Ingersoll Rand RS-Series Fixed Speed Air Compressor

TRANSPORTATION

Ensure the machine is secured against movement during transportation.

RECEIPT

Before signing the delivery receipt, inspect for damage and missing parts. If damage or missing parts are apparent, make the appropriate notation on the delivery receipt, then sign the receipt. Immediately contact the carrier for an inspection. All material shall be held in the receiving location for the carrier’s inspection. Delivery receipts that have been signed without a notation of damage or missing parts are considered to be delivered “clear.” Subsequent claims are then considered to be concealed damage claims. Settle damage claims directly with the transportation company.

If you discover damage after receiving the compressor (concealed damage), the carrier shall be notified within 15 days of receipt, and an inspection shall be requested by telephone with confirmation in writing. On concealed damage claims, the burden of establishing that the compressor was damaged in transit reverts to the claimant.

Read the compressor nameplate to verify it is the model ordered, and read the motor nameplate to verify it is compatible with your electrical conditions. Make sure electrical enclosures and components are appropriate for the installation environment.

UNPACKING AND HANDLING

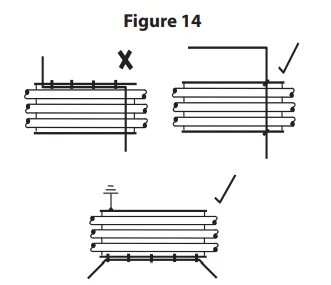

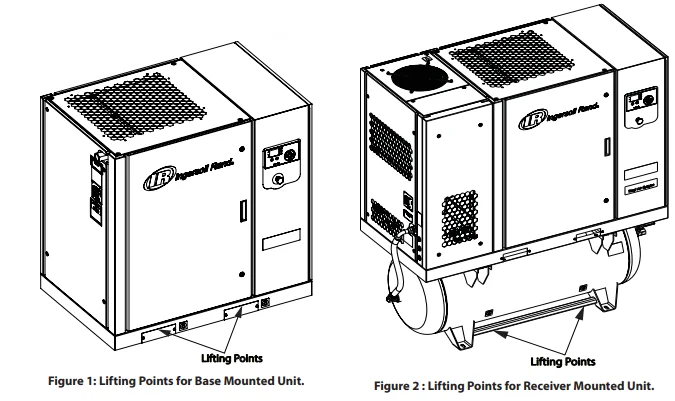

The compressor will normally be delivered with a polyethylene or other cover. If a knife has to be used to remove this cover, ensure that the exterior paintwork of the compressor is not damaged. Incorporated within the base of the compressor are slots to enable a forklift truck to move the compressor. Ensure truck forks are fully engaged on both sides. Once the packaging and pallet are discarded and the compressor is in its final position, remove the yellow painted transit brackets from the resilient mounts and store for future use or discard.

For RS15-22ie:

- Two brackets from the motor sub base and (1) one bracket from the separator tank.

For RS11-22i:

- One bracket from the separator tank.

LONG-TERM STORAGE

If the product will not be commissioned within six months of receipt, it should be prepared for long-term storage. Please contact Ingersoll Rand for details.

INSTALLATION

LOCATION IN PLANT

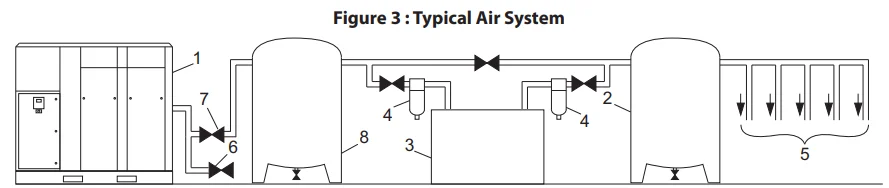

Key

- Compressor

- Air Receiver Dry Tank

- Air Dryer

- Compressed Air Filters

- System Demand Points

- Vent/Drain Trap

- Isolation Valve

- Air Receiver (“Wet Tank”)

- The customer can install a flexible element between the machine and the pressure system to avoid vibration transmission.

- The compressor can be installed on any level floor capable of supporting it. A dry, well-ventilated area where the atmosphere is as clean as possible is recommended.

- The area selected for the location of the compressor should be free of dust, chemicals, metal filings, paint fumes, and overspray.

