Vermont Castings Defiant Wood-Burning Stove

THE INSIDE STORY

Economics & Efficient Combustion The How & Why

It has been our experience· that if you understand the inner workings of your stove you will be better equipped to use your stove wisely and to gain maximum savings and pleasure from its daily use. That is why this section on the efficiency and combustion principles of the stoves is included before you reach the installation information.

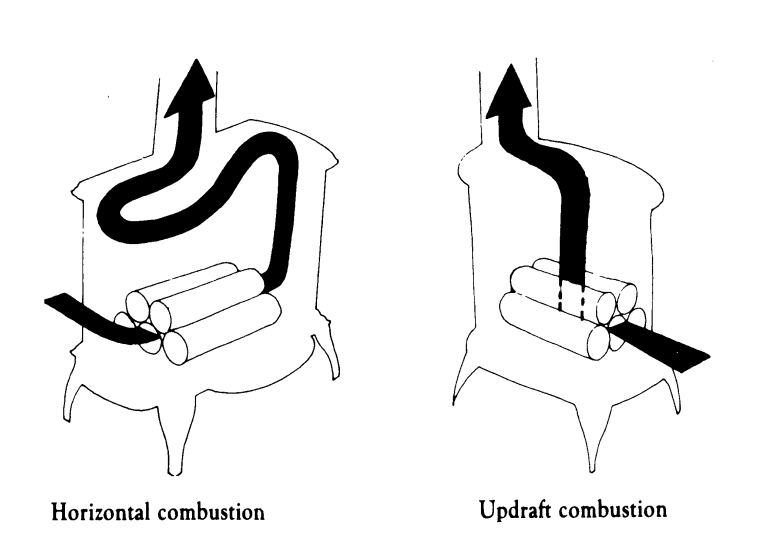

Our four stoves share the same design and combustion principles. The Intrepid differs a little in interior arrangement and air flow patterns. Intrepid owners, see The Intrepid, page 5. Let us start your tour of the inner workings of the stoves with a discussion of horizontal combustion, a fundamental concept behind the operation of our wood stoves. In horizontal combustion, the flames move horizontally as they leave the primary combustion zone. Many stoves employ updraft combustion, in which flames rise up through the fuel load. All wood loaded into an updraft stove becomes part of the fire mass unless oxygen is restricted to a low level. Our horizontal flame path allows only the bottom of the wood load to burn. The logs on top are dried by heat and fall into the flame area as those below are consumed. Thus, a full wood load can provide heat all night long. The use of horizontal combustion allows us to place the fuel in a magazine where the fueling of the fire is automatically accomplished by gravity. Most wood burners will use the horizontal combustion mode under normal conditions as it will ordinarily produce more usable heat in the room per pound of wood loaded into the stove than the updraft mode. However, where special conditions need to be met, such as low draft, extra heat in extreme weather, or an unseasoned wood supply, for example, the updraft mode may serve you better. Our stoves are combustion-controlled (sometimes called “air-tight”) in either mode. The burn rate and heat output may be controlled by adjusting the thermostat lever.

Fuel Limiting:

There are two ways to control the volume of power output in a combustion device: fuel limiting and oxygen limiting. An automobile is fuel-limited. If you need more power, you supply the engine with more fuel. If you make an uncontrolled amount of gasoline available to the spark plugs at once, the engine

becomes an inefficient source of power.

An updraft stove places the entire fuel supply in the combustion zone at once. If the fire is partially smothered to control the rate of the burn, thick smoke, and low efficiencies may result. Our magazine system uses no more than the amount of fuel necessary in the combustion zone at any one time in order

to produce the maximum amount of heat for which the stove was designed. In order to slow the fire below these points, we use oxygen limiting with an automatic thermostat which provides the fire with an appropriate level of oxygen.

Air Control Systems

Primary Air Systems

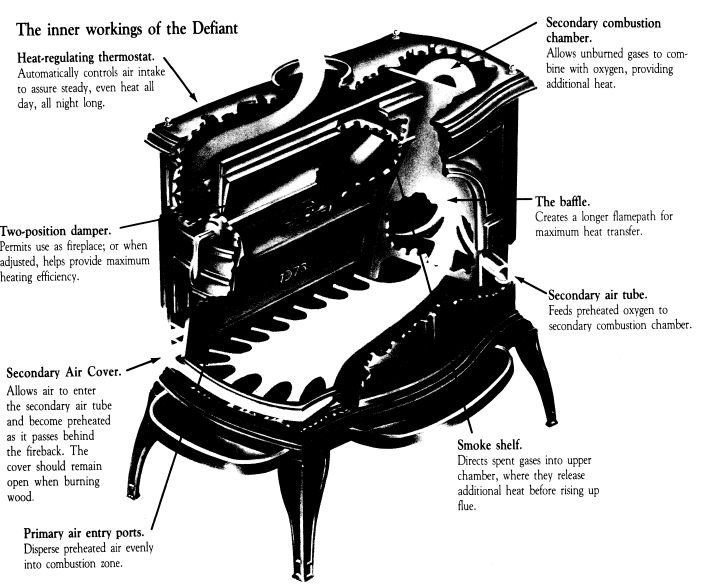

In both our wood and coal stoves, oxygen enters the thermostatically controlled Inlet Air Shutter and travels through passages where it is heated before being fed to the fire mass through the Primary Air Ports. When fuel is heated and bums, the volatile combustible gases naturally locked in it are driven off. In an updraft combustion stove or fireplace, these volatiles may be left unburned for two reasons. First, by the time the gases have left the fuel, they are too cool to ignite. Second, the oxygen that enters the stove is usually consumed by the glowing coals at the base of the fire mass, so the gases rise through an atmosphere too deficient in oxygen to allow combustion to take place. The loss of volatile gases is serious in the case of wood, for it represents approximately half the total heat value.

Secondary Air Systems

Our stoves facilitate the burning of these volatiles in several ways. By using horizontal combustion, the gases are forced to pass close to hot coals which maintain a sufficiently high temperature (as high as 1200° Fahrenheit) for ignition. Our stoves also employ a sophisticated system that introduces another source of preheated air (secondary air) to encourage the combustion of these volatile gases. The secondary combustion of gases that, because of an insufficient oxygen supply, were unable to ignite within the primary combustion zone, are encouraged to release their heat. Secondary air treatment of the coal stoves is different because of the individual characteristics of coal and wood.

