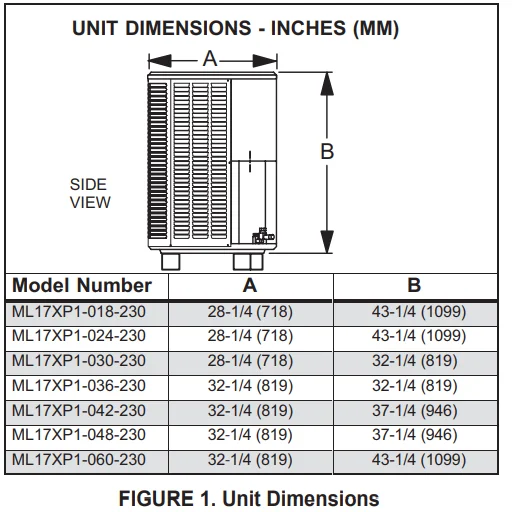

Lennox Merit Series ML17XP1 Heat Pump

INSTALLATION INSTRUCTIONS

Merit® Series ML17XP1 Units

HEAT PUMP

508263-01

6/2022

General

This ML17XP1 outdoor heat pump with all-aluminum coil is designed for use with HFC-410A refrigerant only. This unit must be installed with an approved indoor air handler or coil. For AHRI Certified system match-ups and expanded ratings, visit www.LennoxPros.com. These instructions are intended as a general guide and do not supersede local codes in any way. Consult the authorities having jurisdiction before installation.

NOTICE!

Charging information is given on the charging procedure sticker on the unit access panel. For more in-depth information, consult the Installation and Service Procedures manual, available on LennoxPros.com or through the Technical Support department at 800-453-6669.

CAUTION

As with any mechanical equipment, contact with sharp sheet metal edges can result in personal injury. Take care while handling this equipment and wear gloves and protective clothing.

IMPORTANT: Special procedures are required for cleaning the all-aluminum coil in this unit. See page 15 in this instruction for information.

STEP 1 – SETTING THE UNIT – Clearances

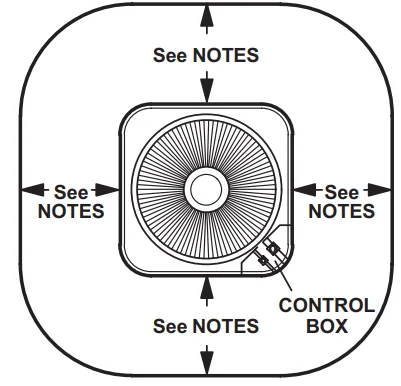

NOTES –

Service clearance of 30 in. (762 mm) must be maintained on one of the sides adjacent to the control box. Clearance to one of the other three sides must be 36 in. (914 mm). Clearance to one of the remaining two sides may be 12 in. (305 mm), and the final side may be 6 in. (152 mm). A clearance of 24 in. must be maintained between two units.

48 in. (1219 mm) clearance required on top of the unit.

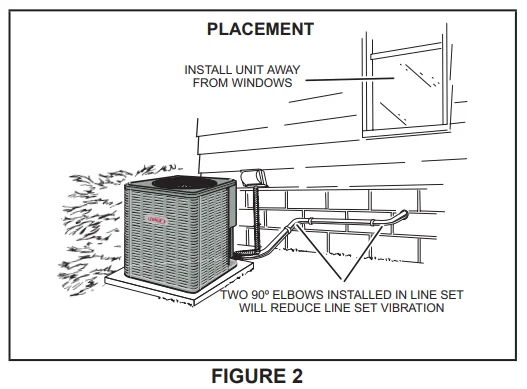

STEP 1 – SETTING THE UNIT (Continued) – Unit Placement

NOTICE!

Roof Damage!

This system contains both refrigerant and oil. Some rubber roofing material may absorb oil, causing the rubber to degrade. Failure to follow this notice could result in damage to the roof surface.

IMPORTANT

This unit must be matched with an indoor coil as specified by AHRI. For AHRI Certified system match-ups and expanded ratings, visit www.LennoxPros.com. Coils previously charged with HCFC-22 must be flushed.

