![]()

Black and Decker JS500 Variable Speed Jigsaws

FUNCTIONAL DESCRIPTION- JS500, JS510G, JS590TP, JS4000

- Variable speed switch

- Lock-on button

- Saw blade locking lever

- Saw blade support roller

- Saw blade

- Shoe plate

- Shoe plate locking knob

- Saw blade storage compartment

- Dust blower

- Dust extraction adaptor (available on select models – check packaging for inclusion)

- Rip fence (available on select models – check packaging for inclusion)

FUNCTIONAL DESCRIPTION – JS600, JS610G

- On/off switch

- Lock-on button

- Variable speed control knob

- Orbital action”Turbo” selector

- Saw blade locking lever

- Saw blade support roller

- Saw blade

- Shoe plate

- Shoe plate locking knob

- Saw blade storage compartment

- Dust blower

- Dust extraction adaptor (available on select models – check packaging for inclusion)

- Rip fence (available on select models – check packaging for inclusion)

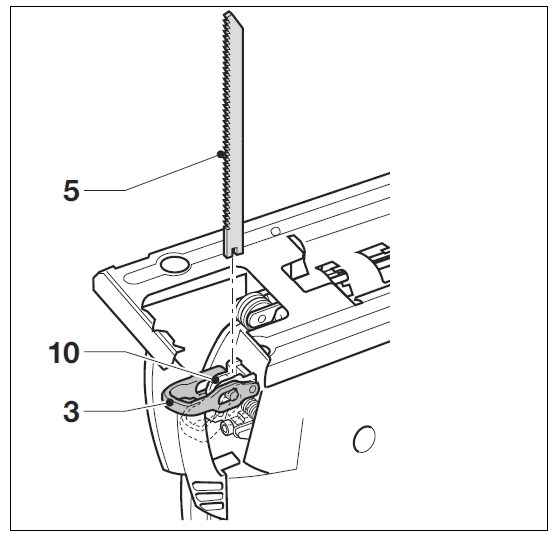

Illustrations A, B for Model JS500, JS510G, JS590TP, JS4000

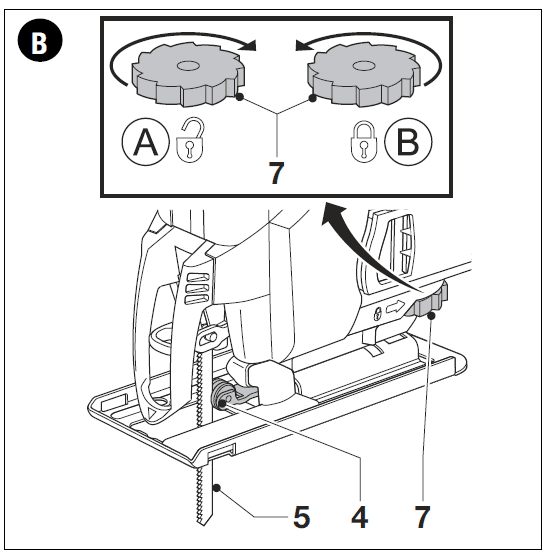

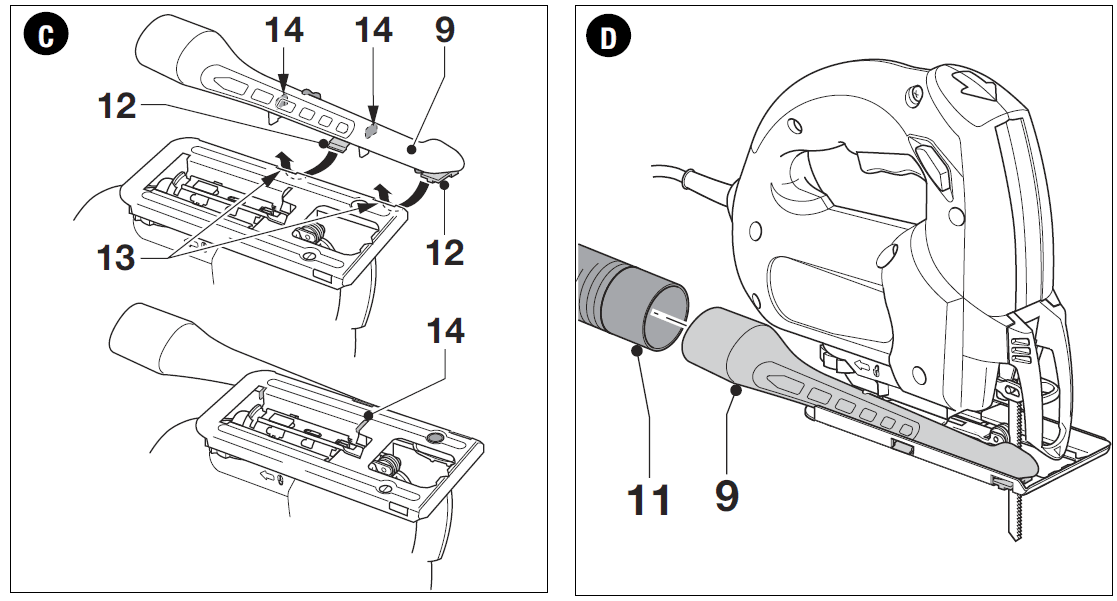

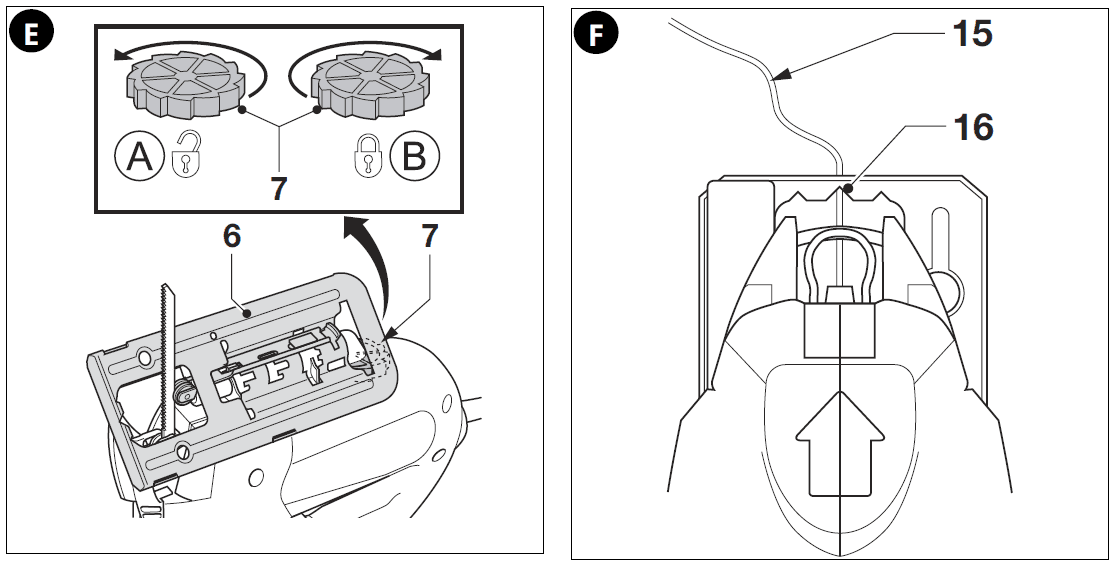

Ills. C, D, E, F for Model JS500, JS510G, JS590TP, JS4000 – Cont.

