Ingersoll Rand T30-2545 Air Compressor Pump

PARTS ORDERING INFORMATION

These products are designed and constructed to provide long, trouble-free service. In time, it may be necessary to order and install new parts to replace those that have been subjected to wear. For your convenience and future reference, it is recommended that the following information be recorded.

Model Number ________________________________

Serial Number _________________________________

Date Purchased ________________________________

When ordering replacement parts, please specify the following:

- Complete model number and serial number as it appears on the data (name) plate.

- Part number(s) and part description as shown in this manual.

- Quantity required.

NOTICE

- Continuing improvement and advancement of design may cause changes to this equipment that are not included in this manual. Manuals are periodically revised to incorporate changes. Always check the manual edition number on the front cover for the latest issue.

- Sections of this manual may not apply to your product.

- Using other than genuine Ingersoll Rand replacement parts may invalidate the warranty.

Return Goods Policy

Ingersoll Rand will not accept any returned goods for warranty or service work unless prior arrangements have been made and written authorization has been provided from the location where the goods were purchased. Products that have been modified without Ingersoll Rand approval, mishandled, or misused will not be repaired or replaced under warranty. A printed copy of the warranty that applies to this product is provided inside the back cover of this manual.

Disposal

When the life of the product has expired, it is recommended that it be disassembled, degreased, and parts separated according to materials so that they may be recycled. Refer all communications to the nearest Ingersoll Rand Office or Distributor.

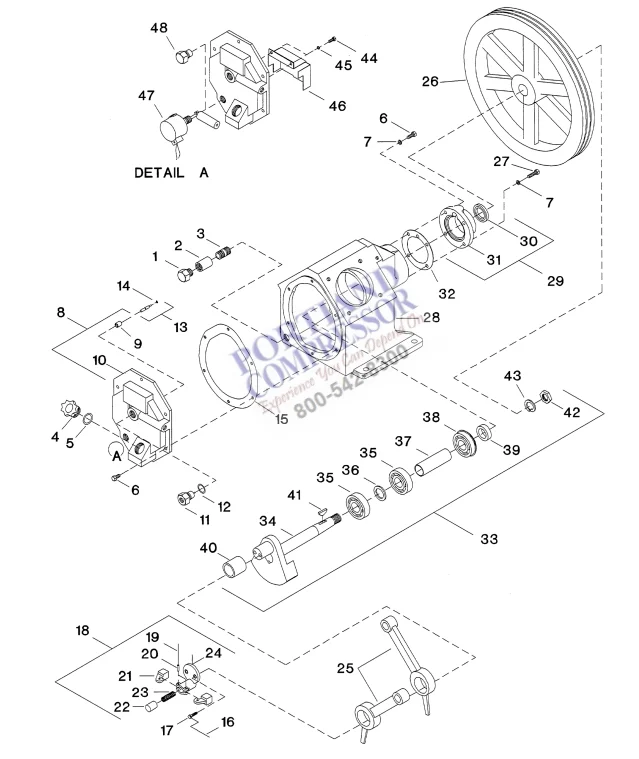

COMPRESSOR PUMP ASSEMBLY DRAWING (VIEW – 1)

