KTM 350 EXC-F Enduro Motorcycle

MOTORCYCLE

Raising the motorcycle with the lift stand

- Note

- Danger of damage The parked vehicle may roll away or fall over.

- Always place the vehicle on a firm and even surface.

- Raise the motorcycle at the frame underneath the engine. Lift stand (54829055000) ( p. 343)

- The wheels should no longer touch the ground.

- Secure the motorcycle against falling over.

Removing the motorcycle from the lift stand

- Note

- Danger of damage The parked vehicle may roll away or fall over.

- Always place the vehicle on a firm and even surface.

- Remove the motorcycle from the lift stand.

- Remove the lift stand.

- To park the motorcycle, press side stand 1 to the ground with your foot and lean the motorcycle on it.

Starting

- Note

- Engine failure High engine speeds in cold engines have a negative effect on the service life of the engine.

- Always warm up the engine at low engine speeds

- Take the motorcycle off of the side stand 1 and secure the side stand with a rubber band 2.

- Shift transmission to neutral.

- (EXC-F US)

- Turn the key in the ignition lock to the position.

- Turn the emergency OFF switch to the position.

- (EXC‑F AU)

- Turn the emergency OFF switch to the position.

- Condition

- Ambient temperature: < 20 °C (< 68 °F)

- Pull the idle speed adjusting screw all the way out.

- Press the electric starter button or press the Kickstarter robustly through its full range.

Starting the motorcycle for a check

- Info

- Press the starter for a maximum of 5 seconds. Wait for at least 5 seconds before trying again.

- Shift transmission to neutral.

- (EXC-F US)

- Turn the key in the ignition lock to the position.

- Turn the emergency OFF switch to the position.

- (EXC‑F AU)

- Turn the emergency OFF switch to the position.

- Press the electric starter button or press the Kickstarter robustly through its full range.

FORK, TRIPLE CLAMP

Bleeding fork legs

- Preparatory work

- Raise the motorcycle with the lift stand. ( p. 11)

- Main work

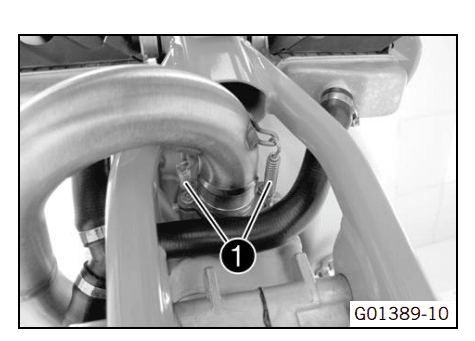

- Release bleeder screws 1

- Any excess pressure escapes from the interior of the fork.

- Tighten the bleeder screws

- Finishing work

- Remove the motorcycle from the lift stan

Loosening the fork protector

- Remove screw 1 and remove the clamp.

- Remove screws 2 on the left fork leg. Push the fork protector downwards.

- Remove the screws on the right fork leg. Push the fork protector downwards.

Positioning the fork protector

- Position the fork protector on the left fork leg. Mount and tighten screws 1

- Guideline

Remaining screws, chassis M6 10 Nm (7.4 lb-ft) - Position the wiring harness.

- Position the brake line. Put the clamp on, and mount and tighten the screws 2

- Position the fork protector on the right fork leg. Mount and tighten the screws.

- Guideline

Remaining screws, chassis M6 10 Nm (7.4 lb-ft)

Removing the fork legs

- Preparatory work

- Remove the headlight mask with the headlight. ( p. 98)

- Raise the motorcycle with the lift stand. ( p. 11)

- Remove the front wheel. ( p. 103)

- Main work

- Remove screw 1 and take off the clamp.

- Remove the cable binder(s).

- Remove screws 2 and take off the brake caliper.

- Allow the brake caliper and brake line to hang tension-free to the side.

Cartridge disassembly

- Info

- The steps are identical for both fork legs.

- Preparatory work

- Disassemble the fork legs. ( p. 19)

- Main work

- Remove the fluid barrier 1 from the piston rod.

Greasing the steering head bearing

- Remove the lower triple clamp. ( p. 32)

- Install the lower triple clamp. ( p. 32)

HANDLEBAR, CONTROLS

Adjusting the basic position of the clutch lever

- Adjust the basic setting of the clutch lever to your hand size by turning and adjusting screw 1.

- Info

- Turn the adjusting screw clockwise to increase the distance between the clutch lever and the handlebar. Turn the adjusting screw counterclockwise to decrease the distance between the clutch lever and the handlebar. The range of adjustment is limited.

- Turn the adjusting screw by hand only, and do not apply any force. Do not make any adjustments while riding

Checking the throttle cable routing

- Preparatory work

- Remove the seat. ( p. 88)

- Remove the fuel tank. ( p. 89)

- Main work

- (EXC‑F EU/AUS/BR, EXC-F SIX DAYS, XCF-W)

- Check the throttle cable routing.