WARNING

To prevent personal injury, as well as damage to panels, unit, or structure, observe the following:

- While installing or servicing this unit, carefully stow all removed panels so that the panels will not cause injury to personnel, objects, or nearby structures. Also, take care to store panels where they will not be subject to damage (e.g., being bent or scratched).

- While handling or stowing the panels, consider any weather conditions (especially wind) that may cause panels to be blown around and damaged.

IMPORTANT

The Clean Air Act of 1990 bans the intentional venting of refrigerant (CFCs, HCFCs, and HFCs) as of July 1, 1992. Approved methods of recovery, recycling, or reclaiming must be followed. Fines and/or incarceration may be levied for noncompliance.

IMPORTANT

Exhaust vents from dryers, water heaters, and furnaces should be directed away from the outdoor unit. Prolonged exposure to exhaust gases and the chemicals contained within them may cause condensation to form on the steel cabinet and other metal components of the outdoor unit. This will diminish unit performance and longevity.

IMPORTANT

This model is designed for use in check/expansion valve systems only. An indoor expansion valve approved for use with HFC-410A refrigerant must be ordered separately and installed before operating the system.

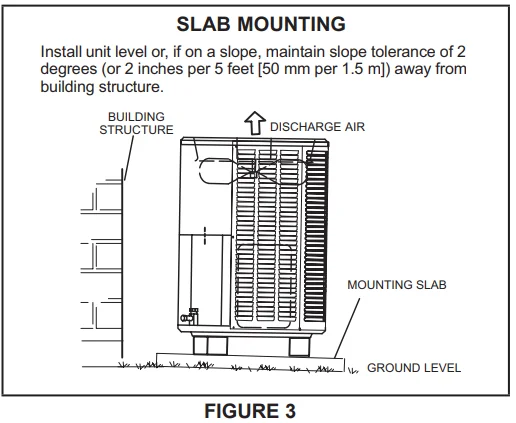

NOTE – An optional Unit Stand-Off Kit (94J45) is available for this unit. Black high-density polyethylene feet raise the unit off of mounting surface, away from damaging moisture. Four feet are furnished per order number.

STEP 2 – REFRIGERANT PIPING

IMPORTANT

If this unit is being matched with an approved line set or indoor unit coil that was previously charged with mineral oil, or if it is being matched with a coil that was manufactured before January 1999, the coil and line set must be flushed before installation. Take care to empty all existing traps. Polyol ester (POE) oils are used in Lennox units charged with HFC-410A refrigerant.

Residual mineral oil can act as an insulator, preventing proper heat transfer. It can also clog the expansion device and reduce system performance and capacity. Failure to properly flush the system per this instruction and the detailed Installation and Service Procedures manual will void the warranty.

Flush the existing line set per the following instructions. For more information, refer to the Installation and Service Procedures manual available on LennoxPros.com.

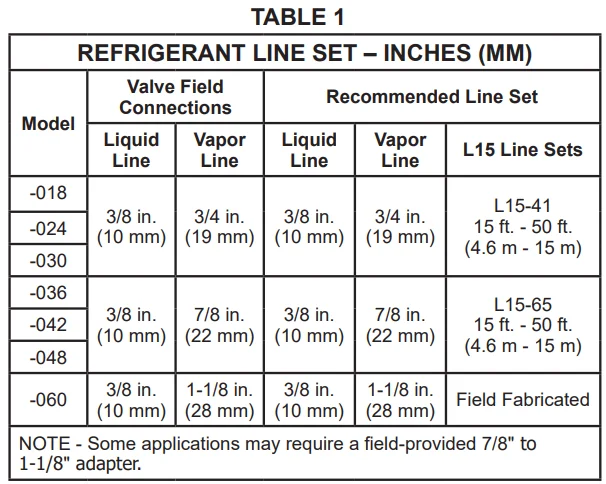

CAUTION – DO NOT attempt to flush and re-use existing line sets or indoor coil when the system contains contaminants (i.e., compressor burnout). If a new line set is being installed, size the piping per Table 1.

NOTE – When installing refrigerant lines longer than 50 feet, refer to the Refrigerant Piping Design and Fabrication Guidelines manual available on LennoxPros.com (Corp. 9351-L9), or contact the Technical Support Department Product Application group for assistance.

NOTE – For new or replacement line set installation, refer to Service and Application Note – Corp. 9112-L4 (C-91-4).