- Hard surfaces may reflect noise with an apparent increase in the decibel level. When sound transmission is important, a sheet of rubber or cork can be installed beneath the compressor to reduce noise. Flexible piping may be required.

- See the general arrangement drawing for minimum space requirements for normal operation and maintenance.

- Minimum space in front of the control panel door, as required by national or local codes, shall be maintained.

- Ambient temperatures higher than 46 °C (115 °F) for RS15-22ie and 40 °C (104 °F) for RS11-22i shall be avoided, as well as areas of high humidity.

NOTICE

- A minimum of 1 m (3.3 ft) all around the compressor is recommended. If headroom is restricted, then the exhaust should be ducted or deflected away from the compressor.

- Screw-type compressors should not be installed in air systems with reciprocating compressors without means of isolation, such as a common receiver tank. It is recommended that both types of compressors be piped to a common receiver tank using individual air lines.

- The compressor is shipped with the shipping restraints in place. Ensure that these are removed to allow free movement of the drive assembly during operation. Each restraint is painted yellow.

DISCHARGE AND CONDENSATE PIPING

It is essential when installing a new compressor (1) to review the total air system. This is to ensure a safe and effective total system. One item that should be considered is liquid carryover. Installation of air dryers (3) is always a good practice since, when properly selected and installed, they can reduce any liquid carryover to zero. An air receiver tank (2) is recommended to ensure that the total system volume is sufficient.

Discharge piping should be at least as large as the discharge connection of the compressor. All piping and fittings should be suitably rated for the discharge pressure. Discharge piping should not exert any unresolved moments or force on the compressor. It is good practice to install line filters (4). Include a vent or drain trap (6) to vent the discharge pipework downstream from the minimum pressure check valve located on the separator tank and upstream of the first system isolation valve (7). This compressor has an internal discharge check valve. An external check valve is not required. An isolation valve (7) is required within 1 m (36 in) of the compressor discharge.

NOTICE: There should be no plastic or PVC piping attached to this compressor or used for any lines downstream, with the exception of condensate removal lines. The discharged air contains a very small percentage of compressor coolant, and care should be taken to ensure that downstream equipment is compatible.

When two rotary compressors are operated in parallel, provide an isolation valve (7) and a drain trap (6) for each compressor before the common receiver. Ensure the discharge piping is arranged to prevent water from being forced into the non-operating compressor. A wet tank (8) is recommended in cases where the air dryer is a regenerative desiccant type to prevent short cycling the compressor during the purging cycle when plant air demand is slow.

The built-in after-cooler reduces the discharge air temperature below the dew point (for most ambient conditions). Therefore, considerable water vapor is condensed. To remove this condensation, each compressor with a built-in after-cooler is furnished with a combination condensate separator/trap. A drip leg assembly and isolation valve should be mounted near the compressor discharge. A drain line should be connected to the condensate drain in the base.

GENERAL ELECTRICAL

- A qualified electrician shall perform all electrical installations and services.

- The compressor shall be properly grounded/earthed in compliance with all applicable standards and regulations (local, state, country, federal, etc.).

- Installation of this compressor shall be in compliance with all applicable standards and regulations (local, state, country, federal, etc.).

- The compressor shall have its own isolator situated adjacent to it. The fuse protecting the circuit and the compressor shall be selected in accordance with recognized code requirements on the basis of the data provided in the specification sheet.

- Feeder cables shall be sized to ensure that the circuit is balanced and not overloaded by other electrical equipment.

- The length of wiring from a suitable electrical feed point is critical, as voltage drops may impair the performance of the compressor.

- Feeder cable connections to incoming terminals L1-L2-L3 shall be tight and clean.

- The applied voltage shall be compatible with the compressor data plate ratings.

- The control circuit transformer has different voltage tappings. Ensure that these are set for the specific applied voltage prior to starting.

- Remove the blind plate to cut a hole for the incoming power connection. If it is necessary to make a hole in the control box in a different location, care should be taken not to allow metal shavings to enter the starter and other electrical components within the box. If another hole is used, the original hole shall be blocked off.

- The feeder cable shall be suitably glanded into the starter box to maintain proper ingress protection. Fixed speed starter.

INTEGRATED DRYER

- Do not connect condensate drains common to other pressurized drain lines in a closed circuit. Make sure the outflow from the condensate drains is unimpeded. Connect the condensate piping in such a way to ensure that sound levels are kept to a minimum during drainage.

