Pit Boss Grills Austin XL Wood Pellet Grill

PARTS & SPECS

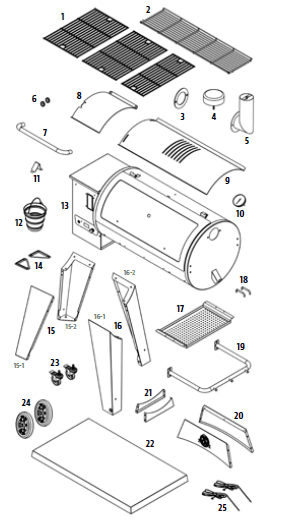

| Part# | Description |

| 1 | Porcelain-Coated Cast-Iron Cooking Grids (x3) |

| 2 | Porcelain-Coated Steel Upper Cooking Rack (x1) |

| 3 | Chimney Gasket (x1) |

| 4 | Chimney Cap (x1) |

| 5 | Chimney Stack (x1) |

| 6 | Lid Handle Bezel (x2) |

| 7 | Lid Handle (x1) |

| 8 | Flame Broiler Slider (x1) |

| 9 | Flame Broiler Main Plate (x1) |

| 10 | Thermometer Kit (x1) |

| 11 | Lid Stopper (x1) |

| 12 | Grease Bucket (x1) |

| 13 | Main Grill / Hopper Assembly (x1) |

| 14 | Support Leg Foot (x2) |

| 15 | Support Leg for Locking Caster Wheel (x2) |

| 16 | Support Leg for Wheel (x2) |

| 17 | Serving Tray (x1) |

| 18 | Serving Tray Handle (x2) |

| 19 | Side Shelf Handle (x1) |

| 20 | Long Support Plate (x2) |

| 21 | Short Support Plate (x2) |

| 22 | Bottom Shelf (x1) |

| 23 | Locking Caster Wheel (x2) |

| 24 | Wheel (x2) |

| 25 | Meat Probe (x2) |

| A | Screw (x18) |

| B | Washer (x18) |

| C | Locking Washer (x18) |

| D | Wheel Cotter Pin (x2) |

| E | Wheel Washer (x2) |

| F | Wheel Axle Pin (x2) |

| G | Screw (x12) |

| H | Screw (x16) |

| MODEL | UNIT ASSEMBLED (WxHxD) | UNIT WEIGHT | COOKING AREA | TEMP. RANGE | DIGITAL FEATURES | |

| PB | PB1000XLW1 | 1,585mm x 1,225mm x 655mm / 62.4” x 48.2” x 25.8” | 82.0 kg / 180.78 lb | Main – 4,110 cm² / 637 sq. in. Upper Rack – 1,851 cm² / 287 sq. in. TOTAL – 5,961 cm² / 924 sq. in. | 82-260°C / 180-500°F | Ten temperature presets, start-up cycle, electric igniter |

ASSEMBLY PREPARATION

Parts are located throughout the shipping carton, including underneath the grill. Inspect the grill, parts, and hardware blister pack after removing them from the protective shipping carton. Discard all packaging materials from inside and outside of the grill before assembly, then review and inspect all parts by referencing the parts list. If any part is missing or damaged, do not attempt to assemble it. Shipping damage is not covered under warranty. Contact your dealer or Pit Boss Customer Service for parts: Monday through Sunday, 4 am – 8 pm PST (EN/FR/ES).

ASSEMBLY INSTRUCTIONS

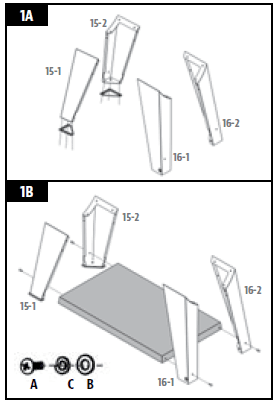

1. INSTALLING THE BOTTOM SHELF

Parts Required

- 2 x Support Leg Foot (#14)

- 2 x Support Leg for Locking Caster Wheel (#15)

- 2 x Support Leg for Wheel (#16)

- 1 x Bottom Shelf (#22)

- 4 x Screw (#A)

- 4 x Locking Washer (#C)

- 4 x Washer (#B)

- 6 x Screw (#G)

Installation

- Secure one support leg foot to the bottom of a support leg for locking the caster wheel using three screws. Repeat installation for other support leg foot. Next, place a piece of cardboard on the floor to prevent scratching the unit and parts during assembly. Prepare the four support legs for installation, arranging the labeled legs as shown in illustration 1A.

- Attach the bottom shelf to one support leg by carefully aligning it into the slotted corner of the support leg, then secure using one screw. Repeat installation for the other three support legs to the remaining three corners of the bottom shelf. Note illustration 1B.

