Craftsman 1450 Series Engine Chipper Shredder

SAFETY INSTRUCTION

TRAINING

- Read, understand, and follow all instructions on the machine and in the manual(s) before attempting to assemble and operate. Keep this manual in a safe place for future and regular reference and for ordering replacement parts.

- Read the Operator’s Manual and follow all warnings and safety instructions. Failure to do so can result in serious injury to the operator and/or bystanders. For questions, call 1-800-659-5917.

- Be familiar with all controls and their proper operation. Know how to stop the machine and disengage it quickly.

- Never allow children under 16 years of age to operate this machine. Children 16 and over should read and understand the instructions and safe operation practices in this manual and on the machine, and be trained and supervised by an adult.

- Never allow adults to operate this machine without proper instruction.

- Keep bystanders, pets, and children at least 75 feet from the machine while it is in operation. Stop the machine if anyone enters the area.

- Never run an engine indoors or in a poorly ventilated area. Engine exhaust contains carbon monoxide, an odorless and deadly gas.

- Do not put hands and feet near rotating parts or in the feeding chambers and discharge opening. Contact with the rotating impeller can amputate fingers, hands, and feet.

- Never attempt to unclog either the feed intake or discharge opening, remove or empty the bag, or inspect and repair the machine while the engine is running. Shut the engine off and wait until all moving parts have come to a complete stop. Disconnect the spark plug wire and ground it against the engine.

ASSEMBLY

IMPORTANT: This unit is shipped without gasoline or oil in the engine. Be certain to service the engine with gasoline and oil as instructed in the Operation section of this manual before operating your machine.

NOTE: Reference to the right and left hand side of the Chipper Shredder is observed from the operating position.

OPENING CARTON

- Cut each corner of the carton vertically from top to bottom.

- Remove all loose parts.

- Remove loose packing material.

REMOVING UNIT FROM CARTON

- Lift the unit from the rear to detach it from the underlying carton material and roll the unit out of the carton.

- Check the carton thoroughly for any other loose parts.

LOOSE PARTS IN CARTON

- Hopper Assembly

- Bag

- Chute Deflector

- Chipper Chute

- Tamper

- Safety Glasses

- Engine Oil

- Owner’s Manual

ATTACHING THE HOPPER ASSEMBLY

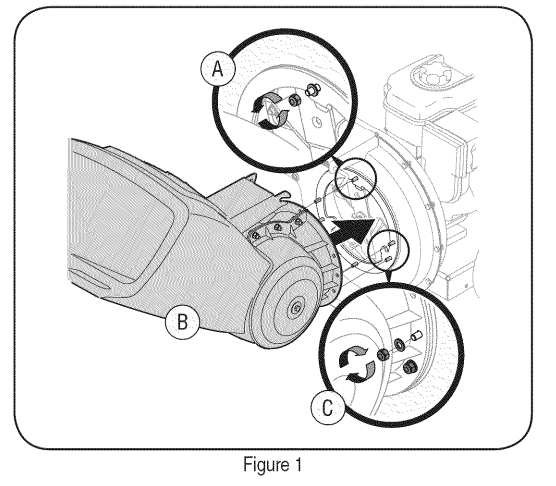

- A. Remove six hex nuts and washers from the weld studs on the impeller housing. Do not remove the support plate. See Figure 1.

B. Place hopper assembly into position in front of impeller housing, aligning holes in hopper assembly collar with weld studs.

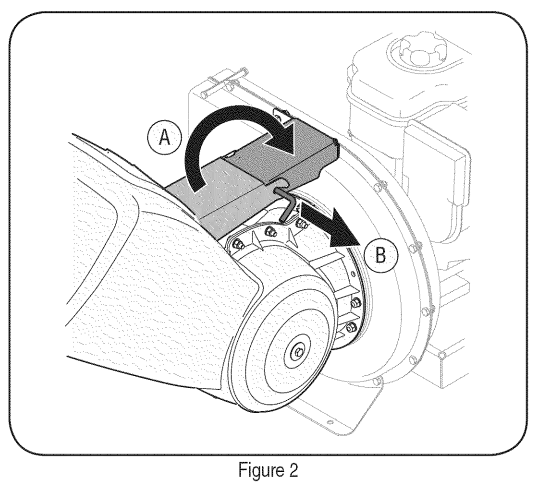

C. Slide hopper assembly onto weld studs and replace washers and hex nuts. Do not tighten completely. - A. Lift the hopper assembly up to the impeller bracket assembly. See Figure 2.

B. Slide the release rod out slightly to hook the hopper bracket onto the rod. See Figure 2.

C. Tighten the six hex nuts that secure the hopper assembly to the impeller housing, and also tighten the hex nuts that secure the hopper bracket to the hopper assembly.

