Warnock Hersey 25-PAF wood and Pellet Stove

IMPORTANT INFORMATION

- Check local installation codes for your area.

- Read and comply with the instructions in this manual.

- This unit should be tested (dry run) before loading pellets.

- Your stove is designed to burn Premium Hardwood Pellets. Pellets with a high ash content will burn dirty and the unit will need cleaning more frequently.

- Be sure your pellets are not damp or wet. Keep sawdust out of the unit.

- Use 3” PELLET VENT PIPE with this stove and follow the manufacturer’s specifications for installation and clearances. Even though this pipe interlocks it is a good idea to seal all connections with high-temperature silicone.

- An outside combustion air connection is mandatory for this unit to work properly. Make this connection using a 1 7/8” I.D. metal pipe (steel, aluminum or copper) and coupler. Be sure to secure the pipe to the unit with aluminum tape or a clamp. Our part number PU-OAK (Outside Air Kit) can be used. The outside end should be covered (screened) to prevent any foreign matter from getting into the system.

- Regularly inspect the ash build-up in the burn pot and, if any crust forms remove it from the burn pot with a poker.

- The ash in the burn pot should be removed regularly, depending on your burn rate. The area to the right and left of the burn pot is for ash storage; keep the air holes in the burn pot clean for a more efficient burn. You should also frequently check the exhaust system.

- Keep pellets and all other combustible materials a safe distance from the stove.

- This unit will require floor protection if it is installed on a combustible surface. The minimum floor protector for this stove is 36” x 36” which should give you at least one inch (1”) of protection at the rear, four inches (4”) on each side, and six inches (6”) minimum in the front of the unit.

- Horizontal runs should not exceed four feet (4’) with a maximum vertical flue height of thirty-five feet (35’). At a height of fifteen feet (15’), the pipe should be increased to 4” PELLET VENT PIPE.

- This unit should be turned off and allowed to cool prior to cleaning. Any ashes should be kept in an airtight metal container completely away from all combustibles and should not be disposed of until they are completely cooled.

- Read the instructions thoroughly concerning the various settings that are available with the digital read-out control board.

Visit our website at www.englandsstoveworks.com for helpful information, frequently asked questions, parts & accessory orders, and more.

Do not allow paint, chemicals, or construction dust on or near your unit. Do not allow liquid or ANY foreign materials on or inside your unit. Shut your unit down and cover it when painting, construction, or similar activity is taking place. Wipe and clean your unit after any construction is done in your home, or if any foreign material gets on or inside your unit. You may also need to remove the rear and side cover plate from your unit (unplug the unit first) and vacuum and clean the motors and inside of your unit.

Some dealers will prepare your unit for operation and even “dry run” it before delivery. If this has not been done, you can follow the steps as listed below.

- Attach the spring handle to the door by turning it counterclockwise. Install the hopper lid latches as illustrated by the drawing at the rear of this manual. Important: Latches must be tight so that the top is sealed to prevent back-burn. Check to ensure the baffle is in place in the firebox.

- Test your 110-volt outlet for current and then plug in the unit. (We highly recommend a surge protector for our pellet stoves).

- It is important to note that this stove is equipped with a dual auger system. The top auger runs intermittently and drops pellets to the bottom auger; the bottom auger runs constantly and simply pushes the pellets forward to the burn pot. The control board setting determines the top auger feed rate.

- The stove has a digital read-out control board and is started by pressing the “ON” touchpad. This will immediately start the upper auger, bottom auger, and exhaust blower. Pressing the arrows under “Heat Range” to a higher setting will make the top auger operate for a longer time; pressing these arrows to a lower setting will make the top auger operate for a shorter time. You may observe the top auger by opening the hopper lid, and the bottom auger by opening the door to the firebox and looking in the burn pot. The room air blower will start later as the stove reaches the pre-set blower temperature (see “Control Board” section for further explanation).

FLUE SYSTEM

Caution: Follow the pipe manufacturer’s installation instructions and directions for passing through combustible walls and ceilings. Check local codes in your area.

This unit is equipped with a negative draft system that pulls air through the burn pot and pushes the exhaust out of the dwelling. If this unit is connected to a flue system other than the way explained in this manual, it will not function properly. The manufacturer will not be held responsible for damage caused by the malfunction of a stove due to improper installation.

Pellet Vent Pipe

The UL-approved pellet vent pipe is a twist lock system; however, it is still recommended that high-temperature silicone be used at each joint. Do not use a “B” vent gas pipe or galvanized pipe with this unit. The pellet pipe is designed to disassemble for cleaning and should be checked several times during the burning season. A pellet vent pipe is not furnished with the unit and must be purchased separately. (Contact us at 800-516-3636 for information on our AC-3000 Through-the-wall kit.) Do not install a flue damper of any kind in this system and do not connect this unit to a flue system serving another heating

appliance.

Through the Wall

To vent the unit through a wall, connect the pipe adapter to the exhaust motor adapter. If the exhaust adapter is at least eighteen inches (18”) above ground level, a straight section of pellet vent pipe can be used through the wall. Your dealer or our factory should be able to provide you with a kit that will handle most of this installation, which will include a wall thimble that will allow the proper clearance through a combustible wall. Once outside the structure, a three-inch (3”) clearance should be maintained to the outside wall and a clean-out tee should be placed on the pipe that extends through the wall. We recommend a minimum of three feet (3’) of vertical pipe with a 90-degree turn away from the house. At this point a one-foot (1’) section should be added with a horizontal cap which would complete the installation.

A wall strap should be placed just below the last 90-degree section to make the system more stable. If you live in an area that has heavy snowfall it is recommended the installation be taller than three feet (3’) to get above the snow drift line. This same installation can be used if your stove is below ground level by simply adding the clean-out section and vertical pipe inside until ground level is reached. With this installation you have to be aware of the snowdrift line, dead grass and leaves. We recommend a three foot (3’) minimum vertical rise on the inside or outside of the house.

