Safe-Air Dowco 771-772 Fire Control Dampers

FIRE & SMOKE AND SMOKE DAMPERS

These operation and maintenance instructions should not serve as a standard basis for all damper products and other manufacturers, but for Safeair-Dowco damper products. All fire smoke and smoke dampers require routine maintenance procedures for dampers to operate as intended in any case in which fire and smoke may occur within the building. Periodic testing of all parts linked to the damper is essential to maintaining a working damper.

Check that all actuators, blades, fans, etc., are functioning properly and that nothing is preventing blades or controls from operating. Be sure to check that nothing is blocking or hindering airway passage. Safeair-Dowco recommends that each routine operation and maintenance procedure follow NFPA 92A, NFPA 80, and NFPA 105 requirements and local authority approvals.

MAINTENANCE:

- Check the interior and exterior sides of dampers for any major defects or material disintegration that may prevent proper functioning of the damper.

- In serious damage, contact Safeair-Dowco http://safeair-dowco.com/contact.php.

- Re-tighten any loose linkage or attached equipment, such as an actuator.

- Shafts, bearings, pivot points, etc., should be cleaned and lubricated with a light spray oil. Any and all access should be removed.

- Use silicone-based lubricant and not petroleum-based lubricant.

- Dampers with non-metallic or carbon sleeve bearings do not require lubrication.

- Blades should be checked for freedom of movement.

- Blades should also be disconnected from their operators and manually checked (blades should move freely with no binding or twisting).

- Motors (electric or pneumatic) should be visually checked through their complete cycle for defects, binding, or misalignment. Operator anchorage and fittings should also be checked.

- The Damper should be operated under normal airflow conditions.

- If, in any case, actuators, blades, or linkage are not properly functioning, contact Safe-Air Dowco at the given inquiry page located above to be further assisted.

TESTING PROCEDURE:

- With the thermal disc intact, heat the thermal disc with a heat source.

- Make sure not to overheat and damage the thermal disc.

- Check that the thermal disc functions properly, as it will activate the actuator to close the damper blades.

- (Be sure to keep your hands out of the path while the blades are closing.)

- When the testing procedure is done, and all parts are working collectively and properly, allow the thermal disc to cool.

- Reset the disc located on the outside of the damper, which will then reopen the damper blades, allowing airflow.

- Record the date of the testing procedure and label it on a sheet.

- Repeat the testing procedure on a set periodic routine.

INSTALLATION INSTRUCTIONS FOR FIRE / SMOKE DAMPERS

Models:

- 771, 771-3

- 772, 772-3

- 772M, 772M-3

- 781, 781-3

- 782, 782-3

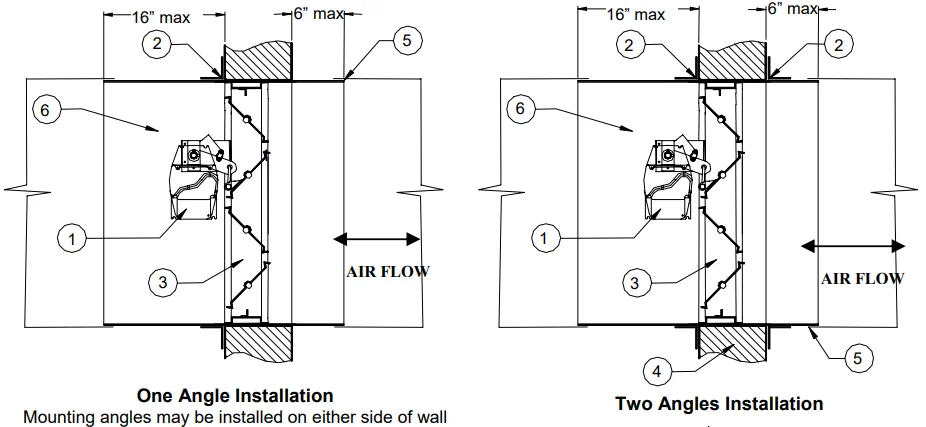

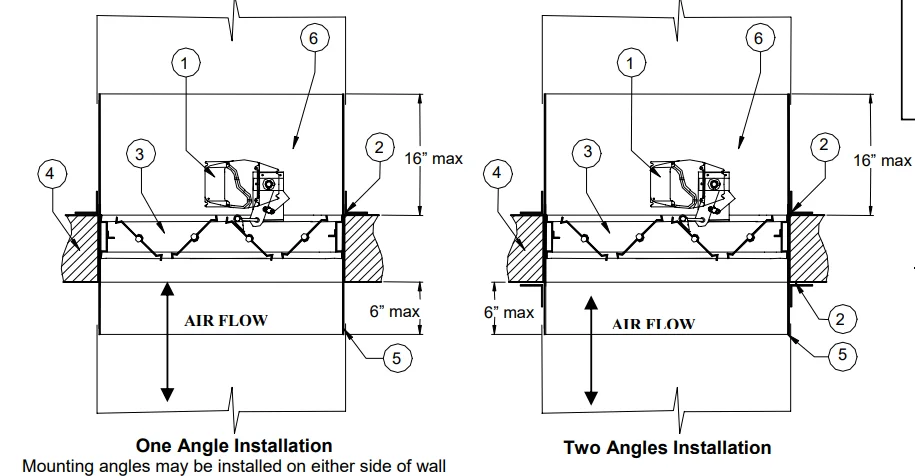

Item Description

- Actuator (external or internal) Location may vary

- Mounting/retaining Angles (All Around the perimeter)

