Saltfire Classic Wood Burning Stove

INTRODUCTION

SAFETY

Safety is the most important consideration when using and installing your stove. If not installed and used correctly, a house fire could result. Installation must comply with the relevant national and local Building Regulations and fire safety standards. IN THE EVENT OF A CHIMNEY FIRE, EVACUATE THE PROPERTY AND CALL THE EMERGENCY SERVICES. Your stove will be heavy, and care needs to be taken when lifting – 2 people will normally be required to lift.

UNPACKING

Your stove will have several of its components stored inside the stove itself for transportation. The flue spigot can also be bolted to the flue outlet – the stove has two options for flue outlet – one on the top and one at the rear.

Most people use the top outlet, but depending on where you intend to position the stove in relation to your chimney, you may wish to use the rear outlet – in this case, remove the blanking plate at the rear and secure it to the top outlet instead.

The collar and blanking plate can be secured with the included bolts and Allen key. Inside the stove, you will find a glove that must be used when opening the door or adjusting air vents when the fire is hot.

INSTALLATION

The installation of your stove must comply with the relevant local and national Building Regulations and fire safety standards.

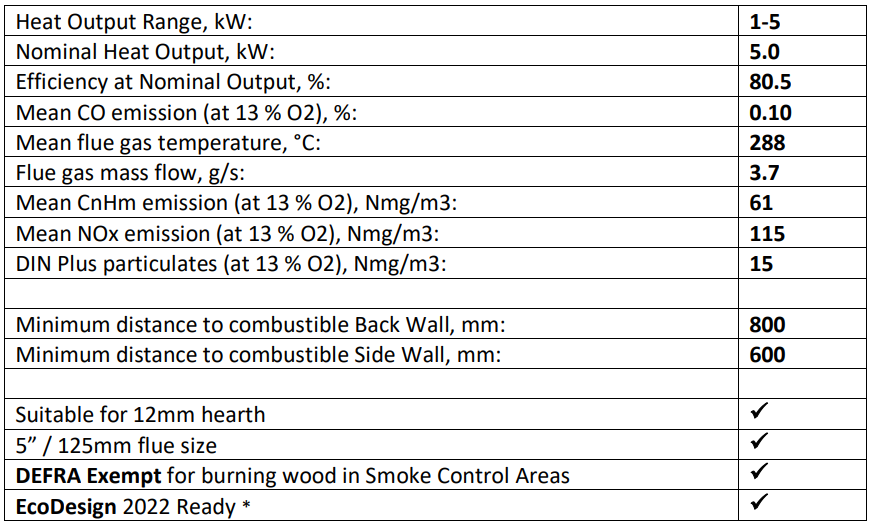

TECHNICAL

Model: “Saltfire Classic”

The Saltfire Classic has passed the testing standard required for EcoDesign when burning wood logs. The stove must not be installed within the specified minimum distances to combustible materials as shown in the table above. Adjacent walls should be of non-combustible materials and construction, preferably masonry or brickwork.

When installed inside a fireplace recess (with solid non-combustible walls), we recommend a minimum 50mm clearance at the sides and rear of the stove to allow good air circulation and achieve the best performance. Approved for burning wood logs in Smoke Control areas (DEFRA). CE tested to EN 13240:2001 by KIWA Gastec (Cheltenham, UK). EcoDesign 2022 is Ready when burning wood.

Your stove will require a constant air supply and should not be used at the same time and in the same room/space as extractor fans or any device that may draw air supply away from the stove. The stove should be installed on a level floor with adequate load-bearing capacity. The stove needs to stand on a hearth of non-combustible materials not less than 12mm thick, conforming to Building Regulations.

A Carbon Monoxide detector must be fitted in the same room as the appliance.

NOT suitable for installation in a shared flue system. If installed in a standard type chimney, a register plate needs to be fitted inside the chimney. When purchasing flue pipe, a 5”/125mm diameter is required for the Saltfire Classic.

The flue pipe must be fitted INSIDE the flue spigot and sealed with a generous amount of Fire Cement. We recommend that you have a qualified fitter install your stove. You can find a HETAS-qualified installer in your area by going to the HETAS website – www.hetas.co.uk.