- Both throttle cables must be routed to the throttle valve body side by side behind the handlebars and above the fuel tank bearing.

- If the throttle cable is not routed as specified:

- Correct the throttle cable routing.

- (EXC-F US)

- Check the throttle cable routing.

- Both throttle cables must be routed to the throttle valve body side by side behind the handlebars and above the fuel tank bearing.

- If the throttle cable is not routed as specified:

- Correct the throttle cable routing

- Finishing work

- Install the fuel tank. ( p. 90)

- Mount the seat. ( p. 89)

EXHAUST

Removing the manifold

- Preparatory work

- Raise the motorcycle with the lift stand. ( p. 11)

- Remove the shock absorber. ( p. 61)

- Remove the main silencer. ( p. 82)

- Main work

- Remove springs 1

- Disconnect the plug-in connector of the lambda sensor and remove the cable binder.

- Expose the cable.

- Remove screw 2 and take off the manifold.

Installing the manifold

- Main work

- Position the manifold and mount springs 1

- Mount and tighten the screw 2.

- Guideline

Remaining screws, chassis M8 25 Nm (18.4 lb ft)

- Connect the plug-in connector of the lambda sensor.

- Route the cable loosely and securely with a cable binder.

- Finishing work

- Install the main silencer. ( p. 82)

- Install the shock absorber. ( p. 61)

- Remove the motorcycle from the lift stand. ( p. 11)

Removing the main silencer

- Allow the exhaust system to cool down. Do not touch hot components.

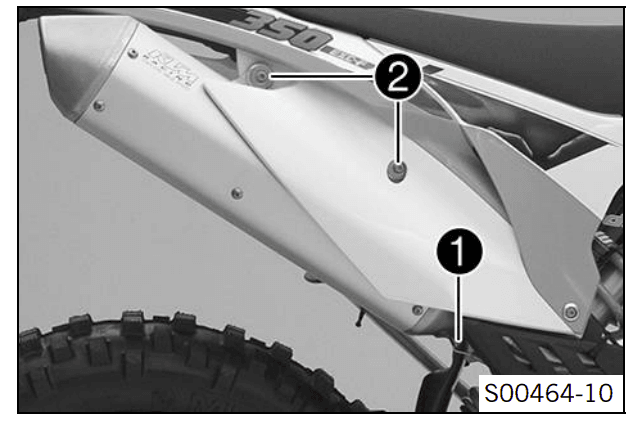

- Disconnect spring 1.

- Remove screws 2 and take off the main silencer.

Installing the main silencer

- Mount the main silencer. Mount screws 1 but do not tighten yet.

- Reconnect spring 2

- Tighten screws 1

- Guideline

Remaining screws, chassis M6 10 Nm (7.4 lb-ft)

Changing the glass fiber yarn filling of the main silencer

- Info

- Over time, the fibers of the glass fiber yarn escape, and the damper “burns” out. Not only is the noise level higher, the performance characteristic changes.

- Preparatory work

- Remove the main silencer. ( p. 82)

- Main work

- (EXC‑F EU/AUS/BR, EXC-F SIX DAYS)

- Remove screw 1 and take off the silencer cap 2 with O-ring 3

- Remove the old glass fiber yarn filling.

- Clean the parts that need to be reinstalled and check for damage.

- Slide the new glass fiber yarn filling 4 into the main silencer.

- Mount the O-ring on the silencer cap.

- Position the silencer cap. Mount and tighten the screws.

(EXC-F US, All XCF-W models)

- Remove the screw 1 of connecting cap 2.

- Take off the connecting cap 2 with perforated pipe, O-ring 3, and glass fiber yarn filling 4.

- Remove screws 5 and silencer cap 6 with O-ring 7.

- Remove the screws 8 and insert 9 them together with the insulating pad 10.

- Clean the parts that need to be reinstalled and check for damage.

- Mount the new insulating pad 10 on insert 9 and secure it with adhesive tape.

- Slide insert 9 with an insulating pad 10 into the main silencer and secure with screws 8

- Mount the O-ring 3 onto the connecting cap 2.

- Slide the new glass fiber yarn filling 4 over the perforated pipe.

- Mount connecting cap 2 and glass fiber yarn filling 4 in the main silencer.

- Info

- Slide the glass fiber yarn filling into the main silencer with a blunt tool.

- Mount and tighten screws 1.

- Mount O-ring on silencer cap 6.

- Position silencer cap 6. Mount and tighten screws 5

AIR FILTER

Removing the air filter box lid

- (EXC‑F EU/AUS/BR, EXC-F SIX DAYS, XCF-W)

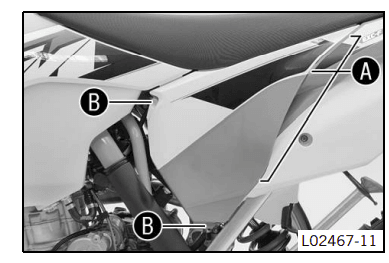

- Pull off the air filter box lid in area A sideways and remove it toward the front.