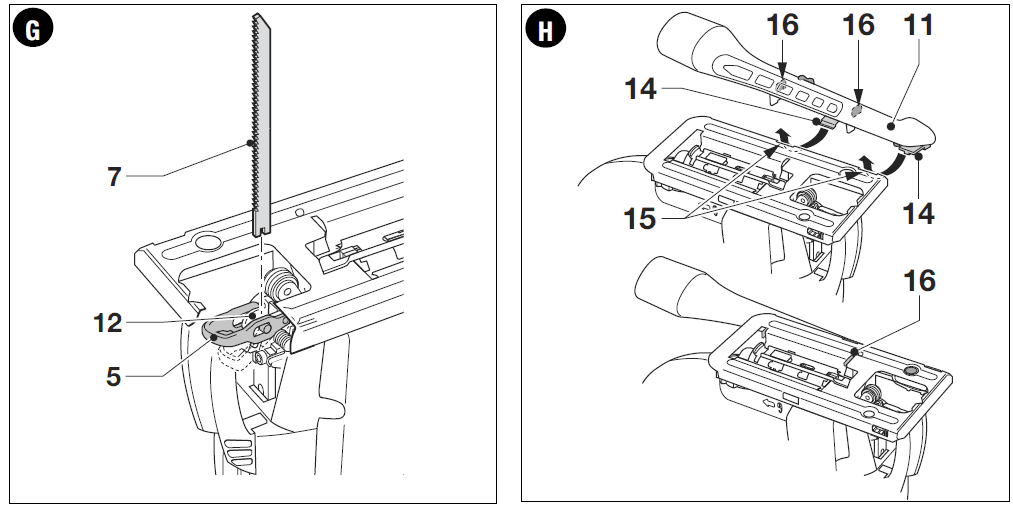

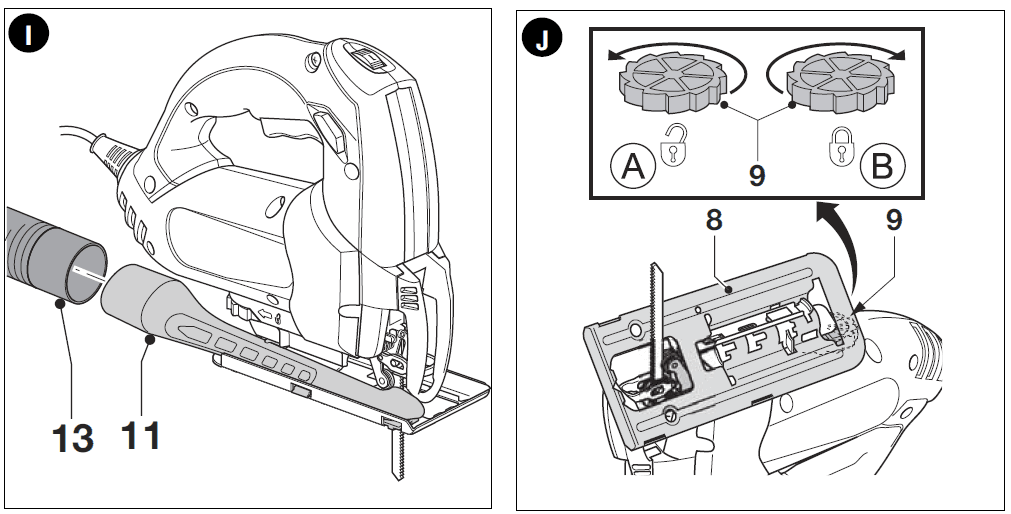

Illustrations G, H, I,J, K for Model JS600, JS610G

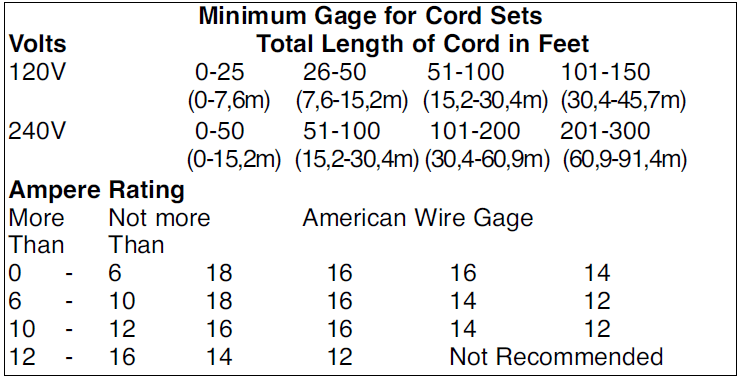

USE OF EXTENSION CORDS

- Make sure the extension cord is in good condition before using. Always use the proper size extension cords with the tool – that is, proper wire size for various lengths of cord and heavy enough to carry the current the tool will draw. Use of an undersized cord will cause a drop inline voltage resulting in loss of power and overheating. For proper size cords see chart below.

MOTOR

- Be sure your power supply agrees with nameplate marking. 120 Volts AC only means your tool will operate on standard 60 Hz household power. Do not operate AC tools on DC. A rating of 120 volts AC/DC means that you tool will operate on standard 60 Hz AC or DC power. This information is printed on the nameplate. Lower voltage will cause loss of power and can result in over-heating. All Black & Decker tools are factory-tested; if this tool does not operate, check the power supply

SAVE THESE INSTRUCTIONS

ASSEMBLY – JS500, JS510G, JS590TP, JS4000

- Fitting the saw blade (fig. A)

- Hold the saw blade (5) as shown, with teeth facing forward.

- Push the lever (3) downwards.

- Insert the shank of the saw blade into the blade holder (10) as far as it will go.

- Release the lever.

- Adjust the blade support roller as described below.

- Adjusting the blade support roller (fig. B)

- After fitting the blade, you need to adjust the blade support roller (4).