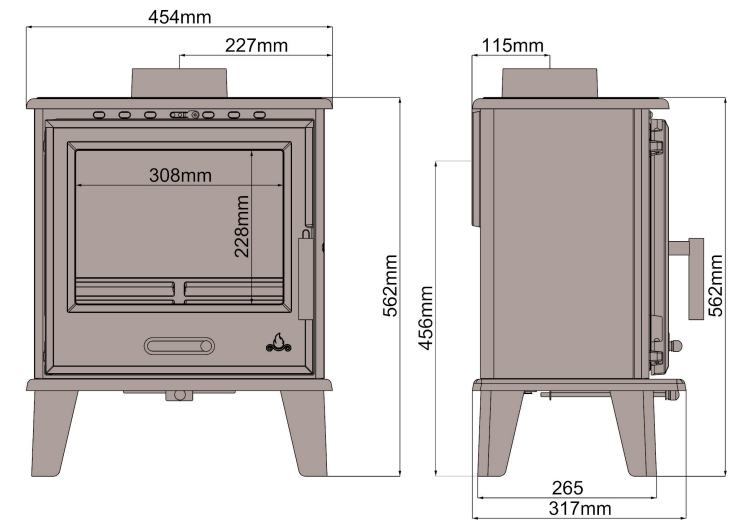

Dimensions

OPERATING INSTRUCTIONS

The Clean Air Act 1993 and Smoke Control Areas

Under the Clean Air Act, local authorities may declare the whole or part of the district of the authority to be a smoke control area. It is an offence to emit smoke from a chimney of a building, from a furnace, or from any fixed boiler if located in a designated smoke control area. It is also an offence to acquire an “unauthorised fuel” for use within a smoke control area unless it is used in an “exempt” appliance (“exempted” from the controls which generally apply in the smoke control area).

The Secretary of State for Environment, Food and Rural Affairs has powers under the Act to authorise smokeless fuels or exempt appliances for use in smoke control areas in England. In Scotland and Wales, this power rests with Ministers in the devolved administrations for those countries. Separate legislation, the Clean Air (Northern Ireland) Order 1981, applies in Northern Ireland.

Therefore, it is a requirement that fuels burnt or obtained for use in smoke control areas have been “authorised” in Regulations and that appliances used to burn solid fuel in those areas (other than “authorised” fuels) have been exempted by an Order made and signed by the Secretary of State or Minister in the devolved administrations. The “Saltfire Classic” has been recommended as suitable for use in smoke control areas when burning seasoned wood.

Further information on the requirements of the Clean Air Act can be found here: http://smokecontrol.defra.gov.uk/. Your local authority is responsible for implementing the Clean Air Act 1993, including the designation and supervision of smoke control areas, and you can contact them for details of Clean Air Act requirements.

FUEL

Wood – All types of wood are suitable, provided they are well-seasoned, UNTREATED, and have a moisture level between 12% and 20%. For soft woods, typically, they will need to have been left in suitable storage for 9+ months in order for the moisture to evaporate. For hardwoods, this will usually be 18 months+. It is recommended that logs should be no more than 5” or 125mm in diameter.

Logs should be no more than 320mm in length. If you are unsure of the moisture content of your fuel, then you can buy a moisture meter, which will indicate the moisture levels in your fuel. Liquid fuels must NEVER be used. WARNING: Wet timber should not be used as this will create excess tar deposits in the chimney and stove and could increase the risk of chimney fire.

Timber that is not of a suitable moisture content will also create more smoke and harmful emissions. Manufactured smokeless coals and anthracite can be used and will all have different qualities and effects. Do NOT use Petro-Coke-based fuels or any petroleum-based fuels, as this will invalidate the warranty. Any coal burned should be coal suitable for a multi-fuel stove (some coal is only for use on open fires and burns too hot for a stove).