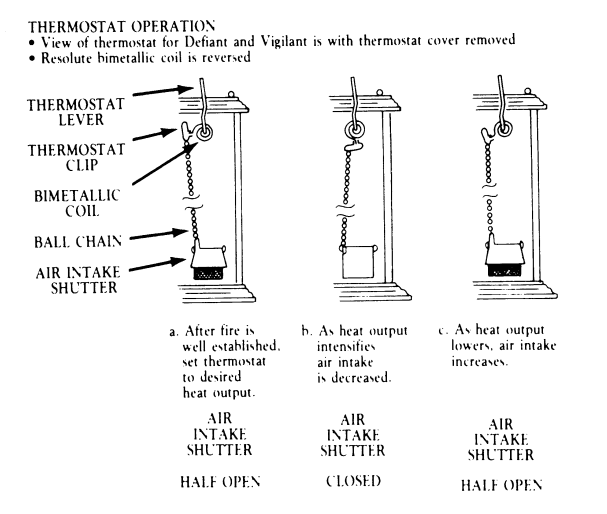

Thermostat Control

The thermostat lever at the back of the stove controls the Inlet Air Shutter, and thus the amount of air entering the stove for combustion. Attached to this lever is a bimetallic coil that contracts or expands to the heat given off from the stove. A ball chain connects the lever to the air inlet shutter, thus regulating

the flow of incoming combustion air. As a result, the stove’s heat output intensifies and the air supply is decreased. The combustion rate slows, heat output drops, and the air supply is again allowed to increase as the bimetallic coil reopens the air intake shutter.

The thermostat lever can be set to accommodate your individual heating requirements. The overall heat output throughout the bum period is determined by the lever setting. The length of burn is similarly related to the lever setting as a high heat output will necessarily allow better fuel consumption than a lower heat output setting. The most efficient use of the stove and fuel can be made by setting the thermometer to allow a moderately hot fire. Long, smoldering bum periods should be avoided.

YOUR WOOD STOVE

The Internal Parts & How They Contribute To Efficient Operation

Secondary Combustion Chamber

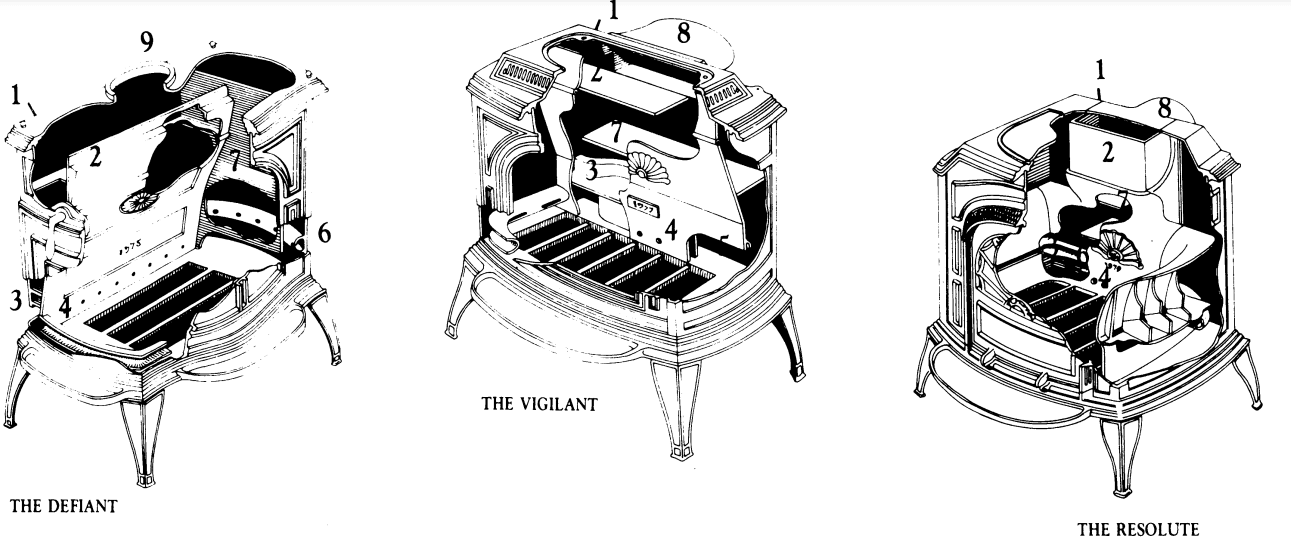

Secondary air enters our wood stoves at the lower left end of the stove through the circular Secondary Air Entrance Port. Under normal conditions, this remains open at all times. This air passes down the Secondary Air Tube where it is preheated. The air supply is then directed into the Secondary Combustion Chamber through numerous airports so that it can mix with and ignite the combustible gases. A Secondary Combustion Chamber allows the gases to expand as they are further heated by their own combustion. A large portion of the stove’s exterior surface encloses this chamber, thus allowing for the transfer of the maximum possible amount of heat to the room. Behind the Fireback are the smoke passages. These passages consist of a series of Baffles that conduct the flue gases in a serpentine manner back and forth across the length of the stove. The gases are channeled close to the thermostat coil in

order to give it maximum sensitivity to the changing fire conditions within the stove. The back of the Vigilant and the back and sides of the Resolute have been deeply convoluted, like old Victorian steam radiators, to provide a large surface of cast iron exposed to the room, ensuring a good radiating surface.

The Flamepath

The Secondary Combustion Chamber, taken together with the smoke passages, makes up the flamepath.

The Defiant’s sixty-inch flamepath is one of the longest of any cast iron stove currently on the market. The Vigilant flamepath measures fifty-five inches; the Resolute fifty inches. A long flame path is important to the heating capability for two reasons.