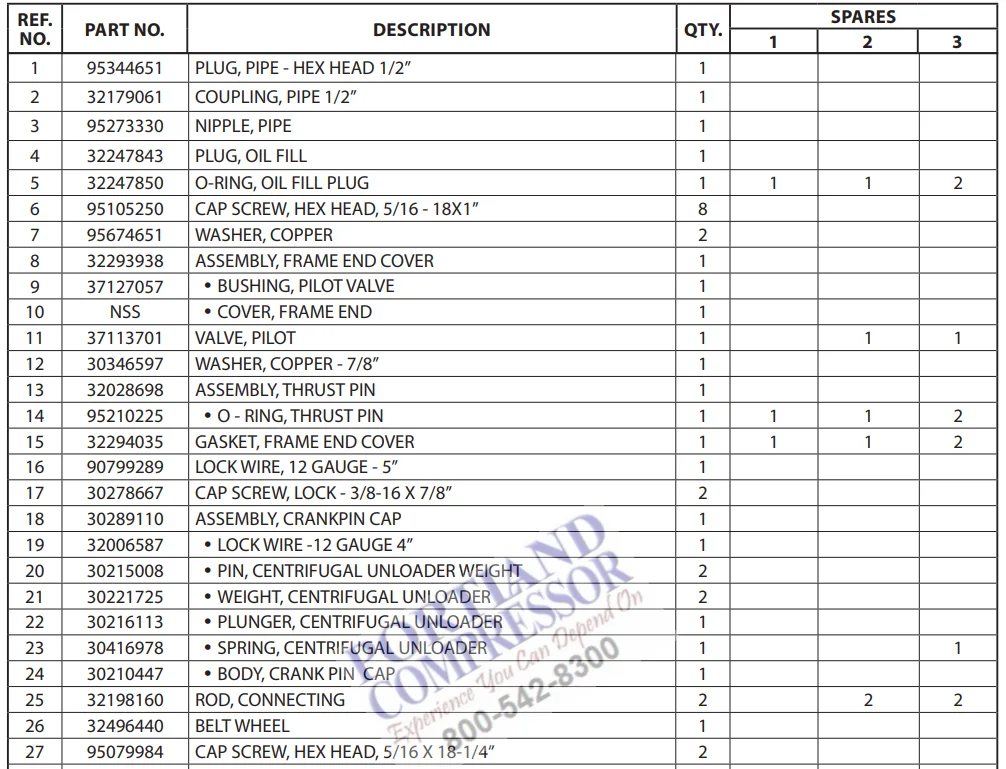

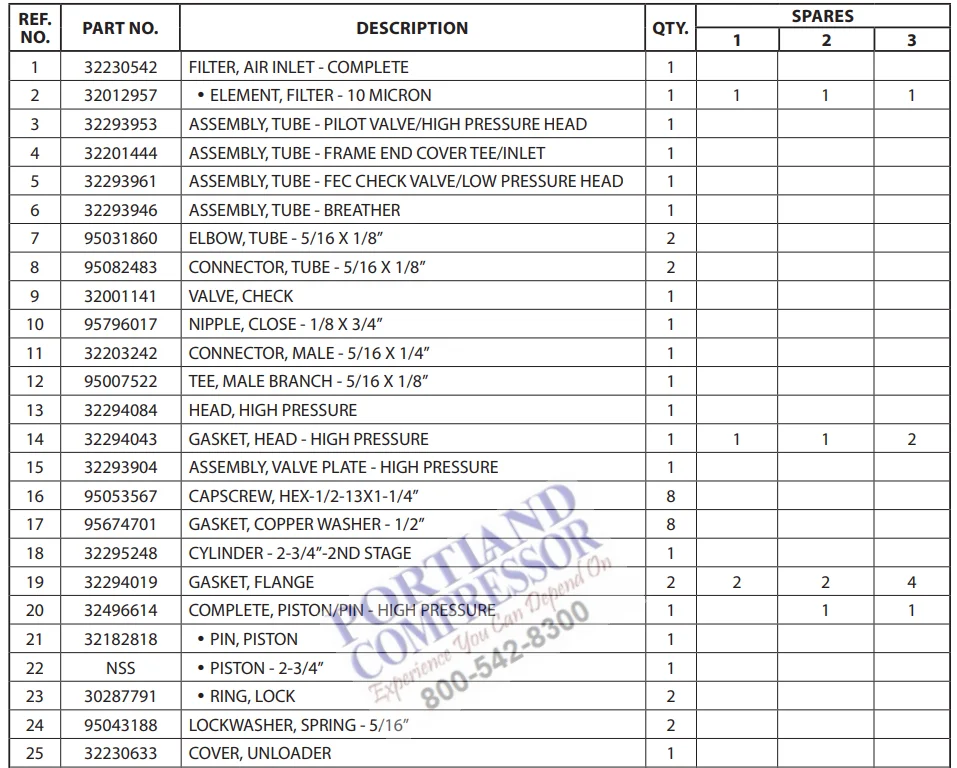

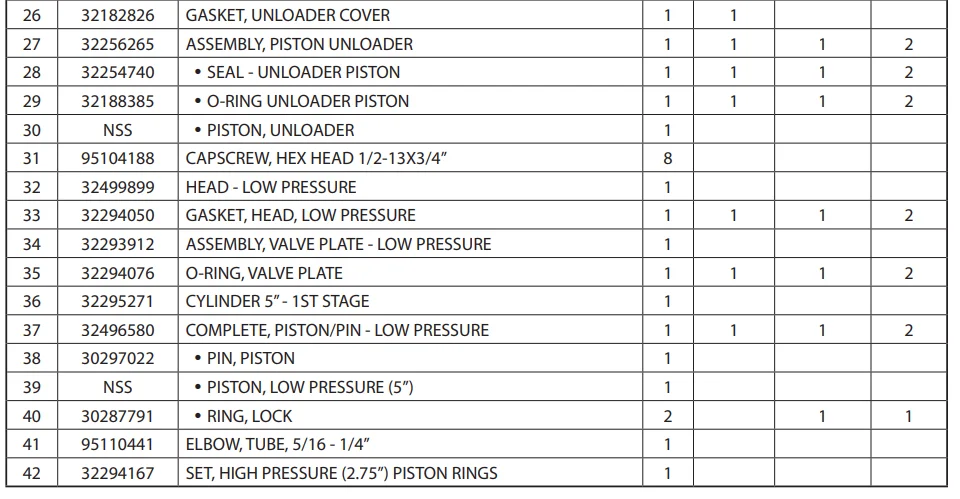

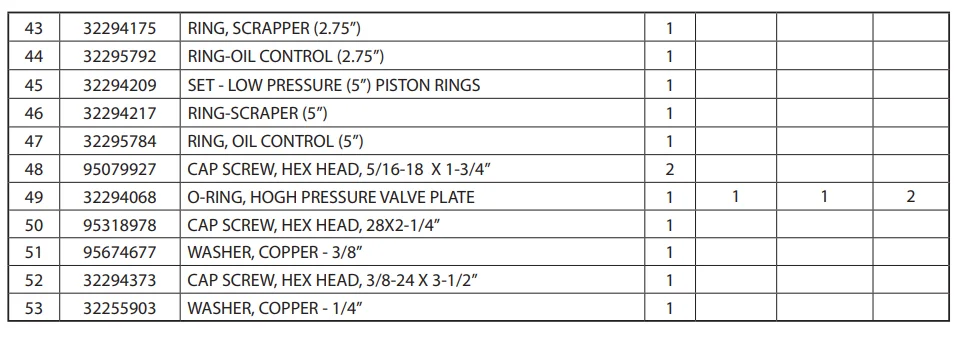

COMPRESSOR PUMP ASSEMBLY DRAWING (VIEW – 1) PARTS LIST

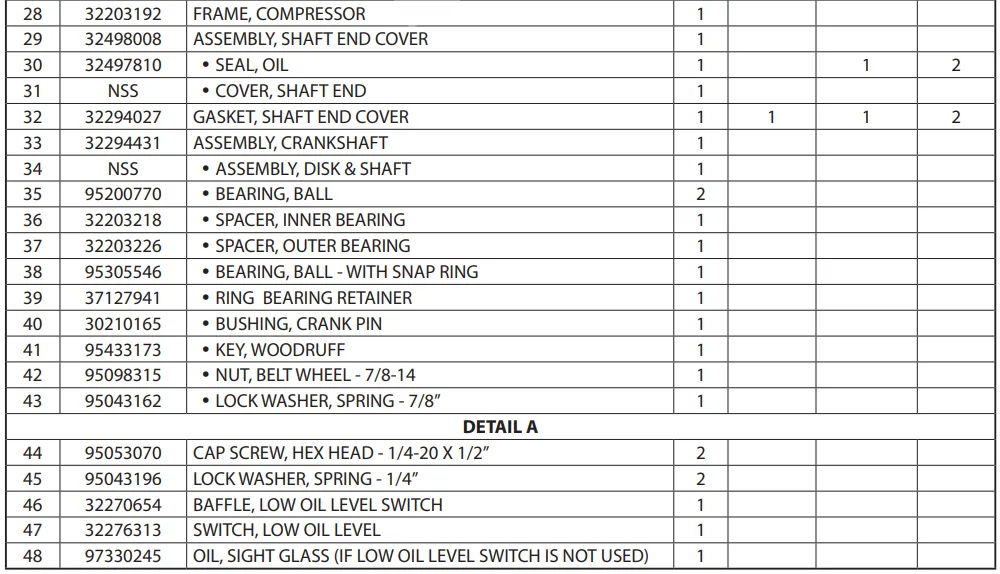

COMPRESSOR PUMP ASSEMBLY DRAWING (VIEW – 2)