AIR INLET CONTROLS

Your stove has three sets of air inlets. The upper vent above the door provides air supply for the air-wash system and allows air into the higher areas of the fire box – this is called the Secondary Air. When this vent is open, the door glass is kept clean by high-speed air rushing downwards across the inside of the glass. By moving the Secondary vent knob to the right, airflow into the stove is increased.

The secondary air vent is set such that the closure plate does not seal fully, thus allowing some constant air supply into the stove. The lower vent knob on the bottom of the door controls the provision of Primary Air – this is the primary source of air supply for combustion. Sliding the knob to the right increases the amount of Primary airflow into the stove. The (third) Tertiary vent control is located underneath the stove and controlled by a lever/knob tucked under the bottom shelf.

Pulling the lever out increases the airflow into the stove. The air is then channelled through a chamber on the back of the stove and enters the firebox via a series of small holes. Pushing the lever fully in closes this air intake partially. This intake cannot be fully closed. This ensures the stove maintains a level of combustion not likely to create excessive smoke.

TOOLS

The glove is provided for adjusting the air inlets and for opening the door when the stove is hot, as these knobs will heat up when in use. NOTE – all parts of the stove will become hot during use, and care needs to be taken to avoid injury through burning.

LIGHTING THE FIRE

- Prior to lighting the fire for the first time, ensure that-

- Installation and building work are complete.

- The chimney is suitable and sound, and has been swept and is free from obstruction.

- Adequate ventilation and provision for combustion air have been made.

- That the stove installation has been carried out in accordance with Building Regulations and any applicable local regulations, as well as these installation instructions.

- That chimney draw has been checked and is within specification. (The stove has been tested at nominal output with a flue draught of 12 Pa) Flue draughts in excess of 18 Pa when warm will have a negative effect on the efficiency, and could cause premature wear and damage to the stove.

ENSURE THAT YOU HAVE READ AND UNDERSTOOD THESE INSTRUCTIONS BEFORE LIGHTING THE FIRE, AND THAT YOU ARE CONFIDENT THE STOVE HAS BEEN INSTALLED CORRECTLY.

The Entire Stove Will Become HOT!

The glove is provided for adjusting the air inlets and for opening the door when the stove is hot, as these knobs will heat up when in use.

GUARANTEE

The main body of your stove is guaranteed for 5 years when all guarantee terms are followed, including registering your guarantee via the website within 30 days of purchase.

Please register here: http://www.defrastoves.com/guarantee-registration.htm. Failure to register within 30 days will limit your guarantee to 12 months from the date of purchase. This does not include glass, grates, baffles, retaining bars, inner linings/firebricks, door seals, paint finish, over-firing, incorrect use, or installation not carried out by a competent person or in accordance with building regulations. You should have zero problems with your stove unless it is abused, and if treated well, your stove will last and last.

What to do in the event of a chimney fire:

- Cut off the air supply to the stove, i.e., close the primary and secondary air supplies.

- Move any combustible materials well away from the stove.

- Get everyone out safely.

- Make sure that the fire brigade has clear access.

- Call 999. If you have any questions or concerns regarding the safe use of your stove, please contact us.

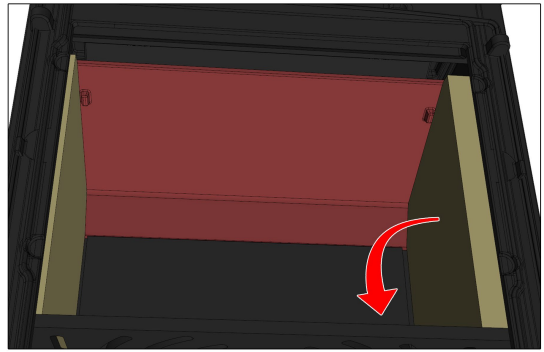

Baffle Plate Removal

Baffle Plate 1

Remove the Side brick to lower baffle plate 1 down, then carefully lift the baffle out of the door opening and remove the firebrick on the opposite side.

