![]()

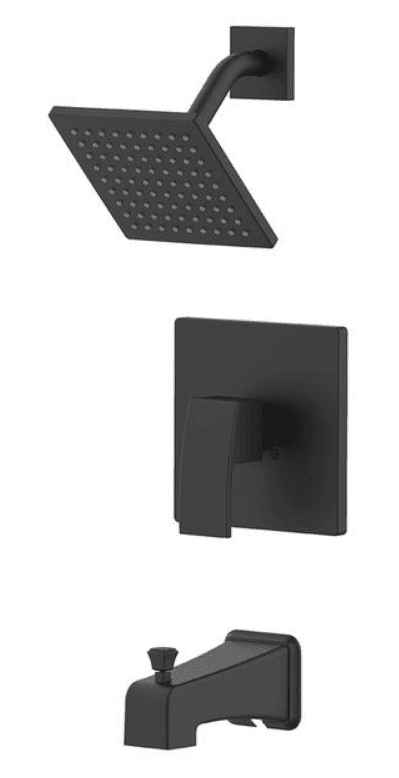

Allen Roth F121E413CP Amari Tub and Shower Faucet

PACKAGE CONTENTS

| PART | DESCRIPTION | QUANTITY |

| A | Showerhead | 1 |

| B | Shower arm | 1 |

| C | Shower arm flange | 1 |

| D | Handle | 1 |

| E | Escutcheon | 1 |

| F | Escutcheon seal | 1 |

| G | Plaster guard | 1 |

| H | Valve body | 1 |

| I | Spout | 1 |

| J | Plug | 1 |

| K | Screen washer | 1 |

HARDWARE CONTENTS

SAFETY INFORMATION

Please read and understand this entire manual before attempting to assemble, operate or install the

product.

NOISE AND WATER HAMMER IN PEX SYSTEMS

As with all plumbing materials under some operating conditions, a water hammer can occur in PEX plumbing systems. The inherent flexibility of PEX drastically reduces the magnitude of pressure surges compared with metallic plumbing materials. Damage to plumbing components in a PEX system due to these pressure surges in highly unlikely, although noise can sometimes result. Fortunately, there are solutions to minimize of eliminate water hammer noise. Clamping or strapping more frequently may help prevent tubing noise. It is very important that the tubing not be in contact with the wall-board, forced air ducts or other high resonance articles. Insufficiently or improperly clamped or strapped tubing may move during fixture operation and hit against these surfaces. Install a water hammer arrester at fixtures where noise is a problem. A water hammer arrester installed within 6 feet of the fixture on the cold water side only will eliminate the source of the noise: the pressure wave. It should be noted that even with an arrester, tubing that is clamped or strapped insufficiently may still hit against something as it moves slightly when the water flow is stopped. Avoid operating fixtures in such a way that causes near-instantaneous shut-off. Simply closing fixtures in a less abrupt manner can eliminate hammer noise.

CAUTION:

Inlet ports are designed to allow for 1/2 in. copper tubing solder connection or 1/2 in. IPS threading coupling connection. For threaded connections, wrap pipe tape around threaded ends before connecting. If soldering connections, remove the plaster guard, and cartridge, and check valves. Connect the water supply to the pipe by soldering. Reassemble check valves, cartridge and plaster guard. Heat damage to these parts may occur and result in the warranty being void on these parts.

WARNING

- This product is engineered to meet the EPA WaterSense flow requirement. The flow rate is governed by the aerator or flow controller. If replacement is ever required, be sure to replace it with a WaterSense-compliant aerator or flow controller to retain the water-conserving flow rate of this

product. - The automatic compensating valve shall be used with a shower rated at 1.3 gpm (4.9 L/min) or higher.

- The shower shall be used with an automatic compensating valve rated at 1.43 gpm (5.4 L/min) or less.

- The product should be installed by a locally licensed plumber.