- (EXC-F US)

- Pull off the air filter box lid in area A sideways and remove it toward the front.

- Installing the air filter box lid

- (EXC‑F EU/AUS/BR, EXC-F SIX DAYS, XCF-W)

- Insert the air filter box lid into the rear area A and clip it into the front area B.

- (EXC-F US)

- Insert the air filter box lid into rear area A and clip it into the front area B

- Sealing the air filter box

- Preparatory work

- Remove the air filter box lid. ( p. 85)

- Main work

- Seal the air filter box in the marked area A.

- Finishing work

- Install the air filter box lid. ( p. 85)

- Removing the air filter

- Note

- Engine failure Unfiltered intake air has a negative effect on the service life of the engine

- Preparatory work

- Remove the air filter box lid. ( p. 85)

- Main work

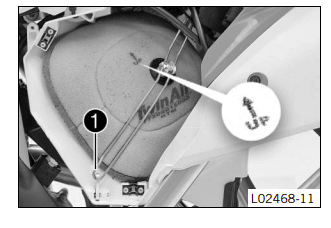

- Detach air filter holder 1 at the bottom and swing it to one side. Remove the air filter with the air filter support.

- Remove the air filter from the air filter support.

Installing the air filter

- Main work

- Mount the clean air filter on the air filter support.

- Grease the air filter in area A.

- Long-life grease ( p. 340)

- Insert both parts together, position them and fasten them using an air filter holder 1.

- The arrow of marking UP faces up.

- Info

- If the air filter is not correctly mounted, dust and dirt can enter the engine and cause damage.

- Finishing work

- Install the air filter box lid. ( p. 85)

TECHNICAL DATA

Engine

| Design | 1-cylinder 4-stroke engine, water-cooled |

| Displacement | 349.7 cm³ (21.34 cu in) |

| Stroke | 57.5 mm (2.264 in) |

| Bore | 88 mm (3.46 in) |

| Compression ratio | 12.3:1 |

| Idle speed | 1,950… 2,050 rpm |

| Control | DOHC, four valves controlled via cam lever, drive via a timing chain |

| Valve diameter, intake | 36.3 mm (1.429 in) |

| Valve diameter, exhaust | 29.1 mm (1.146 in) |

| Valve clearance | |

| Intake at: 20 °C (68 °F) | 0.10… 0.15 mm (0.0039… 0.0059 in) |

| Exhaust at: 20 °C (68 °F) | 0.13… 0.18 mm (0.0051… 0.0071 in) |

| Crankshaft bearing | 2 cylinder bearings |

| Conrod bearing | Slide bearing |

| Piston pin bearing | Not a bearing bush – DLC-plated piston pins |

| Pistons | Forged light-alloy |

| Piston rings | 1 compression ring, 1 oil scraper ring |

| Engine lubrication | Pressure circulation lubrication with two Eaton pumps |

| Primary transmission | 24:73 |

| Clutch | Multidisc clutch in oil bath/hydraulically activated |

| Transmission ratio | |

| 1st gear | 14:32 |

| 2nd gear | 16:26 |

| 3rd gear | 20:25 |

| 4th gear | 22:23 |

| 5th gear | 25:22 |

| 6th gear | 26:20 |

| Alternator | 12 V, 168 W |

| Ignition | Contactless controlled fully electronic ignition with digital ignition adjustment |

| Spark plug | NGK LMAR9AI-8 |

| Spark plug electrode gap | 0.8 mm (0.031 in) |

| Cooling | Water cooling, permanent circulation of coolant by water pump |

| Starting aid | Kickstarter and electric starter |

| Valve – run-out | |

| At the valve plate | ≤ 0.05 mm (≤ 0.002 in) |

| Valve spring | |

| Minimum length | 42.00 mm (1.6535 in) |

| Valve – sealing seat width | |

| Intake | 1.40 mm (0.0551 in) |

| Exhaust | 1.40 mm (0.0551 in) |

| Valve spring seat – thickness | 0.90… 1.10 mm (0.0354… 0.0433 in) |

| Camshaft bearing – sleeve bearing | |

| Radial clearance | 0.020… 0.054 mm (0.00079… 0.00213 in) |

| Wear limit | 0.065 mm (0.00256 in) |

| Cylinder/cylinder head – distortion of sealing area | ≤ 0.10 mm (≤ 0.0039 in) |