The considerable heat of the flue gases is transferred to the surface of the stove, where in tum it is given off to the room, rather than being lost up the chimney. Secondly, because the passages are adjacent to the combustion chamber, higher temperatures are maintained within the fire mass itself, which aids

in the burning of the volatiles. It can easily be seen that unless the flame path is concentrated tightly within the stove, the heat of the flue gases will not contribute to the temperature of the primary fire mass, nor will the gases maintain their necessary high temperatures in order to ensure combustion of the volatiles.

The Damper

The damper is the last of the important internal parts. In its vertical or up position, the damper is closed and flames exit from the stove by way of the long flamepath described, allowing the horizontal combustion mode. When lowered flat, the damper is open and the stove is converted to an updraft combustion device, allowing flue gases to escape directly from the magazine into the chimney connector. (The various requirements of the two functions are explained in the section titled “Operation.”) It is important to note the relation of the handle to the damper. On the Defiant and Vigilant, when the damper is closed, both it and the handle are vertical. On the Resolute, the spirally wound wire handle is down when the damper is closed and up when it is open.

Smoke will come out of any opened loading door if the damper is closed. The interlock with the damper handle and the loading door on the Defiant is designed to prevent opening the door while the damper is closed. The griddle of the Vigilant will not open all the way should you forget to lower the damper first.

These serve as reminders that you can only load wood smokelessly when your stove is in an updraft configuration and the damper is in the open position. The section on Operation will explain the proper steps to take before closing the damper when you use the horizontal burning mode.

- Thermostat

- Damper

- Secondary Air Entrance Port

- Primary Air Ports

- Secondary Combustion Chamber

- Secondary Air Tube

- The Baffles

- Reversible Flue Collar

- Top or Rear Exit Model

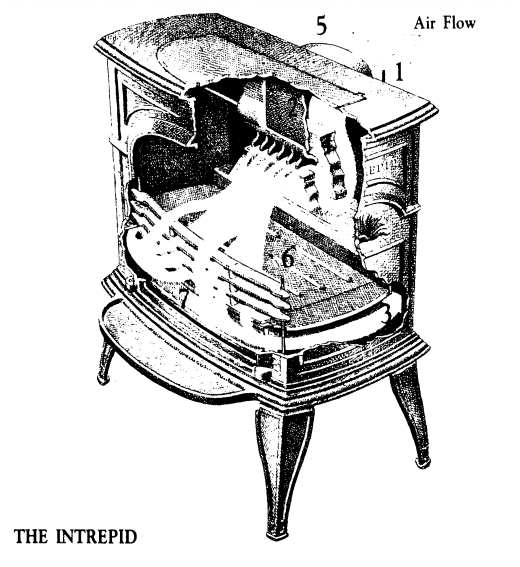

THE INTREPID

The Intrepid is designed with several features that differ from our three larger parlor stoves. Air flow patterns, ash removal, and maintenance procedures are specific to the Intrepid are described here. Basic combustion principles remain the same for all four stoves, so the operation and installation sections of the manual apply equally well to the Intrepid.

Air Flow

Glass doors for fire-viewing are a standard feature in the Intrepid. Airflow through the stove is designed so pre-heated air washes past the glass to prevent carbon deposits from forming. Combustion air enters through the air inlet in the back of the stove, passes forward through the air tubes at the left and right sides of the bottom of the stove, and flows past the glass. Some of the air goes directly back through the fire mass and provides air for combustion in the primary combustion zone. Excess air flows over the fire mass and contributes to further combustion.

Damper Open Operation

When the damper is open (handle pointed forward) the stove is in the damper open mode. Fire and smoke leaving the primary combustion zone go directly to the flue collar and chimney connector. These exhaust gases carry heat to the flue. A warm flue is helpful in establishing and maintaining good draft. Updraft operation will be used when starting a fire, loading your stove, or enlivening the fire after a long bum. It may also be used anytime a warmer flue will provide better performance.

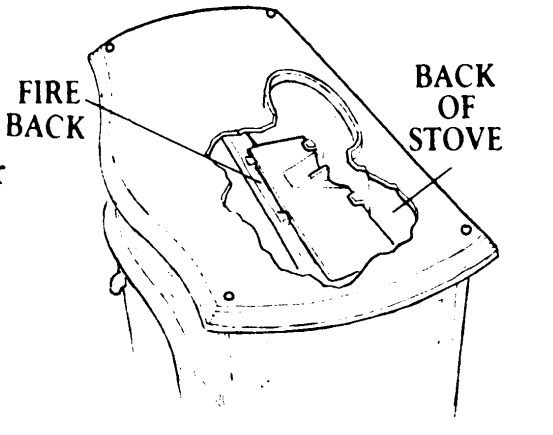

Damper Closed Operation

When the damper is closed (handle pointed down) the stove is in the damper closed mode. Fire and smoke leaving the primary combustion zone are directed through the louvers in the Upper Fireback, down through the firebrick-lined secondary chamber then to the flue collar and chimney connector. The high temperatures maintained in the secondary combustion chamber encourage further burning of volatile gases in the smoke. Horizontal operation will usually be used during extended burns.

Ash Handling

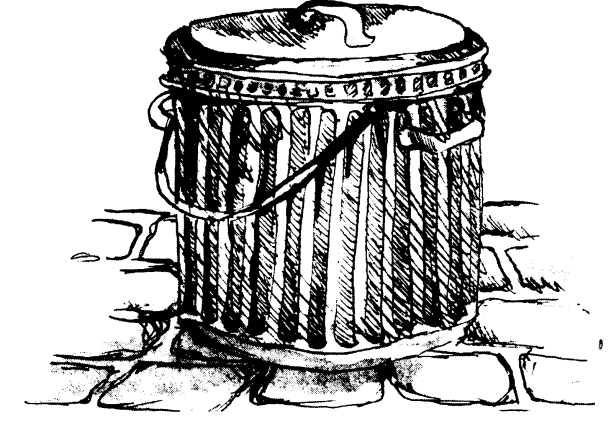

Slots in the bottom grate allow ash to fall through into the ash pan. Slicing the ashes on the bottom grate with the slicer/poker will help the ashes fall through the slots. Empty the ash pan once a day or as necessary to keep the ash pan from overflowing. Use the hook on the end of the slicer/poker to pull the ash pan part way out of the stove. Wear heavy gloves as you draw the pan out of the stove and dispose of

the ashes properly. Your metal ash container must have a tight-fitting lid and be located outdoors, away from any combustible material.

