Metabo HPT EC711S Air Compressor

IMPORTANT INFORMATION

- Read and understand all of the operating instructions, safety precautions, and warnings in the Instruction Manual before operating or maintaining this compressor.

- Most accidents that result from compressor operation and maintenance are caused by the failure to observe basic safety rules or precautions. An accident can often be avoided by recognizing a potentially hazardous situation before it occurs, and by observing appropriate safety procedures.

- Basic safety precautions are outlined in the “SAFETY” section of this Instruction Manual and in the sections that contain the operation and maintenance instructions.

- Hazards that must be avoided to prevent bodily injury or machine damage are identified by WARNINGS on the compressor and in this Instruction Manual.

- Never use this compressor in a manner that has not been specifically recommended by Metabo HPT, unless you first confirm that the planned use will be safe for you and others.

MEANINGS OF SIGNAL WORDS

- WARNING: Indicates a potentially hazardous situation which, if ignored, could result in death or serious personal injury.

- CAUTION: Indicates a potentially hazardous situation which, if not avoided, may result in minor or moderate injury, or may cause machine damage.

- NOTE: Emphasizes essential information.

OPERATION AND MAINTENANCE

NOTE:

- The information contained in this Instruction Manual is designed to assist you in the safe operation and maintenance of the compressor.

- Some illustrations in this Instruction Manual may show details or attachments that differ from those on your own compressor.

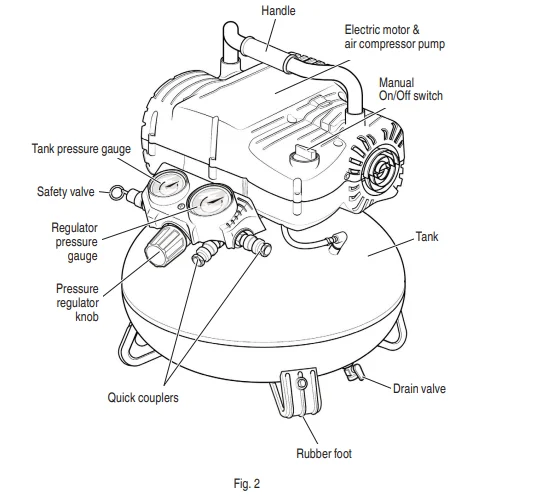

NAME OF PARTS

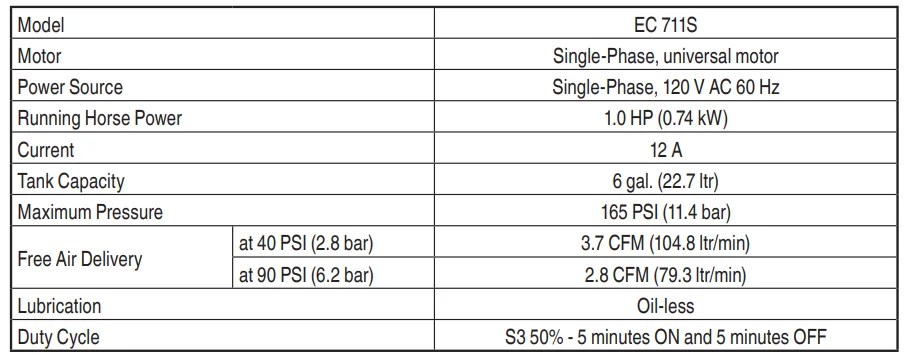

SPECIFICATIONS

KNOW YOUR AIR COMPRESSOR

Before attempting to use this product, familiarize yourself with all operating features and safety rules. (Fig. 2)

OIL-FREE UNIVERSAL MOTOR

Your air compressor features permanently lubricated bearings.

ON/OFF POWER SWITCH

This switch is used to start or stop the air compressor. Moving the switch to the (ON) position will provide automatic power to the pressure switch, which will allow the motor to start when the air tank pressure is below the factory-set cut-in pressure. When in the (ON) position, the pressure switch stops the motor when the air tank pressure reaches the factory-set cut-out pressure. Moving the switch to the (OFF) position will remove power from the motor and stop the air compressor.