- Turn the locking knob (7) in direction A.

- Slide the blade support roller against the rear of the blade. The blade must locate in the central recess of the roller.

- Turn the locking knob (7) in direction B to lock the shoe plate in place.

- Connecting a vacuum cleaner to the tool (fig. C & D)

- Align the dust extraction adaptor (9) with the saw shoe as shown.

- Insert the ribs (12) into the slots (13).

- Rotate the adaptor until it locks into position. Make sure that the ribs (14) are correctly seated.

- Connect the vacuum cleaner hose (11)(not supplied) to the adaptor. Dust extraction is not possible when making bevel cuts.

USE

- WARNING: Never use the tool when the saw shoe is loose or removed.

Adjusting the shoe plate for bevel cuts (fig.E)

The shoe plate can be set to a left or right bevel angle of up to 45°.

- Turn the locking knob (7) in direction A to release the shoe plate (6).

- Pull the shoe plate (6) backwards and set it to the required angle. You can use the scale or a protractor to check the angle.

- Turn the locking knob (7) in direction B to lock the shoe plate in place.

- To reset the shoe plate for straight cuts:

- Turn the locking knob (7) in direction A to release the shoe plate (6).

- Pull the shoe plate backwards and set it to an angle of approximately 0.

- Push the shoe plate forward.

- Turn the locking knob (7) in direction B to lock the shoe plate in place. Make sure that the shoe plate is supported by the guide ribs.

- Switching On and Off

- To switch the tool on, press the variable speed switch (1). The tool speed depends on how far you depress the switch.

- For continuous operation, press the lock-on button (2) and release the variable speed switch. This option is available only at full speed.

- To switch the tool off, release the variable speed switch. To switch the tool off, when in continuous operation, press the variable speed switch once more and release it.

- How to Use the Sightline® Feature (fig.F)

- Use a pencil to mark the cutting line.

- Position the jigsaw over the line (15). Viewing from directly above the jigsaw the line of cut can be easily followed. Should this view be restricted for any reason, the indent (16) can be used as an alternate cutting guide.

ASSEMBLY – JS600, JS610G

- WARNING: Before attempting any of the following operations, make sure that the tool is switched off and unplugged and that the saw blade has stopped. Used saw blades can be hot.

- Fitting the saw blade (fig. G)

- Hold the saw blade (7) as shown, with teeth facing forward.

- Push the lever (5) downwards.

- Insert the shank of the saw blade into the blade holder (12) as far as it will go.

- Release the lever.

- Connecting a vacuum cleaner to the tool (fig. H & I)

- Align the dust extraction adaptor (11) with the saw shoe as shown.

- Insert the ribs (14) into the slots (15).

- Rotate the adaptor until it locks into position. Make sure that the ribs (16) are correctly seated.

- Connect the vacuum cleaner hose (13) (not supplied) to the adaptor. Dust extraction is not possible when making bevel cuts.

USE

- WARNING: Never use the tool when the saw shoe is loose or removed.

- Adjusting the shoe plate for bevel cuts (fig. J)

- The shoe plate can be set to a left or right bevel angle of up to 45°.

- Turn the locking knob (9) in direction A to release the shoe plate (8).

- Pull the shoe plate (8) backwards and set it to the required angle. You can use the scale or a protractor to check the angle.

- Turn the locking knob (9) in direction B to lock the shoe plate in place.

- To reset the shoe plate for straight cuts:

- Turn the locking knob (9) in direction A to release the shoe plate (8).

- Pull the shoe plate backwards and set it to an angle of approximately 0.

- Push the shoe plate forward.

- Turn the locking knob (9) in direction B to lock the shoe plate in place. Make sure that the shoe plate is supported by the guide ribs.

- Variable Speed Control

- Set the variable speed control knob (3) to the required speed range. Use a high speed for wood, medium speed for aluminum and PVC and low speed for metals other then aluminum.

- Orbital Action Turbo Selector

- For fast and efficient straight cuts in wood, set the turbo orbital action selector (4) to “max”.

- For accurate straight and curve cutting and a smooth surface finish, set the turbo selector (4) to “min”.

- The turbo orbital action selector (4) can also be set to the middle position between “max” and “min” for a moderate speed of cut and finish.

- Note: Orbital Action not recommended when scrolling.

- Switching On and Off

- To switch the tool on, press the on/off switch (1).

- For continuous operation, press the lock-on button (2) and release the on/off switch.