- Thermostat

- Damper

- Air Ports

- Firebrick-Lined Secondary Combustion Chamber

- Reversible Flue Collar

- Bottom Grate

- Ash Pan

When you replace the ash pan in the Intrepid, be sure it is seated properly and pushed all the way to the rear of the stove so it does not block the front ends of the air tubes. Too much ash on the bottom of the stove may prevent proper seating of the ash pan.

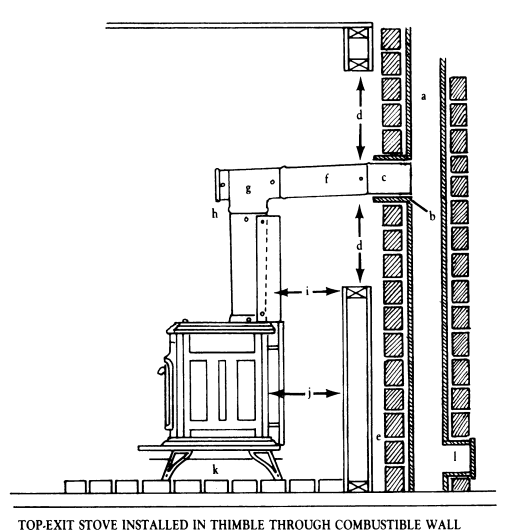

INSTALLATION

A separate bulletin, “The Vermont Castings Installation Planning Guide” also entitled the “Tech Book”, contains detailed information to help you plan your installation. Read this manual and the Guide before installing your stove. Building and safety codes vary in different localities. Check your installation plans with local officials before you install your stove.

The Resolute and Intrepid have been tested for use in mobile homes. Special mobile home chimney, clearance, and installation requirements are detailed in the Mobile Home Components Installation Instructions. When either the Vigilant or Resolute is equipped with a Vermont Castings Energy Extender, clearance requirements may change. The Energy Extender Installation Instructions give special clearance information. The set screw in the lower left front of the Vigilant and Resolute will be removed if the stove is converted to coal burning. The hole should be plugged· when burning wood. Packed inside your stove is a “Fall-Away Insert Handle” to operate the doors and damper. So that it will stay cool, store the handle in the hole drilled in one of the stove legs. Defiant owners: Install the smoke shelf by closing the damper and angling the shelf through the flue collar opening. Position the shelf as shown.

Set Up

Our stoves are heavy and require at least two people to move and set them up. To make the job a bit easier, you may lift off the loading doors and remove the griddle.

DO NOT TRY TO MOVE THE STOVE ALONE AS THE STOVE CAN BE DAMAGED BY MISHANDLING.

Place the stove close to its final position before installing the stove legs. You will find stove leg assembly instructions in the leg bolt package. The griddle has not been painted in order to allow cooking directly on its surface. In order to protect the surface from rust during shipping, a coating of grease has been applied. Be sure to wash the griddle thoroughly with soap and water. As the stove is used, the griddle will gradually darken to match the color of the stove.

So that you can easily secure the first section of stove pipe to the stove, three holes have been drilled in the flue collar and three sheet metal screws are included in the leg bolt package. If you have ordered any accessories such as andirons or heat shields, they will come with their own installation instructions. Generally speaking, nothing more complicated than a screwdriver is involved in the installation of accessories.