- Ensure that all condensate is disposed of in a responsible manner, in compliance with all applicable standards and regulations (local, state, country, federal, etc.).

- The ambient air around the dryer and compressor shall not contain solid or gaseous contaminants. All compressed and condensed gases can generate acids or chemical products, which may damage the compressor or components inside the dryer. Take particular care with sulphur, ammonia, chlorine, and installations in marine environments.

INTEGRATED DRYER POWER SUPPLY

For RS15-22ie:

The dryer is powered from the in-built power supply system from the compressor. The compressor should be connected to a three-phase supply in accordance with local requirements and codes.

For RS11-22i:

The dryer is powered from a single-phase supply that must be supplied separately from the compressor’s three-phase supply. The dryer should be connected to a single-phase supply in accordance with local requirements and codes.

OPERATING INSTRUCTIONS (GENERAL)

BASIC OPERATION

NOTICE: The language and unit of measure displayed on the controller will be preset before leaving the factory. If these are required to be changed, contact your local Ingersoll Rand service provider.

PRIOR TO STARTING

- Check that the coolant level is at least visible in the center of the sight glass and add coolant if necessary. Refer to the maintenance procedures for setting the correct level.

- Ensure that the discharge air isolation valve is open. Switch ON the main electrical isolation switch. The control panel will illuminate, indicating that the line and control voltages are available.

INITIAL CHECK SEQUENCE

- The controller will perform an initial check sequence if the compressor receives initial power to the controller or has experienced a trip reset. While the initial check sequence occurs, the controller will display a “Checking Machine” message.

- During the initial check sequence, the controller will check the control system for proper operation. During this time, if any items are found inoperative, a trip will occur, and the compressor will not start.

After completion of the initial check sequence, the controller will then display “READY TO START.” This process should be completed within 10 seconds.

START SEQUENCE

For Fixed Speed (FS) machines, the compressor will initially start when the operator presses the start button or when the compressor receives a remote start signal. The compressor will be automatically loaded/unloaded when discharge pressure rises above/below the configurable setpoint. When the machine stops, it will go through a blowdown sequence to release pressure.

STOP SEQUENCE

The compressor can be stopped by a local or remote stop, a shutdown due to a trip, or an emergency stop. All of the above conditions will cause the compressor to stop immediately, except for the local or remote stop. A local or remote stop will open the blowdown valve, and the compressor will run for 10 seconds before stopping. The machine must run unloaded for 10 seconds before restarting.

NOTICE: If the compressor has to be stopped in an emergency, depress the emergency stop button located underneath the instrument panel.

EMERGENCY STOPPING

- If the compressor has to be stopped in an emergency, press the emergency stop button located underneath the instrument panel.

- This will override the normal unload/stop button and will immediately stop the compressor.

RESTARTING AFTER EMERGENCY STOPPING

- If the compressor has been switched OFF because of a compressor malfunction, identify and correct the fault before attempting to restart.

- If the compressor has been switched OFF for reasons of safety, ensure that the compressor can be operated safely before restarting.

- Refer to the instructions before STARTING and START SEQUENCE earlier in this section before restarting the compressor.

X-SERIES SYSTEM CONTROLS CONNECTION

CONNECTION TO X-SERIES SYSTEM CONTROLS

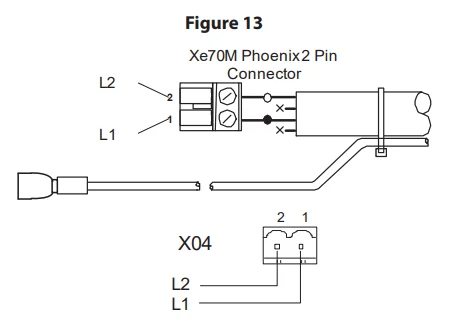

The Xe-70M controller is designed to interface to an Ingersoll Rand X-Series System Controller using Belden 9841 or equivalent RS-485 cable. In order to connect to the network, the cable must be connected to port X04 on the controller, as shown in the diagrams below. Note that up to 8 (X8I) or 12 (X12I) devices can be daisy-chained together in an X-Series network.

RS-485 NETWORK

![]() RS-485 data communications and other low-voltage signals can be subject to electrical interference. This potential can result in intermittent malfunction or an anomaly that is difficult to diagnose. To avoid this possibility, always use earth shielded cables, securely bonded to a known good earth at one end. In addition, give careful consideration to cable routing during installation.