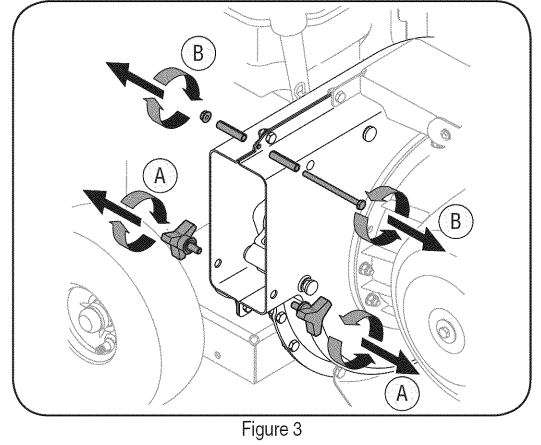

ATTACHING THE CHUTE DEFLECTOR

- A. Remove the wing knobs from each side of the lower impeller housing. See Figure 3.

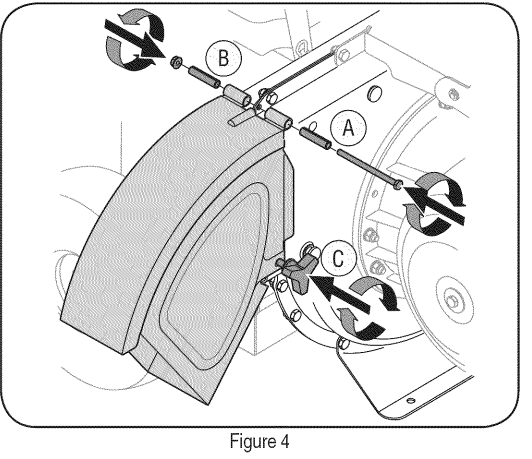

B. Remove the hex lock nut, spacers, and hex bolt from the top of the impeller housing. - A. Align the chute deflector in position on the discharge opening and insert the hex bolt with the spacer through the hinge on the chute deflector (spacers fit inside the hinges). See Figure 4.

B. Place the second spacer over the hex bolt inside the other hinge and secure with a hex lock nut.

C. Secure both sides of the chute deflector to the impeller housing using wing knobs previously removed.

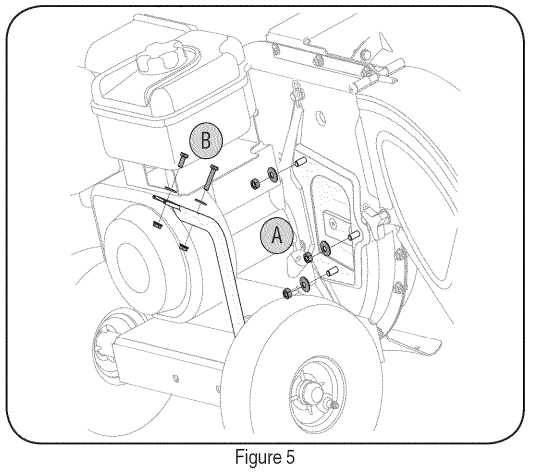

ATTACHING THE CHIPPER CHUTE

- A. Remove the three cupped washers and hex nuts from the weld studs around the opening on the side of the impeller housing. See Figure 5.

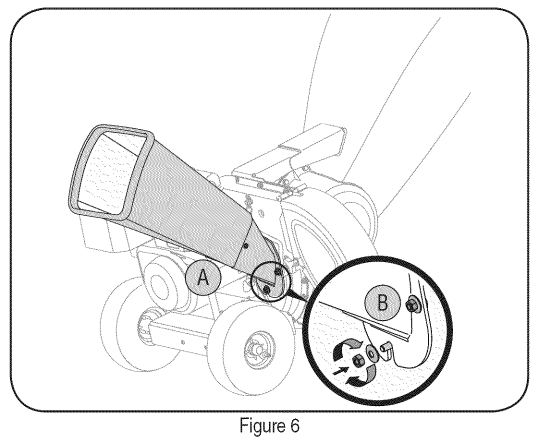

B. Remove the hex bolts, flat washers, and lock nuts from the two holes on the upper end of the support brace. - A. Align the chipper chute over the weld studs, so the slot in the bottom of the chute is facing down. See Figure 6.

B. Secure the chipper chute with the three cupped washers (cupped side against the chipper chute) and the hex nuts previously removed. Do not tighten the nuts at this time. - The chipper shredder was shipped with one end of the support brace already secured to the lower frame. Loosen but do not remove the bolts securing the brace to the frame.