| Piston – diameter | |

| Size I | 87.965… 87.975 mm (3.46318… 3.46358 in) |

| Size II | 87.976… 87.985 mm (3.46362… 3.46397 in) |

| Cylinder – drill hole diameter | |

| Size I | 88.000… 88.012 mm (3.46456… 3.46503 in) |

| Size II | 88.012… 88.025 mm (3.46503… 3.46554 in) |

| Piston/cylinder – mounting clearance | |

| Size I | 0.025… 0.047 mm (0.00098… 0.00185 in) |

| Size II | 0.027… 0.049 mm (0.00106… 0.00193 in) |

| Wear limit | 0.070 mm (0.00276 in) |

| Piston ring – end gap | |

| Compression ring | ≤ 0.40 mm (≤ 0.0157 in) |

| Oil scraper ring | ≤ 0.80 mm (≤ 0.0315 in) |

| Connecting rod – axial play of lower conrod bearing | 0.20… 0.45 mm (0.0079… 0.0177 in) |

| Crankshaft – axial play | 0.50… 0.60 mm (0.0197… 0.0236 in) |

| Crankshaft – run-out at bearing pin | ≤ 0.03 mm (≤ 0.0012 in) |

| Clutch facing discs – thickness of total package | ≥ 26.4 mm (≥ 1.039 in) |

| Oil pressure regulator valve | |

| Minimum length of pressure spring | 23.5 mm (0.925 in) |

| Shift shaft – sliding plate/shift quadrant clearance | 0.40… 0.80 mm (0.0157… 0.0315 in) |

| Engine oil consumption | ≤ 20 ml/h (≤ 0.68 fl. oz./hr) |

| Nozzle, crank chamber ventilation | M4 | 2 Nm (1.5 lbf ft) | Loctite® 243™ |

| Oil nozzle for alternator cooling | M4 | 2 Nm (1.5 lbf ft) | Loctite® 243™ |

| Oil nozzle for balancer shaft lubrication | M4 | 2 Nm (1.5 lbf ft) | Loctite® 243™ |

| Oil nozzle for conrod bearing lubrica- tion | M4 | 2 Nm (1.5 lbf ft) | Loctite® 243™ |

| Screw, oil nozzle for piston cooling | M4 | 2 Nm (1.5 lbf ft) | Loctite® 243™ |

| Locking screw for bearing | M5 | 6 Nm (4.4 lbf ft) | Loctite® 243™ |

| Oil channel screw plug in alternator cover | M5 | 1.2 Nm (0.89 lbf ft) | Loctite® 648™ |

| Oil nozzle for cam lever lubrication | M5 | 3 Nm (2.2 lbf ft) | Loctite® 243™ |

| Oil nozzle for clutch lubrication | M5 | 6 Nm (4.4 lbf ft) | Loctite® 243™ |

| Oil nozzle, piston cooling | M5 | 2 Nm (1.5 lbf ft) | Loctite® 243™ |

| Screw, clutch spring | M5 | 6 Nm (4.4 lbf ft) | – |

| Screw, crankshaft position sensor | M5 | 6 Nm (4.4 lbf ft) | Loctite® 243™ |

| Screw, locking lever | M5 | 6 Nm (4.4 lbf ft) | Loctite® 243™ |

| Screw, oil pump cover | M5 | 6 Nm (4.4 lbf ft) | Loctite® 243™ |

| Screw, stator | M5 | 6 Nm (4.4 lbf ft) | Loctite® 243™ |

| Nut, cylinder head | M6 | 10 Nm (7.4 lbf ft) | Lubricated with engine oil |

| Nut, water-pump wheel | M6 | 6 Nm (4.4 lbf ft) | Loctite® 243™ |

| Screw, alternator cover | M6 | 6 Nm (4.4 lbf ft) | – |

| Screw, clutch cover | M6 | 10 Nm (7.4 lbf ft) | – |

| Screw, clutch slave cylinder | M6 | 10 Nm (7.4 lbf ft) | – |

| Screw, engine case | M6 | 10 Nm (7.4 lbf ft) | – |

| Screw, exhaust flange | M6 | 10 Nm (7.4 lbf ft) | Loctite® 243™ |

| Screw, kick starter stop | M6 | 10 Nm (7.4 lbf ft) | Loctite® 243™ |

| Screw, oil filter cover | M6 | 10 Nm (7.4 lbf ft) | – |

| Screw, shift drum locating | M6 | 10 Nm (7.4 lbf ft) | Loctite® 243™ |

| Screw, shift lever | M6 | 14 Nm (10.3 lbf ft) | Loctite® 243™ |

| Screw, starter motor | M6 | 10 Nm (7.4 lbf ft) | – |

| Screw, timing chain guide rail | M6 | 10 Nm (7.4 lbf ft) | Loctite® 243™ |

| Screw, timing chain securing guide | M6 | 10 Nm (7.4 lbf ft) | Loctite® 243™ |

| Screw, valve cover | M6 | 8 Nm (5.9 lbf ft) | – |

| Screw, water pump cover | M6 | 10 Nm (7.4 lbf ft) | – |

| Stud, cylinder head | M6 | 10 Nm (7.4 lbf ft) | – |

| Screw, camshaft bearing bridge | M7x1 | 14 Nm (10.3 lbf ft) | Lubricated with engine oil |