RS-485 data communications and other low-voltage signals can be subject to electrical interference. This potential can result in intermittent malfunction or an anomaly that is difficult to diagnose. To avoid this possibility, always use earth shielded cables, securely bonded to a known good earth at one end. In addition, give careful consideration to cable routing during installation.

- Never route an RS-485 data communications or low-voltage signal cable alongside a high-voltage 3-phase power supply cable. If it is necessary to cross the path of a power supply cable(s), always cross at a right angle.

- If it is necessary to follow the route of power supply cables for a short distance (for example, from a compressor unit to a wall along a suspended cable tray), attach the RS-485 or signal cable on the outside of an earthed cable tray such that the cable tray forms an earthed electrical interference shield.

- Where possible, never route an RS-485 or signal cable near equipment or devices that may be a source of electrical interference (for example: 3-phase power supply transformer, high voltage switchgear unit, frequency inverter drive module, radio communications antenna).

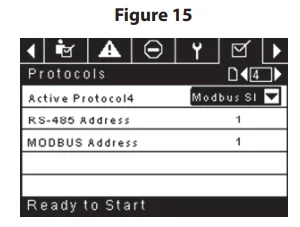

RS-485 ADDRESS SELECTION

Each compressor connected to the network will have a unique assigned address, starting at compressor 1, increasing sequentially to the number of compressors connected to the network. The RS-485 address for each compressor is set on the General Settings Tab, Page 7. The controller’s default RS-485 Address setting is 1. Additionally, the active protocol must be set to Airbus485.

ENABLING SYSTEM CONTROL CAPABILITIES

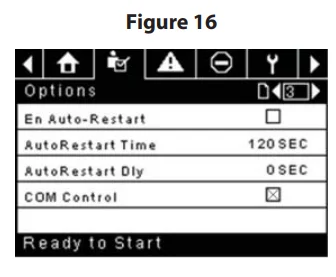

- In order to communicate properly with the X-Series system controller, the Xe-70M must have the following setpoints correctly set. On the Operator Settings tab, page 3 (Fixed Speed) or page 2 (Variable Speed). Verify that the COM control setpoint is enabled (the checkbox is filled in) as shown below. If this setpoint is not selected, the system controller will be unable to load or unload the machine.

- Additionally, for fixed speed machines, make sure that the Enable Auto-Restart setpoint is enabled (the checkbox is filled in) or the compressor will continue to run when unloaded by the system controller.

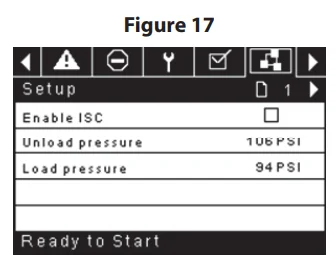

- After the address and COM control have been set, be sure that Integral Sequencing (ISC) is disabled by navigating to Integral Sequencing, page 1, and verifying that the Integral Sequencing setpoint is disabled (checkbox not filled in) as shown below. Once these setpoints are correctly set and the machine is started locally, the system controller should see status information from the compressor and be able to take control.

WARRANTY

The Company warrants that the equipment manufactured by it and delivered hereunder will be free of defects in material and workmanship for a period of twelve months from the date of placing the Equipment in operation or eighteen months from the date of shipment from the factory, whichever shall first occur.

The Purchaser shall be obligated to promptly report any failure to conform to this warranty, in writing to the Company in said period, whereupon the Company shall, at its option, correct such nonconformity by suitable repair to such equipment or furnish a replacement part F.O.B. point of shipment, provided the Purchaser has stored, installed, maintained, and operated such Equipment in accordance with good industry practices and has complied with specific recommendations of the Company. Accessories or equipment furnished by the Company,

but manufactured by others, shall carry whatever warranty the manufacturers have conveyed to the Company and which can be passed on to the Purchaser. The Company shall not be liable for any repairs, replacements, or adjustments to the Equipment or any costs of labor performed by the Purchaser or others without the Company’s prior written approval. The effects of corrosion, erosion, and normal wear and tear are specifically excluded. Performance warranties are limited to those specifically stated within the Company’s proposal. Unless responsibility for meeting such performance warranties is limited to specified tests, the Company’s obligation shall be to correct in the manner and for the period of time provided above.