COMPRESSOR PUMP ASSEMBLY (VIEW – 2) PARTS LIST

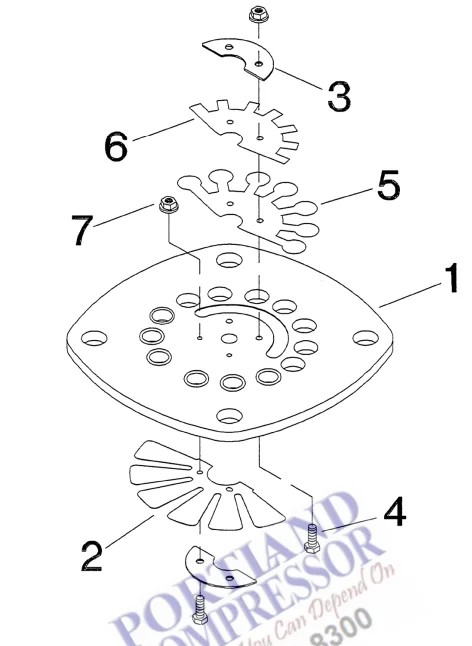

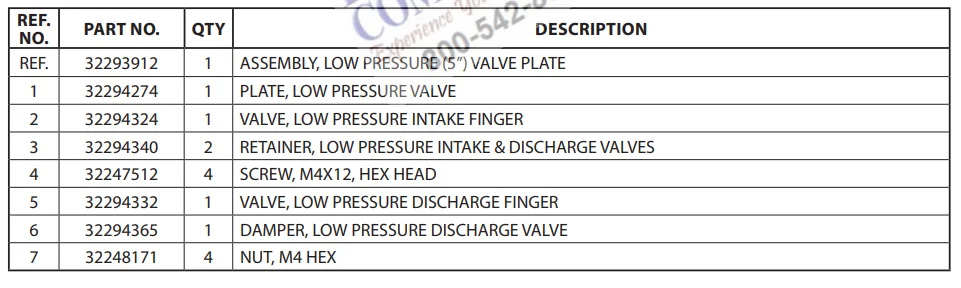

LOW PRESSURE (FIRST STAGE) VALVE PLATE ASSEMBLY DRAWING AND PARTS LIST

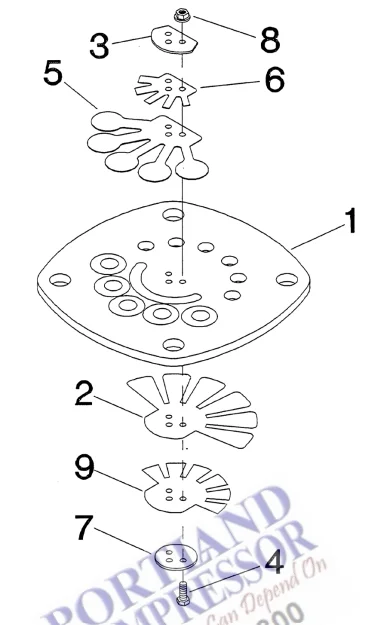

HIGH PRESSURE (SECOND STAGE) VALVE PLATE ASSEMBLY DRAWING AND PARTS LIST

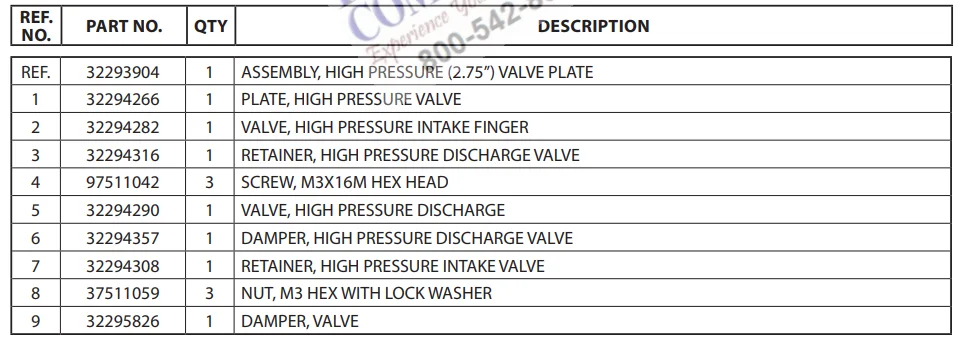

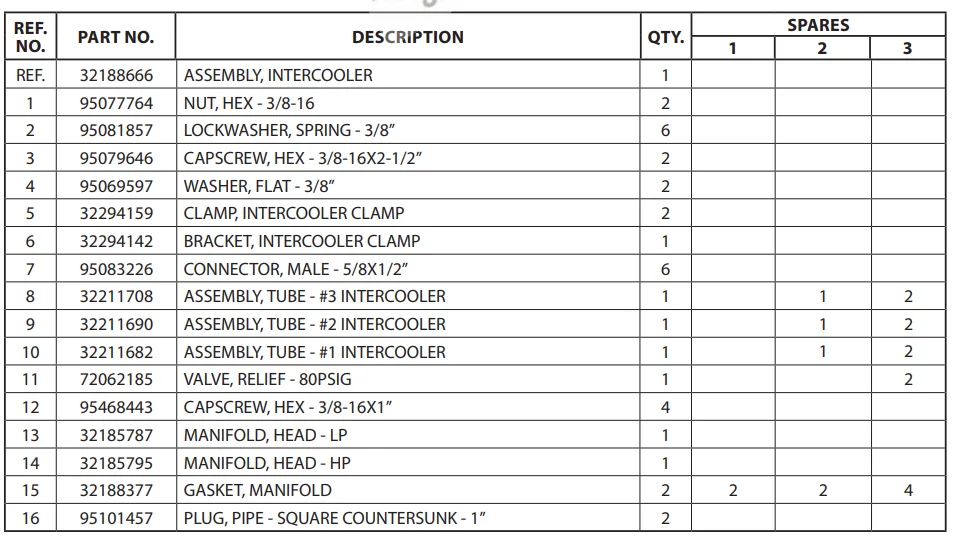

INTER COOLER ASSEMBLY DRAWING AND PARTS LIST