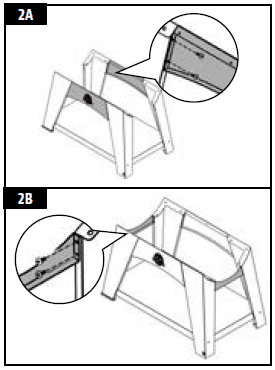

COMPLETING THE CART

Parts Required

- 2 x Long Support Plate (#20)

- 2 x Short Support Plate (#21)

- 16 x Screw (#H)

Installation

- Install one long cart plate to the front two support legs of the unit. Secure using two screws on each side. Ensure the flat side of the support plate is facing outwards. Repeat the same installation to mount the other long support plate to the other support legs. Note illustration 2A for support plate arrangement.

- Next, secure the short support plates to the opposing sides of the cart. Secure using two screws on each side. Note illustration 2B.

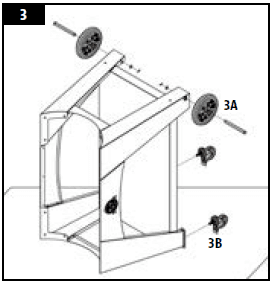

3. CONNECTING THE WHEELS TO THE CART

Parts Required

- 2 x Wheel (#24)

- 2 x Wheel Axle Pin (#F)

- 2 x Wheel Washer (#E)

- 2 x Wheel Cotter Pin (#D)

- 2 x Locking Caster Wheel (#23)

Installation

- Lay the cart on its side to install the wheels. Attach the large wheel to the support leg by inserting the wheel axle pin through the wheel, support leg hole, and then secure using the wheel cotter pin. Repeat installation for the other wheel on the same side. Note 3A.

- Insert each locking caster wheel into the bottom of each support leg by hand-tightening into the hole. It will secure into the self-clinching nut. Ensure the locking caster wheel is inserted completely by ensuring it cannot rotate any further. Note 3B.

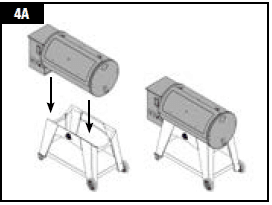

4. INSTALLING THE MAIN GRILL TO THE CART

Parts Required

- 1 x Main Grill (#13)

- 12 x Screw (#A)

- 12 x Locking Washer (#C)

- 12 x Washer (#B)

- 6 x Screw (#G)

Installation

- Prepare the main barrel to be mounted to the cart. Carefully, lift the cart into an upright position, with the wheels on the bottom. Position the cart next to the main grill, with both facing the same direction. Lock the caster wheels on the cart. Using a second person, prepare to lift the main grill onto the cart. With one person lifting from the hopper side, and the other person lifting from the opposing barrel end, carefully lift the main grill, and slowly lower onto the cart. Note illustration 4A.

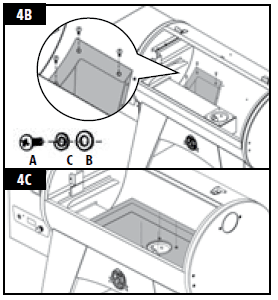

- Next, open the main grill lid and remove the four screws in the center of the large diffuser plate. Remove from the main barrel and set aside. Adjust the rotation as needed to align the screw holes of the main barrel to the cart. Once placed, secure each leg to the main grill barrel using three screws. Note illustration 4B.

5. SECURING THE LID STOPPER

Parts Required

- 1 x Lid Stopper (#11)

Installation

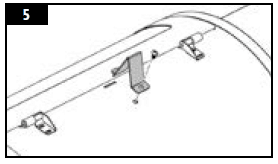

- Secure the lid stopper onto the top of the main barrel using the preinstalled screw on the top of the main barrel.

6. ASSEMBLING THE LID HANDLE

Parts Required

- x Lid Handle (#7)

- x Lid Handle Bezel (#6)

Installation

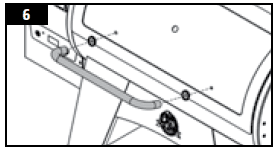

- Remove the pre-installed screws from the lid handle. From inside the barrel lid, insert one screw to protrude to the outside. Add a bezel on the screw, then hand-tighten the screw (from the inside) into the lid handle. Repeat for the other side.

7. INSTALLING THE THERMOMETER

Parts Required

- 1 x Thermometer Kit (#10)

Installation

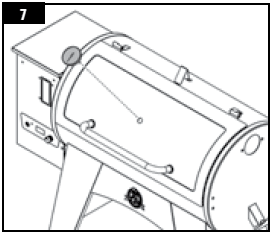

- Remove the pre-installed nut from the thermometer.