| Screw plug, crankshaft location | M8 | 10 Nm (7.4 lbf ft) | – |

| Screw, kick starter | M8 | 25 Nm (18.4 lbf ft) | Loctite® 243™ |

| Screw, timing chain tensioning rail | M8 | 15 Nm (11.1 lbf ft) | Loctite® 243™ |

| Screw, engine sprocket | M10 | 60 Nm (44.3 lbf ft) | Loctite® 2701™ |

| Plug, oil channel | M10x1 | 15 Nm (11.1 lbf ft) | Loctite® 243™ |

| Rotor screw | M10x1 | 70 Nm (51.6 lbf ft) | Thread, oiled with engine oil/cone degreased |

| Screw plug, cam lever axis | M10x1 | 10 Nm (7.4 lbf ft) | – |

| Screw, unlocking of timing chain ten- sioner | M10x1 | 10 Nm (7.4 lbf ft) | – |

| Spark plug | M10x1 | 10… 12 Nm (7.4… 8.9 lbf ft) | – |

| Nut, cylinder head | M10x1.25 | Tightening sequence: Tighten diagonally. 1st tightening stage 10 Nm (7.4 lbf ft) 2nd tightening stage 30 Nm (22.1 lbf ft) 3rd tightening stage 50 Nm (36.9 lbf ft) | Thread, oiled with engine oil/cone greased |

| Stud, cylinder head | M10x1.25 | 20 Nm (14.8 lbf ft) | Loctite® 243™ |

| Screw, camshaft drive sprocket | M12x1 | 70 Nm (51.6 lb-ft) | Loctite® 243™/cone degreased |

| Engine coolant temperature sensor | M12x1.5 | 12 Nm (8.9 lb-ft) | – |

| Oil drain plug with magnet | M12x1.5 | 20 Nm (14.8 lbf ft) | – |

| Plug, oil pressure regulator valve | M12x1.5 | 20 Nm (14.8 lbf ft) | – |

| SAS screw plug (EXC-F US) | M12x1.5 | 20 Nm (14.8 lb-ft) | – |

| Oil drain plug | M14x1.5 | 15 Nm (11.1 lbf ft) | – |

| Nut, SAS valve (EXC-F US) | M16 | 15 Nm (11.1 lb-ft) | – |

| Nut, inner clutch hub | M18x1.5 | 100 Nm (73.8 lb-ft) | Loctite® 243™ |

| Nut, primary gear | M18LHx1.5 | 100 Nm (73.8 lb ft) | Loctite® 243™ |

| Screw plug, oil screen | M20x1.5 | 15 Nm (11.1 lb-ft) | – |

| Plug, timing chain tensioner | M24x1.5 | 25 Nm (18.4 lbf ft) | – |

| Screw, alternator cover | M24x1.5 | 18 Nm (13.3 lbf ft) | – |

| Engine oil | 1.2 l (1.3 qt.) | Engine oil (SAE 10W/50) ( p. 338) | |

| Alternative engine oil for harsh operating conditions and increased performance | Engine oil (SAE 10W/60) (00062010035) ( p. 338) | ||

| Coolant | 1.2 l (1.3 qt.) | Coolant ( p. 338) |

| Coolant (mixed ready to use) ( p. 338) |

| Total fuel tank capacity, approx. (EXC‑F EU/AUS/BR, EXC-F SIX DAYS) | 9 l (2.4 US gal) | Super unleaded (ROZ 95/RON 95/PON 91) ( p. 339) |

| Total fuel tank capacity, approx. (EXC-F US, All XCF-W models) | 8.5 l (2.25 US gal) | Super unleaded (ROZ 95/RON 95/PON 91) ( p. 339) |