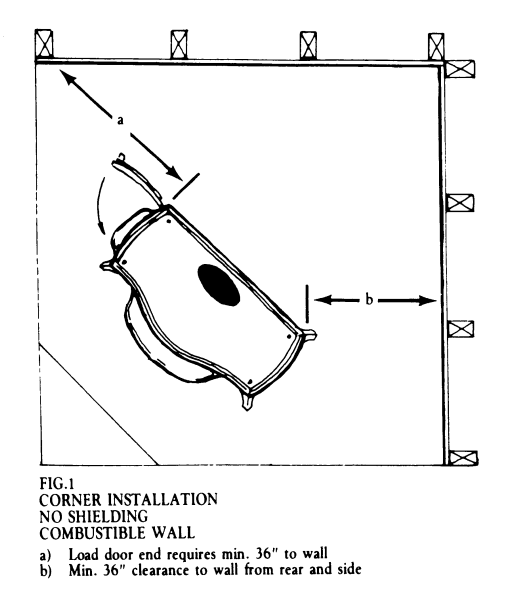

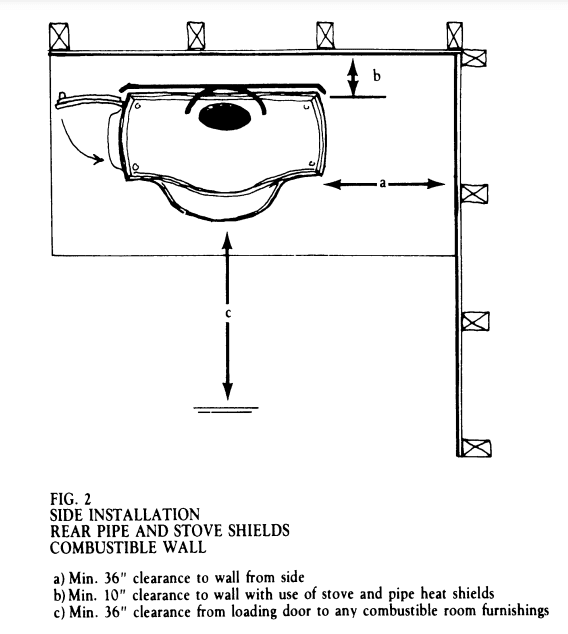

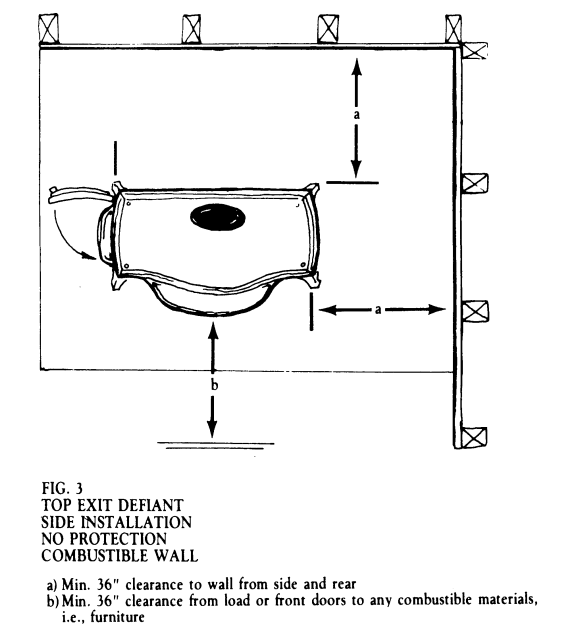

Clearances

It is important for proper installation that the stove is located with adequate clearance (empty space) to combustible walls and room furnishings. The recommended minimum clearance for stoves is usually 36″. Vermont Castings stoves have been tested by independent laboratories for installation with reduced clearances when specific clearance reduction systems are used. Clearance reductions may vary depending on the stove and type of installation.

Consult the Vermont Castings Installation Planning Guide or Tech Book for specific clearance reductions for Vermont Castings stoves.

Chimneys

Many homes are already equipped with a sound freestanding masonry chimney or a fireplace chimney. Either of these can provide an excellent flue through which to. vent a wood or coal stove, provided they are built according to local building codes. We recommend that prior to installing a stove into an existing flue, you have the chimney inspected by a qualified professional. Your local building inspector will know who is qualified to assess the condition of your chimney. If your masonry chimney is not constructed

with a clay tile liner, we cannot recommend that you use it in its existing state with any wood or coal-burning device. An unlined chimney may have unseen loose mortar which could allow chimney gases to escape into the house, or, a chimney fire could ignite nearby wooden members.

If you are building a chimney from scratch, we cannot stress strongly enough the importance of an interior chimney. When properly built, it is the best chimney of all, and will more than repay you for the space that it requires. Besides minimizing the condensation of creosote, the draft produced in an interior masonry chimney will be stronger, helping the stove bum more efficiently. In new masonry construction, allow for the use of a minimum of eight by eight-inch clay flue tile. The chimney must be constructed

in accordance with your local building code.

You may prefer to install a factory-built metal chimney. Prefabricated chimney systems require no foundation and are relatively quick and easy to install. Other advantages of prefabricated chimneys are that they generally require less space and are less expensive than their masonry counterpart. Make sure that such a chimney is approved for solid fuel and is listed by a nationally recognized testing laboratory such as the Underwriters Laboratory (UL). It must be installed in accordance with the manufacturer’s

instructions. CLASS B-type chimneys may not be used with wood or coal stoves. These flues are designed to vent gas appliances only. There are several prefabricated chimney designs available; we recommend those that will help maintain high flue gas temperatures, such as the double wall or static air insulated

type. Ask your local dealer about specific manufacturers. Do not connect the stove to a chimney flue serving another appliance.

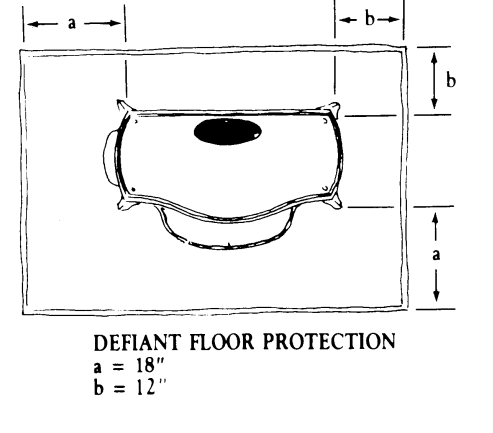

Floor Protection

Even though temperatures under our stoves are significantly lower than those to the sides of the stoves, no stove should ever be installed on a combustible surface because of the possibility of falling embers. Our stoves have generous ships, but some coals may escape from time to time. For this reason, and to provide heat protection to your floor, we recommend you install a hearth consisting of two sheets of ¼-inch asbestos cement board or equivalent)’ covered by one sheet of 24 gauge galvanized sheet metal.

If you prefer a more decorative hearth cover than the above recommendations, the installation of an optional Vermont Castings bottom heat shield will allow the use of a variety of materials. Details concerning those options are printed in Vermont Castings’ Installation Planning Guide or Tech Book. We recommend that your hearth or stove pad extend a minimum of twelve inches beyond the back and sides of the stove and eighteen inches beyond the front and loading door end. This means that the minimum hearth pad dimensions for the three stoves are as follows:

We recommend that your hearth or stove pad extend a minimum of twelve inches beyond the back and sides of the stove and eighteen inches beyond the front and loading door end. This means that the minimum hearth pad dimensions for the three stoves are as follows:

- Defiant: 64 inches wide x 48 inches deep

- Vigilant: 53 inches wide x 48 inches deep

- Resolute: 52 inches wide x 46 inches deep

- Intrepid: 46 inches wide x 46 inches deep

The hearth pad must also cover the floor directly under the stovepipe and extend two inches on either side of the pipe.

With the legs installed, the hearth in place, the flue connections made, and the stovepipe connections secured the only additional preparation that needs to be done is the addition of about 11/2 inches of ashes or sand to the bottom of the Defiant, Vigilant and Resolute as an insulating, protective layer. This

should be spread evenly across the bottom of the stove to protect the bottom of the stove as well as the floor beneath from excessive heat. Ashes taken from another stove or fireplace are preferable, but sand may be used as well.