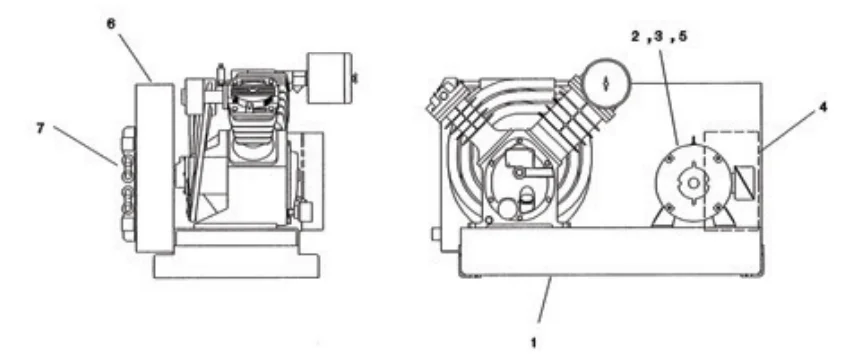

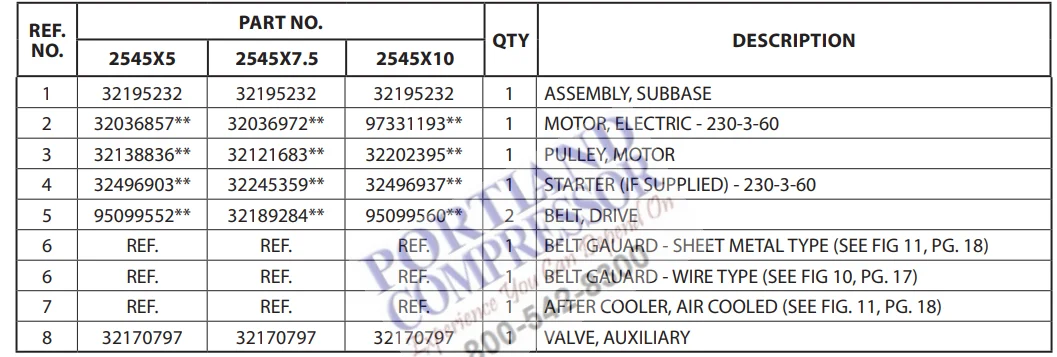

TYPICAL BASEPLATE MOUNTED ELECTRIC PACKAGES

**= PART NUMBER VARIES. SUPPLY MODEL NUMBER, SERIAL NUMBER, AND COMPLETE MOTOR NAMEPLATE DATA WHEN ORDERING. REF. = REFERENCE PAGE NUMBER (S) GIVEN IN DESCRIPTION COLUMN.

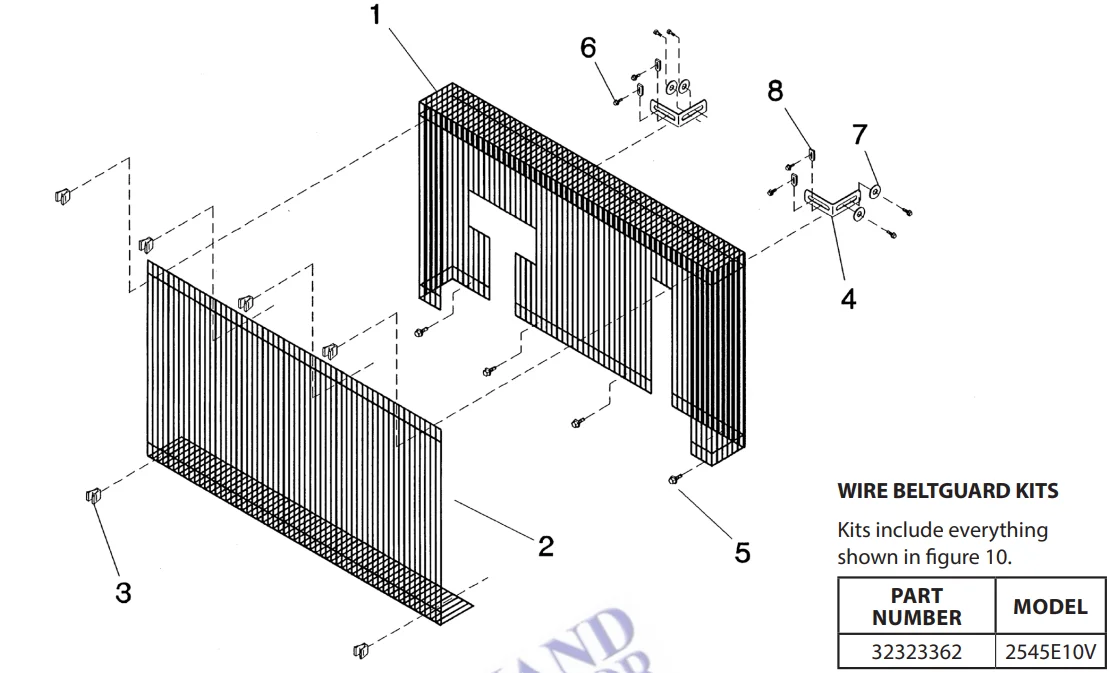

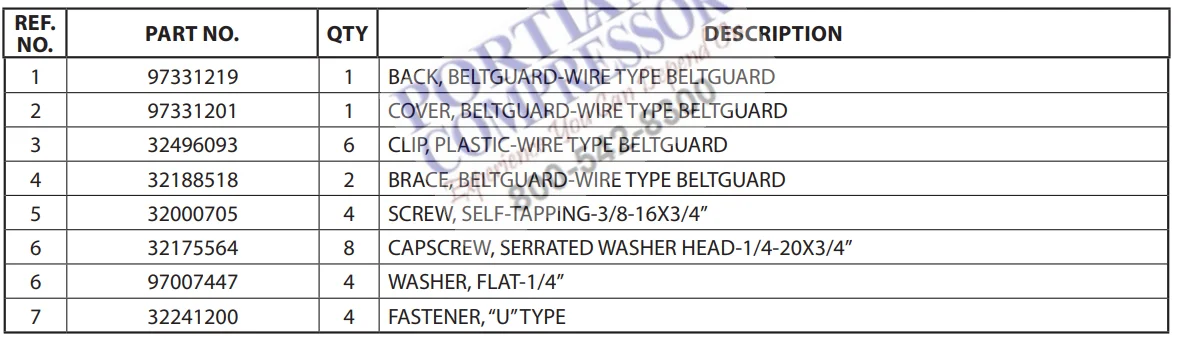

NOTE: AIR COOLED AFTERCOOLER CANNOT BE MOUNTED ON WIRE BELTGUARD.

