Adexa IBT Series Planetary Mixer

INTRODUCTION

Dear User, Thank you for choosing Adexa.

- Presentation of IBT SERIES PLANETARY MIXER, preparation of operation, usage, information about cleaning and maintenance is described in this manual.

- This manual has been drawn up to provide the customer with all information about the machine and relevant standards, as well as use and maintenance instructions that allow the appliance to be used at its best, keeping efficiency integral over time.

- This manual must be conserved and kept intact until disposal of the machine.

- This manual is to be provided to people using the machine and for its periodic maintenance.

Caution: USERS ARE RESPONSIBLE FOR IMPROPER USE OF THIS MANUAL!

- Model: IBT 64-VE

- Serial Number:

Adexa Direct Ltd.

Address: Unit 1 White Lane Farm, Tongham, Surrey, GU10 1BU

Tel: 01483 931040

www.adexa.co.uk – [email protected]

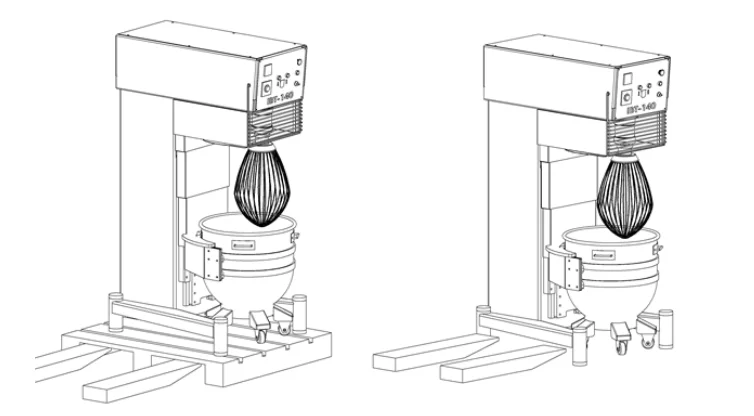

HANDLING AND TRANSPORTATION

Your machine has been delivered to you packaged on a pallet. The transport of the machine must be done as shown in the picture above; another way of transport can cause damage to your machine.

- While the goods are being transported, they shouldn’t be left suspended (hung in the air), and transport should be done with suitable equipment.

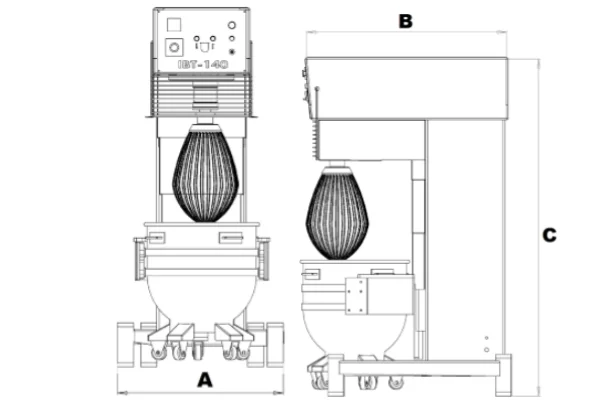

- Sizes and weights of the machines are given in the Technical Specifications section.

- Blanks, holes, arms, and parts located on the machines should not be used for transport. Transport methods, except for the schema, can cause damage to the machine.

- To prevent any work accidents while transporting the machine, strictly obey the rules of Occupational Health and Safety. Do not move it without taking necessary security precautions.

- Responsible staff in transport have to use safety equipment such as a hard hat (helmet), gloves, and steel-toe shoes.

- By considering the weight of the machine, appropriate equipment must be used for transport. Before moving, the weight of the machine, external dimensions, lifting points, and center of gravity must be carefully checked.

- Before moving machinery, the dimensions of the door or partition should be checked to see whether it is appropriate.

- Operations such as acceleration and braking while lifting and handling the machine must not be done in a manner harmful to employees.

- The machine should not be lifted and moved except for the above schema.

- Check the packaging and the product to see if it is damaged during shipping. If there has been any damage during transport, report to the shipping company, insurance company, and Dirmak.

- Certainly, take photos from various angles of the damaged machine. It is necessary for the authority to define the problem.

- Take out and check the packaged machine, and if there is related equipment, check the bill of consignment to see if the materials are sent in full. Please inform Dirmak of any missing material.

- Packaging must be opened by authorized personnel who know the product.

- Never put a load on the machine.

