your dryer will present any kind of problem, please contact your local authorized Ingersoll Rand distributor. Please note that, when necessary, the use of original spare parts will ensure efficiency and long duration to your dryer. Due to the continuous technological evolution, Ingersoll Rand reserves the right to modify the specifications contained in this manual without giving previous notice.

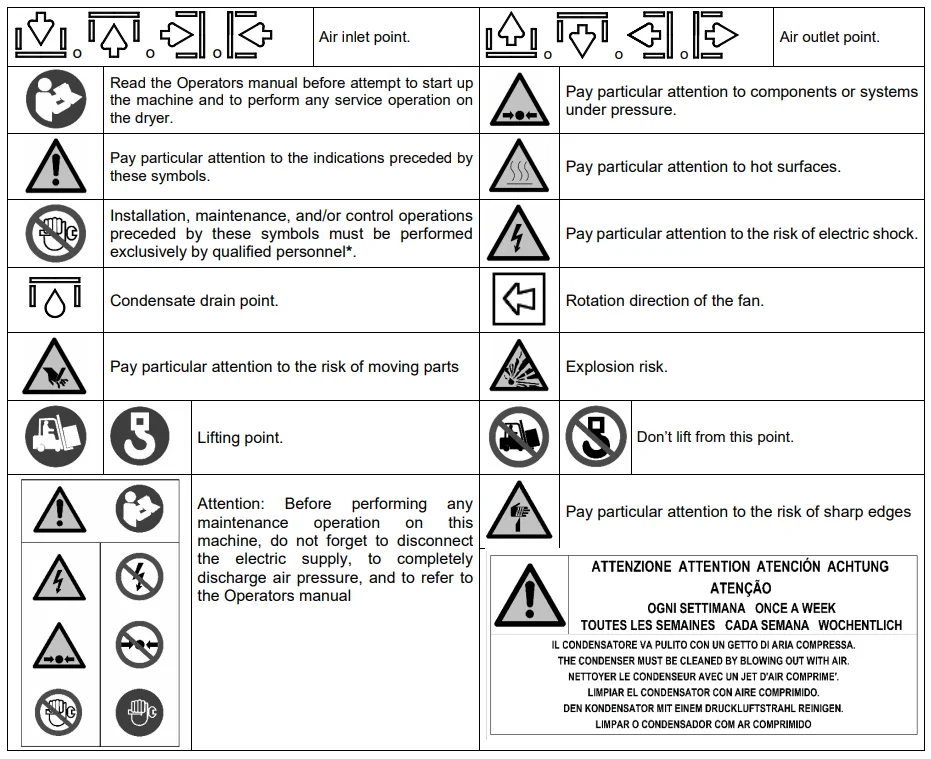

SYMBOLS AND LABELS USED IN THE MANUAL AND ON THE DRYER

* Qualified personnel must be trained and certified in accordance with local laws and regulations.

WARRANTY

The Company warrants that the equipment manufactured by it and delivered hereunder will be free of defects in material and workmanship for a period of twelve months from the date of placing the Equipment in operation or eighteen months from the date of shipment from the factory, whichever shall first occur. The Purchaser shall be obligated to promptly report any failure to conform to this warranty, in writing to the Company in said period, whereupon the Company shall, at its option, correct such nonconformity, by suitable repair to such equipment or, furnish a replacement part F.O.B. point of shipment, provided the Purchaser has stored, installed, maintained and operated such Equipment in accordance with good industry practices and has complied with specific recommendations of the Company. Accessories or equipment furnished by the Company, but manufactured by others, shall carry whatever warranty the manufacturers have conveyed to the Company and which can be passed on to the Purchaser. The Company shall not be liable for any repairs, replacements, or adjustments to the Equipment or any costs of labor performed by the Purchaser or others without Company’s

prior written approval.

The effects of corrosion, erosion, and normal wear and tear are specifically excluded. Performance warranties are limited to those specifically stated within the Company’s proposal. Unless responsibility for meeting such performance warranties are limited to specified tests, the Company’s obligation shall be to correct in the manner and for the period of time provided above. THE COMPANY MAKES NO OTHER WARRANTY OR REPRESENTATION OF ANY KIND WHATSOEVER, EXPRESSED OR IMPLIED, EXCEPT THAT OF TITLE, AND ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE ARE HEREBY DISCLAIMED. Correction by the Company of nonconformities, whether patent or latent, in the manner and for the period of time provided above, shall constitute fulfillment of all liabilities of the Company for such nonconformities, whether based on contract, warranty, negligence, indemnity, strict liability or otherwise, with respect to or arising out of such Equipment. The Purchaser shall not operate Equipment which is considered to be defective, without first notifying the Company in writing of its intention to do so. Any such use of Equipment will be at Purchaser’s sole risk and liability. Note that this is the Ingersoll Rand standard warranty. Any warranty in force at the time of purchase of the equipment or negotiated as part of the purchase order may take precedence over this warranty.