PREPARATION

Before beginning the product assembly, make sure all parts are present. Compare parts with the package contents list and hardware contents list. If any part is missing or damaged, do not attempt to

assemble the product. Estimated Assembly Time: 40 minutes

Tools Required for Assembly (not included): Adjustable Wrench, Screwdriver, Safety Googles. Helpful Tools (not included): Supply stops, Supply tubing/fittings, and Basin wrench.

- Prior to beginning installation, turn off the cold and hot water lines and turn on the old faucet to

release built-up pressure. - When installing your new faucet, first hand-tighten connector nuts. Connections that are too tight will reduce the integrity of the system.

If you are replacing your plumbing valve, please review the four common plumbing methods

illustrated below: CPVC, PEX, IPS, and Copper. Remove the existing handle and valve trim before replacing your valve. Please follow all local building and plumbing codes.

A. CPVC

B. PEX

C. IPS

D. COPPER

ASSEMBLY INSTRUCTIONS

- Shut off the main water supply before installation.

- Note the installation distance between the shower arm (B), handle (D), and spout (I).

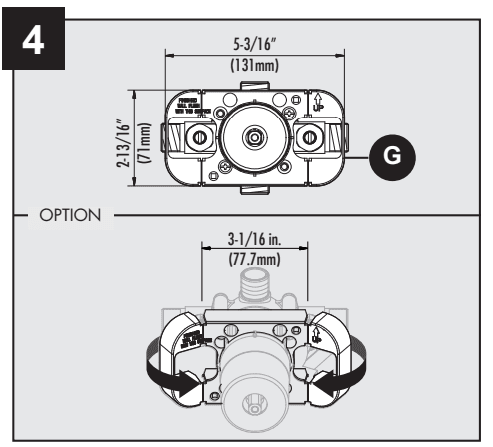

- Thin Wall Installation:

- Use this method when shower walls are thinner than 1/4 inch, such as fiberglass tub surrounds, and will be the main source of support for the valve. The plaster guard remains

attached to the valve. See figure at right.

- Thick Wall Installation:

Use this method when the shower wall is greater than 1/4 inch thick. “Thick walls” are usually built up with materials such as cement board, drywall, tile, etc. The valve is secured by straps (not included) holding the water inlet lines to the framing members (2x4s). The plaster guard is positioned so that it is flush with the finished wall. This ensures that the valve will be in the correct position to accept the trim.

- Use this method when shower walls are thinner than 1/4 inch, such as fiberglass tub surrounds, and will be the main source of support for the valve. The plaster guard remains

- The plaster guard (G) is adjustable to accommodate the installation needs.

- For pipe 4:

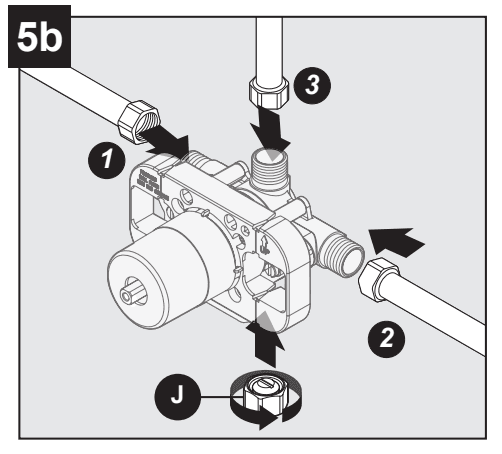

- Use 1/2 in. copper or IPS pipe only. If soldering connections, cartridge, and integral stops must be removed to avoid heat damage. Reinstall when connections are completed and the valve has cooled.

- Note: Includes a valve plug (J) so the fixture can be used in Shower Only applications.

- Use 1/2 in. copper or IPS pipe only. If soldering connections, cartridge, and integral stops must be removed to avoid heat damage. Reinstall when connections are completed and the valve has cooled.

- Install stub-out pipe (not included) for the spout. Use proper length stub-out pipe so pipe threads will extend 1-1/2 to 2 inches beyond the finished wall.