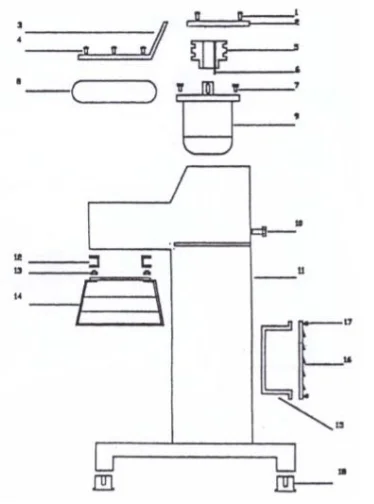

3 PRESENTATION

This introduction manual contains information for the installation, operation, and maintenance of the planetary mixers, which are produced by DİRMAK.

Main parts of the machine:

- Bowl (made from stainless steel sheet)

- Apparatus

- Reduction and transmission system

- Driving motor

- Command and safety system

- Frame

OPERATION OF THE MACHINE

This type of machine is used to mix several food materials homogeneously. The apparatus, which is turned by the main driving motor, mixes the food in the bowl until it is taken to the appropriate shape. The machine has to be filled according to its capacity.

4 INSTALLATION AND OPERATION

- When the machine is delivered, it should be checked if there is any visible damage because it during transport.

- Please report to the producer if there is visible damage or a missing part.

- Place the machine on the flat floor on its four feet properly in accordance with the operation regulations.

Electrical Connections:

Connect the electricity according to the values described on the label.

WARNING: Cut and lock the electricity before making the electrical connection.

WARNING: Connect the circuit breaker plug for each machine.

WARNING: Do not operate the machine without a residual current relay and earthing.

WARNING: Check the apparatus for turning arrow directions which are shown on…

OPERATION

In this part, all information and instructions have been given in order to operate the machine. The operator must know these instructions before using it.

OPERATION CONTROL AND INDICATORS

- Start (Green Button): Provides a way to start the operation of the machine.

- Time Relay (Timer): Provides for operating the machine for a set time and stops automatically at the end of the cycle.

- Emergency Stop (Red Mushroom Button): Stops operation. Turn the button and re-operate.

- Protector Switch: Provides no operation if the protector is not closed. It is designed for the safety of the operator.

- Bowl Switch: Provides non-operation if the bowl is not in the operating position.

- Speed Switch: Makes the selection of the motor speed.

DAILY OPERATION

- Control the machine if it is clean; if not, clean it properly.

- Close the circuit breaker.

- Load according to the function of the work and the capacity of the machine.

- Put the dust mask on while loading flour into the bowl.

- While loading flour, prevent dispersion of the flour by putting a little distance between the flour bag and the bowl.

- Install all the protectors in their place and close them.

WARNING: Do not disable the protectors designed for operational safety.

WARNING: Do not move the machine during operation.

WARNING: Do not put anything on the machine during operation.

WARNING: Do not touch the moving parts of the machine during operation.

WARNING: Clean the machine when the operation is completed. Do not use hard materials for cleaning the machine; otherwise, your machine will be scratched and will lose its hygienic features.

MAINTENANCE

This section describes the regular maintenance work to be done. When these maintenance tasks are carried out:

- The machine performs the mixing efficiently.

- Food products prepared by the machine become suitable for human health.

- The machine will be long-lasting.

- Minimum time loss due to malfunction.

- Prevents small malfunctions from becoming grave.

Periodic Maintenance:

Per weekly:

- Clean the outer surface with warm water.

- Clean the bowl and spiral with a plastic or horse-hair made brush and take off the remaining.

Per month:

- Control the tension of the V belts.

- Control the connection bolts.

Your machine will serve you without any problem for a long time if you carry out the periodic maintenance regularly. Apply to our authorized service if any error occurs.

WARNING: Do not perform any maintenance while the machine is working.

WARNING: Disconnect electricity before starting any maintenance.

WARNING: The ball bearings do not need any greasing. Do not grease.

