Trane XL14i Heat Pump

Features and Benefits

- Climatuff compressor

- Efficiency up to 15.25 SEER and 9.6 HSPF

- All aluminum Spine Fin™ coil

- WeatherGuard™ II top shields unit

- DuraTuff™ base, fast complete drain, weather proof

- WeatherGuard™ fasteners

- XL seacoast shield

- Industry leading appearance

- Tarpaulin gray cabinet with anthracite gray top

- Low sound with advanced fan system and compressor sound insulator

- Quick-Sess™ cabinet, service access and refrigerant connections with full coil protection

- Demand defrost control with diagnostics

- Glossy corrosion resistant finish

- Internal compressor pressure/ temperature protection

- 018,024,060 ship with start kit

- Liquid line filter-drier

- Comfort “R”™ mode approved

- Easy single side service

- Multi-use liquid and suction line service valves

- Easy top & fan removal

- Full length control and service valve cover

- R-22 refrigerant

- Compressor sump heat

- S.E.E.T. design testing

- 100% line run test

- Low ambient cooling to 55°F as shipped

- Low ambient cooling to 40°F with EDC accessory AY28X084

- Low ambient cooling to 30°F with EDC accessory AY28X084 and TXV

- Extended warranties available

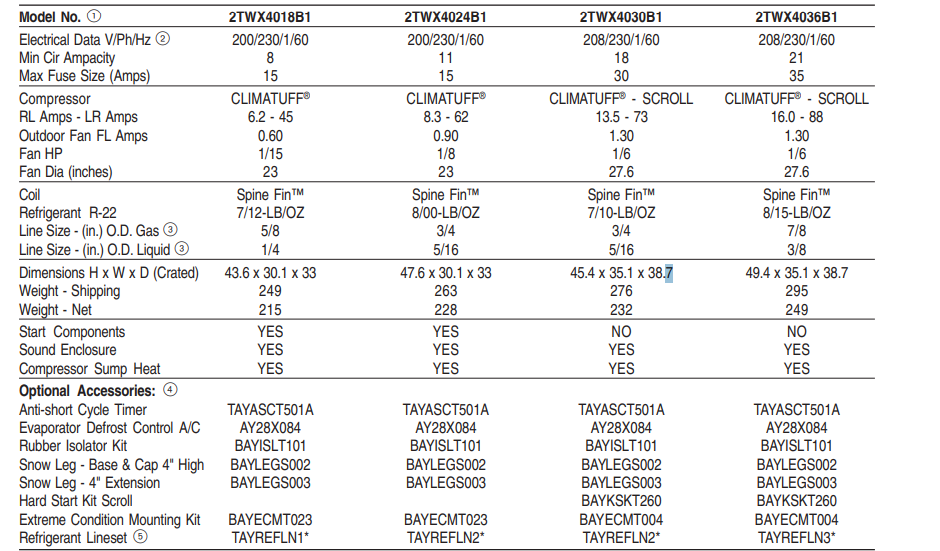

General Data

Product Specifications

- Certified in accordance with the Air-Source Unitary Heat Pump Equipment certification program which is based on ARI Standard 210/240.

- Calculated in accordance with N.E.C. Only use HACR circuit breakers or fuses.

- Standard line lengths – 60′. Standard lift – 60′ Suction and Liquid line. For Greater lengths and lifts refer to refrigerant piping software Pub# 32-3312-0†. (†denotes latest revision)

- For accessory description and usage, see page 5.

- = 15, 20, 25, 30, 40 and 50 foot lineset available.

A-weighted Sound Power Level [dB(A)]

Accessory Description and Usage

Anti-Short Cycle Timer Solid state timing device that prevents compressor recycling until 5 minutes have elapsed after satisfying call or power interruptions. Use in area with questionable power delivery, commercial applications, long lineset, etc.

- Evaporator Defrost Control SPST Temperature actuated switch that cycles the condenser off as indoor coil reaches freeze-up conditions. Used for low ambient cooling to 30°F with TXV.

- Rubber Isolators 5 large rubber donuts to isolate condensing unit from transmitting energy into mounting frame or pad. Use on any application where sound transmission needs to be minimized.