- Insert the thermometer into the hole provided on the top of the lid on the main barrel, then secure by re installing the nut from the inside. Rotate the thermometer so the text is level and upright.

8. PLACING THE GREASE BUCKET

Parts Required

1 x Grease Bucket (#12)

Installation

- Unscrew the six screws along the outside of the hopper that secure the hopper safety screen to the interior, and remove the safety screen to access the grease bucket. Replace the hopper safety screen, and re-install the six screws to secure. Note illustration 8A.

- Place the grease bucket on the spout hook on the end of the main barrel. Ensure it is level to avoid grease spills. Note illustration 8B.

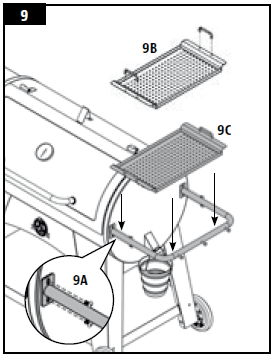

9. MOUNTING SIDE SHELF HANDLE, SERVING TRAY

Parts Required

- 1 x Side Shelf Handle (#19)

- 1 x Serving Tray (#17)

- 1 x Serving Tray Handles (#18)

Installation

- Remove the four pre-installed screws from the side of the main barrel. Mount the side shelf handle onto the main barrel using four screws previously removed. Note 9A.

- Mount serving tray handles to serving tray using the two pre-installed screws on each handle. Note 9B. Place the serving tray onto the side shelf handle. It will rest directly on the frame of the side shelf handle. Note 9C.

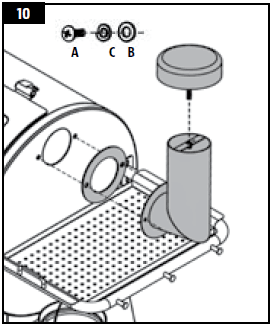

10. SECURING THE CHIMNEY

Parts Required

- 1 x Chimney Gasket (#3)

- 1 x Chimney Cap (#4)

- 1 x Chimney Stack (#5)

- 2 x Screw (#A)

- 2 x Locking Washer (#C)

- 2 x Washer (#B)

Installation

- Locate the chimney opening on the side of the main barrel. From the outside, secure the chimney gasket and chimney stack to the side panel using two screws. Next, twist the chimney cap onto the top.

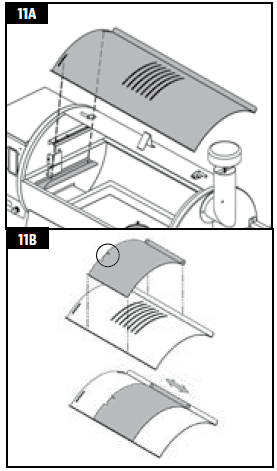

11. INSTALLING THE COOKING COMPONENTS

Parts Required

- 3 x Cooking Grids (#1)

- 1 x Upper Cooking Rack (#2)

- 1 x Flame Broiler Main Plate (#9)

- 1 x Flame Broiler Slider (#8)

Installation

- Insert the flame broiler main plate into the main grill, right side first. Rest the flame broiler main plate on the built-in ledge (on the inside right) of the main grill that directs grease toward the grease bucket. Slide the entire piece to the left side, and the two slots on the flame broiler main plate will fit into the rounded ledge above the fire pot. It will sit slightly at a downward angle. Note illustration 8A.

- Place the flame broiler slider on top of the flame broiler main plate, covering the slotted openings. Ensure the raised tab is on the left, to easily adjust for direct or indirect flame when cooking. Note illustration 8B.

- Place the cooking grids, side-by-side, on the grid ledge inside the main grill.

- The unit is now completely assembled.

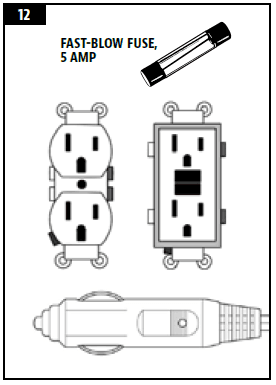

12. CONNECTING TO A POWER SOURCE

NOTE: Before plugging your Pit Boss into any electrical outlet, ensure the temperature dial is in the OFF position.

- STANDARD OUTLET

This appliance requires 110 volt, 60hz, 275w, 5 amp service. It must be a 3-prong grounded plug. Ensure the grounded end is not broken off before use. The control uses a 5 amp, 120 volt, fast-blow fuse to protect the board from the igniter. - GFCI OUTLETS

This appliance will work on most GFCI outlets, with a recommended size of 15 amp service. If your GFCI outlet is highly sensitive to power surges, it will likely trip during the start-up phase of operation. During the start-up phase, the igniter draws 200-700 watts of electricity, which can be too much power for a GFCI outlet to handle. Each time it trips, it increases in sensitivity. If the GFCI keeps tripping, replace the outlet or change to a non-GFCI outlet. - ON THE ROAD

Disconnect the igniter from the main wiring harness. Use the manual start-up procedure. A Pit Boss unit can operate using a 12-volt, 100-watt inverter plugged into your automobile outlet. To use the automatic igniter, it is recommended to use a minimum of a 1000-watt inverter.