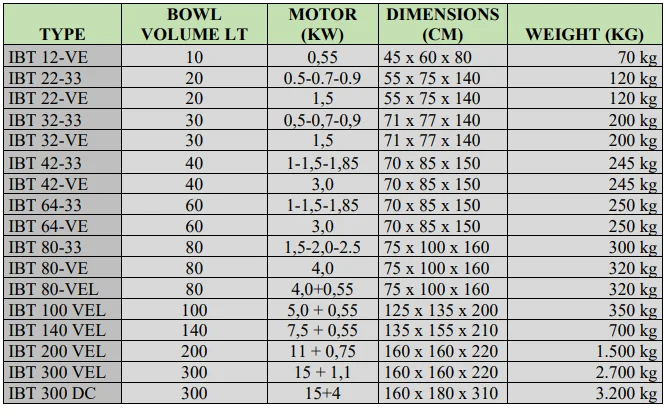

LOADING DIMENSIONS AND TECHNICAL SPECIFICATIONS

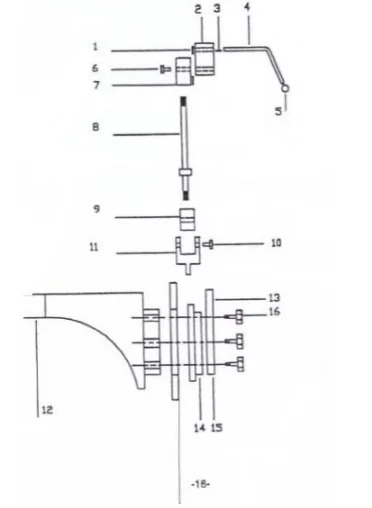

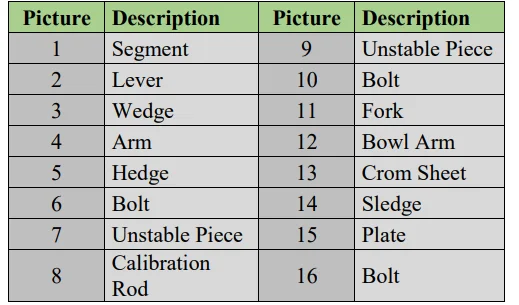

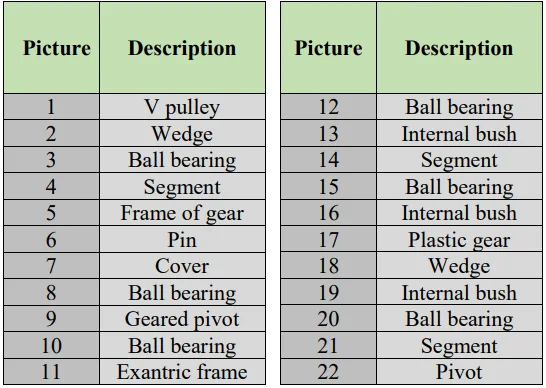

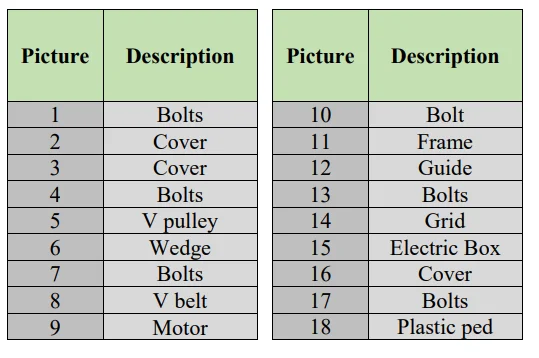

SPARE PARTS LIST

LIFT GROUP SPARE PARTS LIST

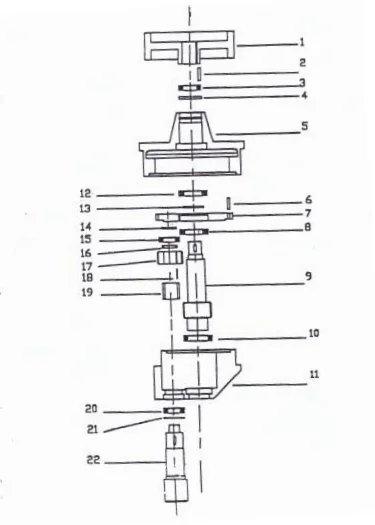

PLANET SYSTEM SPARE PARTS LIST

FRAME GROUP SPARE PARTS LIST

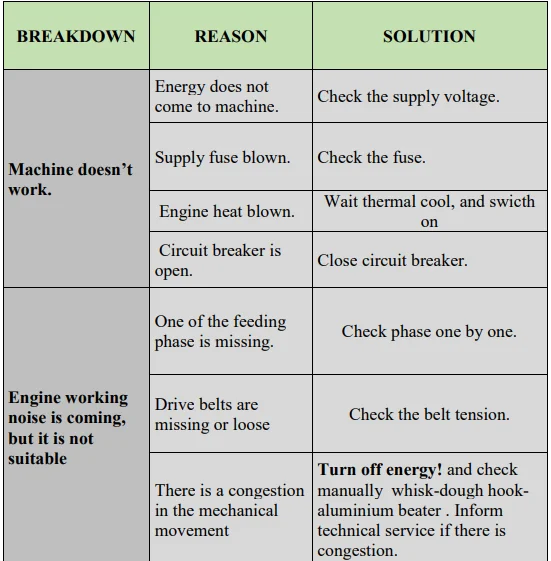

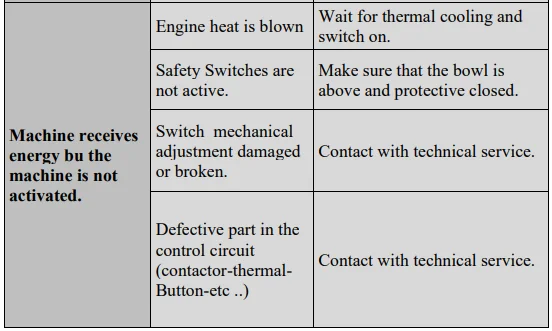

SOLUTION TABLE FOR POSSIBLE ERRORS

ABOUT USAGE ERRORS

- Usage errors cause shortening of the device’s life by damaging the product.

- The engine may be stopped in case of a brownout or overload. In such a situation, push the stop button and unload the material. Before starting it, please wait for the cool down of the engine.

- Please close the protection cap carefully so as not to harm it.

LIFE TIME OF THE PRODUCT

Life lifetime of the product is 10 years, under the condition of recommended instructions.

WARRANTY

Machines manufactured by Dirmak Makina are warranted for a period of time, including all parts, materials, labor, and manufacturing defects, on condition that the use is as specified in the user manual and not intervened for maintenance, repair, or any other reason by service personnel except for Dirmak Makina authorized. Repair time during the warranty period is added to the warranty period. If a breakdown of the product in the warranty period is reported, as well as materials and manufacturing errors, and if this situation becomes absolute as a result of our investigations, maintenance and repairs will be made free of charge without the costs of spare parts.

Fixation of the technical methods to be applied in rectifying the fault and determination of the replaced parts belong to us. Rectifying the fault can be done in the product area or in an authorized service station. Customer confirmation is essential. If authorized service personnel of Dirmak Makina determine that repair of the product is impossible in the report, the product will be replaced with a new one.

Customer confirmation is essential. The warranty in this document is valid “ in case the customer fulfills its responsibilities ”. The customer will inform Dirmak Makina in writing to Dirmak Makina, conflict situation with authorized service personnel. If the problem still continues, the ultimate application address is the Ministry of Industry and Trade / Measurement and Quality Control General Directorate. Dirmak Makina accepts being announced to the public by the Ministry of Industry and Trade.