| Fuel reserve, approx. | 1.5 l (1.6 qt.) |

| Frame | Central tube frame made of chrome molybdenum steel tubing |

| Fork (EXC‑F EU/AUS/BR/US, XCF‑W) | WP Suspension Up Side Down 4860 MXMA PA |

| Fork (All SIX DAYS models) | WP Suspension Up Side Down 4860 4CS |

| Suspension travel (EXC‑F EU/AUS/BR/US, XCF‑W) | |

| Front | 300 mm (11.81 in) |

| Suspension travel (All SIX DAYS models) | |

| Front | 300 mm (11.81 in) |

| Suspension travel | |

| Rear | 335 mm (13.19 in) |

| Fork offset | 20 mm (0.79 in) |

| Shock absorber | WP Suspension PDS 5018 DCC |

| Brake system | Disc brakes, brake calipers on floating bearings |

| Brake discs – diameter | |

| Front | 260 mm (10.24 in) |

| Rear | 220 mm (8.66 in) |

| Brake discs – wear limit | |

| Front | 2.5 mm (0.098 in) |

| Rear | 3.5 mm (0.138 in) |

| Tire air pressure off-road | |

| Front | 1.0 bar (15 psi) |

| Rear | 1.0 bar (15 psi) |

| Road tire pressure (All EXC‑F models) | |

| Front | 1.5 bar (22 psi) |

| Rear | 1.5 bar (22 psi) |

| Final drive (EXC‑F EU, EXC‑F AU, EXC-F SIX DAYS) | 14:52 (13:52) |

| Final drive (EXC‑F BR, All XCF-W models) | 13:52 |

| Final drive (EXC-F US) | 14:52 |

| Chain | 5/8 x 1/4″ |

| Rear sprockets available | 38, 40, 42, 45, 48, 49, 50, 51, 52 |

| Steering head angle | 63.5° |

| Wheelbase | 1,482±10 mm (58.35±0.39 in) |

| Seat height unloaded | 970 mm (38.19 in) |

| Ground clearance unloaded | 345 mm (13.58 in) |

| Homologated weight without fuel, approx. (EXC‑F EU/AUS/BR, EXC-F SIX DAYS) | 108 kg (238 lb.) |

| Homologated weight without fuel, approx. (EXC-F US) | 109.5 kg (241.4 lb.) |

| Weight without fuel, approx. (All XCF-W models) | 107.2 kg (236.3 lb.) |

| Maximum permissible front axle load | 145 kg (320 lb.) |

| Maximum permissible rear axle load | 190 kg (419 lb.) |

| Maximum permissible overall weight | 335 kg (739 lb.) |

| Battery (EXC‑F EU/AUS/US, EXC-F SIX DAYS, XCF-W) | YTX4L-BS | Battery voltage: 12 V Nominal capacity: 3 Ah Maintenance-free |

| Battery (EXC‑F BR) | YTX5L-BS | Battery voltage: 12 V Nominal capacity: 4 Ah Maintenance-free |

| Speedometer battery | CR 2430 | Battery voltage: 3 V |

| Fuse | 58011109105 | 5 A |

| Fuse | 75011088010 | 10 A |

| Fuse | 58011109120 | 20 A |

| Headlight | HS1 / socket PX43t | 12 V 35/35 W |

| Parking light | W5W / socket W2.1×9.5d | 12 V 5 W |

| Indicator lamps | W2.3W / socket W2x4.6d | 12 V 2.3 W |

| Turn signal (EXC‑F EU/AUS/BR, EXC-F SIX DAYS) | R10W / socket BA15s | 12 V 10 W |

| Turn signal (EXC-F US) | RY10W / socket BAU15s | 12 V 10 W |

| Brake/tail light | LED | |

| License plate lamp (All EXC‑F models) | W5W / socket W2.1×9.5d | 12 V 5 W |

| Validity | Front tires | Rear tires |

| (EXC-F US, EXC‑F EU, EXC‑F AU) | 80/100 – 21 M/C 51M TT MAXXIS MAXX CROSS SI | 140/80 – 18 M/C 70R TT MAXXIS MAXX ENDURO |

| (EXC-F US, EXC‑F BR, EXC-F SIX DAYS) | 90/90 – 21 M/C 54M M+S TT Metzeler MCE 6 Days Extreme | 140/80 – 18 M/C 70M M+S TT Metzeler MCE 6 Days Extreme |

| (All XCF-W models) | 90/90 – 21 54M TT Dunlop GEOMAX AT81F | 110/100 – 18 64M TT Dunlop GEOMAX AT81 |

| Additional information is available in the Service section under: http://www.ktm.com | ||

EXC‑F EU/AUS/BR/US, XCF‑W

| Fork part number | 14.18.7L.67 |

| Fork | WP Suspension Up Side Down 4860 MXMA PA |

| Compression damping | |

| Comfort | 22 clicks |

| Standard | 20 clicks |

| Sport | 18 clicks |

| Rebound damping | |

| Comfort | 20 clicks |

| Standard | 18 clicks |

| Sport | 16 clicks |

| Spring preload – Preload Adjuster | |

| Comfort | 1 turn |

| Standard | 2 turns |

| Sport | 2 turns |

| Spring length with preload spacer(s) | |

| Weight of rider: 65… 75 kg (143… 165 lb.) | 513 mm (20.2 in) |

| Weight of rider: 75… 85 kg (165… 187 lb.) | 513 mm (20.2 in) |

| Weight of rider: 85… 95 kg (187… 209 lb.) | 513 mm (20.2 in) |

| Spring rate | |

| Weight of rider: 65… 75 kg (143… 165 lb.) | 4.0 N/mm (22.8 lb/in) |

| Weight of rider: 75… 85 kg (165… 187 lb.) | 4.2 N/mm (24 lb/in) |

| Weight of rider: 85… 95 kg (187… 209 lb.) | 4.4 N/mm (25.1 lb/in) |

| Fork length | 940 mm (37.01 in) |

| Air chamber length | 110+10 mm (4.33+0.39 in) −20 −0.79 |

| Fork oil per fork leg | 620 ml (20.96 fl. oz.) | Fork oil (SAE 4) (48601166S1) ( p. 339) |