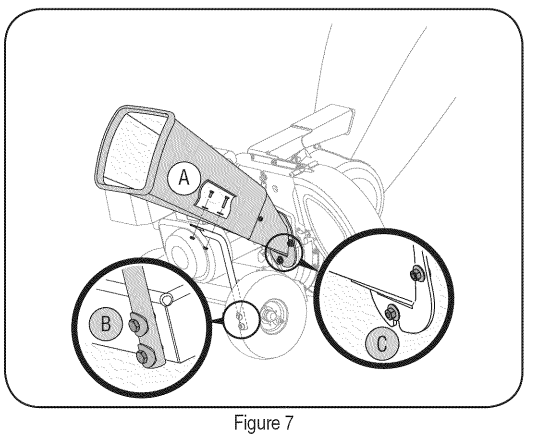

A. Align the holes in the chute with the holes in the top of the brace and attach the brace to the chipper chute with hardware previously removed. The flat washers should be placed under the bolt heads and against the inside surface of the plastic chipper chute. Tighten securely. See Figure 7.

B. Tighten the bolts securing the support brace to the frame.

C. Tighten the three nuts on the weld studs holding the chipper chute to the impeller housing.

OPERATION

Now that you have set up your chipper shredder for operation, get acquainted with its controls and features. These are described below and illustrated on this page. This knowledge will allow you to use your new equipment to its fullest potential.

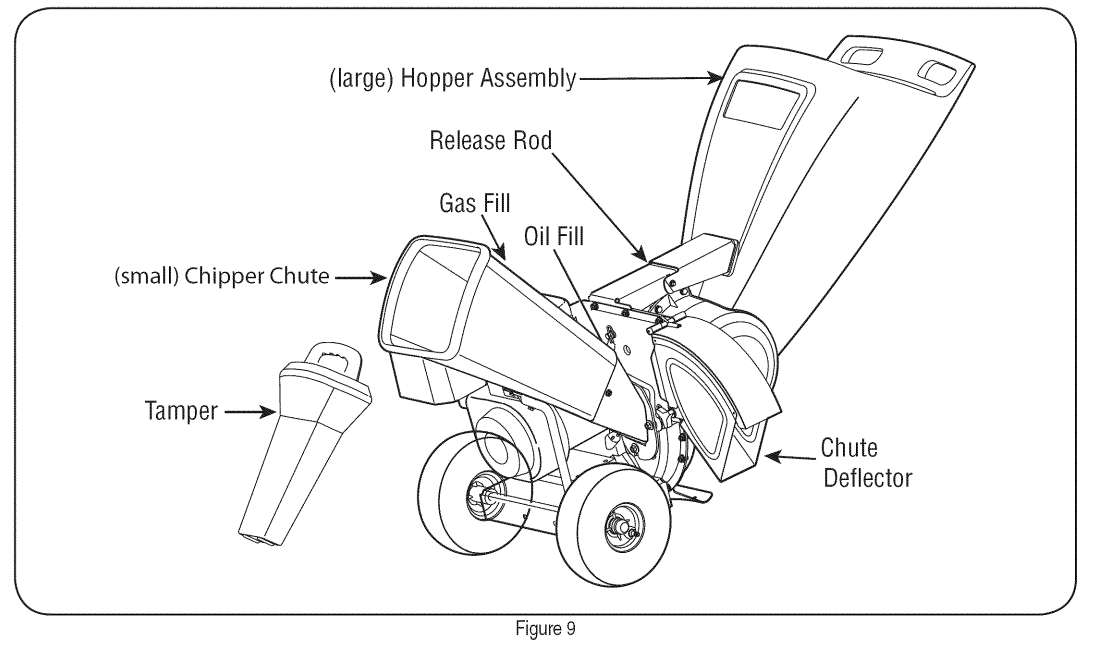

CHIPPER CHUTE

Allows twigs and small branches up to 3” in diameter to be fed into the impeller for chipping. See Figure 9.

HOPPER ASSEMBLY

Allow leaves and small branches up to 1/2 diameter to be fed into the impeller for chipping and shredding. Material can be raked into the hopper assembly by lowering the hopper assembly. See Figure 9.

RELEASE ROD

The release rod is located on the impeller bracket assembly, and it is used to release or lock the hopper when raising or lowering. See Figure 9.

CHUTE DEFLECTOR

Chipped and shredded debris is discharged out of the chute deflector. The unit may be operated with or without the collection bag attached to the chute deflector. See Figure 9.

TAMPER

This plug is inserted into the chipper chute to push twigs and small branches towards the impeller blades without endangering your hands.

THROTTLE CONTROL

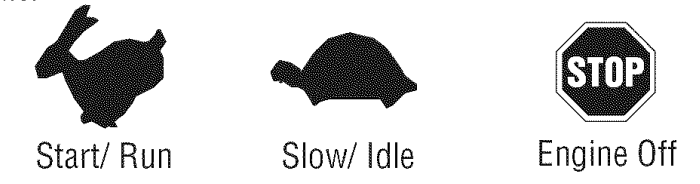

This lever controls the engine speed and the stop function. Through three separate positions on the lever from left to right, the operation is as follows:

GAS AND OIL FILL-UP

Qil (one bottle shipped with unit)

First Time Use

- Remove oil fill plug.