GENERAL INFORMATION

FUNCTIONAL DESCRIPTION

Ingersoll Rand refrigerated air dryers remove moisture from compressed air. Moisture is detrimental to pneumatically operated appliances, controls, instruments, machinery and tools. Compressed air enters the patented aluminum heat exchanger, where it is cooled down to the dew point temperature in two different stages: In the first air/air sector, compressed inlet air is cooled thanks to the colder compressed air coming out counterflow from the condensate separator. In the second refrigerant/air sector, compressed air temperature is further lowered to the dew point temperature. During this two stages almost all the oil and water vapours contained in compressed air are condensed to liquid and are successively be separated from the compressed air in the condensate separator and drained out by the automatic drain. At this point the obtained cold air re-enters the counterflow of the initial air/air exchanger and it is reheated by the inlet hot ai,r with the consequence of energy recovering and also reduction of the relative humidity contained in the outflowing air. This dryer can be easily installed into various pneumatic systems in which dry air is required or desired. Please refer to the Principles of Operation for complete operating details. The dryer comes provided with all the control, safety and adjustment devices; therefore, no auxiliary devices are needed. A system overload not exceeding the maximum operative limits can worsen the operational performance of the dryer (high dew point), but it will not affect its safety. The electric diagram (attachment B) shows the minimum protection degree IP 42. Improper grounding can result in electrical shock and can cause severe injury or death. This product must be connected to a grounded, metallic, permanent wiring system or an equipment-grounding terminal or lead on the product. All grounding must be performed by a qualified electrician and comply with national and local electrical codes. In the event of an electrical short circuit, grounding reduces the risk of electric shock by providing an escape wire for the electric current. Ground must be established with a bare grounding wire sized according to the voltage and minimum branch circuit requirements. Ensure good bare metal contact at all grounding connection points, and ensure all connections are clean and tight. Check grounding connections after initial installation and periodically thereafter to ensure good contact and continuity have been maintained. Check with a qualified electrician or service technician if the grounding instructions are not completely understood, or if in doubt as to whether the product is properly grounded. This dryer is designed to work only with compressed air. For a different use, please contact your distributor, Ingersoll Rand.

INSTALLATION

ACCEPTANCE AND HANDLING

Upon receiving your Ingersoll Rand air dryer, please inspect the unit closely. If rough handling is detected, please note it on your delivery receipt, especially if the dryer will not be uncrated immediately. Then, obtain the freight carrier’s signed agreement to any noted damages: this is a precondition for any insurance claims by the customer. It is mandatory to keep the dryer always in a vertical position, as indicated by the symbols present on the packaging. For handling, use devices having sufficient capacity for the weight of the machine. Remove the packaging after having positioned the dryer in the installation site. For unpacking, refer to section 2.3. Under no circumstances should any person attempt to lift heavy objects without proper lifting equipment (i.e., crane, hoist, slings or forklift). Lifting any unit without proper lifting equipment may cause serious injury. Use forklift channels where provided.

STORAGE AND INSTALLATION LOCATION

If not in use, the dryer can be stored in its packaging in a dust-free and protected site between 32°F (0°C) and 120 °F (50 °C), and a specific humidity not exceeding 90 %. Should the stocking time exceed 12 months, please contact your local Ingersoll Rand authorized distributor. If the dryer is not used, it will be placed in a site with the following conditions:

- The machine must be protected from atmospheric agents and not directly exposed to sunlight.

- A seating base flat and capable of holding the weight of the machine.

- Ambient temperature complying with the nominal data of the dryer.

- The dryer should be located in a clean area, without a forced air draft that can affect the fan control system.

- Make sure to leave sufficient clearance (20 inches, 500 mm) around the dryer in order to allow an adequate cooling of the machine and for maintenance and/or control operations. The incoming air must be free from smoke or flammable vapours, which could lead to explosion or fire risks.

UNPACKING

The packaging is made of carton or of cellophane. We recommend that you keep the original packaging for the device in case it has to be transported to another location or sent to a service center. Dispose of the various packaging materials in compliance with the relevant rules locally in force.

- unpack the device, removing the strapping from the carton. Always wear safety gloves when using scissors or other tools to cut the straps or the cellophane.

- remove the carton or the cellophane;

- In case it’s necessary,y another handling of the device, refer to section 2.1;

- remove the pallet (if present);

- Remove the operating manual, accessories, and key from the device.

START UP

Ensure that the dryer is bypassed, or there is no load on the cooler. Switch on the main electrical isolation switch (if present). The control panel will show the message OFF, indicating that the line and control voltages are available.

Start sequence

The dryer will initially start by pressing and holding the local ON/OFF button. The start sequence will progress only if there are no active alarms. The compressor motor will start AFTER 120 SECONDS. The fan motor will start simultaneously with the compressor for D225-600IN-A models, after 30 seconds for smaller models. Mod.D780-950IN-A: The fan motor is controlled only by the fan pressure switch.