ELECTRIC MOTOR & AIR COMPRESSOR PUMP

The motor is used to power the pump. The electric motor has a thermal overload protector. If the motor overheats for any reason, the thermal overload will cut off power, thus preventing the motor from being damaged. Wait until the motor is cool. The motor resets automatically.

Air compressor pump: To compress air, the piston moves up and down in the cylinder. On the down stroke, air is drawn in through the air intake valve while the exhaust valve remains closed. On the upstroke, air is compressed, the intake valve closes, and compressed air is forced out through the exhaust valve, into the discharge line, through the check valve, and into the air tank.

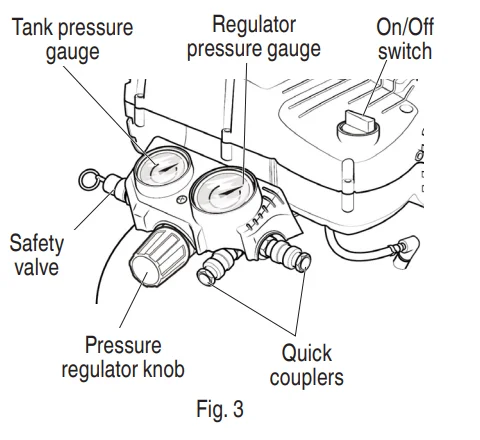

SAFETY VALVE

This valve is designed to prevent system failures by relieving pressure from the system when the compressed air reaches a predetermined level. The valve is preset by the manufacturer and must not be modified in any way.

DRAIN VALVE

The drain valve is used to remove moisture from the air tank.

TANK PRESSURE GAUGE

The tank pressure gauge indicates the pressure of the air in the tank.

REGULATOR PRESSURE GAUGE

The current line pressure is displayed on the regulator pressure gauge. This pressure can be adjusted by rotating the pressure regulator knob.

PRESSURE REGULATOR KNOB

Use the pressure regulator knob to adjust the amount of air being delivered through the hose. The air pressure coming from the air tank is controlled by the regulator knob. Turn the pressure regulator knob clockwise to increase discharge pressure and counterclockwise to decrease discharge pressure. Follow the tool operating instructions for the recommended pressure range.

AIR TANK

The tank is used to store compressed air.

QUICK COUPLER

The outlet is used to connect the 1/4 in. NPT air hose.

OVERLOAD PROTECTOR

This air compressor is equipped with a thermal overload device, which will turn the air compressor off automatically if it becomes overheated. If the motor turns OFF repeatedly, check for the following possible causes first:

- Low voltage from the outlet.

- Lack of proper ventilation or outside air, or room temperature too high.

- Extension cord too long or wrong gauge wire used.

To reset the air compressor:

- Turn the air compressor off.

- Unplug the air compressor and allow it to cool for 30 minutes.

- Plug the air compressor into an approved outlet.

- Turn the air compressor on.

DUTY CYCLE:

To avoid overheating of the electric motor, this compressor is designed for intermittent operation as indicated on the dataplate: S3 50 means 5 minutes ON and 5 minutes OFF.If the compressor run time exceeds the S3 50 duty cycle, then the application requires more air than the compressor is capable of delivering. To ensure tool performance, the SCM output of the compressor should exceed the CFM requirement of the tool by 20%.

ASSEMBLY

UNPACKING

This product has been shipped completely assembled.

- Carefully remove the compressor and any accessories from the box. Make sure that all items listed in the packing list are included.

- Inspect the compressor carefully to make sure no breakage or damage occurred during shipping.

- Do not discard the packing material until you have carefully inspected and satisfactorily operated the compressor.

PACKING LIST

- Air Compressor

- Instructions Manual

WARNING: If any parts are missing, do not operate the compressor until the missing parts are replaced. Failure to do so could result in possible serious personal injury.

WARNING: Do not attempt to modify this compressor or create accessories not recommended for use with this compressor. Any such alteration or modification is a misuse and could result in a hazardous condition leading to possible serious personal injury.