- Damper Unit

- Wall / Floor Opening (Concrete, Metal, or Wood)

- Duct / Sleeve break-away connection

- Sleeve

- Caulking

Typical installation details

- Retaining Angles: Minimum 1 ½” x 1 ½” x 0.054 (18 ga). Retaining angles must overlap the structural opening by at least 1” and cover the corners of openings.

- Clearance: 1/8 inch per linear foot, both dimensions (see Note 1 below).

- For two-angle installation, secure retaining angles to sleeve only, 8” on centers with:

- 1/2″ long welds, or

- 1/4” bolts and nuts, or

- No. 10 steel screws, or

- Minimum 1/16” steel rivets.

- For one-angle installation, secure retaining angles to the wall/floor opening, 8” on centers with:

- 1/4” bolts and nuts, or

- No. 10 sheet metal steel screws, or

- Minimum 3/16” steel rivets.

Notes: Fire/Smoke damper sleeve clearance within the wall opening.

- Clearance requirements between the sleeve and wall or floor shall be a minimum of 1/8 per foot of width and height of sleeve. The maximum size of the opening shall be 2” larger in width or height than the allowed minimum size. The sleeve may rest on the bottom of the opening and needs to be centered. (Fractional dimensions shall be taken as the next largest whole foot.) Example: A 30-inch x 24-inch fire damper sleeve is installed in a wall opening. The opening shall be 30-3/8 inches wide (1/8 inch x 3 feet) by 24-1/4 inches high (1/8 inch x 2 feet).

- The sleeve is retained in the wall opening by the use of steel retaining angles (A). These must overlap the edge of the framing by a minimum of one (1) inch beyond all. The retaining angle would be 1-3/8 inches (good practice calls for an additional safety factor by making the angle, in this case, 1-1/2 inches wide).

- The dimensions required for the opening shall be those remaining after the opening has been framed and fire-resistive materials provided where required. The fire-resistive materials shall be equal to the requirements for fire-resistive materials used in the constructed wall so that a continuous rating exists at the wall penetration. The contractor erecting the wall is responsible for providing the fire-resistive material and the correct size openings to achieve the required clearance.

- Dampers must be installed in accordance with these instructions to meet the requirements of UL 555 and UL 555S. The installation of the damper and all duct connections to the damper sleeve shall conform to the latest editions of NFPA 90A, Standard for the Installation of Air Conditioning and Ventilating Systems, the SMACNA Fire, Smoke, and Radiation Damper Installation Guide, and U.L. Classifications R7861.

For More Manuals By Safe-Air Dowco, Visit ManualsLibraryy

Safe-Air Dowco 771-772 Fire Control Dampers-FAQS

How does a fire control damper work?

A fire damper stays open during normal operation. When high heat from a fire reaches a preset temperature, the fusible link melts and the damper blades snap shut to block flames and hot gases.

What is the difference between fire dampers and smoke dampers?

Fire dampers respond to heat, while smoke dampers react to smoke detection signals. Combination dampers close when either heat or smoke is detected.

What activates a Safe-Air Dowco 771-772 fire damper?

These dampers are activated by heat-responsive fusible links. Once the link melts, spring tension forces the blades closed automatically.

Are fire dampers normally open or closed?

Fire dampers are normally open and only close when exposed to high temperatures or when manually released for testing.

At what temperature do fire dampers close?

Most fire dampers close when temperatures reach approximately 165°F to 212°F (74°C–100°C), depending on the installed fusible link rating.

How can I tell if a fire damper is open or closed?

If air is flowing through the duct, the damper is open. No airflow usually means the damper has closed. Visual inspection through an access panel also confirms blade position.

How do I check if a fire damper is working properly?

Manually release the fusible link or test mechanism and confirm that the blades fully close. After testing, reinstall the fusible link to restore operation.

How do you reset a fire damper after activation?

If triggered accidentally, reset the system by replacing or re-installing the fusible link and ensuring the blades return to the open position.

Can fire dampers reset automatically?

Some systems reset when the fire alarm system is reset, but fusible-link fire dampers usually require manual reset.

What are common signs of a faulty fire damper?

Common issues include stuck blades, corroded springs, damaged fusible links, dirt buildup, or failure to close during testing.