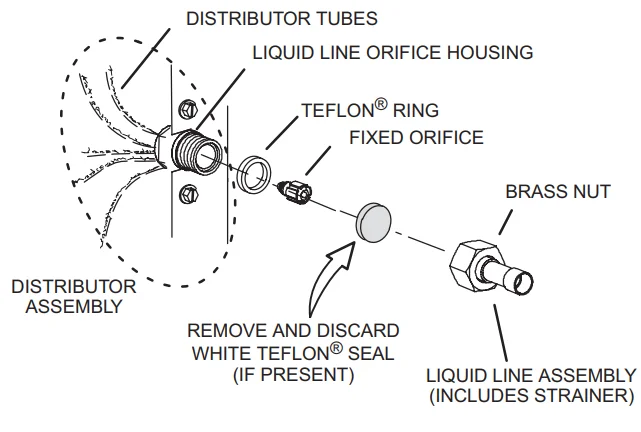

1A TYPICAL EXISTING FIXED ORIFICE REMOVAL PROCEDURE (UNCASED COIL SHOWN)

- On fully cased coils, remove the coil access and plumbing panels.

- Remove any shipping clamps from the liquid line and distributor assembly.

- Using two wrenches, disconnect the liquid line from the liquid line orifice housing. Take care not to twist or damage distributor tubes during this process.

- Remove and discard fixed orifice, valve stem assembly (if present), and Teflon® washer as illustrated above.

- Use a field-provided fitting to temporarily reconnect the liquid line to the indoor unit’s liquid line orifice housing.

OR

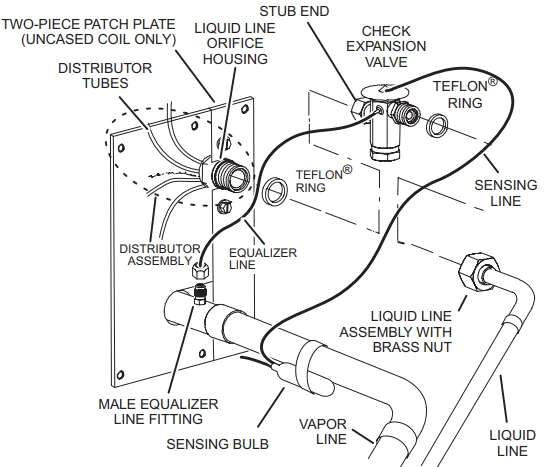

1B TYPICAL EXISTING EXPANSION VALVE REMOVAL PROCEDURE (UNCASED COIL SHOWN)

- On fully cased coils, remove the coil access and plumbing panels.

- Remove any shipping clamps from the liquid line and distributor assembly.

- Disconnect the equalizer line from the check expansion valve equalizer line fitting on the vapor line.

- Remove the vapor line sensing bulb.

- Disconnect the liquid line from the check expansion valve at the liquid line assembly.

- Disconnect the check expansion valve from the liquid line orifice housing. Take care not to twist or damage distributor tubes during this process.

- Remove and discard the check expansion valve and the two Teflon® rings.

- Use a field-provided fitting to temporarily reconnect the liquid line to the indoor unit’s liquid line orifice housing.

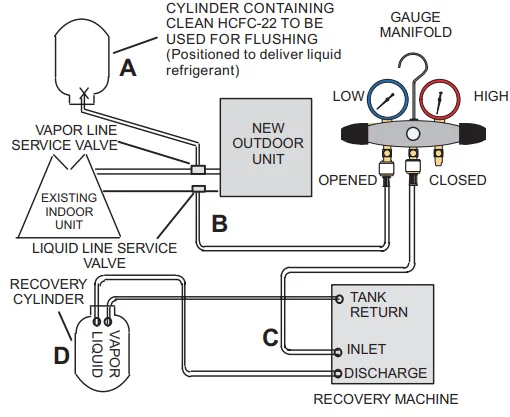

2 CONNECT GAUGES AND EQUIPMENT FOR FLUSHING PROCEDURE

- HCFC-22 cylinder with clean refrigerant (positioned to deliver liquid refrigerant) to the vapor service valve.

- HCFC-22 gauge set (low side) to the liquid line valve.