Stop sequence

The dryer can be stopped locally from the control panel. After having pressed the ON/OFF switch for 1 second, the compressor and the fan motor (only the compressor on D780-950IN-A) keep on running for a further 10 seconds in order to rebalance the internal pressures. The dryer can also stopped due to an alarm or energy saving condition (ESA or ES2). Any alarm will de−energize the compressor, the fan motor can still run (only on D12-600IN-A), it depends on the type of alarm (see Display indications chapter). If the shutdown is due to an alarm, a message will blink on the display indicating the reason for the shutdown. Energy saving condition (ESA or ES2) occurs when the dew point stands below the set value for a long time in order to save energy and avoid heat exchanger freezing. This situation can happen when athe mbient temperature is low, and there is no compressed air load. Mod.D780-950IN-A: The fan motor is controlled only by the fan pressure switch.

Variable speed fan control (Mod. D12–600IN-A)

A patented microprocessor allows to adjust dryer’s cooling capacity by changing the fan motor speed. If the dew point is greater than the set value, the fan speed is increased; if the dew point is smaller than the set value, the fan speed is decreased. The range can be from 0 to 100% and the higher is the fan speed, the faster the fan LED blinks. You can read the exact value by pressing the UP button. If the velocity is 100% you will read FL (Full Load). Under load standard condition the fan speed is usually at 100%, if there is no load, the fan velocity can oscillate between 0 and 20%.

In models D225-600IN-A, in order to adjust the greater dryer’s cooling capacity, a hot gas by-pass valve cooperates with the variable speed system.

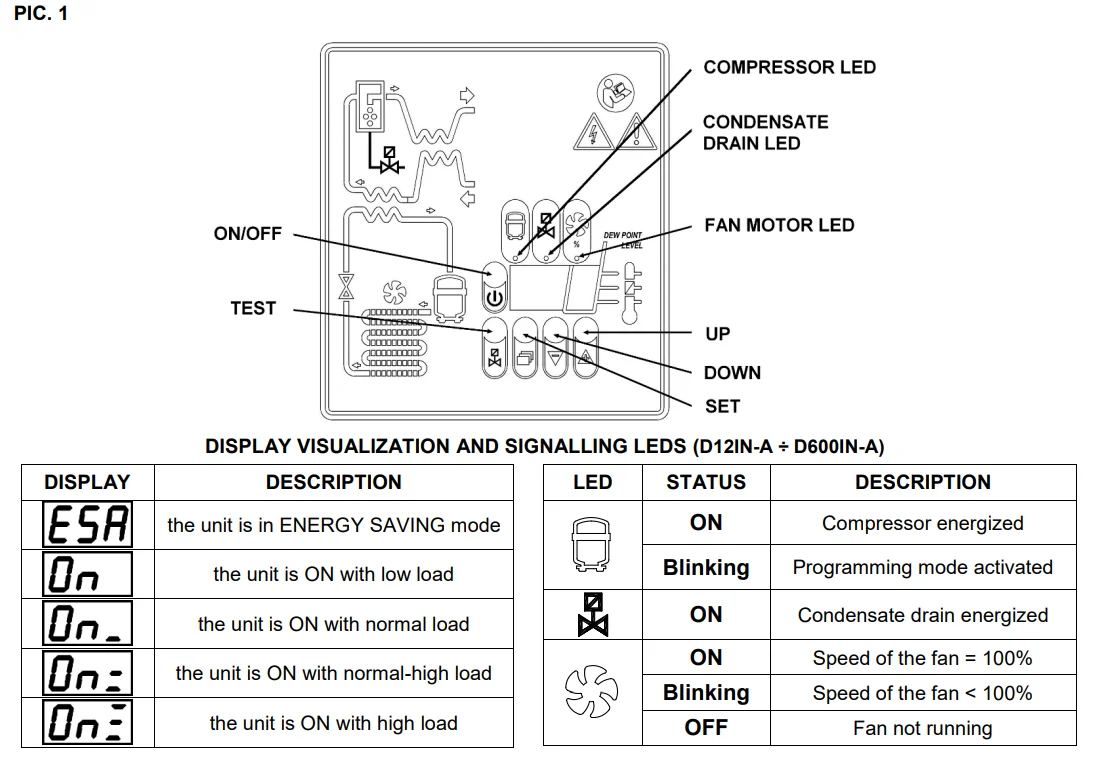

CONTROL PANEL

The dryers are provided with an electronic control system. All adjustments and resets can be performed by means of the digital panel located on the front of the dryer. The control panel is composed of 5 keys (ON/OFF, TEST, SET, DOWN, and UP) and a 3-digit display, with three signalling LEDs indicated by icons (PIC 1)

KEYS FUNCTION

- TEST: When pushed for 3 sec. During normal operation, it activates the condensate drain. (Not used on No loss condensate drain)

- SET: When pushed and released during normal operation, it displays the parameter C1. When pushed for 10 seconds, it allows to enter the C8 and C9 condensate drain parameters programming menu (see

relevant table). When pushed after having set new configuration values, it stores the applied modifications. - DOWN: When pushed while setting the drain set point, it decreases the displayed value of one unit per second, during the first 10 seconds, then of one unit every 0,1 sec. When pushed for 10 seconds during normal operation, it starts an automatic test cycle of the controller.