- With the chipper shredder on level ground, use a funnel to empty the entire contents of all bottles provided into the engine.

- Replace oil fill plug and tighten.

Subsequent Uses

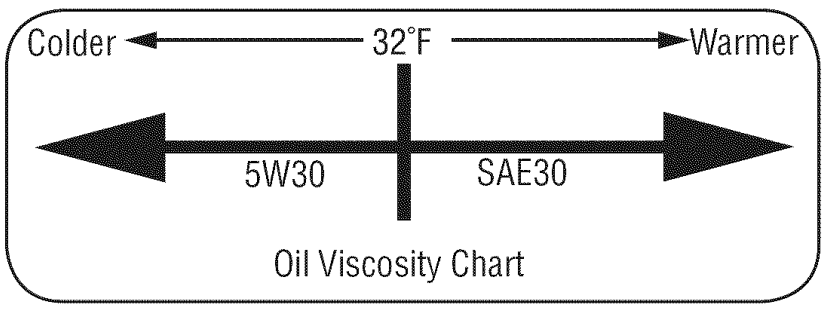

Only use high-quality detergent oil rated with API service classification SF, SG, or SH. Select the oil’s SAE viscosity grade according to the expected operating temperature. Follow the chart below.

Although multi-viscosity oils (SW30, 10W30, etc.) improve starting in cold weather, they will result in increased oil consumption when used above 32°F. Check your engine oil level more frequently to avoid possible engine damage from running low on oil.

- Check the oil level by removing the oil fill plug and looking into the oil fill hole. Oil should be visible up to the threads of the oil fill plug, almost to the point of overflowing. Fill if necessary. Capacity is approximately 28 oz. Overfilling can cause a hazardous situation; be sure to wipe up any spilled or excess oil.

- Replace the oil fill plug and tighten.

- Keep oil level at FULL. Running the engine with too little oil can result in permanent engine damage.

Gasoline

- Remove the fuel cap from the fuel tank.

- Make sure the container from which you will pour the gasoline is clean and free from rust or foreign particles. Never use gasoline that may be stale from long periods of storage in its container. Gasoline that has been sitting for any period longer than four weeks should be considered stale.

- Fill fuel tank with clean, fresh, unleaded regular gasoline only. Do not use gasoline containing METHANOL. Replace the fuel cap.

SHREDDING

Yard waste such as leaves and pine needles can be placed in the hopper for shredding. After the material has been processed by the shredder blade and flails, it will be forced out of the chute deflector and, if attached, into a debris collection bag. Observe the following guidelines when shredding yard debris:

- Never attempt to shred material other than normal yard debris (leaves, twigs, pine cones, etc.)

- Avoid shredding fibrous plants such as tomato vines, palm fronds, etc., until they are thoroughly dried out. Fresh vines do not shred well and tend to wrap themselves around the impeller and flails.

- Place reasonable amounts of debris into the hopper at a time. Do not overload the hopper.

- Allow the material in the hopper to be drawn into the blades and shredded before adding additional debris to the hopper. Failure to due so may result in a clogged hopper, clogged chute deflector or a stalled engine.

CHIPPING

Branches up to 3″ in diameter can be fed into the chipper chute. Observe the following guidelines when chipping branches:

- Keep both hands firmly on the branch as you feed it into the chipper chute.

- Never feed more than one branch into the chipper chute at a time.

- Never feed anything other than branches (or wood) into the chipper chute.

- Apply intermittent pressure (force, in short pulses) while feeding larger (3-inch diameter) branches into the chipper chute, to avoid bogging or stalling the engine.

IMPORTANT: Never feed branches with a diameter greater than three (3) inches into the chipper chute. Doing so can result in serious damage to your unit’s chipper blades, flails, or impeller.

NOTE: For best performance, always operate the unit with sharp chipper blades. If a noticeable loss in performance is encountered while chipping branches, the chipper blades should be replaced.

LOWERING THE HOPPER ASSEMBLY

- With one hand, grasp the handle at the top of the hopper assembly and lift slightly.

- With the other hand, pull out on the release rod and lower the hopper assembly to the ground.

TO EMPTY BAG

- Unclip the drawstring and loosen the bag from the chute deflector opening.

- Empty the bag and reattach it to the discharge chute opening. Pull on the drawstring until the bag is tight around the chute opening and clip the drawstring tight against the chute deflector.

IMPORTANT: The flail screen is located inside the housing in the discharge area. If the flail screen becomes clogged, remove and clean as instructed in the Service and Maintenance section. For best performance, it is also important to keep the chipper blades sharp.