All SIX DAYS models

| Fork part number | 24.18.7N.67 |

| Fork | WP Suspension Up Side Down 4860 4CS |

| Compression damping | |

| Comfort | 15 clicks |

| Standard | 13 clicks |

| Sport | 11 clicks |

| Rebound damping | |

| Comfort | 15 clicks |

| Standard | 13 clicks |

| Sport | 11 clicks |

| Spring length with preload spacer(s) | 472 mm (18.58 in) |

| Spring rate | |

| Weight of rider: 65… 75 kg (143… 165 lb.) | 4.0 N/mm (22.8 lb/in) |

| Weight of rider: 75… 85 kg (165… 187 lb.) | 4.2 N/mm (24 lb/in) |

| Weight of rider: 85… 95 kg (187… 209 lb.) | 4.4 N/mm (25.1 lb/in) |

| Fork length | 932 mm (36.69 in) |

| Air chamber length | 100 mm (3.94 in) |

| Oil capacity per fork leg | 635 ml (21.47 fl. oz.) | Fork oil (SAE 4) (48601166S1) ( p. 339) |

| Shock absorber part number | 12.18.7L.67 |

| Shock absorber | WP Suspension PDS 5018 DCC |

| Compression damping, low-speed | |

| Comfort | 25 clicks |

| Standard | 20 clicks |

| Sport | 15 clicks |

| Compression damping, high-speed | |

| Comfort | 2 turns |

| Standard | 1.5 turns |

| Sport | 1.25 turns |

| Rebound damping | |

| Comfort | 28 clicks |

| Standard | 24 clicks |

| Sport | 22 clicks |

| Spring preload | 8 mm (0.31 in) |

| Spring rate | |

| Weight of rider: 65… 75 kg (143… 165 lb.) | 66 N/mm (377 lb/in) |

| Weight of rider: 75… 85 kg (165… 187 lb.) | 69 N/mm (394 lb/in) |

| Weight of rider: 85… 95 kg (187… 209 lb.) | 72 N/mm (411 lb/in) |

| Spring length | 250 mm (9.84 in) |

| Gas pressure | 10 bar (145 psi) |

| Static sag | 33… 35 mm (1.3… 1.38 in) |

| Riding sag | 105… 115 mm (4.13… 4.53 in) |

| Fitted length | 417 mm (16.42 in) |

| Damper oil | Shock absorber fluid (SAE 2.5) (50180751S1) ( p. 339) |

Chassis tightening torques

| Screw, pressure regulator | EJOT PT® K60x25‑Z | 3 Nm (2.2 lbf ft) | – |

| Spoke nipple, front wheel | M4.5 | 6 Nm (4.4 lbf ft) | – |

| Spoke nipple, rear wheel | M4.5 | 6 Nm (4.4 lbf ft) | – |

| Screw, battery terminal | M5 | 2.5 Nm (1.84 lb ft) | – |

| Screw, intake air temperature sensor | M5 | 2 Nm (1.5 lb ft) | – |

| Screw, shock absorber adjusting ring | M5 | 5 Nm (3.7 lb ft) | – |

| Screw, spoiler on fuel tank (EXC-F US, All XCF-W models) | M5x12 | 1.5 Nm (1.11 lb-ft) | – |

| Nut, cable on the starter motor | M6 | 4 Nm (3 lb-ft) | – |

| Remaining nuts, chassis | M6 | 10 Nm (7.4 lb-ft) | – |

| Remaining screws, chassis | M6 | 10 Nm (7.4 lb-ft) | – |

| Screw, ball joint of push rod on foot brake cylinder | M6 | 10 Nm (7.4 lbf ft) | Loctite® 243™ |

| Screw, chain sliding guard | M6 | 6 Nm (4.4 lbf ft) | Loctite® 243™ |

| Screw, front brake disc | M6 | 14 Nm (10.3 lb ft) | Loctite® 243™ |

| Screw, rear brake disc | M6 | 14 Nm (10.3 lb ft) | Loctite® 243™ |

| Screw, throttle grip | M6 | 5 Nm (3.7 lb-ft) | – |

| Fuel connection on fuel pump | M8 | 10 Nm (7.4 lb-ft) | – |

| Nut, foot brake lever stop | M8 | 20 Nm (14.8 lb-ft) | – |

| Nut, rear sprocket screw | M8 | 35 Nm (25.8 lb-ft) | Loctite® 2701™ |

| Nut, rim lock | M8 | 12 Nm (8.9 lb-ft) | – |

| Remaining nuts, chassis | M8 | 25 Nm (18.4 lb-ft) | – |

| Remaining screws, chassis | M8 | 25 Nm (18.4 lb-ft) | – |

| Screw, bottom triple clamp (All SIX DAYS models) | M8 | 15 Nm (11.1 lb-ft) | – |