ATTACHING HOSE

- Insert the hose into the quick coupler already installed on the compressor (Fig. 3). WARNING: Do not attach any tools to the open end of the hose until start-up has been completed.

- Firmly grasp the open end of the hose; hold it facing away from yourself and others.

BREAKING IN THE PUMP

- Check and tighten all bolts, fittings, etc.

- Turn the pressure regulator knob fully clockwise to open the air flow. (Fig. 3)

- Place the switch in the OFF (0) position and plug in the power cord.

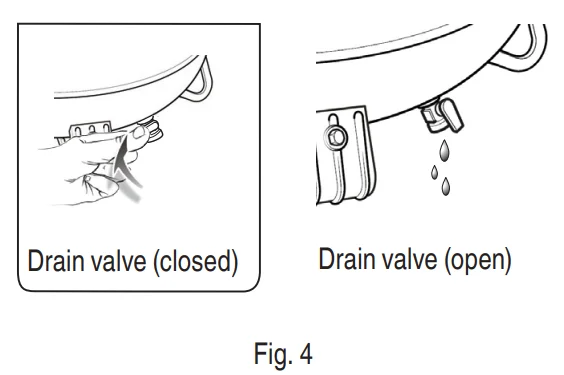

- Open the drain valve completely (Fig. 4).

- Turn the air compressor ON (I) and run the air compressor for 10 minutes to break in the pump parts.

- Place the switch in the OFF (0) position.

- Close the drain valve (Fig. 4).

APPLICATIONS

Air compressors are utilized in a variety of air system applications. Match hoses, connectors, air tools, and accessories to the capabilities of the air compressor. You may use this compressor for the purposes listed below:

- Operating air-powered tools requiring less than 2.8 SCM @ 90 PSI.

- Powering pneumatic nail guns, inflating tires, and cleaning/blowing with pressurized air.

WARNING: Do not allow familiarity with the compressor and tools to make you careless. Remember that a careless fraction of a second is sufficient to inflict serious injury.

WARNING: Always wear safety goggles or safety glasses with side shields when operating a compressor. Failure to do so could result in objects being thrown into your eyes, resulting in possible serious injury.

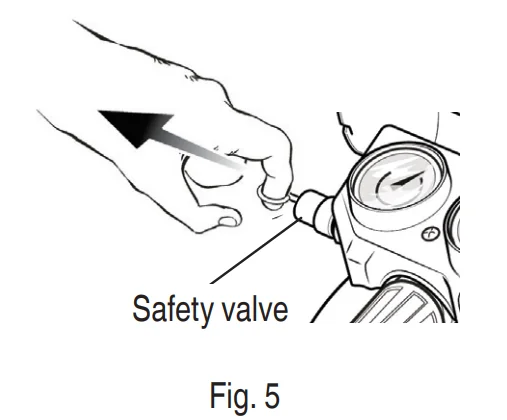

CHECKING THE SAFETY VALVE

Before starting the compressor, pull the ring on the safety valve to make sure that the safety valve operates smoothly. (Fig. 5) Do not use the compressor if the safety valve is stuck or does not operate smoothly. Have a defective safety valve replaced by a Metabo HPT authorized service center.

WARNING: Drain the tank to release air pressure before pulling the ring on the safety valve.

WARNING: Risk of bursting. If the safety valve does not work properly, over-pressurization may occur, causing air tank rupture or an explosion.

USING THE AIR COMPRESSOR

- Temperature Operating temperatures are between 32°F and 104°F (0°C and 40°C). CAUTION: Never operate in temperatures below 32°F (0°C) or above 104°F (40°C). WARNING: Always ensure the ON/OFF switch is in the OFF (0) position and the regulator pressure gauge reads zero before changing air tools or disconnecting the hose from the air outlet. Failure to do so could result in possible serious personal injury.