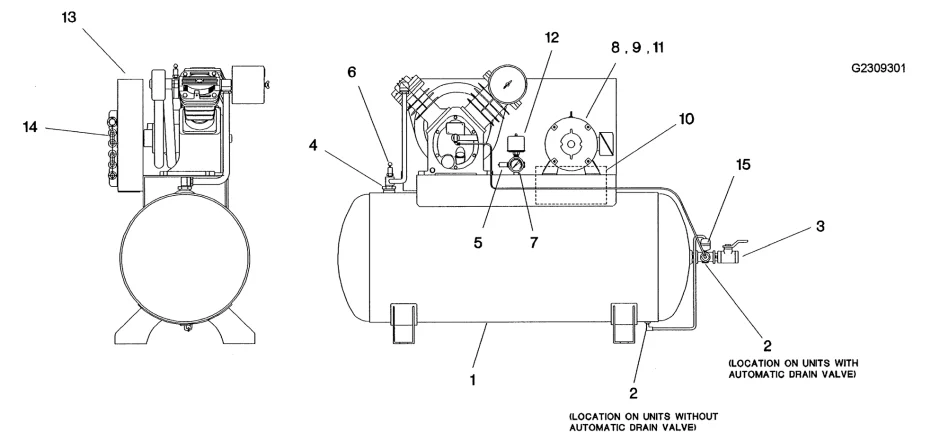

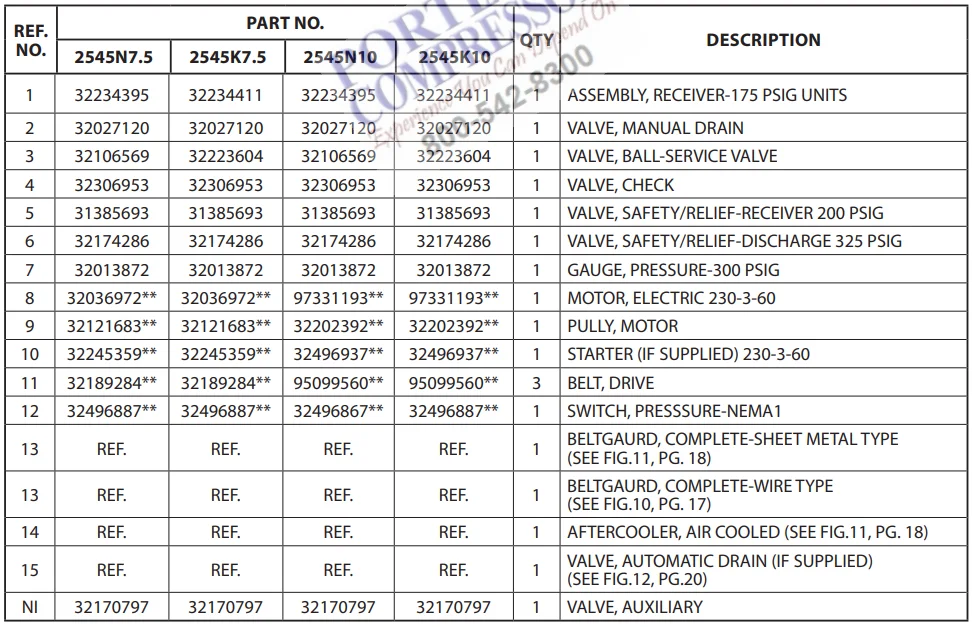

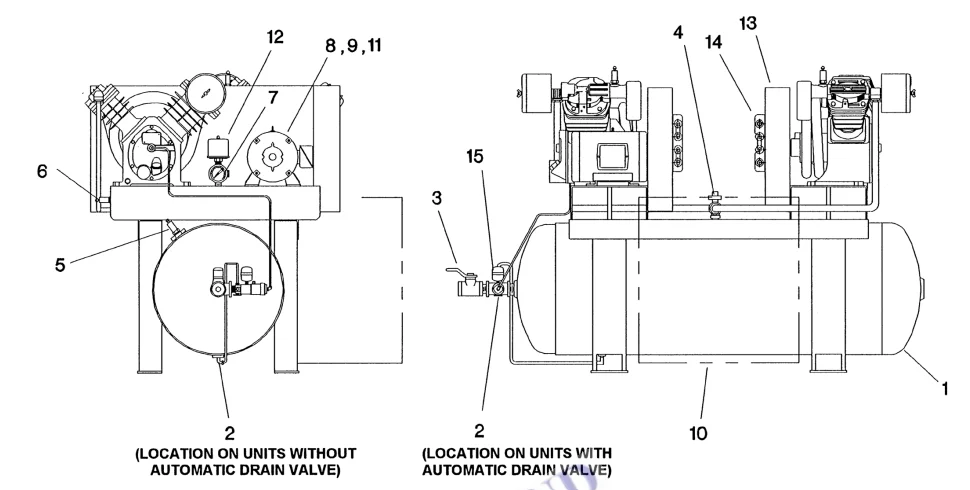

TYPICAL SIMPLEX HORIZONTAL RECEIVER MOUNTED ELECTRIC PACKAGES

**= PART NUMBER VARIES. SUPPLY MODEL NUMBER, SERIAL NUMBER, AND COMPLETE MOTOR NAMEPLATE DATA WHEN ORDERING. REF. = REFERENCE PAGE NUMBER (S) GIVEN IN DESCRIPTION COLUMN.

NOTE: AIR COOLED AFTERCOOLER CANNOT BE MOUNTED ON WIRE BELTGUARD.