GRILL ENVIRONMENT

- WHERE TO SET UP THE GRILL

With all outdoor appliances, outside weather conditions play a big part in the performance of your grill and the cooking time needed to perfect your meals. All Pit Boss units should keep a minimum clearance of 305mm (12 inches) from combustible constructions and this clearance must be maintained while the grill is operational. This appliance must not be placed under an overhead combustible ceiling or overhang. Keep your grill in an area clear of combustible materials, gasoline, and other flammable vapors and liquids. - COLD WEATHER COOKING

As it becomes cooler outside, that does not mean that grilling season is over! The crisp cool air and the heavenly aroma of smoked foods will help cure your winter blues. Follow these suggestions on how to enjoy your grill throughout the cooler months:- If smoking at low temperatures fails, increase the temperature slightly to achieve the same results.

- Organize – Get everything you require ready in the kitchen before you head outdoors. During the winter, move your grill to an area that is out of the wind and direct cold. Check local bylaws regarding the proximity of your grill about your home and/or other structures. Put everything you need on a tray, bundle up tight, and get it done!

- To help keep track of the outside temperature, place an outdoor thermometer close to your cooking area. Keep a log or history of what you cooked, the outdoor temperature, and the cooking time. This will help later down the road to help you determine what to cook and how long it will take.

- In very cold weather, increase your preheating time by at least 20 minutes.

- Avoid lifting the lid any more than necessary. Cold gusts of wind can completely cool your grill temperature. Be flexible with your serving time; add extra cooking time each time you open the lid.

- Have a heated platter or a dish cover ready to keep your food warm while making the trip back inside.

- Ideal foods for winter cooking are those that require little attention, such as roasts, whole chickens, ribs, and turkey. Make your meal preparation even easier by adding simple items such as vegetables and potatoes.

- HOT WEATHER COOKING

As it becomes warmer outdoors, the cooking time will decrease. Proper dress is important when it gets hot: shorts, a shirt, shoes, hat, apron, and a generous slab of suntan lotion is recommended.

Follow these few suggestions on how to enjoy your grill throughout the hot months:

- Adjust your cooking temperatures downward. This helps to avoid unwanted flare-ups.

- Use a meat thermometer to determine the internal temperature of your foods. This helps in preventing your meat from overcooking and drying out.

- Even in hot weather, it is still better to cook with the lid of your grill down.

- You can keep foods hot by wrapping them in foil and placing them in an insulated cooler. Stuff crumpled up newspaper around the foil and this will keep food hot for 3 to 4 hours.

For more manuals by Pit Boss Grills visit, ManualsLibraryy

Pit Boss Grills Austin XL Wood Pellet Grill-FAQs

What is the temperature range of the Smoke setting on the Pit Boss Austin XL?

The Smoke setting maintains a temperature between 180-210°F (80-100°C). Close the lid and set your desired temperature after starting.

Why does my Pit Boss grill keep shutting off?

If the grill doesn’t detect a flame, it stops feeding pellets and turns off the blower fan as a safety feature. This could indicate a failed igniter rod that needs replacement.

How long does it take to preheat a Pit Boss grill?

It typically takes about 5 to 6 minutes to reach the desired cooking temperature.

How do I burn off my pellet grill before cooking?

Set the grill to its highest temperature and let it run for 30 minutes. Afterward, you can start cooking or initiate the shutdown cycle, which lasts about 25 minutes.

How do I smoke ribs on a Pit Boss grill?

Place the ribs on the center rack and smoke for 2.5 hours, spritzing every 25-30 minutes with a mixture of apple juice and cider vinegar (3:1 ratio). After smoking, coat the ribs with softened butter before continuing the cooking process.

Why does my grill keep turning off?

A grill that won’t stay lit may have a clogged burner, a stuck regulator, or a faulty valve or hose. Check and clean these components to resolve the issue.

Does the fan run continuously on a Pit Boss grill?

The fan runs for about 15 minutes after turning off the grill to cool down the system.

What does the P setting on the Pit Boss grill do?

The “P” setting controls the auger pause time. Higher P settings increase the pause duration, affecting pellet feeding and temperature control.

Should I use aluminum foil on my pellet grill?

Avoid covering internal parts with foil, as it can disrupt airflow and interfere with the grill’s heat and airflow sensors, affecting performance.