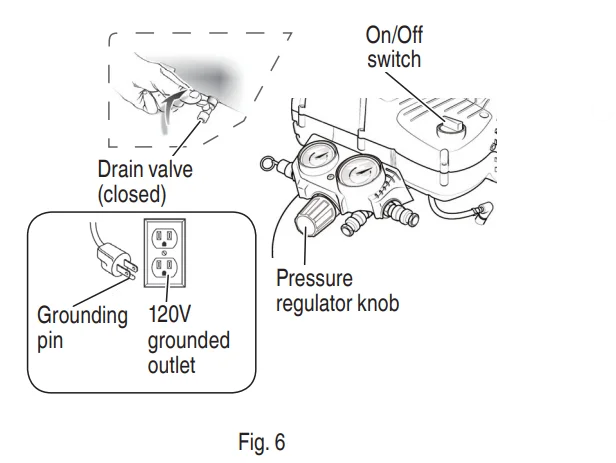

- Ensure the tank drain valve is closed (Fig. 6).

- Ensure the ON/OFF switch is in the OFF (0) position and the air compressor is unplugged (Fig. 6).

- Ensure the pressure regulator knob is turned fully counterclockwise (Fig. 6).

- If not already installed, attach the hose to the compressor.

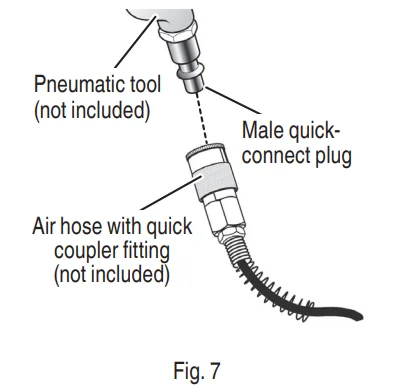

- Connect the air-powered tools to the air hose by inserting the male quick-connect plug into the quick coupler at the end of the hose (Fig. 7).

- Connect the power cord to the power supply. NOTE: If the compressor is connected to a circuit protected by a fuse, use time delay fuses. Time delay fuses should be marked “D” in Canada and “T” in the U.S.

- Turn the ON/OFF switch to the ON (1) position.

- Rotate the pressure regulator knob to the desired line pressure. Turning the knob clockwise increases air pressure at the outlet; turning the knob counterclockwise reduces air pressure at the outlet. NOTE: Before connecting or disconnecting air tools, turn the regulator knob counterclockwise to stop the flow of air.

- Following all safety precautions in this manual and the manufacturer’s instructions in the air tool manual, you may now use your air-powered tool.

- If using an inflation accessory with a quick-connect fitting, control the amount of air flow with the pressure regulator knob. Turning the knob fully counterclockwise will completely stop the flow of air. NOTE: Always use the minimum amount of pressure necessary for your application. Using a higher pressure than needed will drain air from the tank more rapidly and cause the unit to cycle on more frequently.

- When finished, always drain the tank and unplug the unit. Never leave the unit plugged in and/or running unattended.

WARNING: Check the air tool manual to ensure the correct air pressure regulator setting for optimum operation of your air tools. If you are using an air tool not originally included in the package contents list (not necessarily supplied with the air compressor model you have purchased), your tool may require more air consumption than this air compressor is designed to supply. Always read your air tool owner’s manual to match the correct air supply to your air tool to avoid damage to the tool or risk of personal injury.

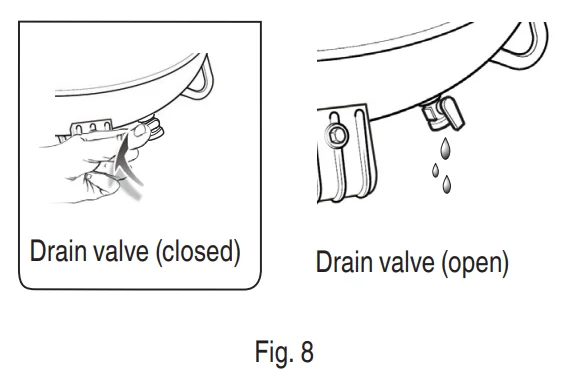

DRAINING THE TANK

To help prevent tank corrosion and keep moisture out of the air used, the tank of the compressor should be drained daily.

To drain the tank: (Fig. 8)

- Verify that the compressor is turned off.

- Holding the handle, tilt the compressor toward the drain valve so that it is set in a lower position.

