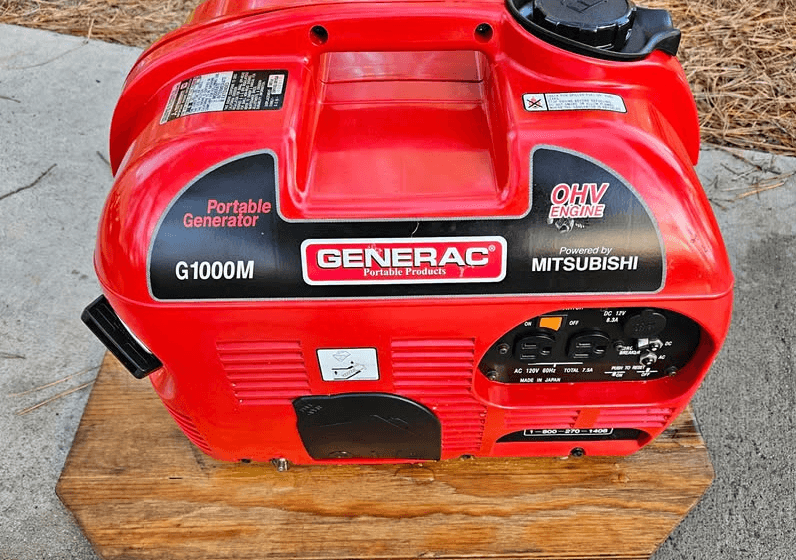

Generac Power Systems G1000M Generator

SAFETY RULES

- This generator set was designed and manufactured for specific applications. Do not attempt to modify the unit or use it for any application it was not designed for. If you have any questions about your generator’s application, ask your dealer/distributor or consult the factory

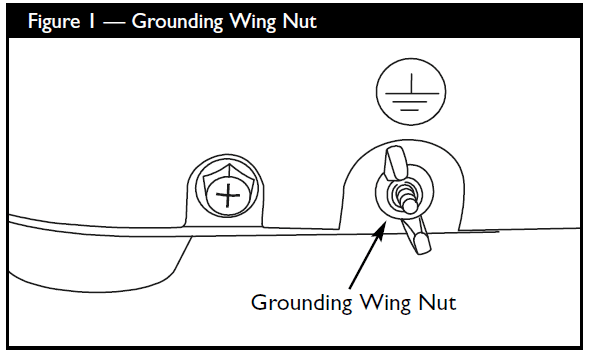

GROUNDING THE GENERATOR

- The National Electrical Code requires that the frame and external electrically conductive parts of this generator be properly connected to an approved earth ground. Local electrical codes may also require proper grounding of the unit. For that purpose, a GROUNDING WING NUT is provided on the generator housing (Figure 1).

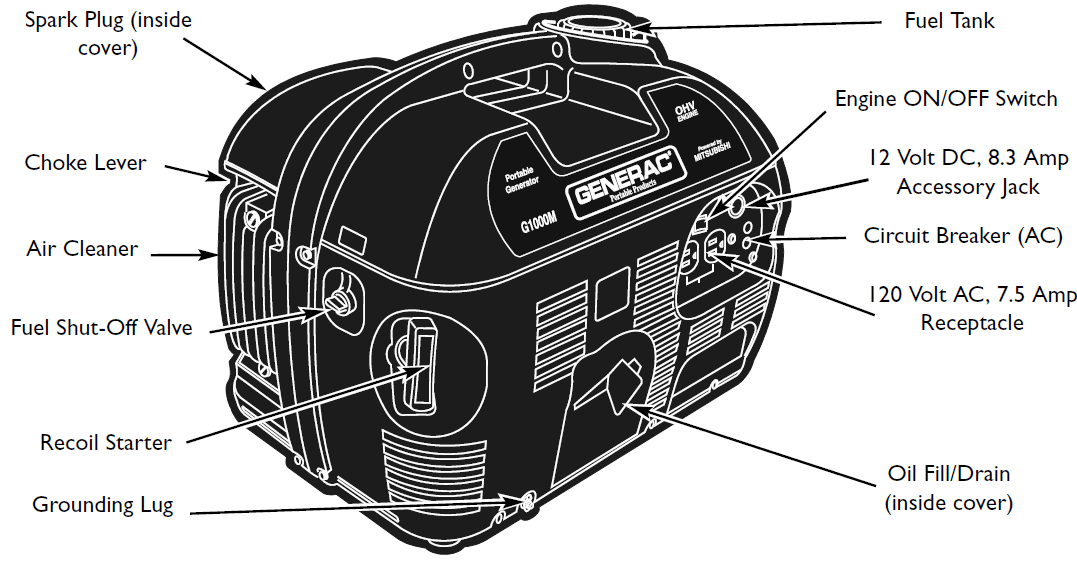

KNOW YOUR GENERATOR

- Read this owner’s manual and safety rules before operating your generator. Compare the illustrations with your generator to familiarize yourself with the locations of various controls and adjustments. Save this manual for future reference.