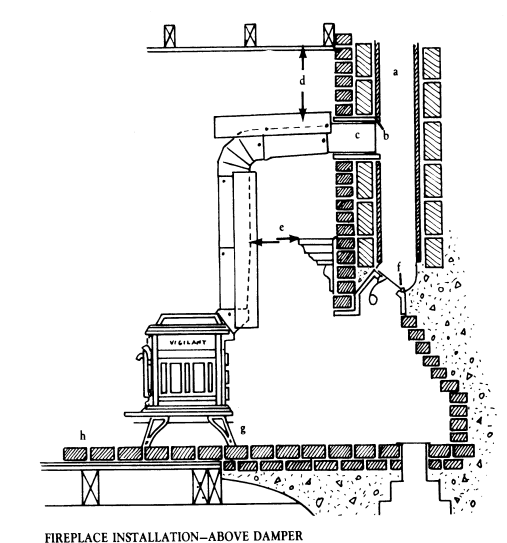

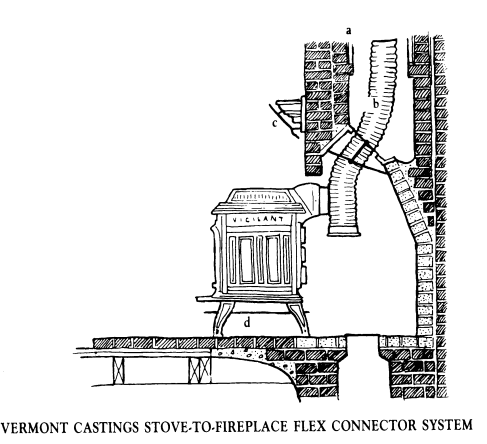

- Tile-lined masonry chimney built to or in compliance of the National Building Code standards

- Vermont Castings Stove-to-FirePlace Flex Connector System

- Combustible mantle protected by custom fabricated heat shield allows 18″ clearance to stove top

- Bottom heat shield

- Hearth extension to provide min. 18″ floor protection from stove front load door and 12 “· from the side of the stove

OPERATION

Cast iron expands as it is heated and contracts as it is cooled. Like an old Model A, your wood stove requires a break-in period to allow the cast iron plates to settle in. If allowed to gradually adjust to these changes, the metal will withstand a great deal of thermal stress with no damage. Extreme, rapid temperature changes, however, may cause the castings to fracture or fatigue. Before kindling your first fire, the bottom of the Defiant, Vigilant and Resolute must be insulated with 1 ½” of sand or ashes. Never start a fire in the stove without this insulating layer. The Intrepid does not require an insulating layer on the bottom.

Be sure to wash the oil coating off of the griddle with warm, soapy water and then towel it dry. The griddle will gradually darken as it is heated.

Daily Maintenance

Good performance depends on airflow through the stove. Every day, clear ash accumulates from the air ports in the back and at the left side of the stove. Develop the habit of burning moderately hot fires twice daily for 30 to 40 minutes in the updraft mode. This will help prevent a build-up of creosote in the flue.

Loading/Fireplace Use

When the stove has been burning in the horizontal mode (damper closed), and you wish to open the doors for loading or viewing, first open the damper and air inlet. This will reestablish a fast, direct airflow through the stove into the flue and prevent smoking when the doors are opened. Check through the side or griddle door and move any wood or coals leaning against the front doors before opening them. When using the stove as a fireplace, always keep the spark screen in place to reduce the hazard of flying sparks or embers.

RECOMMENDATIONS

All stoves behave differently; even a single stove will react differently to different types of wood and chimneys. It will take time to accustom yourself to your new stove and to its responses to various conditions. Remember, our Customer Service Personnel or Authorized Dealers are always a phone call

or letter away if you encounter a particularly perplexing problem. Listed below are a number of ideas that will help you get the maximum benefits from your stove. The most exacting situation occurs when the stove is used around the clock as the primary heat source. Although these suggestions are aimed primarily at this usage, they should be helpful to all.

Wood should not be cut too small, as this speeds up the gasification process and causes it to bum too quickly. If you are having trouble getting the stove to hold a fire for as long as you would like, perhaps your wood is too small. Anything over twelve inches long and four inches measured across the end of the log will do. The stoves work well with as large a piece of wood as can be fit in. Irregular shapes with stubs of branches that hold the logs apart are not good, and rotten wood is the worst. Burning and rotting are similar chemically; so, in effect, rotten wood is partially consumed and has already given up some, if not most, of its heat value. Under no circumstances should a piece of wood with ice or

snow on it ever be put into any stove. The sudden thermal shock can crack the iron. Leaning an ice-covered piece against the stove to melt the ice is also likely to cause damage. We do not warrant our stoves against such abuse.

MAINTENANCE

ASH REMOVAL

During constant use, ashes should be removed every few days, or when they have built up around the air distribution ports to noticeably affect operation. This is easily done when the stove has died down with only a log or so left, as in the mommy. To empty the ashes, a few shovel scoops is all that is required.

They may be taken from any door that allows good access, even with a log or two still left within the firebox. In order to achieve the high efficiencies that horizontal combustion offers, it is necessary to bum the primary fire mass in as compact and hot a manner as possible. Burning logs lying directly on a good bed of hot coals, which in turn are insulated from the cooling iron of the bottom, is the best way to do this. Grates with relatively cool air circulating underneath, tend to disperse the high temperatures required by allowing coals to fall from the fire zone. Grates make it more difficult to control oxygen flow to the fire mass.

NEW STOVES

New stoves should be carefully checked within the first month of service.

- Be sure leg bolts are snug.

- New gaskets may compress quickly at first. Handle adjustment may be necessary.

- Inspect chimney connector and flue for signs of creosote build-up. Rapid accumulation of deposits in the stove or chimney system may indicate a need for changes in stove operation.

- Inspect the whole chimney system to ensure all joints are secure and tight.

- Check to see that glass panels or cast iron panels in doors are secure. Snug up retaining screws if necessary.

PORCELAIN ENAMEL

Clean your enamel stove with a cleaner specifically designed for porcelain-enamel surfaces. Wipe any spills immediately, the cleaner may damage brass trim or handles.