- The HCFC-22 gauge set the center port to inlet on the recovery machine with an empty recovery tank connected to the gauge set.

- Connect the recovery tank to the recovery machine per the machine instructions.

3 FLUSHING LINE SET

The line set and indoor unit coil must be flushed with at least the same amount of clean refrigerant that previously charged the system. Check the charge in the flushing cylinder before proceeding.

- Set the recovery machine for liquid recovery and start the recovery machine. Open the gauge set valves to allow the recovery machine to pull a vacuum on the existing system line set and indoor unit coil.

- Position the cylinder of clean HCFC-22 for delivery of liquid refrigerant and open its valve to allow liquid refrigerant to flow into the system through the vapor line valve. Allow the refrigerant to pass from the cylinder and through the line set and the indoor unit coil before it enters the recovery machine.

- After all of the liquid refrigerant has been recovered, switch the recovery machine to vapor recovery so that all of the HCFC-22 vapor is recovered. Allow the recovery machine to pull the system down to 0.

- Close the valve on the inverted HCFC-22 drum and the gauge set valves. Pump the remaining refrigerant out of the recovery machine and turn the machine off.

STEP 2 – REFRIGERANT PIPING – Brazing Procedures

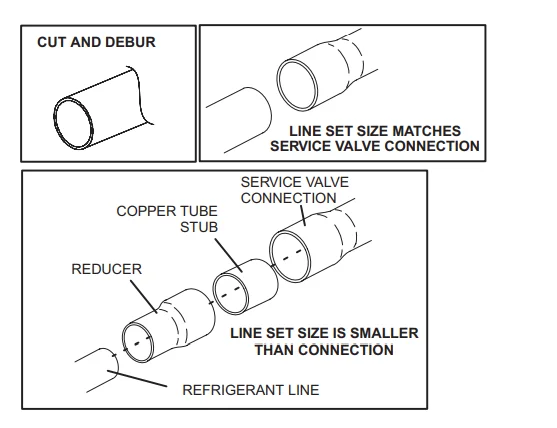

1 CUT AND DEBUR

Cut ends of the refrigerant lines square (free from nicks or dents) and debur the ends. The pipe must remain round. Do not crimp the end of the line.

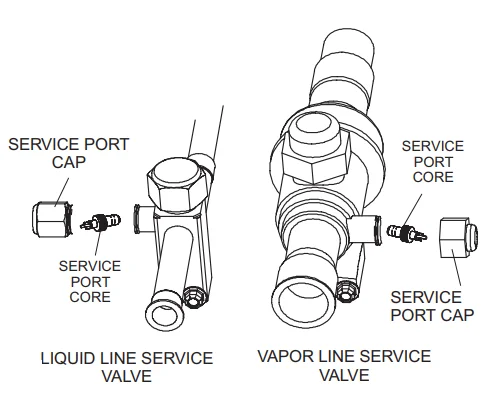

2 CAP AND CORE REMOVAL

Remove the service cap and core from both the vapor and liquid line service ports.

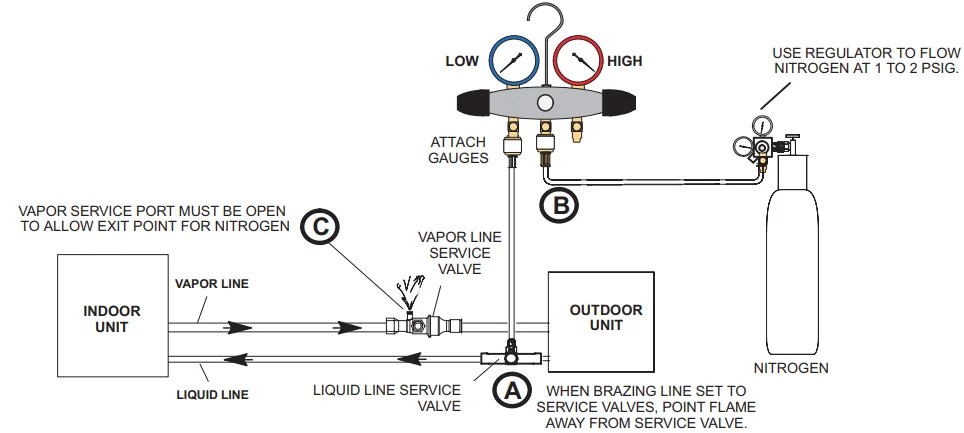

3 ATTACH THE MANIFOLD GAUGE SET FOR BRAZING LIQUID AND VAPOR LINE SERVICE VALVES

Flow-regulated nitrogen (at 1 to 2 psig) through the low-side refrigeration gauge set into the liquid line service port valve, and out of the vapor line service port valve.