- Hard Start kit Start capacitor and relay to assist compressor motor startup. Use in areas with marginal power supply, on long linesets, low ambient conditions, etc.

- Extreme Condition Mount Kit Bracket kits to securely mount condensing unit to a frame or pad without removing any panels. Use in areas with high winds, or on commercial roof tops, etc.

ARI Standard Capacity Rating Conditions

ARI STANDARD 210/240 RATING CONDITIONS

- Cooling 80°F DB, 67°F WB air entering indoor coil, 95°F DB air entering outdoor coil.

- High Temperature Heating 47°F DB, 43°F WB air entering outdoor coil, 70°F DB air entering indoor coil.

- Low Temperature Heating 17°F DB, 15°F WB air entering outdoor coil, 70°F DB air entering indoor coil.

- Rated indoor airflow for heating is the same as for cooling.

ARI STANDARD 270 RATING CONDITIONS

(Noise rating numbers are determined with the unit in cooling operation.) Standard Noise Rating number is at 95°F outdoor air.

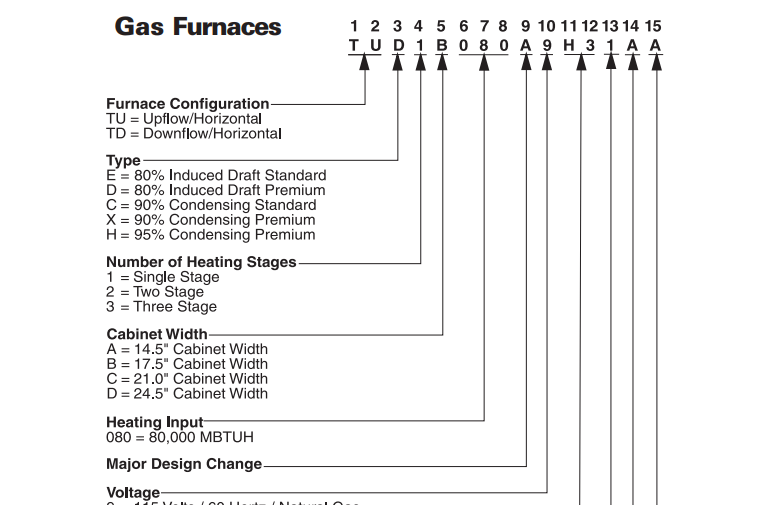

Model Nomenclature

Outdoor Units

Gas Furnaces

Heat Pump/ Cooling Coils

Air Handlers Residential

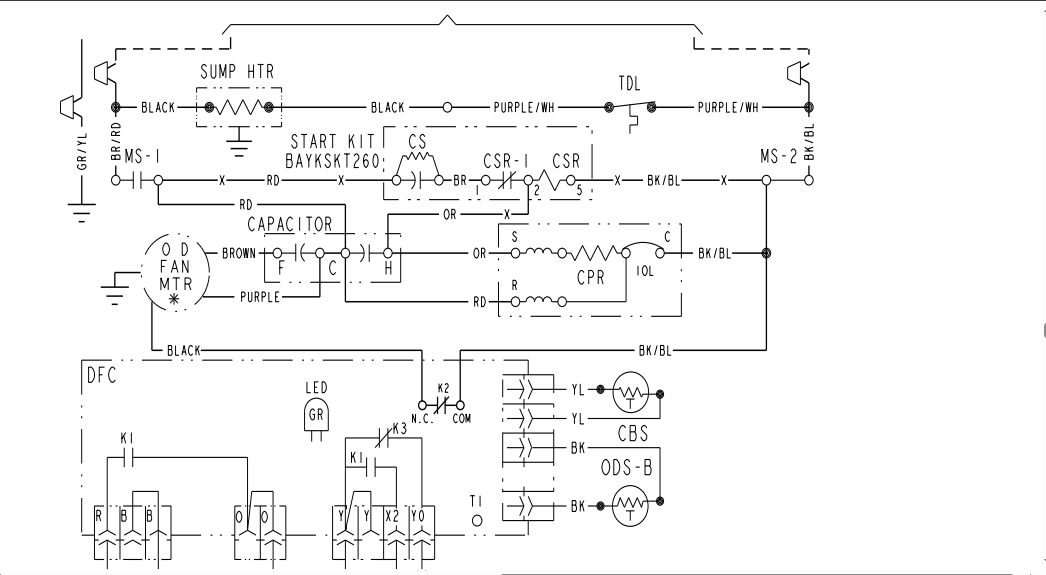

Electrical Data

2TWX4018,024B

2TWX4030,036,42B

2TWX4048B

2TWX4060B

LEGEND

SYMBOLS

Dimensions

2TWX4 Outline Drawing

Mechanical Specification Options

General

The 2TWX4 shall be fully charged from the factory for matched indoor section and up to 15 feet of piping. This unit must be designed to operate at outdoor ambient temperatures as high as 115°F. Cooling capacities shall be matched with a wide selection of air handlers and furnace coils that are ARI certified. The unit is certified to UL 1995. Exterior must be designed for outdoor application.

Casing

Unit casing is constructed of heavy gauge, galvanized steel and painted with a weather-resistant powder paint. Corrosion and weatherproof CMBP-G30 DuraTuff™ base.

Refrigerant Controls

Refrigeration system controls include the condenser fan and compressor contactor. High and low pressure controls are inherent to the compressor. Another standard feature is the liquid line dryer

Compressor

The Climatuff compressor features internal over temperature and pressure protector, total dipped hermetic motor and thermostatically controlled sump heater. Other features include: roto lock suction and discharge refrigeration connections, centrifugal oil pump, and low vibration and noise.

Condenser Coil