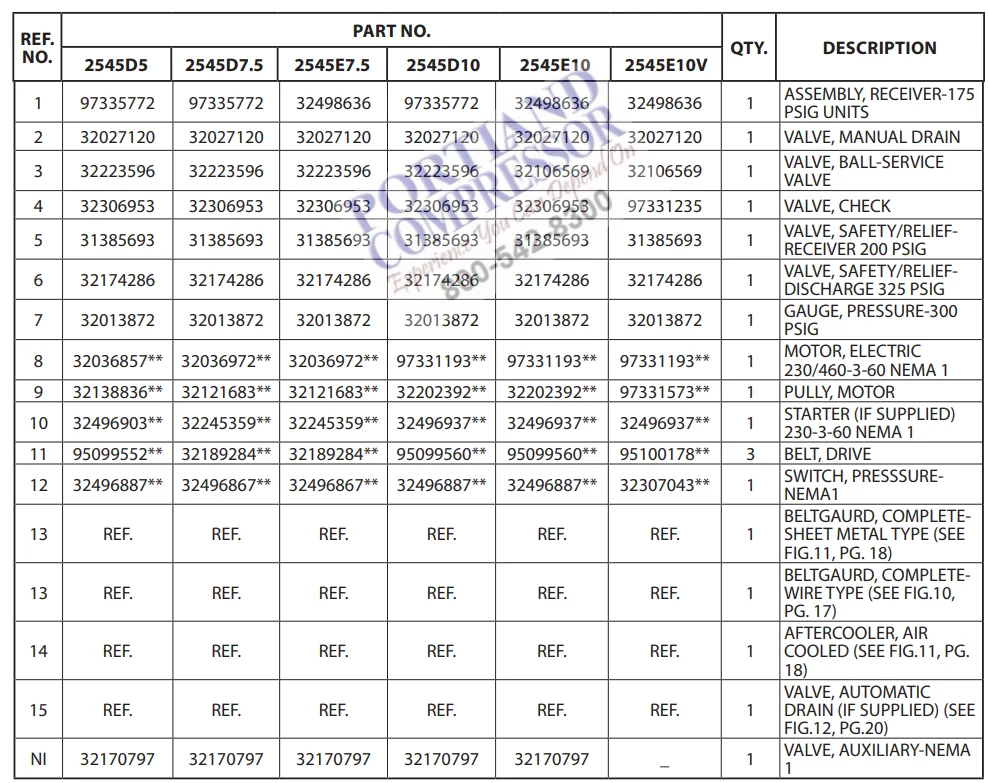

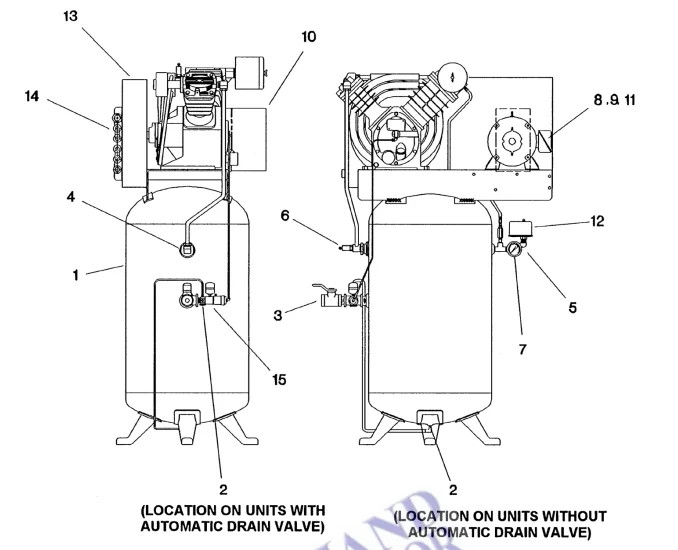

TYPICAL VERTICAL RECEIVER MOUNTED ELECTRIC PACKAGES

**= PART NUMBER VARIES. SUPPLY MODEL NUMBER, SERIAL NUMBER, AND COMPLETE MOTOR NAMEPLATE DATA WHEN ORDERING. REF. = REFERENCE PAGE NUMBER (S) GIVEN IN DESCRIPTION COLUMN.

NOTE: AIR COOLED AFTERCOOLER CANNOT BE MOUNTED ON WIRE BELTGUARD.

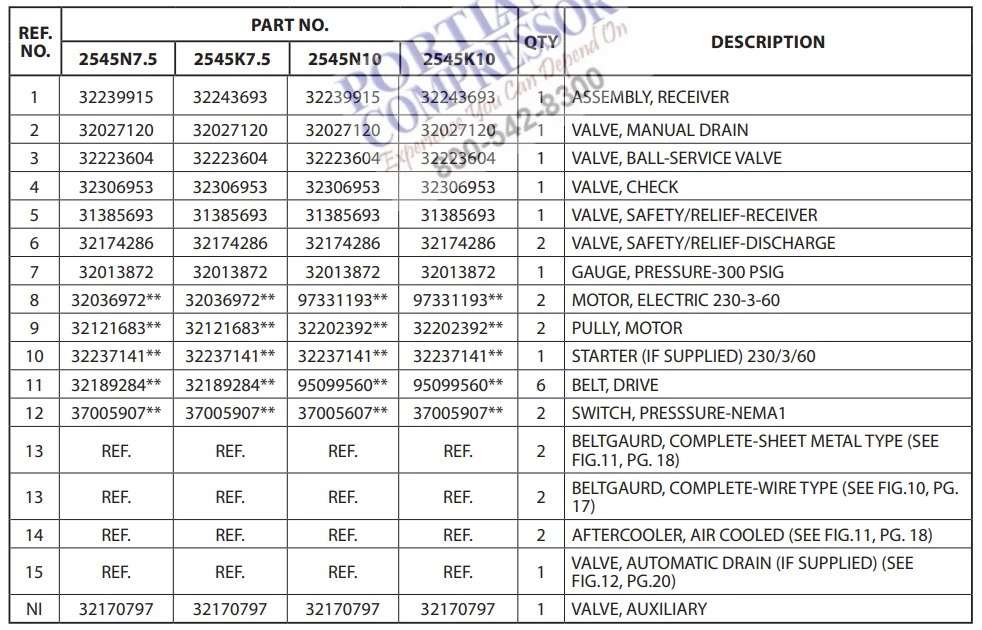

TYPICAL DUPLEX RECEIVER MOUNTED PACKAGES

**= PART NUMBER VARIES. SUPPLY MODEL NUMBER, SERIAL NUMBER, AND COMPLETE MOTOR NAMEPLATE DATA WHEN ORDERING. REF. = REFERENCE PAGE NUMBER (S) GIVEN IN DESCRIPTION COLUMN.

NOTE: AIR COOLED AFTERCOOLER CANNOT BE MOUNTED ON WIRE BELTGUARD.