- Connect the gauge set’s low-pressure side to the liquid line service valve (service port).

- Connect the gauge set center port to the bottle of nitrogen with the regulator.

- Remove the core from the valve in the vapor line service port to allow nitrogen to escape.

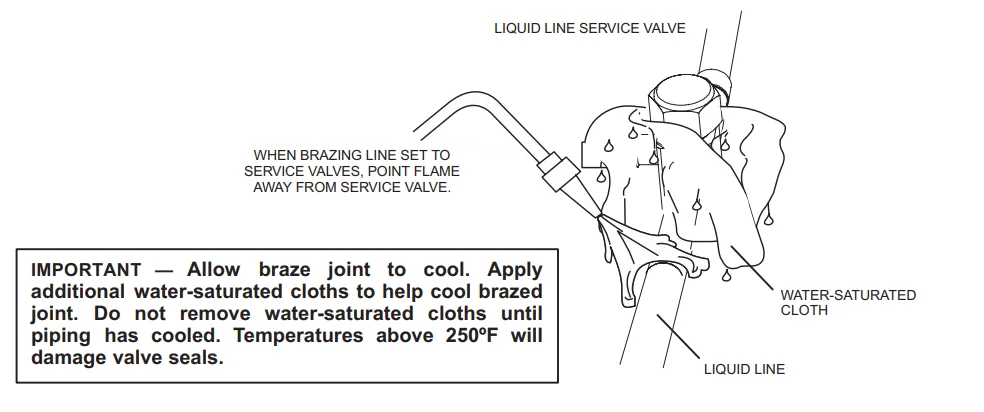

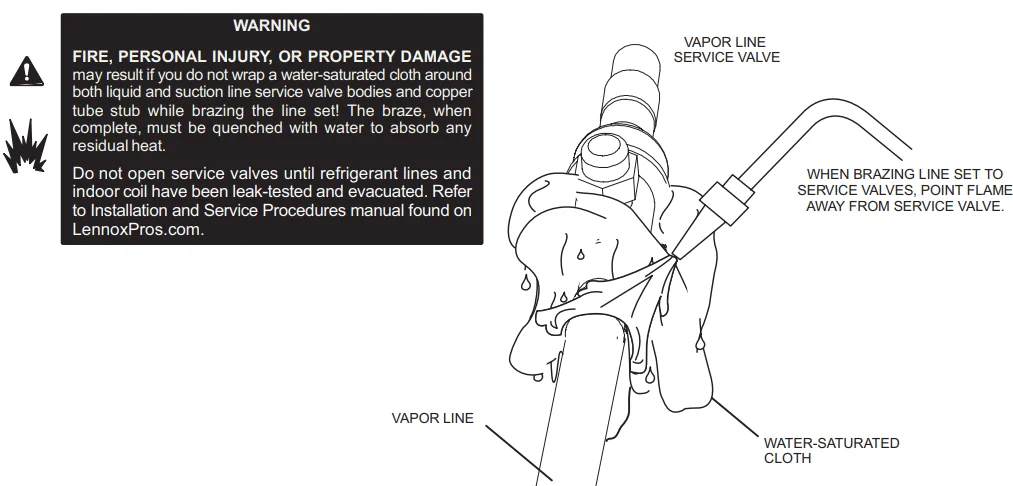

4 WRAP SERVICE VALVES

To help protect service valve seals during brazing, wrap water-saturated cloths around service valve bodies and copper tube stubs. Use additional water-saturated cloths underneath the valve body to protect the base paint.

5 FLOW NITROGEN

Flow-regulated nitrogen (at 1 to 2 psig) through the refrigeration gauge set into the valve stem port connection on the liquid service valve and out of the vapor valve stem port. See steps 3A, 3B, and 3C on manifold gauge set connections.