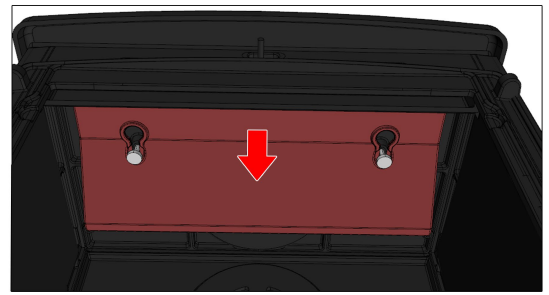

Baffle Plate 2

Baffle plate 2 will release by sliding the baffle plate backwards to release from the two support bolts

Troubleshooting Solutions for Stove Problems

Installing and using your stove correctly will provide years of warmth with little effort, but using it incorrectly will make it difficult to achieve the results you expect and can cause damage. Combustion is a complex chemical process with many variables, all of which need to be correct for your stove to burn correctly. Taking the time to understand these variables and the combustion process will make your life with your new stove a happy one.

1. The stove is difficult to light/keep lit

Common causes:

- Damp fuel – Wood should be maximum 20% moisture and ideally 12-15%. We strongly advise purchasing a digital moisture meter to test your logs. Always split logs in half and test the centre of the log.

- Poor draught and chimney strength – Your chimney needs to pull through adequate air for combustion. Flue draught should be between 12Pa and 18Pa – if in doubt, consult a local expert.

- Logs too big – Always start fires small and gradually build them up. Begin with paper or solid firelighters, building a small fire with kindling (small sticks of wood) until the kindling is well alight and hot. Then, gradually build the fire with your wood logs (not too thick). Splitting the logs will increase the surface area, allowing more thorough burning. Once the firebox is up to temperature, slightly larger logs can be added.

- Chimney/flue blocked – Excessive soot should not be allowed to build up in the flue – flues should be professionally cleaned when required and, in any case, at least once per year, or more if your chimney/fuel type is causing excessive soot to build up.

2. Fuel burns too quickly

The rated output on your stove is based on burning dry seasoned hardwood and refueling every hour. By turning down the vent controls, the fuel will burn more slowly and last longer.

Common causes:

- Excessively strong chimney draught – If by turning down the vents the fire still burns too quickly, this is normally due to excessively strong draught on the chimney. This will lead to over-firing of the stove, which is inefficient, losing excessive heat into the chimney, and pulling too much cold air through the house. A flue damper fitted into the first section of flue pipe can help to calm a chimney draught.

- Fuel type/size – Try experimenting with different types of wood/fuel and different-sized logs. Coal and slightly larger logs will burn more slowly. Softwood such as pine will burn particularly fast. Kiln-dried wood is NOT recommended – it is likely to burn too fast – always use seasoned, naturally dried logs (hardwood) where possible.

3. Smoke comes back into the room

A small amount of smoke entering the room when you open the stove door is normal, but it should stop after a few seconds. If smoke ever leaks constantly into the room, stop using the fire immediately, shut down all vents on the stove, open windows, and exit the room. Do not use the stove until a local expert has established the problem.

Common causes:

- Insufficient air supply into the room – do you have an air brick of sufficient size to feed the stove with air?

- Blocked chimney – have the chimney swept and checked by a registered chimney sweep.

- Insufficient chimney draught – can be due to a variety of reasons – please refer to previous text under “Poor draught and chimney strength”.

- Rapid condensation of the gases – causing them to slow down and back up in the chimney – this can be due to too broad a chimney/flue, relative to the size of the appliance, or the flue not being adequately insulated. You may need a flue liner and/or insulation in the chimney.

4. Glass gets dirty quickly

Common causes:

- Top vents not open – Your stove has a top vent, which controls the Airwash system – the top vent needs to be constantly open adequately to ensure enough air is coming into the stove. No Airwash will work fully when the stove is burning very slowly (slumbering).

- Primary Vent left open – Primary vent when left open will interfere with the operation of the Secondary (Airwash), causing blackening of the window. Always shut Primary once fire is established, and only ever open as much as necessary to get the fire going or to give a short ‘boost’ to new wood when refuelling.

- Poor fuel – Wet wood or softwood (e.g., pine) will produce a lot of tar, creosote, and soot, dirtying the glass and eventually blocking the flue.