- UP: When pushed while setting the drain set point, it increases the displayed value of one unit per second, during the first 10 seconds, then of one unit every 0,1 sec.

- ON / OFF: Pressed, it activates or deactivates the dryer. When the dryer is deactivated, the display shows OFF.

NOTE: When the controller is in the OFF position, some parts of the dryer may still be energized. Therefore, for safety purposes, disconnect the electrical power before performing any operation on the machine.

CONDENSATE DISCHARGE PARAMETERS PROGRAMMING

Push the SET key for 10 seconds to enter the parameters configuration menu: the display will show in sequence the set point value, the code of the first modifiable parameter (C8) and its value). Only if strictly necessary, use the UP and/or DOWN keys to change the displayed parameter value. Press the SET key to store the previously changed parameter value or to browse the parameters without changing them. 15 seconds after the last performed operation, the controller will return automatically to the normal operation mode.

MAINTENANCE, TROUBLESHOOTING, AND DECOMMISSIONING

MAINTENANCE

Attention! Perform pressure test with inert gases only (helium, nitrogen).

Before attempting any maintenance operation, make sure that:

- No parts of the system are under pressure.

- No parts of the system are electrically powered.

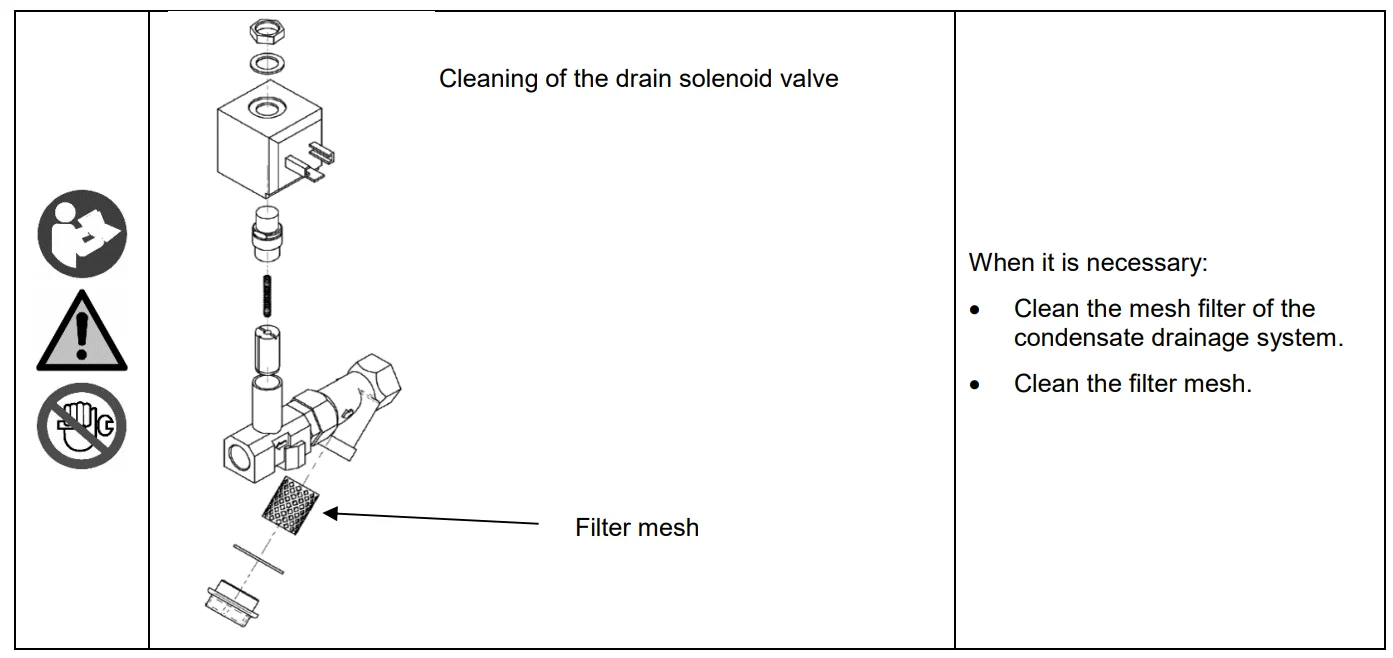

- WEEKLY OR EVERY 40 HOURS OF OPERATION

- Verify the temperature on the control panel display is acceptable.

- Visually check if the condensate is drained regularly.

- Clean the filter mesh of the condensate drain system.