6 BRAZE LINE SET

Wrap both service valves with water-saturated cloths as illustrated here and as mentioned in step 4, before brazing to the line set. Cloths must remain water-saturated throughout the brazing and cool-down process.

7 PREPARATION FOR THE NEXT STEP

After all connections have been brazed, disconnect the manifold gauge set from the service ports. Apply additional water-saturated cloths to both service valves to cool piping. Once piping is cool, remove all water-saturated cloths.

Homeowners Information

CAUTION

Before attempting to perform any service or maintenance, turn the electrical power to the unit OFF at the disconnect switch. In order to ensure peak performance, your system must be properly maintained. Clogged filters and blocked airflow prevent your unit from operating at its most efficient level. The system should be inspected and serviced before each cooling and heating season by a licensed professional HVAC service technician (or equivalent).

Heat Pump Operation

Your new Lennox heat pump has several characteristics that you should be aware of:

- Heat pumps satisfy heating demand by delivering large amounts of warm air into the living space. This is quite different from gas- or oil-fired furnaces or an electric furnace, which deliver lower volumes of considerably hotter air to heat the space.

- Do not be alarmed if you notice frost on the outdoor coil in the winter months. Frost develops on the outdoor coil during the heating cycle when temperatures are below 45°F (7°C). An electronic control activates a defrost cycle lasting 5 to 15 minutes at preset intervals to clear the outdoor coil of the frost.

- During the defrost cycle, you may notice steam rising from the outdoor unit. This is a normal occurrence. The thermostat may engage auxiliary heat during the defrost cycle to satisfy a heating demand; however, the unit will return to normal operation at the conclusion of the defrost cycle.

Homeowner Maintenance

The following maintenance may be performed by the homeowner.

- Contact a licensed professional HVAC technician to schedule inspection and maintenance appointments for your equipment before each heating and cooling season.

- Check the indoor unit filter each month and replace the filter if necessary.

- Have your Lennox dealer show you where your indoor unit filter is located. It will be either at the indoor unit (installed internally or externally to the cabinet) or behind a return air grille in the wall or ceiling. Check the filter monthly and clean or replace it as needed. Disposable filters should be replaced with a filter of the same type and size.

- Check the indoor unit drain line for obstructions monthly. The indoor coil is equipped with a drain pan to collect condensate formed as your system removes humidity from the inside air. Have your dealer show you the location of the drain line and how to check for obstructions. (This would also apply to an auxiliary drain, if installed.)

- Check the area around the outdoor unit monthly and remove any obstructions that may restrict airflow to the outdoor unit. This would include grass clippings, leaves, or papers that may have settled around the unit.

- Trim shrubbery away from the unit and periodically check for debris that collects around the unit.

- During the winter months, keep the snow level below the louvered panels.

NOTE – The filter and all access panels must be in place at any time the unit is in operation. If you are unsure about the filter required for your system, call your Lennox dealer for assistance.

Thermostat Operation

See the thermostat homeowner’s manual for instructions on how to operate your thermostat.

Pre-Service Check

If your system fails to operate, check the following before calling for service:

- Verify room thermostat settings are correct.

- Verify that all electrical disconnect switches are ON.

- Check for any blown fuses or tripped circuit breakers.

- Verify unit access panels are in place.

- Verify the air filter is clean.

If service is needed, locate and write down the unit model number and have it handy before calling.

Extended Power Outage

The heat pump is equipped with a compressor crankcase heater, which protects the compressor during cold-weather operation. If power to your unit has been interrupted for several hours or more, set the room thermostat selector to the EMERGENCY HEAT setting to obtain temporary heat without the risk of serious damage to the heat pump. In EMERGENCY HEAT mode, all heating demand is satisfied by auxiliary heat; heat pump operation is locked out. After a six-hour compressor crankcase warm-up period, the thermostat can be switched to the HEAT setting, and normal heat pump operation may resume.

Professional Maintenance

Your heating and air conditioning system should be inspected and maintained twice each year (before the start of the cooling and heating seasons) by a licensed professional HVAC technician. You can expect the technician to check the following items. These checks may only be conducted by a licensed professional HVAC technician.