SERVICE AND MAINTENANCE

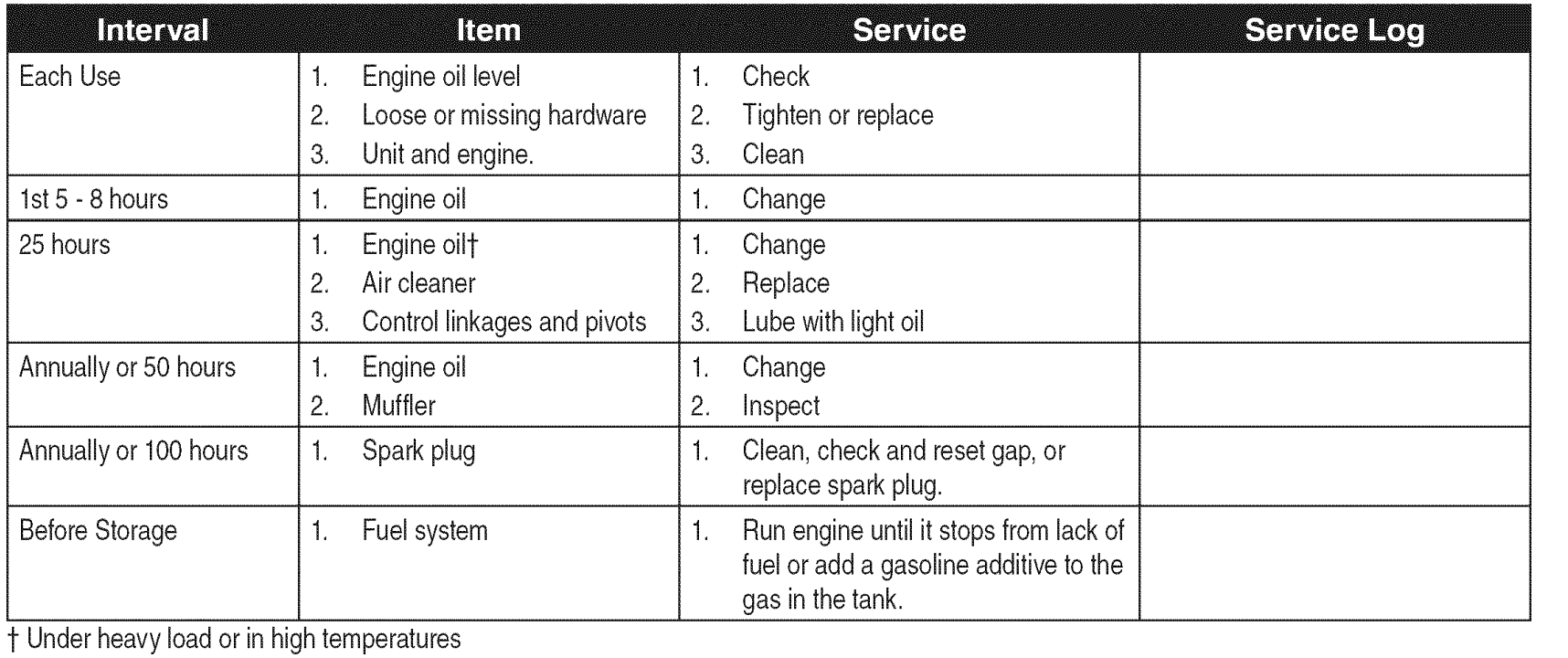

MAINTENANCE SCHEDULE

WARNING

Before performing any type of maintenance/service, disengage all controls and stop the engine. Wait until all moving parts have come to a complete stop. Disconnect the spark plug wire and ground it against the engine to prevent unintended starting. Always wear safety glasses during operation or while performing any adjustments or repairs

Follow the maintenance schedule given below. This chart describes service guidelines only. Use the Service Log column to keep track of completed maintenance tasks. To locate the nearest Sears Service Center or to schedule service, simply contact Sears at 1-800-4-MY-HOME®.

GENERAL RECOMMENDATIONS

- Always observe all safety rules found on product labels and in this operator’s manual when performing any maintenance. Safety rules can be found on the product labels and in this Operator’s Manual beginning on page 3.

- The warranty on this chipper shredder does not cover items that have been subjected to operator abuse or negligence. To receive full value from the warranty, the operator must maintain the equipment as instructed here.

- Some adjustments will have to be made periodically to maintain your unit properly.

- Periodically check all fasteners and make sure these are tight.