- MONTHLY OR EVERY 200 HOURS OF OPERATION

- Clean the condenser with compressed air, taking care not to damage the condenser fins..

- At the end of the above mentioned operations, check if the dryer is working properly.

- Check the condition of any filters installed with the dryer. Replace elements as needed.

- YEARLY OR EVERY 2000 HOURS OF OPERATION

- Check if the flexible tube used for condensate drainage is damaged and replace it if necessary.

- Check if all connecting pipes are properly tightened and fixed.

- At the end of the above mentioned operations, check if the dryer is working properly.

- EVERY 24 MONTHS OR EVERY 4000 HOURS OF OPERATION (Mod. D780IN-A ÷ D950IN-A)

- Replace the fan pressure switch.

In case of replacement of one or more components of the device, dispose of it along with the eventual packaging of the replacement part, as reported in point 4.3.

- Replace the fan pressure switch.

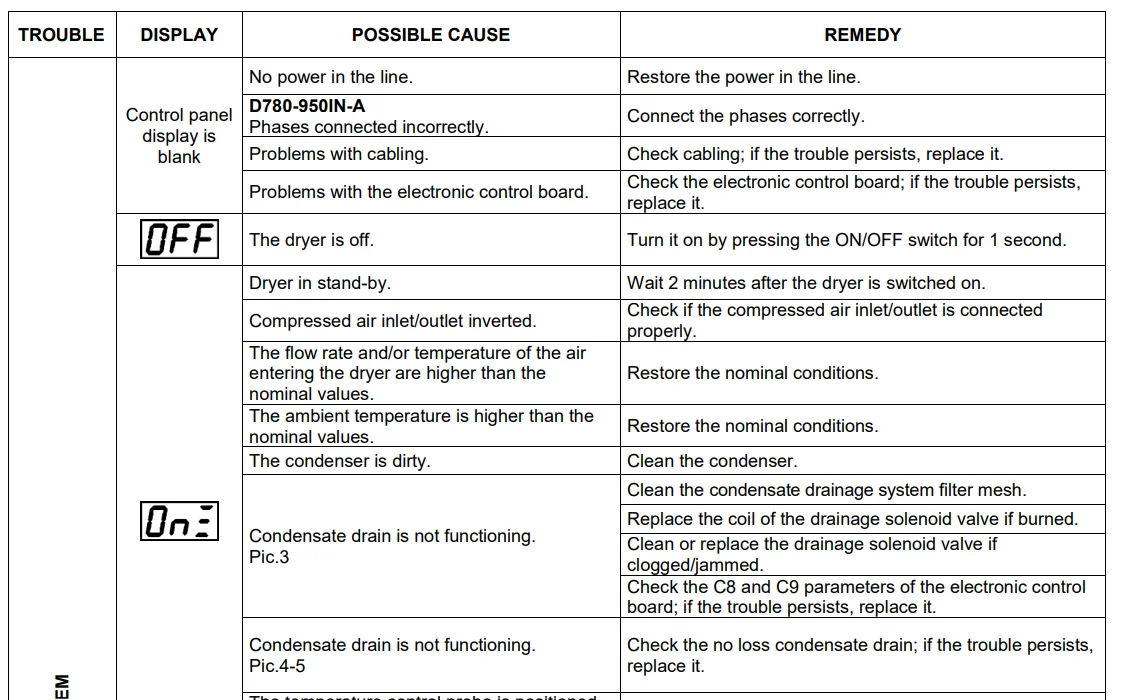

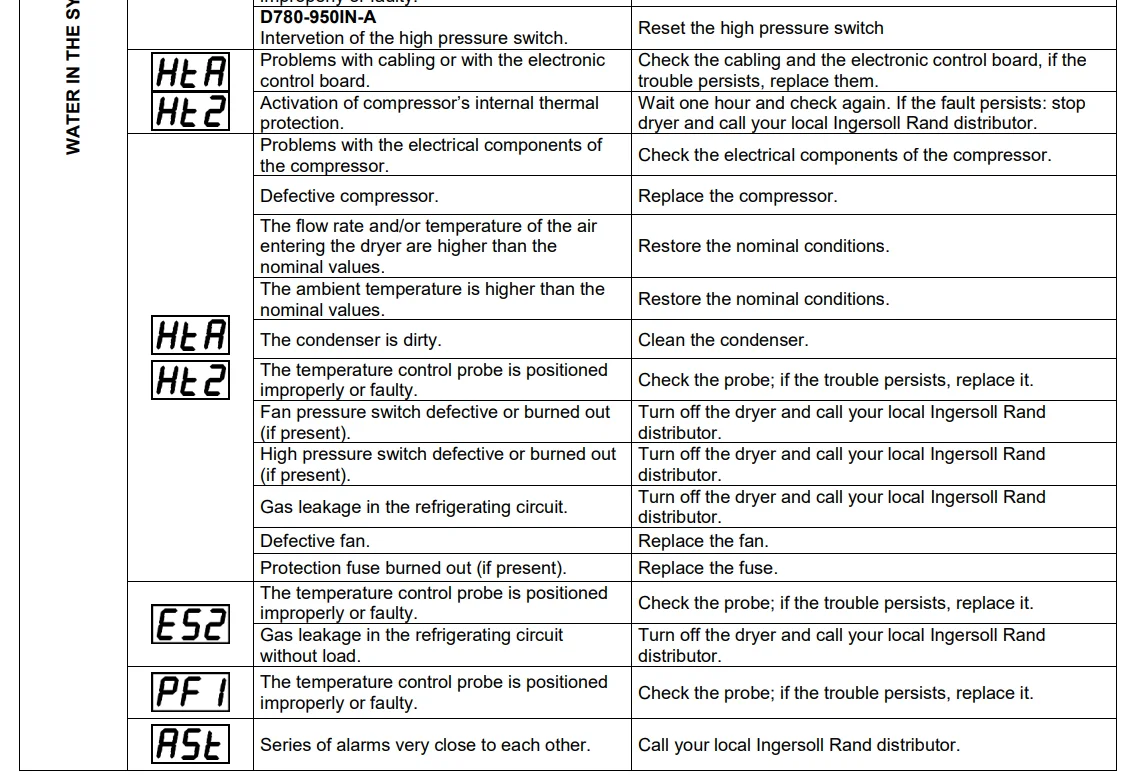

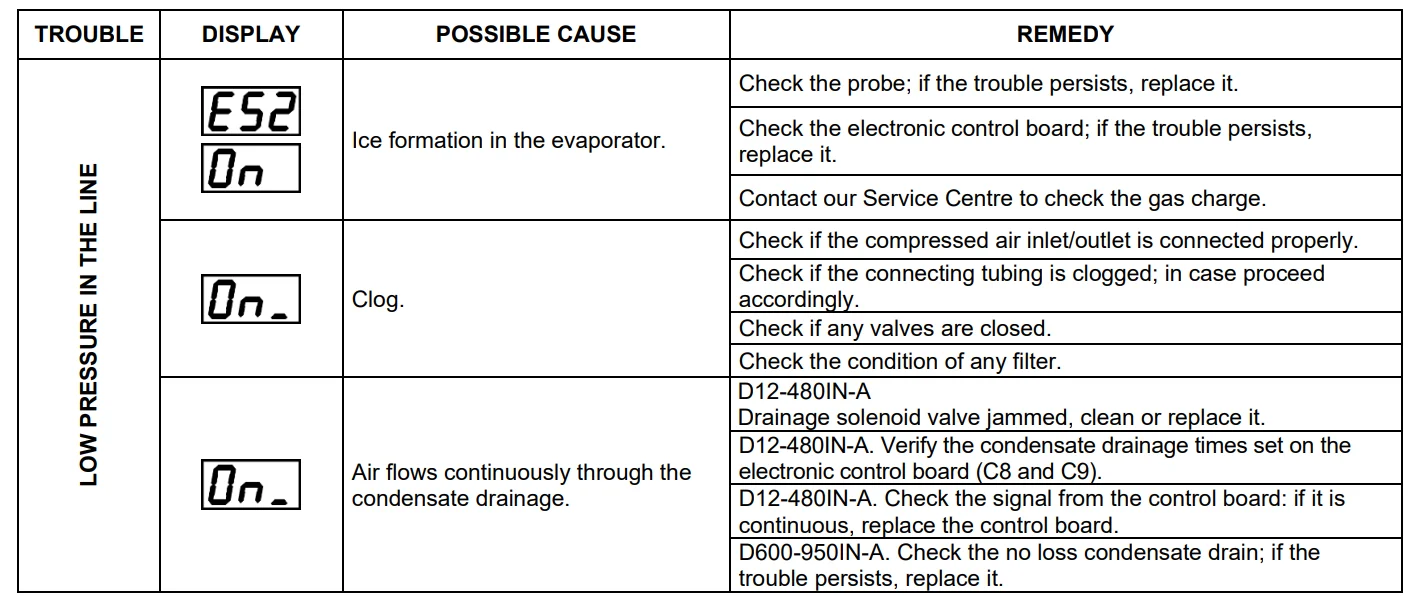

TROUBLESHOOTING

- Troubleshooting and eventual control and/or maintenance operations must be performed by qualified personnel.

- For maintaining the refrigerating circuit of the machine, contact a refrigeration engineer.