Outdoor Unit

- Inspect component wiring for loose, worn, or damaged connections. Also, check for any rubbing or pinching of wires. Confirm the proper voltage plus amperage of the outdoor unit.

- Check the cleanliness of the outdoor fan and blade condition (cracks) and clean or replace them, if necessary.

- Inspect base pan drains for debris and clean as necessary.

- Inspect the condition of refrigerant piping and confirm that pipes are not rubbing copper-to-copper. Also, check the condition of the insulation on the refrigerant lines. Repair, correct, or replace as necessary.

- Test capacitor. Replace as necessary.

- Inspect contactor contacts for pitting or burn marks. Replace as necessary.

- Check the outdoor fan motor for worn bearings/bushings. Replace as necessary.

- Inspect and clean outdoor coils, if necessary, and note any damage to coils or signs of leakage.

Indoor Unit (Air Handler or Furnace)

- Inspect component wiring for loose, worn, or damaged connections. Confirm the proper voltage plus amperage of the indoor unit.

- Inspect and clean or replace air filters in the indoor unit.

- Check the cleanliness of the indoor blower and clean the blower, if necessary.

- Inspect the indoor coil drain pans and condensate drains for rust, debris, obstructions, leaks, or cracks. Pour water in pans to confirm proper drainage from the pans through to the outlet of the pipe. Clean or replace as necessary.

- Inspect and clean the indoor coil, if necessary.

- Inspect the condition of the refrigerant lines and confirm that pipes are not rubbing copper-to-copper. Also, ensure that refrigerant pipes are not being affected by indoor air contamination. Check the condition of insulation on the refrigerant lines. Repair, correct, or replace as necessary.

- Inspect the duct system for leaks or other problems. Repair or replace as necessary.

- Check for bearing/bushing wear on the indoor blower motor. Replace as necessary.

- If your heat pump is matched with a gas- or oil-fired furnace for auxiliary heating, indoor unit service will also include inspection and cleaning of the burners, and a full inspection of the gas valve, heat exchanger, and flue (exhaust) system.

General System Test with System Operating

- Your technician should perform a general system test. He will turn on the air conditioner to check operating functions such as the startup and shut-off operations. He will also check for unusual noises or odors, and measure indoor/outdoor temperatures and system pressures as needed. He will check the refrigerant charge per the charging sticker information on the outdoor unit.

- Verify that the system total static pressure and airflow settings are within specific operating parameters.

- Verify the correct temperature drop across the indoor coil.

For More Manuals By Lennox, Visit ManualsLibraryy.

Lennox Merit Series ML17XP1 Heat Pump-FAQs

What is the heating capacity of the Lennox ML17XP1?

The Lennox ML17XP1-036 is a 3-ton central heat pump that provides 36,000 BTU for both heating and cooling, offering powerful year-round comfort for medium-sized homes.

How does the Lennox ML17XP1 heat pump work?

The ML17XP1 transfers heat rather than generating it. In winter, it absorbs heat from outdoor air and moves it indoors; in summer, it reverses the process to expel heat outside, keeping your home comfortable efficiently.

What is the SEER rating of the Lennox ML17XP1?

This model offers up to 17.00 SEER and 9.60 HSPF (equivalent to 16.20 SEER2 and 8.20 HSPF2), making it an ENERGY STAR® certified system that balances comfort and cost-effectiveness.

How long does a Lennox heat pump typically last?

With proper maintenance, Lennox heat pumps last about 10 to 12 years, depending on climate and usage conditions.

At what temperature does a heat pump go into defrost mode?

The ML17XP1 enters defrost mode when the outdoor coil temperature drops to about 32°F (0°C). This process removes ice from the outdoor coil to maintain efficiency.

What causes a Lennox heat pump to freeze?

Common causes include cold outdoor temperatures, airflow restrictions, or low refrigerant levels. If you notice ice buildup, turn off the unit and call a professional for inspection.

How can I tell if my heat pump is working properly?

Ensure your thermostat is functioning, air filters are clean, and the outdoor unit is clear of debris. The system should switch smoothly between heating and cooling modes without unusual noise.

Why is my Lennox heat pump not heating properly?

Check if your thermostat is set correctly and powered. Also, inspect for tripped breakers, blocked airflow, or a dirty filter. If issues persist, contact a certified technician for service.