- Slipped installation: Install tub spout (I). Tighten the set screw using a hex wrench.

- Threaded installation: Apply thread tape on the pipe nipple threads. Remove the adapter assembly (including plastic adapter, plastic washer, O-Ring), and back out the set screw. Slide spout (I) over the pipe with the spout tight to the wall, tighten the set screw.

- Threaded installation: Apply thread tape on the pipe nipple threads. Remove the adapter assembly (including plastic adapter, plastic washer, O-Ring), and back out the set screw. Slide spout (I) over the pipe with the spout tight to the wall, tighten the set screw.

- Install shower arm (B) and shower arm flange (C) to vertical shower pipe elbow.

- Install shower head (A) to shower arm (B). Hand tighten the shower head.

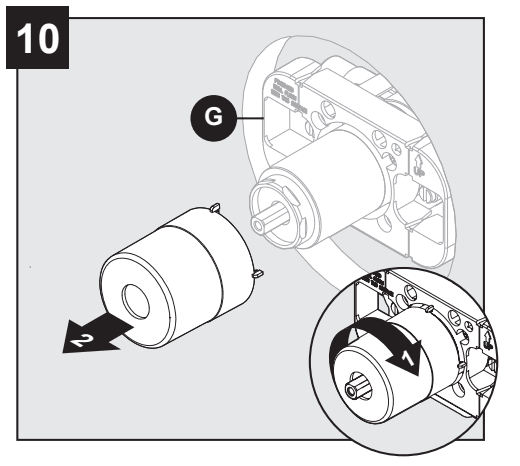

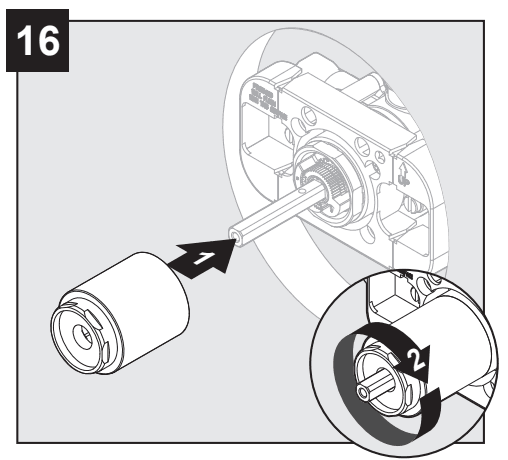

- Remove the plastic cap on the plaster guard (G) by twisting it clockwise.

- Turn on the main water supply.

- Turn on the water and check for leaks.

- Remove the valve cap.

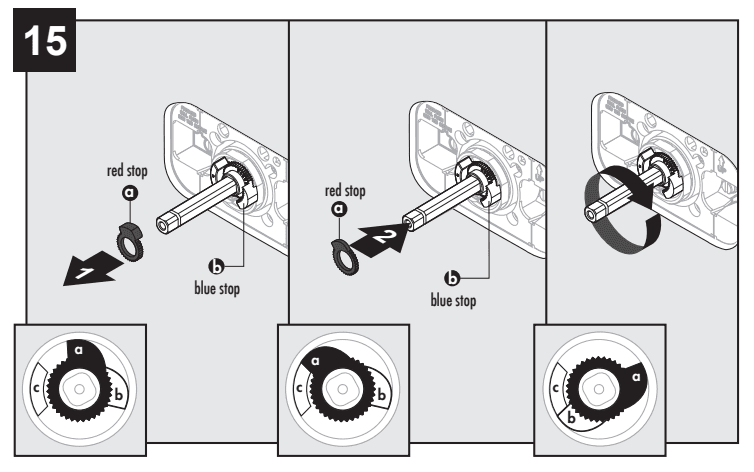

- Turn the valve counterclockwise to the full position. After several minutes, check the temperature using the thermometer. Slowly turn the valve clockwise to adjust the maximum water temperature to the desired temperature.