ENGINE MAINTENANCE

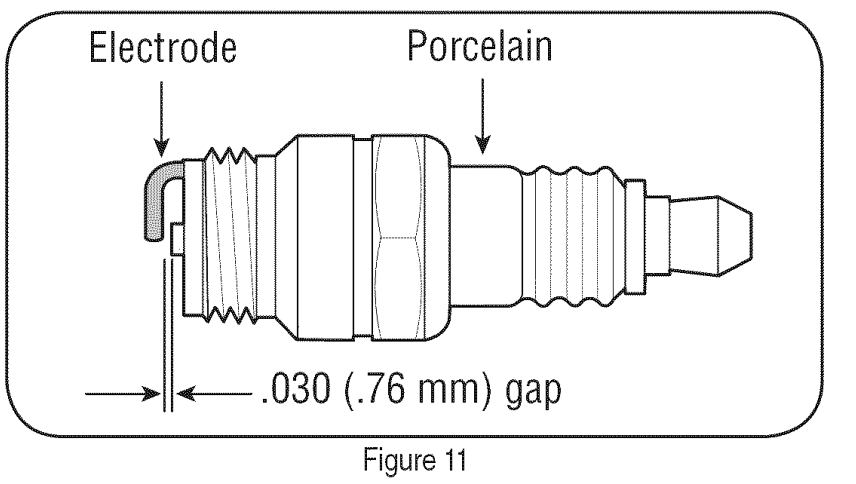

Checking the Spark Plug

Clean the spark plug and reset the electrode gap to 0.030″ at least once a season; replace every 100 hours of operation.

- Clean the area around the spark plug base. Do not sandblast the spark plug. Spark plug should be cleaned by scraping or wire brushing and washing with a commercial solvent.

- Remove and inspect the spark plug. Check the gap to make sure it is set at.030″ See Figure 11.

- Replace the spark plug if the electrodes are pitted, burned, or the porcelain is cracked.

Servicing the Air Cleaner

CAUTION

Do not use pressurized air or solvents to clean the air cleaner cartridge.

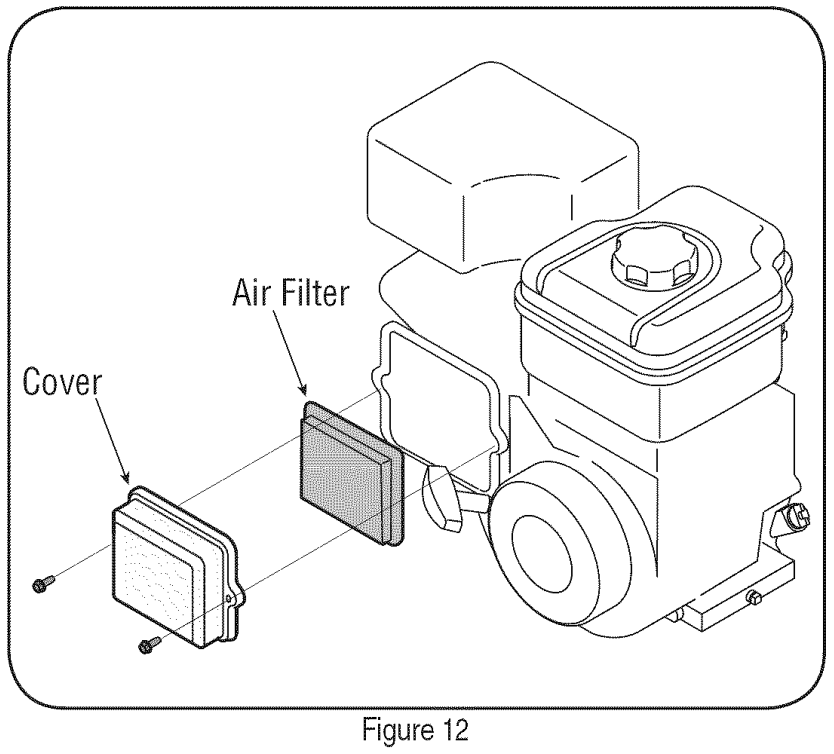

The air cleaner prevents damaging dirt, dust, etc., from entering the carburetor and being forced into the engine and is important to engine life and performance. Never run the engine without an air cleaner completely assembled.

Replace the air cleaner every 25 hours of operation.

- Loosen the screws that hold the air filter cover.

- Open the cover and remove the air filter. See Figure 12.

- Discard the old air filter.

- Install a new air filter.

- Close the cover and tighten the screws.

NOTE: If the filter is torn or damaged in any way, replace it.

Check Engine Oil

- Make sure the engine is level and the area around the oil fill cap is clean.

- Remove oil fill cap.

- Oil should be near the top of the oil fill cap threads, almost to the point of overflowing

Change Engine Oil

- Only use high-quality detergent oil rated with API service classification SF, SG, or SH. Select the oil’s SAE viscosity grade according to the expected operating temperature. Refer to the operation section for the viscosity chart.

- Change engine oil after the first five to eight hours of operation, and every fifty hours or every season thereafter. Change oil every twenty-five hours when operating the engine under heavy load or in high temperatures.