- To switch the tool off, release the on/off switch. To switch the tool off, when in continuous operation, press the on/off switch once more and release it.

- How to Use the Sightline® Feature (fig.K)

- Use a pencil to mark the cutting line.

- Position the jigsaw over the line (17). Viewing from directly above the jigsaw the line of cut can be easily followed. Should this view be restricted for any reason, the indent (18) can be used as an alternate cutting guide.

HINTS FOR OPTIMUM USE

- General

- Use a high speed for wood, a medium speed for aluminum and PVC and a low speed for metals other then aluminum.

- Sawing laminates

- As the saw blade cuts on the upward stroke, splintering may occur on the surface closest to the shoe plate.

- Use a fine-tooth saw blade.

- Saw from the back surface of the workpiece.

- To minimize splintering, clamp a piece of scrap wood or hardboard to both sides of the workpiece and saw through this sandwich.

- Sawing metal

- Be aware that sawing metal takes much more time than sawing wood.

- Use a saw blade suitable for sawing metal.

- When cutting thin metal, clamp a piece of scrap wood to the back surface of the workpiece and cut through this sandwich.

- Spread a film of oil along the intended line of cut.

- CAUTION: Do not use vacuum adapter when cutting metal. Metal filings will be hot and may cause a fire.

- Rip Fence

- Ripping and circle cutting without a pencil line are easily done with a rip fence and circle guide (available as standard equipment on some models or at extra cost).

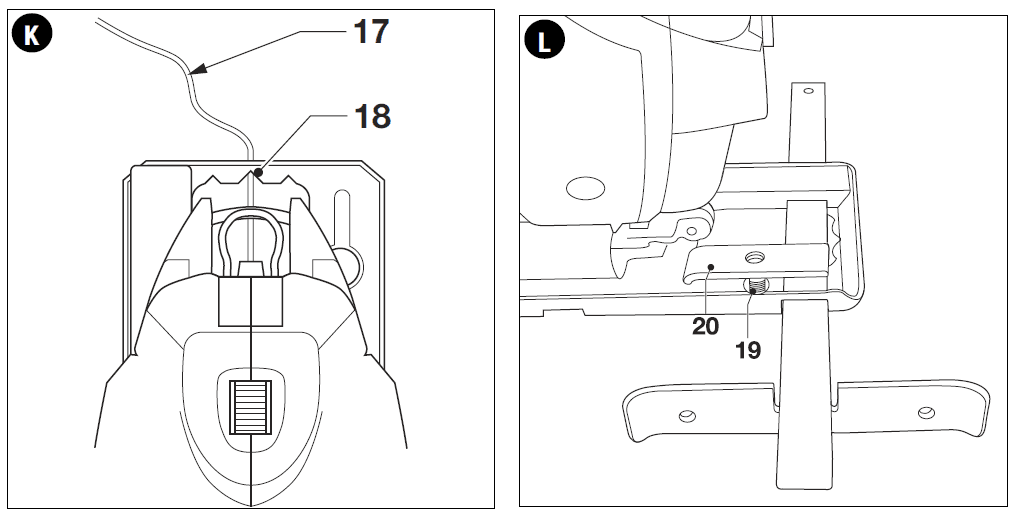

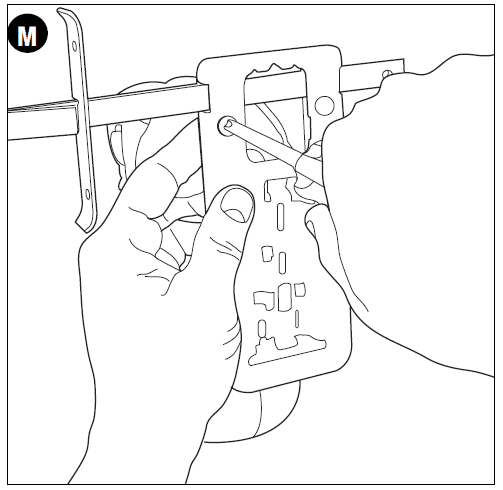

- Attaching Rip Fence (fig.L & M)

- Insert rip fence into slot on the right side of saw shoe as shown with cross bar facing down.

- Place screw (19) into hole in bottom of shoe.

- Align clamp bar (20) over screw with lipped edge facing down and pointing towards the rear of the saw.

- Using a phillips screwdriver, run the screw into the threaded hole in the bar clamp.

- Adjust to width of cut and tighten screw.

- Circle Cutting

- Insert rip fence into slot on the right side of saw shoe with cross bar facing up.