- 12 Volt DC, 8.3 Amp Accessory Jack — May be used to power 12 Volt DC electrical devices or recharge 12 Volt DC batteries.

- 120 Volt AC, 7.5 Amp Receptacles — May be used to supply electrical power for the operation of 120 Volt AC, single phase, 60 Hz electrical lighting, appliance, tool, and motor loads.

- Air Cleaner — Uses a foam element to limit the amount of dirt and dust that enters the engine.

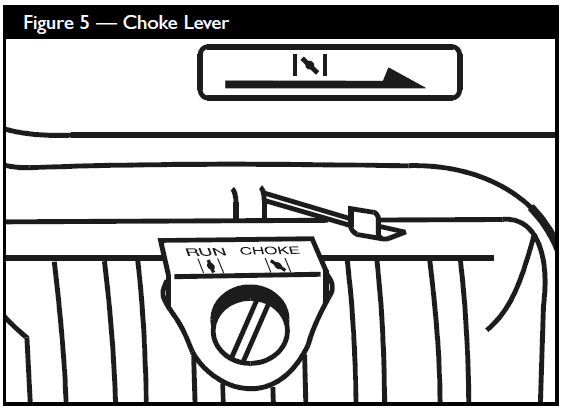

- Choke Lever — Used to manually provide proper starting mixture when engine is cold.

- Circuit Breaker (AC) — Receptacles are provided with a push-to-reset circuit breaker to protect the generator against electrical overload.

- Engine ON/OFF Switch — Used to stop a running engine.

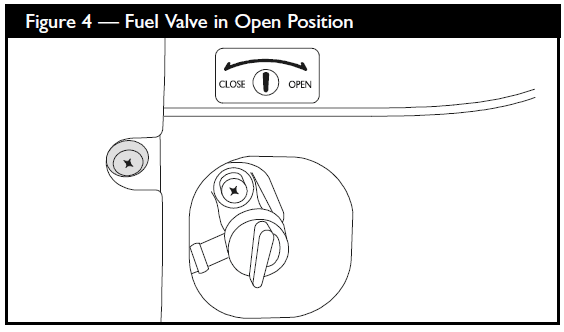

- Fuel Shut-Off Valve — Use this valve to turn the fuel supply on and off.

- Fuel Tank — Capacity of 1.2 U.S. gallons (4.5 liters) of fuel.

- Grounding Lug — Use this connection to ground the generator properly. See ”Grounding the Generator” on page 6.

- Oil Fill/Drain — Access to oil fill dipstick and engine oil drain plug.

- Recoil Starter — Used for starting the engine.

- Spark Plug — Access to engine spark plug

BEFORE STARTING ENGINE

Add Oil

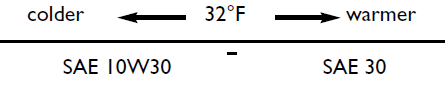

- NOTE: When adding oil to the engine crankcase in the future, use only high-quality detergent oil rated with API service classification SG, SF/CC, and CD. Select the oil’s viscosity grade according to your expected operating temperature:

- SAE 10W-30 is recommended for general all temperatures use. Multi-viscosity oils (10W30, etc.) improve starting in cold weather, but these oils will result in increased oil consumption. Check your engine oil level more frequently to avoid possible damage from running low on oil.

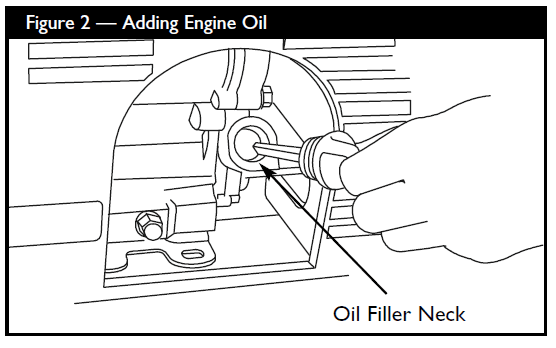

To Add Engine Oil:

- Place the generator on a level surface.

- Remove the oil fill cover.

- Remove oil filler cap and wipe dipstick clean (Figure 2).

Add Gasoline

- Use clean fresh UNLEADED gasoline with a pump rating of 86 or higher. Do not use premium or leaded gasoline. Do Not mix oil with gasoline.