IMPORTANT: The temperature control probe is extremely delicate. Do not remove the probe from its position. In case of any kind of problem, please contact your local Ingersoll Rand distributor

Pic.3 drain solenoid valve

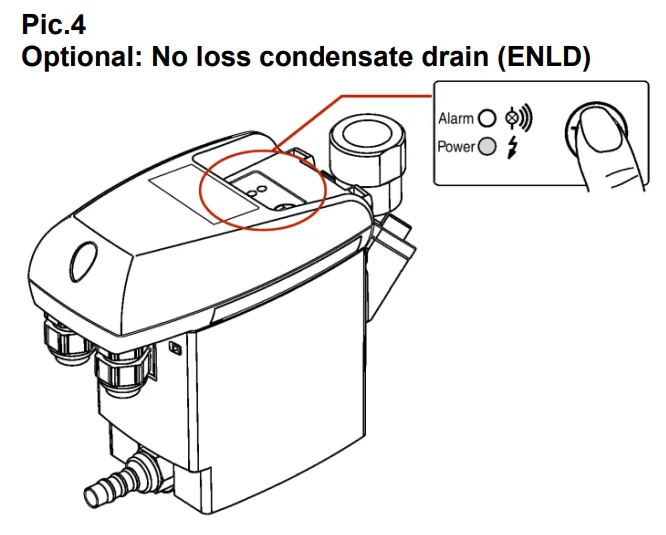

Electronic drain discharge ENLD is the new discharger applicable to any compressed air system. It eliminates the condensate without wasting compressed air. Electronic drain discharge starts automatically, without the need of any adjustment. The condensate discharge occurs to the use of an electronic sensor, which detects the amount of condensate in the integrated water collecting tank. The level sensor drives start and duration of the drainage, so as to prevent any wasting of compressed air. At the end of installation, put the system under pressure and push the TEST key repeatedly to eliminate the air bubbles contained in the discharger inlet fittings. Please refer to the attached CD of the discharger for complete instructions. To this, the ENLD warranty conditions.

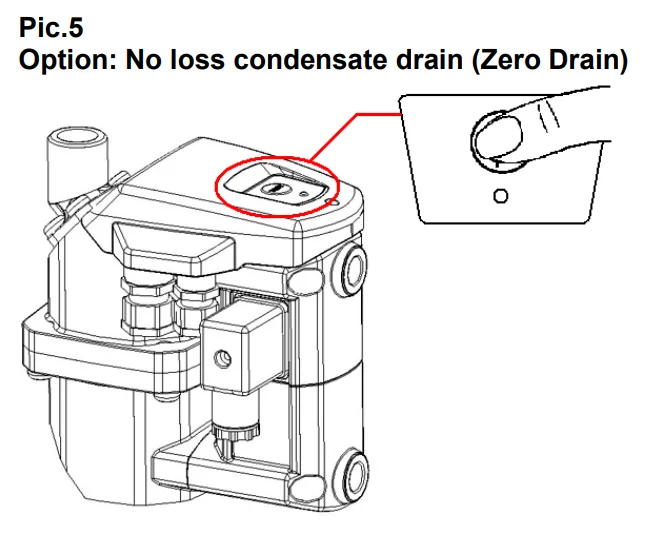

Zero Drain is the new electronic drain discharger applicable to any compressed air system. It eliminates the condensate without wasting compressed air. Electronic drain discharge starts automatically, without the need of any adjustment. The condensate discharge occurs to the use of an electronic sensor, which detects the amount of condensate in the integrated water collecting tank. The level sensor drives start and duration of the drainage, so as to prevent any wasting of compressed air. At the end of installation, put the system under pressure and push the TEST key repeatedly to eliminate the air bubbles contained in the discharger inlet fittings. The Zero Drain unit is equipped with a remote alarm connection (dry contact, triggered when the drain is in alarm for more than 30 seconds): see terminal block diagrams (attachment B) for further details.