| Screw, bottom triple clamp (EXC‑F EU/AUS/BR/US, XCF‑W) | M8 | 15 Nm (11.1 lb ft) | – |

| Screw, chain sliding piece | M8 | 15 Nm (11.1 lb-ft) | – |

| Screw, engine brace | M8 | 33 Nm (24.3 lb ft) | Loctite® 2701™ |

| Screw, fork stub | M8 | 15 Nm (11.1 lb ft) | – |

| Screw, front brake caliper | M8 | 25 Nm (18.4 lbf ft) | Loctite® 243™ |

| Screw, handlebar clamp | M8 | 20 Nm (14.8 lbf ft) | – |

| Screw, side stand attachment | M8 | 45 Nm (33.2 lbf ft) | Loctite® 2701™ |

| Screw, subframe | M8 | 35 Nm (25.8 lbf ft) | Loctite® 2701™ |

| Screw, top steering stem (All SIX DAYS models) | M8 | 17 Nm (12.5 lbf ft) | Loctite® 243™ |

| Screw, top steering stem (EXC‑F EU/AUS/BR/US, XCF‑W) | M8 | 20 Nm (14.8 lbf ft) | – |

| Screw, top triple clamp (All SIX DAYS models) | M8 | 17 Nm (12.5 lbf ft) | – |

| Screw, top triple clamp (EXC‑F EU/AUS/BR/US, XCF‑W) | M8 | 20 Nm (14.8 lbf ft) | – |

| Engine attachment bolt | M10 | 60 Nm (44.3 lbf ft) | – |

| Remaining nuts, chassis | M10 | 45 Nm (33.2 lbf ft) | – |

| Remaining screws, chassis | M10 | 45 Nm (33.2 lbf ft) | – |

| Screw, handlebar holder | M10 | 40 Nm (29.5 lb-ft) | Loctite® 243™ |

| Nut, fuel pump fixation | M12 | 15 Nm (11.1 lb-ft) | – |

| Screw, bottom shock absorber | M12 | 80 Nm (59 lb-ft) | Loctite® 2701™ |

| Screw, top shock absorber | M12 | 80 Nm (59 lb ft) | Loctite® 2701™ |

| Nut, seat fixing | M12x1 | 20 Nm (14.8 lb ft) | – |

| Nut, swingarm pivot | M16x1.5 | 100 Nm (73.8 lbf ft) | – |

| Nut, rear wheel spindle | M20x1.5 | 80 Nm (59 lbf ft) | – |

| Screw, top steering head | M20x1.5 | 12 Nm (8.9 lbf ft) | – |

| Screw-in nozzles, cooling system | M20x1.5 | 12 Nm (8.9 lbf ft) | Loctite® 243™ |

| Screw, front wheel spindle | M24x1.5 | 45 Nm (33.2 lbf ft) | – |

For more manuals by KTM visit, ManualsLibraryy

KTM 350 EXC-F Enduro Motorcycle-FAQs

Is the KTM 350 EXC-F street legal?

Yes, the KTM 350 EXC-F is a dual-sport motorcycle that is street-legal and designed for both on-road and off-road use.

What is the average fuel efficiency of the KTM 350 EXC-F?

The KTM 350 EXC-F averages 53.9 miles per gallon based on user data.

How often should I change the oil on a KTM 350 EXC-F?

For trail and lane riding, it is recommended to change the oil every 15 hours of use.

Which KTM bike has the highest top speed?

The KTM RC 390 has a top speed of approximately 170 km/h.

How much power does the KTM 350 EXC-F produce?

The 2024 KTM 350 EXC-F produces 51 horsepower and features an improved center of gravity for better handling.

Is the KTM 350 EXC-F fuel-injected?

Yes, the KTM 350 EXC-F is equipped with a fuel-injected DOHC engine, offering excellent power delivery and a superior power-to-weight ratio.

What are the updates to the 2024 KTM 350 EXC-F?

The 2024 model includes a black powder-coated frame, improved grip-textured frame protectors, a new forged one-piece side stand, and enhanced durability.

How long does a KTM engine last?

KTM engines can last up to 50,000 km with proper maintenance. Some riders report needing engine rebuilds after 40,000+ km due to lightweight components designed for high performance.

What is the fuel tank capacity of the KTM 350 EXC-F?

The KTM 350 EXC-F has a fuel tank capacity of 8.5 liters.

Are KTM bikes easy to maintain?

KTM bikes are relatively easy to maintain with consistent care. Regular servicing ensures longevity and minimizes avoidable issues.

How many kilometers is synthetic blend oil good for?

Synthetic blend oil is typically recommended for 12,000 to 16,000 kilometers, but always refer to your owner’s manual for specific guidance.