For More Manuals By Adexa, Visit ManualsLibraryy.

Adexa IBT Series Planetary Mixer-FAQs

What is a planetary mixer used for?

Planetary mixers are designed to mix, whip, and knead a wide range of ingredients. They are ideal for dough, batters, cream, and other mixtures, making them perfect for bakeries, restaurants, and commercial kitchens.

Why is it called a planetary mixer?

The name comes from the motion of the mixing attachment, which rotates on its axis while moving around the bowl, similar to the movement of planets. This ensures thorough and uniform mixing of all ingredients.

What are the main attachments for a planetary mixer?

Most planetary mixers come with a dough hook for kneading dough, a wire whisk for whipping cream or egg whites, and a flat beater for batters and general mixing tasks.

How long do planetary mixers last?

With proper care and maintenance, commercial planetary mixers can last between ten and twenty years.

How do I maintain an Adexa planetary mixer?

Maintenance includes cleaning the bowl and attachments after every use, lubricating moving parts as recommended in the manual, regularly checking the motor and electrical components, and following a scheduled preventive maintenance plan.

What is the working principle of a planetary mixer?

The mixer operates by moving the attachment in a planetary motion. The attachment rotates around its own axis while traveling around the bowl, ensuring all ingredients are mixed evenly.

How do I choose the right planetary mixer?

Choosing the right mixer depends on the bowl capacity for your batch size, the motor power to handle heavier dough, and the versatility of attachments for various mixing tasks.

What is the benefit of a planetary mixer over a regular mixer?

Planetary mixers offer more even mixing, can handle heavier loads, and are versatile for multiple tasks, including kneading, whipping, and blending.

Which is better: planetary mixer or spiral/dough mixer?

Planetary mixers are versatile, suitable for batters, dough, and creams, while spiral mixers are best for large batches of bread or pizza dough but are less adaptable for other tasks.

Can a planetary mixer handle large batches?

Yes, commercial planetary mixers like the Adexa IBT Series can handle small to medium batches effectively. For very large production, industrial models are available.