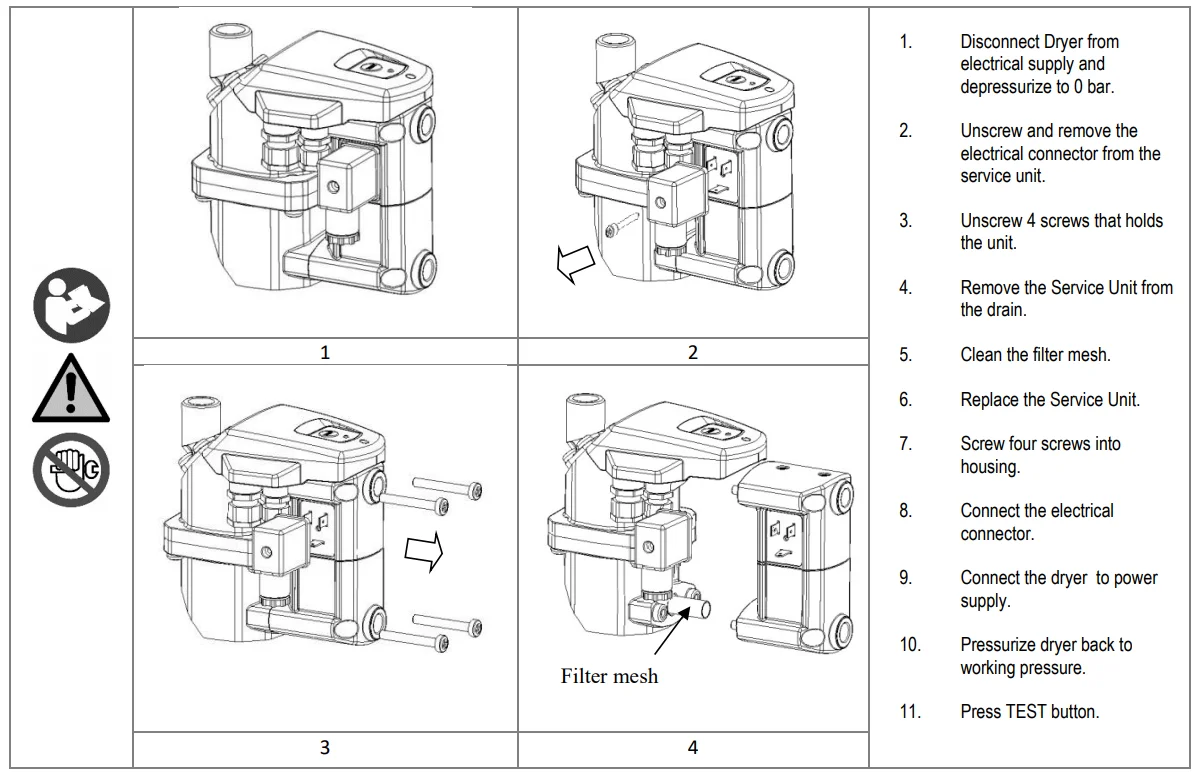

Maintenance

Zero Drain is equipped with Service Unit, which is recommended to be changed every year to ensure proper working conditions.

Should the discharger not operate correctly, try to act on the TEST key to clean the mesh filter. Never remove the discharger body. Should the malfunction persist, contact our Customer Service. Before carrying out any work on the electrical parts, make sure that the main switch interrupts the electricity supply to the dryer and then affix appropriate warning signs to avoid the machine being reconnected to the electricity mains!

DECOMMISSIONING

All work on the dryer may only be carried out by specialist personnel!

Follow this procedure if you need to shut down the dryer:

- Stop the device and permanently isolate it from the electricity mains.

- Disconnect the power cable.

- Take pressure off the air circuit.

- Empty the tank and the internal cooling medium circuits.

- If the device has to be dispatched, use the original or similar packaging and keep the device in an upright position.

Before carrying out any work on the electrical parts, make sure that the main switch interrupts the electricity supply to the dryer and then affix appropriate warning signs to avoid the machine being reconnected to the electricity mains! Please consult the contents and the safety instructions in the relevant sections of these instructions for details of the correct handling and storage of the chiller. Remove any residual cooling medium from the dryer in a manner appropriate to its properties and in accordance with the legislation in force. If the device has to be demolished: Never open the sealed cooling assembly (compressor, evaporator, and condenser) if there may be any refrigerant or lubricating oil present! Send the chiller to an approved waste disposal company in accordance with current environmental protection legislation. The other materials/waste constituents must be treated in line with the provisions of the valid legislation..

For more manuals by Ingersoll-Rand, visit ManualsLibraryy

Ingersoll Rand D-Series Non-Cycling Refrigerated Air Dryer-FAQs

What is a non-cycling refrigerated air dryer?

A non-cycling refrigerated air dryer runs continuously while powered on. It keeps the refrigeration system active at all times and uses a hot gas bypass valve to maintain stable temperature and dew point, even during low air demand.

What is the difference between cycling and non-cycling air dryers?

Cycling dryers turn the refrigeration system on and off based on air demand to save energy. Non-cycling dryers operate continuously, providing consistent performance but with steady power consumption.

What is the main purpose of a refrigerated air dryer?

Its primary function is to remove moisture from compressed air. It cools the air so water vapor condenses into liquid, which is then separated and drained, preventing corrosion and equipment damage.

How does a refrigerated air dryer remove moisture?

The dryer lowers the temperature of compressed air. As the air cools, moisture condenses into water droplets that are collected and discharged from the system.

What is the difference between a refrigerated and desiccant dryer?

Refrigerated dryers typically achieve dew points around 35–50°F. Desiccant dryers can reach extremely low dew points (as low as -100°F), making them suitable for sensitive industrial applications.

What does CFM mean in air dryers?

CFM stands for Cubic Feet per Minute. It measures the airflow capacity of the dryer and indicates how much compressed air it can handle.

What is SCFM vs. CFM?

SCFM (Standard Cubic Feet per Minute) measures airflow under standardized conditions. CFM reflects actual airflow. SCFM is more useful when comparing compressor and dryer performance.

Does a refrigerated air dryer consume a lot of electricity?

Power consumption depends on capacity, but non-cycling dryers run continuously. They are energy-efficient for steady loads but may use more energy than cycling models during low demand.