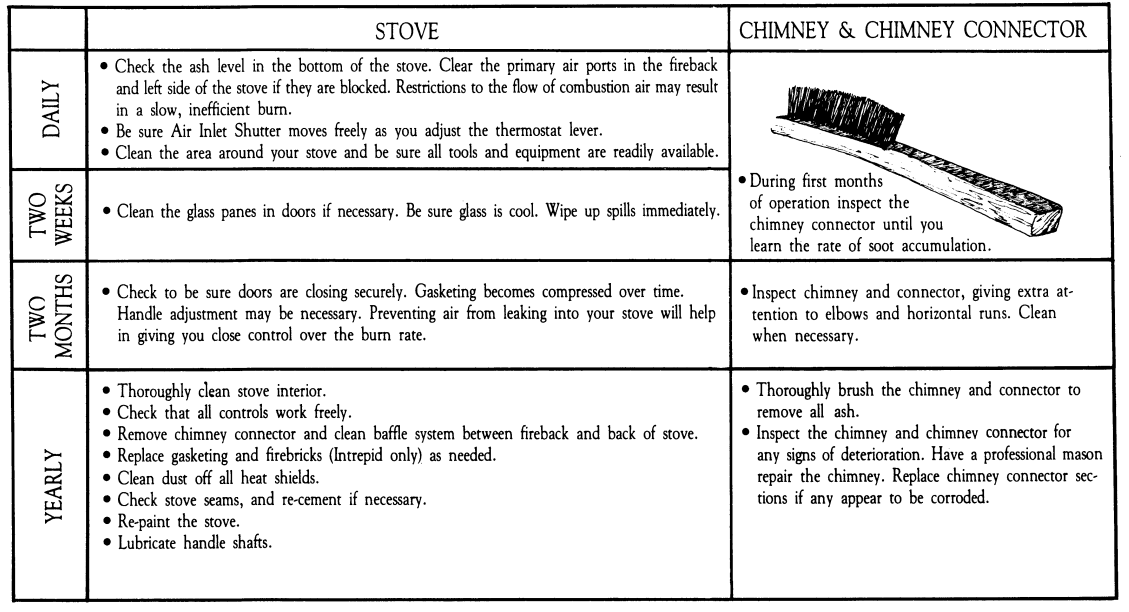

MAINTENANCE GUIDELINES

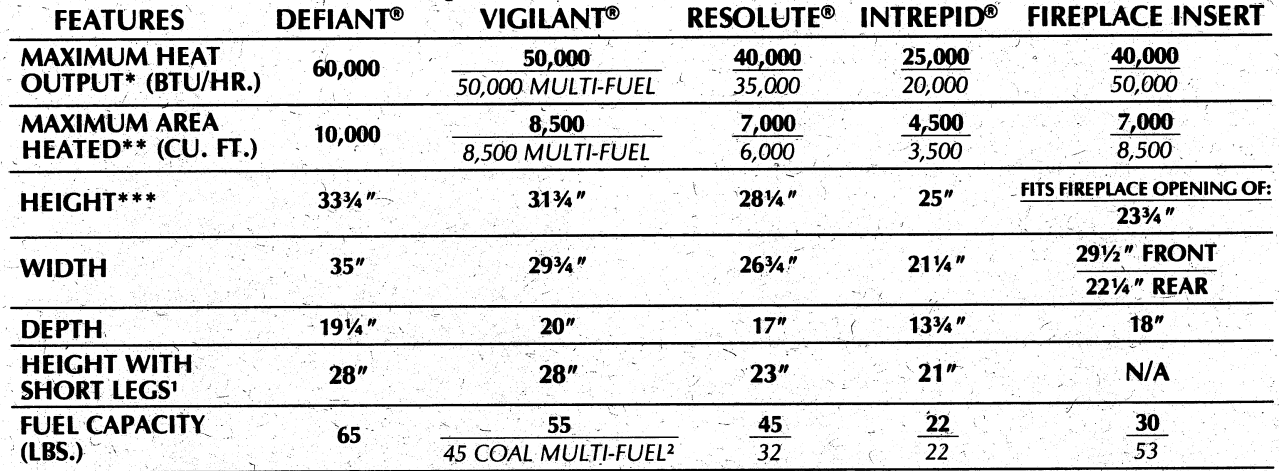

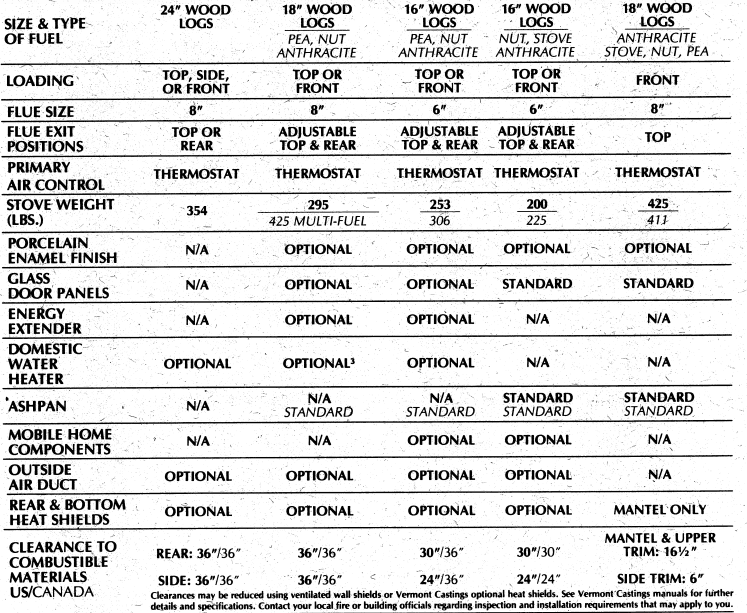

STOVE DIMENSIONS

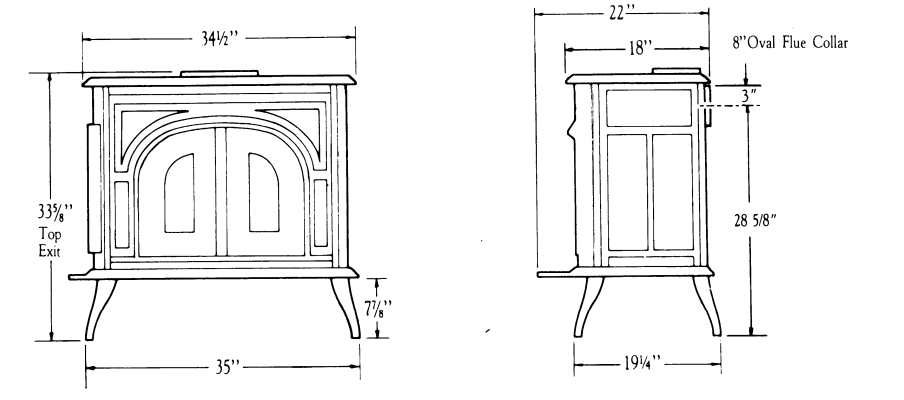

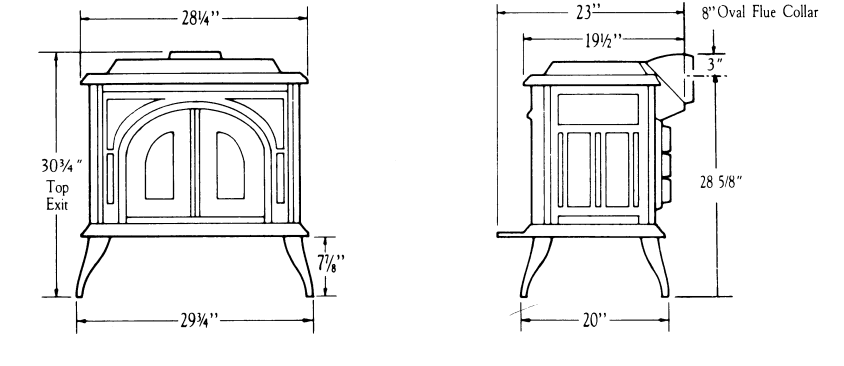

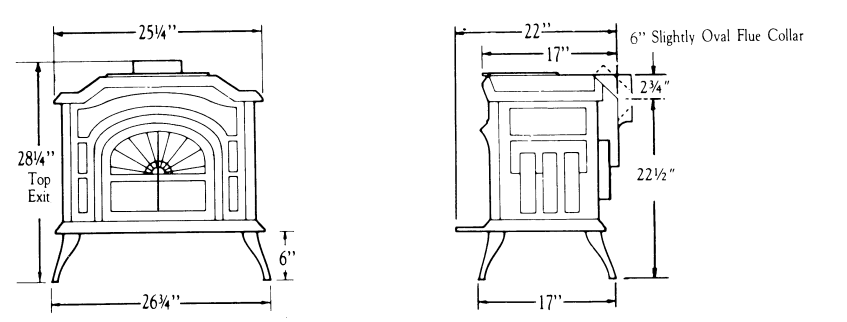

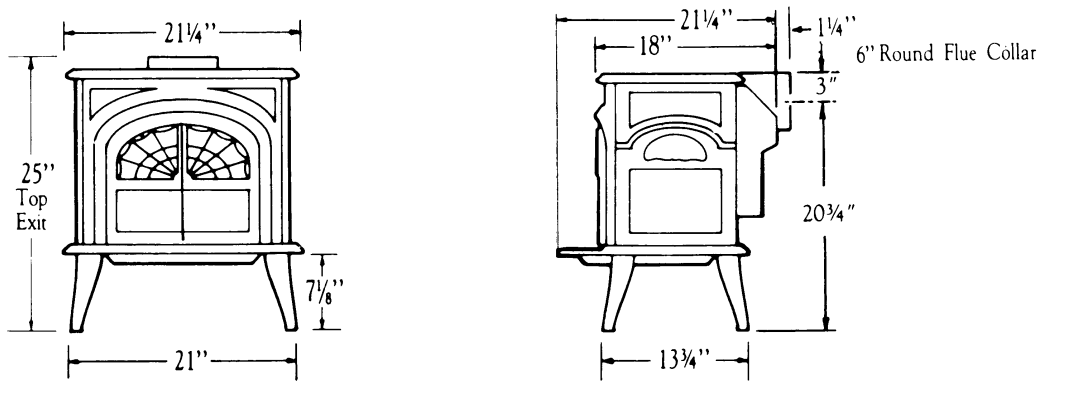

The following elevations indicate dimensions that will enable you to plan your installation as accurately as possible. Variables inherent in the manufacturing process can result in differences of up to 3/8″ between these dimensions and those of your stove. Be careful to plan stove placement so as not to restrict the side loading access to the Defiant or the top loading access to the Vigilant, Resolute, and Intrepid. Some installations, such as a low fireplace, will require a reduction in the height of the stove. By substituting short legs for standard-length legs, the height of each stove can be reduced as indicated.

Defiant®

Short legs reduce the height of the Defiant by 4¾”.

Vigilant

Short legs reduce the height of the Vigilant by 4W’.

Resolute®

Short legs reduce the height of the Resolute by 3″.

Intrepid.

Short legs reduce the height of the Intrepid by 4″.

SPECIFICATIONS

For more manuals by Vermont Castings, visit ManualsLibraryy

Vermont Castings Defiant Wood-Burning Stove-FAQs

How long does a Vermont Castings stove last?

With proper maintenance, a high-quality wood-burning stove can last 10-20 years, or even longer if well cared for.

How can I check if my wood stove is safe?