TYPICAL WIRE BELTGUARD

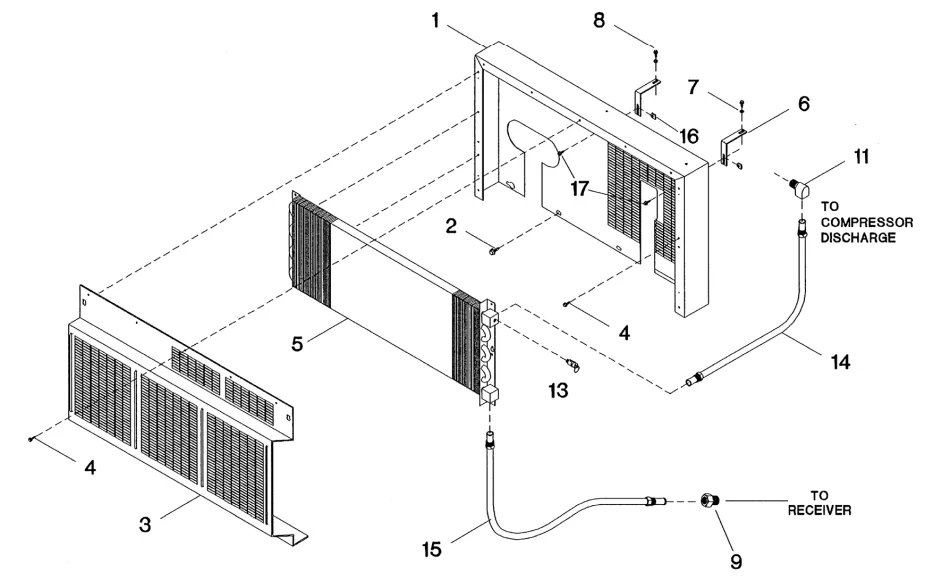

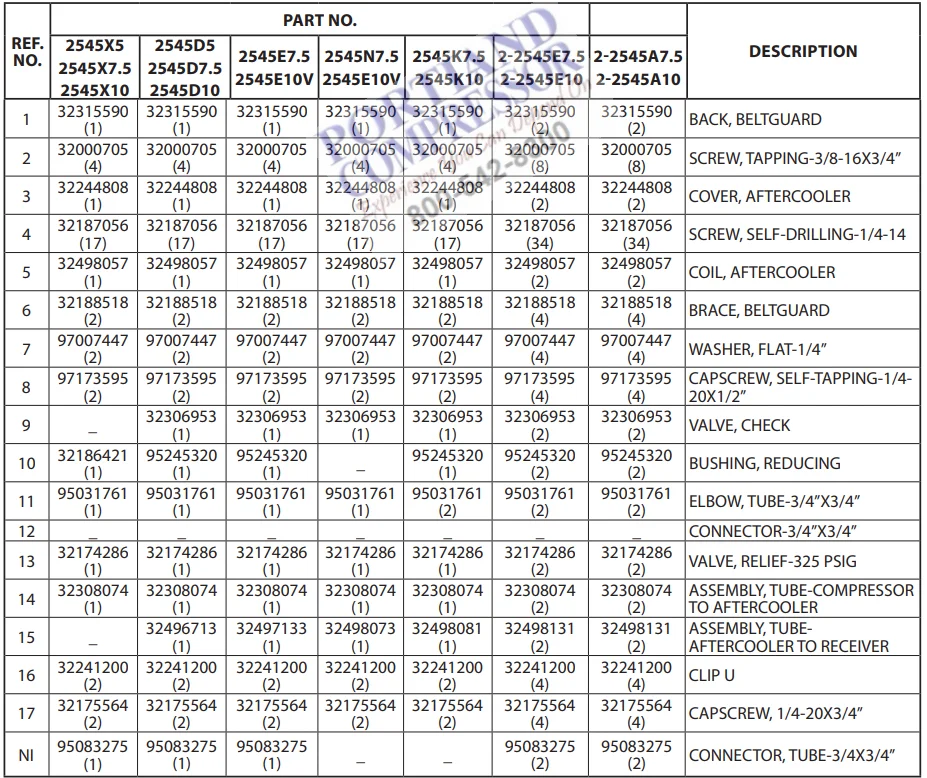

TYPICAL BELTGUARD & AIR COOLED AFTERCOOLER

RECOMMENDED PARTS LIST

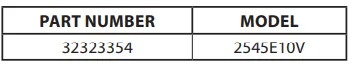

AIR COOLED AFTERCOOLER ADDITION KITS

Air-cooled after-cooler addition kits allow for the addition of an air-cooled after-cooler to your unit. Kits include front and back cover, after cooler coil, safety/relief valve, silencer, tubing and mounting hardware.

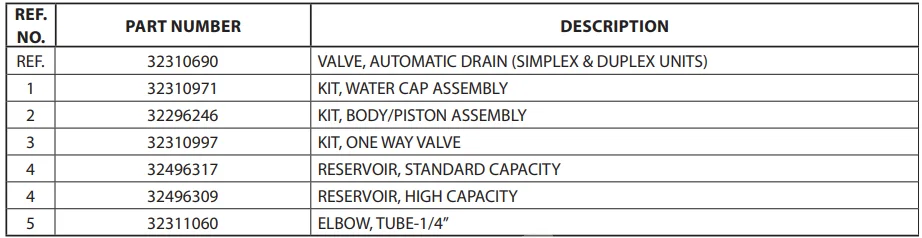

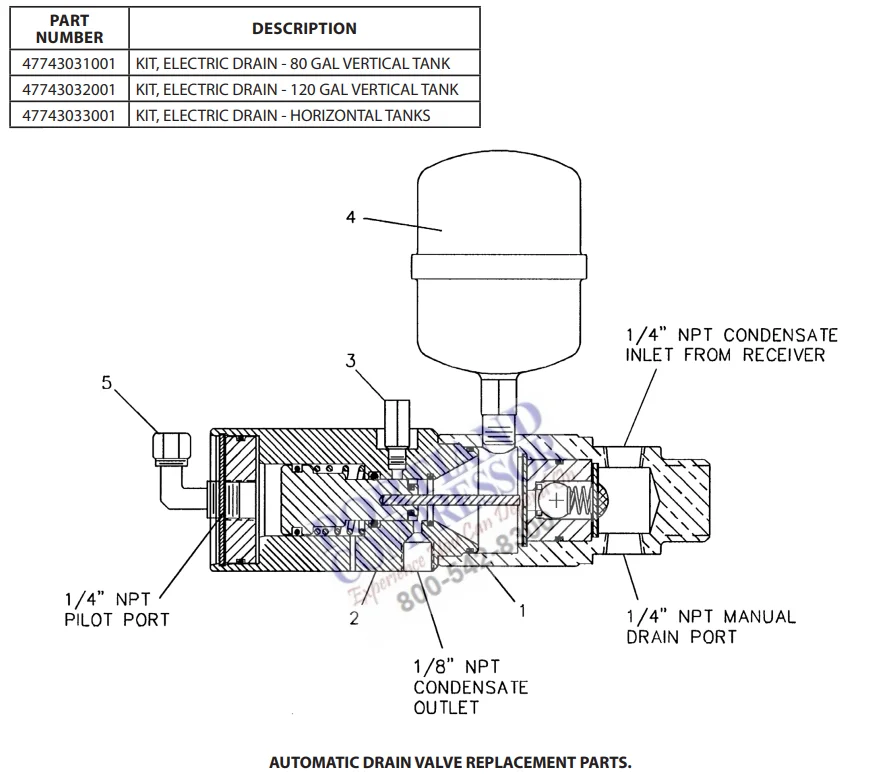

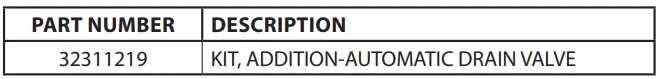

The automatic drain valve removes condensed water and oil from the compressed air system without restricting air flow, creating pressure drops or opening the system to the atmosphere. Its unique design maintains system pressure and volume during operation, and increases productivity.

- The high-capacity reservoir gives the automatic drain valve twice as much condensate storage capacity during the pumping cycle. This larger reservoir is available as an upgrade. A larger reservoir is recommended for use on heavily-loaded simplex compressors with long pumping cycles and/or operation in extremely humid environments. If the pumping cycle exceeds one hour, then an electric timer kit should be used.

AUTOMATIC DRAIN VALVE TIMER KITS

- An automatic drain valve timer kit resolves application problems in which an existing automatic drain valve cycles too infrequently. A timer generates the pneumatic signals for actuating the automatic drain valve. With a timer, the automatic drain valve operates independently of the compressor upload cycles.