CAUTION: The maximum water temperature should never be set above 120°F (49°C). - Remove the red stop (a) and replace it with the stationary stop (c) to prevent the valve stem from turning further. Turn the lever to the off position once the temperature is set.

NOTE: Do not move the blue stop (b). Seasonal maintenance of the maximum outlet temperature may be required due to changes in groundwater temperature. - Replace the valve cap.

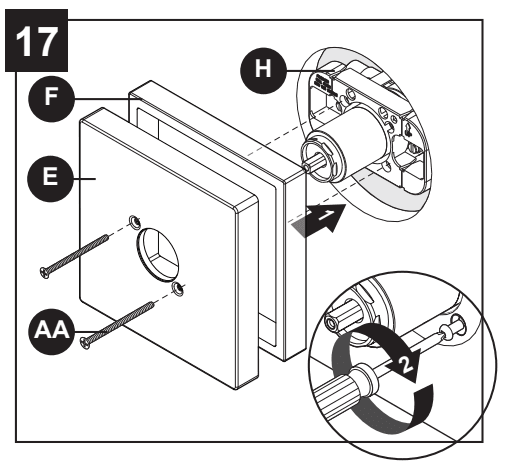

- Install escutcheon (E) and escutcheon seal (F) with screws (AA) to valve body (H).

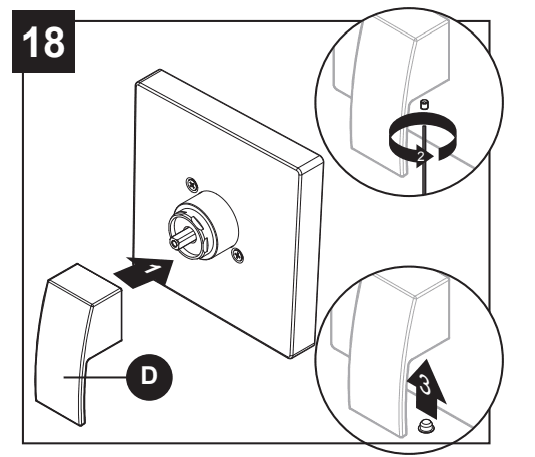

- Install handle (D) with screw and insert handle cap.

BACK-TO-BACK INSTALLATION

- Remove the valve cap.

- Remove red stop (a) and blue stop (b) and rotate the valve 180°.

- Replace red stop (a) and blue stop (b). Replace the valve cap.

CLEANING SCREEN WASHER

- Use a clean strap wrench (not included) to remove the shower head (A) from the shower arm (B).

- Use a flathead screwdriver (not included) to carefully remove the screen washer.

- Gently clean the screen washer with a toothbrush (not included).

- Reinstall the screen washer and shower head (A). Hand tighten the shower head.

CARE AND MAINTENANCE

- To protect and maintain the finish of your faucet, clean it only with a soft, damp cloth.

- Do not use a detergent or cleanser that may harm the finish.

TROUBLESHOOTING

| PROBLEM | POSSIBLE CAUSE | CORRECTIVE ACTION |

| Hot and cold are reversed. | Lines reversed or cartridge installed upside down. | Rotate the cartridge stem 180° so that the notch is facing down towards the drain. |

| There is no or a low water flow. | One or both water supplies are not turned on. | Turn both water supply valves counterclockwise to the on position. |

| There is leaking or dripping from the spout after turned off the handle. | Grommets not sealing properly. Misplacement of temperature limit stops. | Replace the cartridge. Reinstall the temperature limit stops over the cartridge stem when the round pit on the stem faces upward. |

| There is only hot water or only cold water from the spouts. | Balancing spool stuck. | Replace the cartridge. |

| Water comes out of the tub spout and showerhead at the same time when turning on. | If the pattern of the water flow switches to the shower from the tub spout, and the leak from the tub spout is less than 0.01 GPM, this is a normal occurrence. Or consider the causes below: | |

| The valve is installed upside down. | Change the pipe to 1/2 in. IPS or COPPER. | |

| The pipe used between the valve and the tub spout is not 1/2 in. IPS, or the COPPER pipe is incorrect. | Relocate the showerhead or valve to ensure the minimal distance of 49 in. | |

| The distance between the valve and the showerhead is less than 49 in. | Remove the tub spout and flush out debris and/or replace the undersized line or fittings. | |

| There is a restriction between the valve and the tub spout. | Remove the valve and reinstall in the proper orientation. |