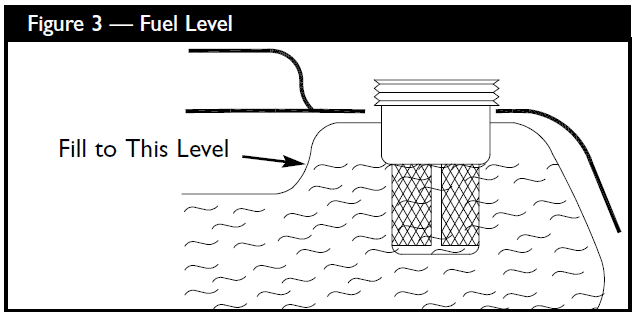

- Clean area around fuel fill cap, remove cap.

- Check the fuel level.

- If fuel level is low, slowly add recommended gasoline to the fuel tank, up to the shoulder of the fuel strainer (Figure 3). Be careful not to overfill (there should be no fuel in the filler neck).

- Install fuel cap and wipe up any spilled gasoline. Occasionally you may hear a light “spark knock” or “pinging” (metallic rapping noise) while operating under

heavy loads. This is no cause for concern. If spark knock or pinging occurs at a steady engine speed under normal load, change brands of gasoline or obtain a higher octane rated fuel. If pinging or spark knock persists, see your local Generac repair center

OPERATING THE GENERATOR

Starting the Engine

Disconnect all electrical loads from the generator. Use the following start instructions:

- Be sure the spark plug wire is attached to the spark plug.

- Turn the fuel valve to the “Open” position (fully clockwise) (Figure 4).

- Slide the choke lever to the “Choke” position (all the way to the right) (Figure 5).

Connecting Electrical Loads

- Let the engine stabilize and warm up for a few minutes after starting.

- Do Not connect 240 Volt loads to 120 Volt receptacles.

- Do Not connect 3–phase loads to the generator.

- Do not connect 50 Hz loads to the generator.

- Plug in and turn on the desired 120 Volt AC, single phase, 60 Hertz electrical loads.

- DO NOT OVERLOAD THE GENERATOR. Add up the rated watts (or amps) of all loads to be connected at one time. This total should not be greater than the rated wattage/amperage capacity of the generator. See “Don’t Overload the Generator” on page 9.

Charging a Battery

- WARNING! Do not permit smoking, open flame, sparks or any other source of heat around a battery. Do not use a lighter or other flame for checking battery fluid levels. Wear protective goggles, rubber apron, and rubber gloves when working around a battery. Battery electrolyte fluid is an extremely caustic sulfuric acid solution that can cause severe burns. Do not permit fluid contact with eyes, skin, clothing, etc. If spill occurs, flush area with clear water immediately.

- Your generator has the capability of recharging a discharged 12 Volt automotive or utility style storage battery. Do not use the unit to charge any 6 Volt batteries. Do not use the unit to crank an engine having a discharged battery

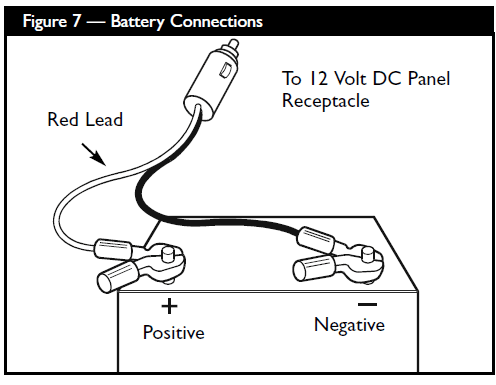

To recharge 12 Volt batteries, proceed as follows:

- If necessary, clean battery posts or terminals.

- Check fluid level in all battery cells. If necessary, add ONLY distilled water to cover separators in battery cells. Do not use tap water.

- If the battery is equipped with vent caps, make sure they are installed and are tight.

- Connect battery charge cable connector plug to the 12 Volt DC panel receptacle.

- Connect battery charge cable clamp with red handle to battery post or terminal indicated by Positive, POS or (+) (Figure 7).

- Connect battery charge cable clamp with black handle to battery post or terminal indicated by Negative, NEG, or (–) (Figure 7).

- Start generator. Let the engine run while the battery recharges.

- When battery has charged, shut down engine (see “Stopping The Engine”)

CONNECTOR PLUGS

12 Volt DC Accessory Jack

- This receptacle allows you to recharge a 12 Volt automotive or utility style storage battery with the battery charge cable provided. Camping-style air pumps, lanterns, fans, or other 12 Volt devices having a cigarette lighter-type plug may also be powered by this outlet (Figure 9).

DON’T OVERLOAD THE GENERATOR

- Overloading a generator in excess of its rated wattage capacity can result in damage to the generator and/or connected electrical devices. Observe the following, to prevent overloading the unit:

- Add up the total wattage of all electrical devices to be connected at one time. This total should NOT