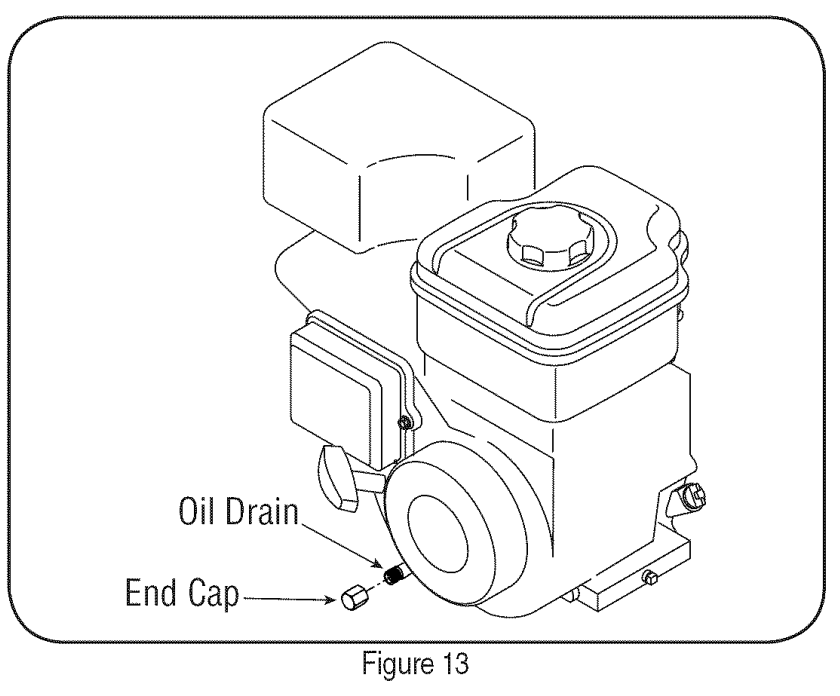

To Drain Oil

- Run the engine to warm the oil.

- With the engine OFF but still warm, disconnect the spark plug wire and keep it away from the spark plug.

- Remove the oil drain cap located at the base of the engine, and drain oil into an appropriate receptacle. See Figure 13.

- When the engine is drained of all oil, replace and tighten the oil drain cap.

- With the engine level, refill with approximately 28 oz. of fresh oil. Fill the oil up into the threads of the oil fill plug, almost to the point of overflowing.

- Replace the oil fill plug and wipe up any oil that may have spilled or overflowed.

- Replace the spark plug wire before starting.

CLEAN EQUIPMENT

- Clean the chipper shredder thoroughly after each use.

- Wash the bag periodically with water. Allow to dry thoroughly in shade.

- If the filter screen becomes clogged, remove and clean it as instructed below.

NOTE: Cleaning with a forceful spray of water is not recommended as it could contaminate the fuel system.

OFF-SEASON STORAGE

WARNING

Never store a chipper shredder with fuel in the tank indoors or in poorly ventilated areas where fuel fumes may reach an open flame, spark, or pilot light, such as on a furnace, water heater, clothes dryer, or gas appliance.

PREPARING THE ENGINE

For engines stored over 30 days:

- To prevent gum from forming in the fuel system or on carburetor parts, run the engine until it stops from lack of fuel, or add a gasoline additive to the gas in the tank. If you use a gas additive, run the engine for several minutes to circulate the additive through the carburetor—after which the engine and fuel can be stored up to six months.

- While the engine is still warm, change the oil. See Change Engine Oil in the SERVICE AND MAINTENANCE section.

- Remove the spark plug and pour approximately 1 oz. (30 ml) of clean engine oil into the cylinder. Pull the recoil starter several times to distribute the oil, and reinstall the spark plug.

- Clean the engine of surface debris,

PREPARING THE CHIPPER SHREDDER

- When storing the chipper shredder in an unventilated or metal storage shed, care should be taken to rustproof the non-painted surfaces. Using a light oil or silicone, coat the equipment, especially any springs, bearings, and cables.

- Remove all dirt from the exterior of the engine and equipment.

- Follow lubrication recommendations.

- Store equipment in a clean, dry area. Do not store next to corrosive materials, such as fertilizer. Do not store in an area where equipment is present that may use a pilot light or has a component that can create a spark.