WARRANTY

The manufacturer warrants this faucet to be free from defects in workmanship and material present at the time of shipment from the factory for a limited lifetime from the date of purchase. This warranty applies only to the original purchaser. The manufacturer agrees to correct such defects at no charge or, at our option, replace the faucet with a comparable or superior model. To obtain warranty service, call our customer service department at 1-866-439-9800 for return authorization and shipping instructions. You may be required to present a copy of your sales receipt as proof of purchase. All costs of removal and reinstallation are the expressed responsibility of the purchaser. Any damage to the faucet by accident, misuse, or improper installation, or by affixing accessories not produced by the manufacturer, are the purchaser’s responsibility. The manufacturer assumes no responsibility whatsoever for faucet installation during the warranty period. There is no further expressed warranty. The manufacturer disclaims any and all implied warranties. The manufacturer shall not be liable for incidental, consequential or special damages arising at or in connection with product use or performance except as may otherwise be accorded by law. This warranty gives you specific legal rights, and you may also have other rights that vary from province to province. This warranty supersedes all prior warranties.

REPLACEMENT PARTS LIST

For replacement parts, call our customer service department at 1-866-439-9800, 8 a.m. – 8 p.m., EST, Monday – Sunday.

| PART | DESCRIPTION | PART# |

| 1 | Index Button | A66D558 |

| 2 | Metal Handle Assembly | A662A63 |

| 3 | Screw Set | A608563 |

| 4 | Escutcheon Assembly | A667B14 |

| 5 | Sleeve | A103322 |

| 6 | Retainer Nut | A103310CP-Z |

| 7 | Ceramic Disc Cartridge | A507190 |

| 8 | Compression Stopper | A507040 |

| 9 | Shower Arm Flange | A006360 |

| 10 | Shower Arm | A020002-S |

| 11 | Shower Head | S1213603 |

| 12 | Spout W/Diverter | A523415 |

For more manuals by Allen Roth, visit ManualsLibraryy

Allen Roth F121E413CP Amari Tub and Shower Faucet-FAQs

What is the maximum temperature setting for the shower valve?

The maximum outlet temperature is 49°C (120°F). Pressure-balanced and thermostatic-mixing valves are designed to prevent exceeding this limit.

How can I increase the water temperature on my tempering valve?

Remove the cap to access the adjusting spindle. Use the built-in adjustment tool to rotate the spindle until you reach the desired temperature.

What is the difference between a shower tap and a faucet?

1. Taps are typically mounted on the wall or counter.

2. Faucets are often integrated into sinks or bathtubs, though some may also be wall-mounted.

How does a faucet washer work?

A faucet washer is a small rubber disk that seals the compression faucet to prevent leaks. Over time, worn washers cause the faucet to drip continuously, even when fully closed.

How does a shower drain system work?

The sloped shower floor directs water toward the drain strainer, which filters out large debris before water flows into the drainpipe via gravity.

Where is the mixing valve located?

The Thermostatic Mixing Valve (TMV) is usually installed near the shower or bathtub, often behind an access panel or inside the wall.

Can I adjust the water heater temperature?

Yes! Many homeowners think they can’t change their water heater’s temperature, but it has an adjustable thermostat that can be set higher or lower in just a few minutes.

What is a shower trim?

A shower trim refers to the visible parts of the shower system, including handles, escutcheons, and external controls that regulate water flow and temperature.

How do I remove an aerator from a faucet?

Use pliers to grip the aerator securely, ensuring you don’t press against the faucet spout. Then, turn the aerator counterclockwise to unscrew it.