THE COMPANY MAKES NO OTHER WARRANTY OR REPRESENTATION OF ANY KIND WHATSOEVER, EXPRESSED OR IMPLIED, EXCEPT THAT OF TITLE, AND ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE ARE HEREBY DISCLAIMED.

Correction by the Company of non-conformities, whether patent or latent, in the manner and for the period of time provided above, shall constitute fulfillment of all liabilities of the Company for such non-conformities, whether based on contract, warranty, negligence, indemnity, strict liability, or otherwise, with respect to or arising out of such Equipment.

The Purchaser shall not operate Equipment which is considered to be defective, without first notifying the Company in writing of its intention to do so. Any such use of Equipment will be at Purchaser’s sole risk and liability.

Note that this is the Ingersoll Rand standard warranty. Any warranty in force at the time of purchase of the compressor or negotiated as part of the purchase order may take precedence over this warranty. Visit ingersollrandproducts.com for more information.

For More Manuals By Ingersoll-Rand, Visit ManualsLibraryy.

Ingersoll Rand RS-Series Fixed Speed Air Compressor-FAQs

What makes the Ingersoll Rand RS-Series different from other air compressors?

The Ingersoll Rand RS-Series is a line of fixed-speed, oil-lubricated rotary screw air compressors designed for industrial use. “Fixed-speed” means the compressor runs at one constant motor speed, delivering consistent airflow and pressure. These units are known for rugged reliability, simpler controls, and cost-effective performance in applications where variable speed adjustment isn’t required.

What are typical applications for an RS-Series compressor?

RS-Series compressors are ideal for medium to heavy industrial environments, including manufacturing shops, fabrication facilities, automotive plants, and woodworking operations. They provide continuous-duty compressed air for tools, production lines, spray booths, and pneumatic systems where reliability and consistent pressure are essential.

How much air does an RS-Series compressor deliver?

Air delivery (measured in CFM – cubic feet per minute) varies by model. Smaller RS-Series units may deliver in the lower range (e.g., 50–100+ CFM), while larger models can exceed 200+ CFM at rated pressures (commonly 100–175 psi). For exact CFM & pressure specs, consult the model plate or official data sheet for your specific unit.

What type of motor does an RS-Series compressor use?

RS-Series compressors are typically equipped with TEFC (Totally Enclosed Fan-Cooled) electric motors designed for industrial environments. These motors provide efficient, continuous operation while protecting against dust and contaminants in shop environments.

Are RS-Series compressors single- or three-phase?

Most Ingersoll Rand RS-Series compressors are available in three-phase electrical configurations, making them suitable for industrial facilities with three-phase power. Some smaller units may offer single-phase options, but three-phase is common for larger horsepower models.

How do I perform routine Maintenance on an RS-Series air compressor?

Routine maintenance includes checking and replacing oil and filters at scheduled intervals, inspecting the separator element, draining condensate from tanks, and monitoring system temperatures. Periodic belt and coupling inspections also help maintain peak performance. Always follow the manufacturer’s maintenance schedule for your specific RS model.

What causes oil carry-over in rotary screw compressors?

Oil carry-over (oil entering the air side) can occur due to excessive oil in the reservoir, worn or clogged separator elements, blocked scavenge lines, or improper operating temperatures. Regular maintenance of the separator filter and correct oil level management helps prevent this issue.

How do you remove excess oil from an RS-Series compressor?

To reduce excess oil without a full drain, shut down the compressor safely and slowly open the oil drain valve to collect small portions of oil into a clean container until the oil level reaches the recommended range visible in the sight glass. Avoid removing oil from a pressurized system and always follow the manufacturer’s shutdown procedures.

Is the Ingersoll Rand RS-Series suitable for continuous operation?

Yes — RS-Series compressors are built for continuous duty cycle operation. Their rotary screw design and oil-lubricated compression allow them to run for extended periods without overheating, making them well-suited to industrial and production environments where air demand is steady and sustained.

What maintenance intervals should I follow for the RS-Series?

Typical maintenance intervals for an RS-Series unit include daily checks for leaks and temperatures, monthly filter inspections, oil changes every 500–1,000 hours (or per manual), and separator element replacement at recommended hours. Always refer to the official Ingersoll Rand service manual for exact intervals based on your usage conditions.