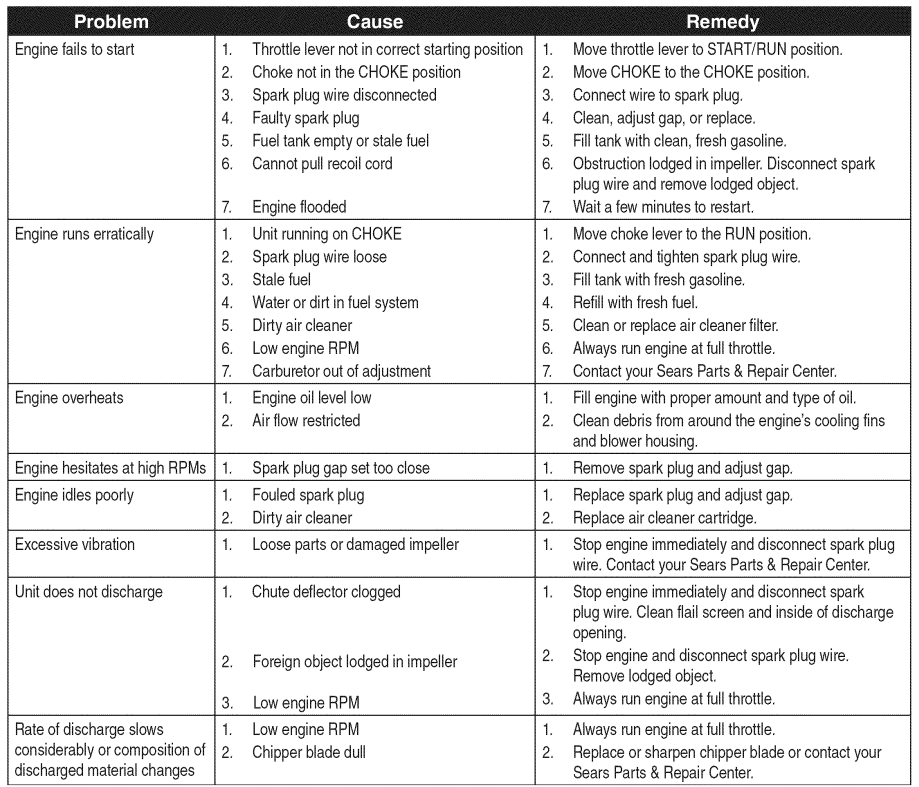

TROUBLESHOOTING

WARNING

Before performing any type of maintenance/service, disengage all controls and stop the engine. Wait until all moving parts have come to a complete stop. Disconnect the spark plug wire and ground it against the engine to prevent unintended starting. Always wear safety glasses during operation or while performing any adjustments or repairs.

REPAIR PROTECTION AGREEMENT

Congratulations on making a smart purchase. Your new Craftsman® product is designed and manufactured for years of dependable operation. But like all products, it may require repair from time to time. That’s when having a Repair Protection Agreement can save you money and aggravation.

Here’s what the Repair Protection Agreement includes:

- Expert service by our 10,000 professional repair specialists

- Unlimited service and no charge for parts and labor on all covered repairs. Product replacement up to $1500 if your covered product can’t be fixed

- Discount of 10% from the regular price of the service and related installed parts not covered by the agreement; also, 10% off the regular price of the preventive maintenance check

- Fast help by phone — we call it Rapid Resolution — phone support from a Sears representative. Think of us as a “talking owner’s manual.”

Once you purchase the Agreement, a simple phone call is all that it takes for you to schedule service. You can call anytime, day or night, or schedule a service appointment online. The Repair Protection Agreement is a risk-free purchase. If you cancel for any reason during the product warranty period, we will provide a full refund. Or, a prorated refund anytime after the product warranty period expires. Purchase your Repair Protection Agreement today! Some limitations and exclusions apply. For prices and additional information in the U.S.A., call 1-800-827-6655.

*Coverage in Canada varies on some items. For full details, call Sears Canada at 1-800-361-6665.

Sears Installation Service

For Sears professional installation of home appliances, garage door openers, water heaters, and other major home items, in the U.S.A. or Canada call 1-800-4-MY-HOME®.

For more manuals by Craftsman, visit ManualsLibraryy

Craftsman 1450 Series Engine Chipper Shredder-FAQs

Why is my chipper shredder not working?

If your chipper shredder stalls or only runs with the choke on, it’s often due to carburetor issues like clogged jets or a dirty float bowl. Cleaning the carburetor, replacing stale fuel, and checking the fuel filter usually fix the problem.

How does a chipper shredder work?

A chipper shredder uses sharp blades and hammers powered by the engine to cut and shred branches, leaves, and yard waste into smaller chips or mulch.

How do I start a chipper shredder?

To start, place the machine on a level surface, set the choke, switch the ignition on, and pull the recoil starter. Once the engine starts, slowly move the choke to the run position.

How do I maintain a chipper shredder?

After each use, clear out any debris, let the engine cool, and wipe the exterior. Change engine oil after the first 8 hours of use, then as recommended. Keep the control linkage clean and lubricate moving parts with light oil.

What is the main function of a chipper shredder?

Its main role is to break down yard waste like branches, twigs, and leaves into smaller pieces for easy disposal, composting, or mulching.

Why is my chipper not turning over?

If the chipper won’t turn, the issue may be with the idler assembly or drive belt tension. Inspect under the belt cover to ensure the belt isn’t slipping and the assembly is adjusted correctly.

How long do chipper shredders last?

With proper maintenance, Craftsman chipper shredders can last for many years. Regular cleaning, oil changes, and timely part replacements extend their lifespan significantly.

What oil does a Craftsman chipper shredder use?

Most Craftsman 1450 Series models use SAE 30 engine oil for warmer climates. For colder conditions, a multi-grade oil like 5W-30 is recommended.