AUTOMATIC DRAIN VALVE ADDITION KITS

- An automatic drain valve addition kit allows you to add an automatic drain valve to simplex electric packages.

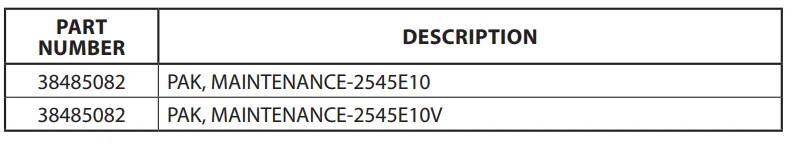

MAINTENANCE PAKS

- Maintenance packs contain all the parts necessary for one complete routine maintenance service of your compressor. All-season T30 select lubricant, air filter elements, gaskets, drive belts, and instructions are standard with all maintenance paks.

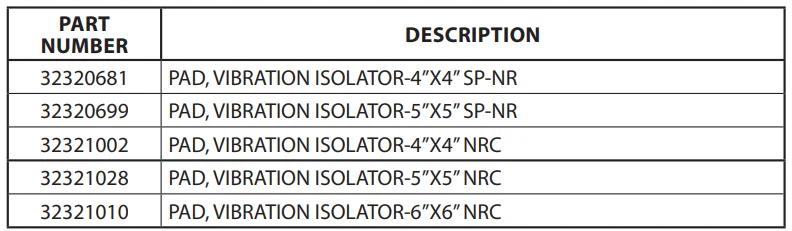

VIBRATION ISOLATOR PADS

- Vibration isolator pads are designed to absorb 40%-60% of the sound and vibration of your compressor.

SP-NR: steel plate bonded between an NR pad and a non-skid oil-resistant ribbed neoprene top pad.

NRC: Two ribbed neoprene pads bonded to a ½” cork pad.

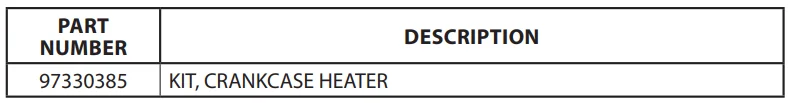

CRANKCASE HEATER KITS

Crankcase heaters are recommended when ambient temperatures are consistently below 32°F (0°C). An easy-to-install external crankcase heater kit is intended for aftermarket use. Two kits may be required for some applications.

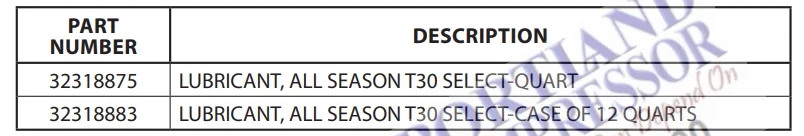

COMPRESSOR LUBRICANT

All-season T30 select is an all-temperature diester synthetic lubricant that is formulated for exceptional lubrication at low, normal, and high operating temperatures.

START-UP-KITS

Each start-up kit contains the necessary quantities of all-season T30 select lubricant and air filter element(s) to start up and maintain your compressor for the first year. Start-up kits for gasoline engine-driven models also include a replacement engine air filter, engine oil filter, and engine lubricant. See the engine manufacturer’s instructions for more detailed engine care information.

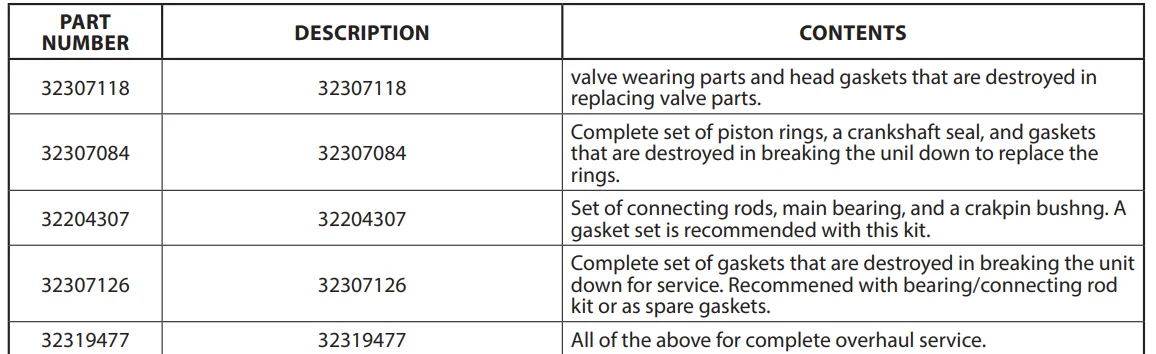

STEP SAVER KITS

Step saver kits provided all of the parts required to perform common repair or scheduled maintenance tasks, such as piston ring replacement or valve replacement.

For more manuals by Ingersoll Rand, visit ManualsLibraryy

Ingersoll Rand T30-2545 Air Compressor Pump-FAQs

What is the Ingersoll Rand T30-2545 air compressor pump?

The T30-2545 is a heavy-duty, two-stage, cast-iron reciprocating air compressor pump designed for industrial and workshop use. It is built for durability, high pressure output, and continuous performance in demanding environments.

How many CFM does the Ingersoll Rand T30 produce?

Performance depends on the motor and tank setup, but many T30 configurations deliver around 30–35 CFM at up to 175 PSI, making it suitable for high-demand air tools and shop equipment.

How much oil does the Ingersoll Rand 2545 pump require?

The T30-2545 pump has an oil capacity of approximately 74 fluid ounces. Always use manufacturer-recommended, non-detergent air compressor oil for best performance.

What does SCFM at 90 PSI mean?

SCFM (Standard Cubic Feet per Minute) measures airflow at a specific pressure. For example, “4.0 SCFM at 90 PSI” means the compressor delivers 4 cubic feet of air per minute at 90 pounds per square inch.

What is the difference between a single-stage and two-stage compressor?

A two-stage compressor like the T30 compresses air twice for higher pressure and better efficiency, making it ideal for heavy-duty applications.

What PSI is needed for automotive painting?

Most automotive spray guns require 10–15 CFM at around 40 PSI for basecoat applications. Always check your paint gun specifications.

How often should I drain the air tank?

Drain the tank daily to remove moisture. Water buildup can cause internal rust and reduce tank lifespan.

Can I use 10W30 motor oil in this compressor?

No. Automotive oils like 10W30 are not recommended. Use synthetic, non-detergent air compressor oil to prevent carbon buildup and extend pump life.

How often should I change the oil?

For optimal performance, change the oil after the initial break-in period and then every 500–1,000 hours of operation, depending on usage conditions.