The Spine Fin™ coil shall be continuously wrapped, corrosion resistant all aluminum with minimum brazed joints. This coil is 3/8 inch O.D. seamless aluminum glued to a continuous aluminum fin. Coils are lab tested to withstand 2,000 pounds of pressure per square inch. The outdoor coil provides low airflow resistance and efficient heat transfer. The coil is protected on all four sides by louvered panels.

Low Ambient Cooling

As manufactured, this unit has a cooling capability to 55°F. The addition of an evaporator defrost control permits operation to 40°F. The addition of an evaporator defrost control with TXV permits low ambient cooling to 30°F.

Accessories

- Thermostats Heating/Cooling (manual and automatic changeover). Sub-base to match thermostat and locking thermostat cover.

- Evaporator Defrost Control See Low Ambient Cooling.

- Outdoor Thermostat Supplemental heat outdoor ambient lockout from 46 to –10°F.

For more manuals by Trane, visit ManualsLibraryy

Trane XL14i Heat Pump-FAQs

How do I know if my heat pump is working properly?

Check for:

Consistent heating/cooling

No unusual noises (grinding, rattling)

Proper defrost cycle in winter

No ice buildup on the outdoor unit

Why does my heat pump run constantly?

Possible causes:

Dirty air filter (restricts airflow)

Low refrigerant (reduces efficiency)

Thermostat issues (incorrect settings)

Extreme cold weather (requires longer cycles)

How do I maintain my Trane heat pump?

Clean/replace air filters monthly

Clear debris around the outdoor unit

Check refrigerant levels (professional service)

Schedule annual maintenance (spring & fall)

Are heat pumps noisy?

No—modern Trane heat pumps operate quietly (similar to a refrigerator). Noise issues usually indicate a problem.

How often should a heat pump cycle on/off?

Normal operation:

2–3 cycles per hour

10–20 minutes per cycle

If it’s short-cycling (under 5 minutes), call a technician.

When should I use emergency heat mode?

Only in extreme cold (below 0°F) or if the heat pump fails. Emergency heat uses more energy and should not run long-term.

How do I check heat pump pressure?

Use a manifold gauge:

Red (high side) – measures discharge pressure

Blue (low side) – measures suction pressure

⚠️ Only HVAC professionals should adjust refrigerant levels.

What is a good SEER rating for a heat pump?

14–16 SEER (standard efficiency)

18+ SEER (high efficiency, better savings)

How often should I service my Trane heat pump?

Twice a year:

Spring (before cooling season)

Fall (before heating season)

What’s the difference between SEER and HSPF?

SEER = Cooling efficiency (higher is better)

HSPF = Heating efficiency (higher is better)