- Insufficient chimney draught – See previous note under “Poor draught and chimney strength”.

- Baffle plates incorrectly fitted – See previous diagram for correct positioning of baffles.

- Fuel loaded too close to the window – The wood needs a good, clear distance away from the glass; otherwise, it will produce thick black marks on the glass and interfere with the Airwash airflow.

5. Not enough heat is being produced

Common causes:

- Poor quality fuel – Logs should be dry, well-seasoned hardwood.

- Poor draught and chimney strength – See previous notes.

- Excessive draught – Too much heat is being lost up the chimney – try a damper in the flue.

- Insufficient air supply – Check air supply is sufficient / vents on the stove are clear. Does the room have a vent?

- Not enough fuel being burned – The rated output of your stove is based on burning beech wood (typical of most hardwoods), refuelling once per hour. 1kg of this wood has approximately 4-5 kWh of energy.

- Larger stove/stove with higher output required for the room size.

6. Too much heat in the room

Common causes:

- Excessive chimney draw – Try fitting a damper unit in the flue.

- Too much air supply – Close down primary vent, then if still too hot, reduce tertiary and secondary vents.

- The stove may be too large for the room size.

7. Grate deformed / Baffle plate deformed

Your stove will have been designed to operate correctly for many years with a relevant quantity of fuel and reloading times. The grate and baffle plate can, over time, start to bow/deform – this can only be caused by very high temperatures. Using Solid Fuel products can accelerate this process, but burning wood at too high a temperature can also cause damage to internal parts.

Common causes:

- Excessive chimney draw – Try a damper in the flue.

- Excessive primary air supply – Close down primary vents.

- Incorrect fuel – NEVER use Petroleum Coke, Bituminous fuel, Housecoal or any unauthorised fuel.

- Stove overloaded – Excessive burning of too much fuel.

The baffle plate and the inner linings of the stove, and the grate are all designed to be replaceable parts – call us if you need to order new ones. If you are experiencing problems, including insufficient heat being provided, to help establish the cause and solution, we will need to know specifically what fuel you are burning and the rate (kg per hour) at which you are burning the fuel, and in the case of wood, the average moisture content of the centre of the logs (we suggest using a moisture meter to check moisture levels in logs).

Only by monitoring this burning rate over the course of several burn cycles can we quantify the outputs being produced and begin to establish the cause of the problem. If you are experiencing these problems, please email us at [email protected] with your invoice number, name, and purchase date, detailing as much information as possible, considering all of the above information (and the general troubleshooting advice we give for all stoves). The more accurate and detailed the information, the quicker we will be able to help you establish improvements you can make to your system.

For More Manuals By Saltfire Stoves, Visit ManualsLibraryy.

Saltfire Classic Wood Burning Stove-FAQs

Q1. How do I use my wood-burning stove for the first time?

Prepare the stove, open all vents, check the damper, warm the flue, build a small fire with kindling, then adjust vents as the fire establishes.

Q2. How do I control the airflow on the stove?

The primary air vent feeds air from below the fire, while the secondary vent directs air above the fuel and across the glass. Adjust them to regulate flame and heat.

Q3. Should the damper be open or closed when burning wood?

Always keep the damper open while burning. Closing it during use can cause smoke buildup and damage your stove.

Q4. Can I keep the stove burning overnight?

Yes. Add seasoned logs, then nearly close the air vents to slow the burn. A small airflow will keep embers alive until morning.

Q5. How long should wood dry before burning?

Logs should be seasoned for at least 12 months. Dry wood sounds hollow when struck together and burns more efficiently.

Q6. Can I leave the stove door open while burning?

No. For safety and efficiency, keep the door closed and use the air vents to control the fire.

Q7. How do I safely put out a fire in the stove?

Let the fire burn down to embers, close the vents, and spread the ash. If needed, add sand or use a fire extinguisher.

Q8. What happens if my stove gets too hot?

Overheating can damage the stove and flue. Reduce airflow immediately by closing vents and allow the fire to burn down.