Look for discoloration on the exterior, which may indicate insulation breakdown. Also, never connect a wood stove to a flue shared with an oil burner.

Is it safe to leave the stove door open while burning?

While it won’t damage the stove, keeping the door open significantly reduces efficiency, as it cools the firebox and prevents proper heat retention.

Why is the glass on my wood stove turning black?

This is usually due to burning unseasoned wood, which causes creosote buildup. It can also happen if the stove is not burning at the correct temperature.

Can I use baby oil to clean my stove?

Yes, a small amount of baby oil can be used to polish the stove’s surface, but avoid excessive use to prevent residue buildup.

What is the key principle behind wood stove efficiency?

Efficient heat is clean heat. A properly functioning wood stove fully combusts wood, converting it into heat, carbon dioxide, and water vapor, leaving behind only ash.

Do wood-burning stoves require ventilation?

Yes, all wood stoves need a proper air supply for combustion and a well-functioning flue to safely vent smoke outside.

What happened to Vermont Castings?

Vermont Castings was sold to Hearth and Home Technologies (HHT), the manufacturer of Harman wood stoves, in October 2014.

How do I light a Vermont Castings gas fireplace?

Turn the gas control knob counterclockwise to “Pilot”, press it in, and hold. Repeatedly press the piezo ignitor until the pilot flame appears. Keep holding the knob for about one minute before releasing.