- Open the drain valve by rotating it 1/4 turn counterclockwise.

- Keep the compressor tilted until all moisture has been removed.

- Drain moisture from the tank into a suitable container. NOTE: Condensate is a polluting material and should be disposed of in compliance with local regulations.

- If the drain valve is clogged, release all air pressure by pulling the safety valve. Remove and clean the valve, then reinstall. WARNING: Unplug the air compressor and release all air from the tank before servicing. Failure to depressurize the tank before attempting to remove the valve may cause serious personal injury.

- Close the drain valve by rotating it 1/4 turn clockwise.

END OF OPERATION/STORAGE

- Turn the ON/OFF power switch to the OFF position.

- Unplug the power cord from the wall outlet and wrap it around the handle area to prevent damage when not in use.

- Open the drain valve located at the lower part of the tank (Fig. 8). Tank pressure should be below 10 psi when draining the tank. WARNING: Risk of bursting. When the tank gets corroded, there is a risk of breakdown. Water will condense in the air tank. If not drained, water will corrode and weaken the air tank, causing a risk of air tank rupture. Drain the tank daily or after 4 hours of use. The drain contains moisture in the air, abrasion particles, rust, etc. To drain the tank, open the valve slowly and tilt the compressor to empty accumulated water. Keep face and eyes away from the drain cock.

- Air hose should be disconnected from the compressor and hung with open ends down to allow any moisture to drain.

- Compressor and hose should be stored in a cool, dry place.

MAINTENANCE

WARNING: When servicing, use only identical replacement parts. Use of any other parts may create a hazard or cause product damage.

WARNING: Always wear safety goggles or safety glasses with side shields during compressor operation or when blowing dust. If the operation is dusty, also wear a dust mask.

WARNING: Always release all pressure, disconnect from the power supply, and allow the unit to cool to the touch before cleaning or making repairs on the air compressor.

GENERAL MAINTENANCE

- Humidity in the air causes condensation to form in the air tank. This condensation should be drained daily and/or every hour, using the instructions found in Draining the Tank.

- The safety valve automatically releases air if the air receiver pressure exceeds the preset maximum. Check the safety valve before each use, following the instructions found in Checking the Safety Valve.

- Inspect the tank yearly for rust, pin holes, or other imperfections that could cause it to become unsafe.

- Avoid using solvents when cleaning plastic parts. Most plastics are susceptible to damage from various types of commercial solvents and may be damaged by their use. Use clean cloths to remove dirt, dust, oil, grease, etc.

WARNING: Do not at any time let brake fluids, gasoline, petroleum-based products, penetrating oils, etc., come in contact with plastic parts. Chemicals can damage, weaken, or destroy plastic, which may result in serious personal injury.

LUBRICATION

All the bearings in this compressor are lubricated with a sufficient amount of high-grade lubricant for the life of the unit under normal operating conditions. Therefore, no further lubrication of the bearings is required.

SERVICE AND REPAIRS

All quality compressors will eventually require servicing or replacement of parts because of wear and tear from normal use. To ensure that only genuine replacement parts will be used, all service and repairs must be performed by a Metabo HPT AUTHORIZED SERVICE CENTER only.

NOTE: Specifications are subject to change without any obligation on the part of Metabo HPT.