- Adjust rip fence so that distance from blade to hole in cross bar is the desired radius and tighten screw.

- Place saw so that center of hole in cross bar is over center of circle to be cut (make pocket cut, drill hole for blade or cut inward from edge of material to get blade into position).

- When saw is properly positioned, drive a small nail through hole in cross bar into exact center of circle to be cut. Using rip fence as a pivot arm, begin cutting circle.

MAINTENANCE

- Use only mild soap and damp cloth to clean the tool. Never let any liquid get inside the tool; never immerse any part of the tool into a liquid.

- IMPORTANT: To assure product SAFETY and RELIABILITY, repairs, maintenance and adjustment should be performed by authorized service centers or other qualified service personnel, always using identical replacement parts.

ACCESSORIES

- Recommended accessories for use with your tool are available from your local dealer or authorized service center. If you need assistance regarding accessories, please call: 1-800-544-6986.

WARNING: The use of any accessory not recommended for use with this tool could be hazardous.

SERVICE INFORMATION

- Black & Decker offers a full network of company-owned and authorized service locations throughout North America. All Black & Decker Service Centers are staffed with trained personnel to provide customers with efficient and reliable power tool service. Whether you

need technical advice, repair, or genuine factory replacement parts, contact the Black & Decker location nearest you. To find your local service location, refer to the yellow page directory under “Tools—Electric” or call: 1-800-544-6986.

FULL TWO-YEAR HOME USE WARRANTY

- Black & Decker (U.S.) Inc. warrants this product for two years against any defects in material or workmanship. The defective product will be replaced or repaired at no charge in either of two ways.

- The first, which will result in exchanges only, is to return the product to the retailer from whom it was purchased (provided that the store is a participating retailer). Returns should be made within the time period of the retailer’s policy for exchanges (usually 30 to 90 days after the sale). Proof of purchase may be required. Please check with the retailer for their specific return policy regarding returns that are beyond the time set for exchanges.

- The second option is to take or send the product (prepaid) to a Black & Decker owned or authorized Service Center for repair or replacement at our option. Proof of purchase may be required. Black & Decker owned and authorized Service Centers are listed under “Tools–Electric” in the yellow pages of the phone directory.

- This warranty does not apply to accessories. This warranty gives you specific legal rights and you may have other rights which vary from state to state. Should you have any questions, contact the manager of your nearest Black & Decker Service Center. This product is not intended for commercial use. Free warning label replacement: If your warning labels become illegible or are missing, call 1-800-544-6986 for a free replacement.

For more manuals by Black and Decker, visit ManualsLibraryy

Black and Decker JS500 Variable Speed Jigsaws-FAQs

What does the variable speed switch on a jigsaw do?

The variable speed switch allows you to control the blade speed based on the pressure applied to the trigger. Releasing the trigger slows or stops the blade.

How does a variable speed drive work?

A variable speed drive regulates power from the electrical supply to the motor, controlling the flow of energy and adjusting the motor speed as needed.

What speed should I use for cutting with a jigsaw?

1. Softwoods: Higher speeds are suitable.

2. Hardwoods: Use slightly lower speeds to avoid burning.

3. Thicker materials: Opt for slower speeds for better control and precision.

Are Black and Decker jigsaw blades interchangeable?

Yes, Black & Decker jigsaws are compatible with any 1/4″ universal shank saw blade, regardless of the brand.

How do I adjust the depth of a jigsaw blade?

Jigsaws typically don’t have a depth adjustment feature. You can use a shorter blade or raise the saw with a block to control the depth.

What type of blade should I use to cut plastic?

1. Carbon Steel (HCS): Suitable for softer plastics.

2. Hardened High-Speed Steel (HSS): Ideal for harder plastics and tougher materials.

What is the pendulum function on a jigsaw?

The pendulum function adds an elliptical motion to the blade, which:

1. Speeds up cutting for thicker or harder materials.

2. Reduces friction and prolongs blade life.

What are the orbital action settings on a jigsaw?

1. Setting 1: Minimal orbital movement for fine, precise cuts.

2. Settings 2-3: More pronounced elliptical motion for faster, rougher cuts in thicker materials.

What is Curve Control in a jigsaw?

Curve Control helps adjust the saw’s cutting path for smooth and controlled cuts, especially when cutting curves or intricate shapes.

Which saw is better for cutting straight lines?

For straight lines, circular saws or table saws are better. Jigsaws excel at cutting curves and intricate shapes.