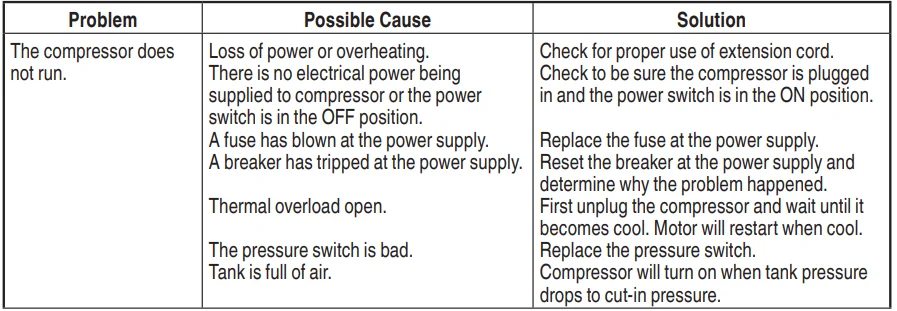

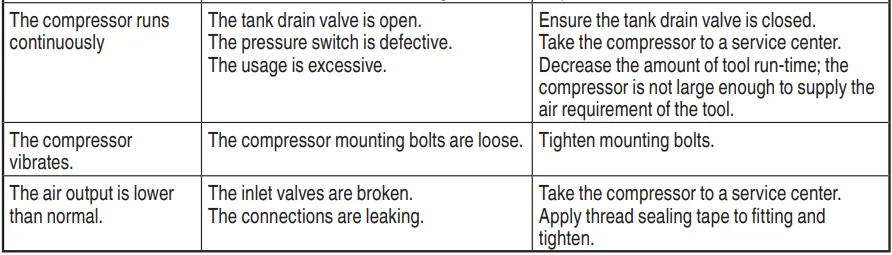

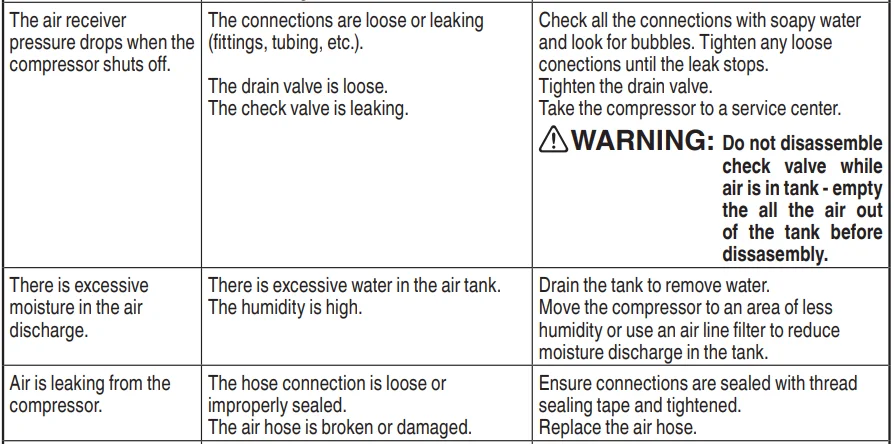

TROUBLESHOOTING

For More Manuals By Metabo HPT, Visit ManualsLibraryy.

Metabo HPT EC711S Air Compressor- FAQs

Who manufactures Metabo HPT air compressors?

Metabo HPT air compressors are made by Koki Holdings, a global power tool manufacturer. Metabo HPT is the North American brand under this company.

What does HPT mean in Metabo HPT?

HPT stands for Hitachi Power Tools. The brand was previously known as Hitachi Power Tools before being renamed Metabo HPT.

Is Metabo HPT the same as Metabo?

No. Metabo HPT and Metabo are different brands. Metabo HPT focuses mainly on the North American market, while Metabo is a German brand known for industrial-grade tools.

Are Metabo HPT air compressors reliable?

Yes, Metabo HPT air compressors are considered durable, reliable, and high-performing, making them suitable for both DIY users and professionals.

How long does a pancake air compressor usually last?

With proper care and regular maintenance, a pancake air compressor can last between 5 and 20 years, depending on usage and operating conditions.

How can I tell if my air compressor is faulty?

Common signs include reduced air pressure, loud noises, overheating, frequent breaker trips, or air leaks.

Do I need to oil the Metabo HPT EC711S air compressor?

The Metabo HPT EC711S is an oil-free air compressor, so it does not require oiling, making maintenance easier.

What is the most common cause of air compressor failure?

The most common causes include lack of maintenance, overheating, and electrical problems. Regular servicing helps prevent these issues.

How many CFM does a pancake air compressor provide?

Most pancake compressors deliver around 2.5 to 3.0 CFM at 90 PSI, which is suitable for nailers, inflators, and small air tools.

What is the air pressure rating of a good air compressor?

For light-duty tasks, 90 PSI is usually sufficient. Professional compressors typically offer 150 PSI or more for demanding applications.