The through-the-wall installation is the least expensive and simplest installation. Never terminate the end vent under a deck, in an alcove, under a window or between two windows. Call (800) 516-3636 to inquire about the AC-3000 Pellet Vent Kit.

Through the Ceiling

When venting the stove through a ceiling, the pipe is connected the same as through the wall, except the clean-out tee is always on the inside of the house. You must use the proper ceiling support flanges and roof flashing that are supplied by the pipe manufacturer – follow the pipe manufacturer’s directions and the illustration in this manual. It is important to note that, if your vertical runs of pipe are more than fifteen feet (15’), at this point the pellet vent pipe size should be increased to four inches (4”) in diameter. Do not exceed four feet (4’) of pipe on a horizontal run; do attempt to use the least number of elbows for your flue system. If an offset is used, it is better to install a 45-degree elbow whenever possible.

Existing Flue System

If you are replacing a wood stove with a pellet unit, the chimney or pipe should be cleaned thoroughly before proceeding with the installation. The flue system should be either masonry or a UL-approved pre-manufactured Class A flue system. The flue thimble or pipe will be either six inches (6”) or eight inches (8”), and the proper reducer (3” to 6” or 3” to 8”) can be purchased or ordered by your local dealer. Connect a three-inch (3”) tee with clean-out to the pipe adapter — seal this with a high-temperature stove cement, then extend the pipe to the installed reducer at your thimble. If the thimble is in the ceiling the pipe will go straight up, but if the thimble is in the wall another 90-degree elbow will be required to make the connection.

Outside Air

Outside air is mandatory for this unit to operate properly. This unit has been designed and tested with this connection because so many homes are airtight and there is not adequate combustion air available from inside the home. The air intake pipe is located at the rear of the burn pot and measures one and one-half inches (1 ½”) in diameter. This connection can be made with 1 7/8” metal pipe and coupler, and should exit through the wall (see “Important Information” section). Our part number PU-OAK (Outside Air Kit) can be used. Be sure to secure the pipe to the unit with aluminum tape or a clamp. The outside end of the pipe should be covered (screened) to prevent foreign matter from entering the system. If your unit is located below ground level, you will need to run the pipe up and then outside the dwelling. If your run of outside air pipe is more than 6’ (six feet), you must increase to 3” diameter pipe.

FLOOR AND WALL PROTECTION

Floor Protection

If your floor is constructed of non-combustible material such as brick or concrete there is no need for floor protection. If your floor is constructed of combustible material such as hardwood, linoleum or carpet, then you will be required to use floor protection between the unit and the combustible. The protection that is chosen should be UL equal and should be large enough to provide at least one inch (1”) behind and four inches (4”) on both sides of the stove. The clearance at the door of the stove should be at least six inches (6”). This add-on furnace pellet unit will need a 36” x 36” floor protector.

Wall Protection

From the rear and sides of this stove, only six inches (6”) of clearance is required to paneling, wallpaper or sheet rock. The pellet vent pipe would require the standard three-inch (3”) clearance as recommended by the manufacturer. Normally additional wall protection is not required with this type of unit.

OPERATING INSTRUCTIONS

CAUTION: Do not operate with the door open; open the door only when lighting.

This stove has an induced draft system and is designed to operate continuously, as the frequent shutdown is not required. The digital control board allows the stove to operate by a time relay-delay system; this system controls the top auger feed rate by operating for a predetermined number of seconds, while the bottom auger operates constantly. The setting of the heat range touchpad will control the heat output and the number of pellets the unit will burn.

Note: This stove uses solid fuel and will not restart automatically.

Horizontal Feed System

This unit has a top and bottom auger separated by four inches (4”), and a 1 RPM motor drives each auger. The top auger drops pellets to the bottom auger tube, and the bottom auger pushes the pellets forward to the burn pot. This assures there is no build-up of fuel in the bottom auger tube. As pellets enter the burn pot the combustion air is drawn across the fuel.

START-UP PROCEDURE

- Verify the hopper is clean & free of foreign matter, and that there is current at your outlet.

- Load the hopper with two bags of pellets (80 lbs. total).

- Close the hopper lid and secure the latches.

- Place a handful of pellets in the burn pot, spread a small amount of firestarter over the top, and ignite the pellets. Wait a few minutes before closing the door and pressing the “ON” touchpad — if the door is closed before the pellets are burning thoroughly, the exhaust blower could put out the fire.

- Recommended fire starter materials: Wax-impregnated wood chips, cardboard cubes, or liquid fire starter designed for pellet stoves. Never use kerosene, gasoline, diesel fuel or any other flammable liquid to start a fire.

- Check to be sure the flame is sustaining itself and is increasing as it involves the fuel bed. If the flame does happen to go out, repeat the above sequence.

- First Fire: Adjust the heat range to a “5” setting and allow the stove to operate in this manner for approximately three (3) hours or more if needed. This will allow the stove to “cure out” as the paint and oils from the manufacturing process burning off. We recommend that you open doors and windows in your dwelling during this process. Subsequent Cold Starts: We recommend that you operate the unit on a “5” setting until the convection (room air) blower begins to operate.

SHUT DOWN PROCEDURE

WARNING: NEVER SHUT DOWN THIS UNIT BY UNPLUGGING IT FROM THE POWER SOURCE. Refer to the following instructions.

Press the “OFF” touchpad to put the stove in the shutdown mode. At this time the red light above the pad will illuminate. The instant this is done, the top auger will stop feeding pellets to the bottom auger, but the room air blower, exhaust blower, and the bottom auger will continue to operate. When the internal temperature of the unit drops to 95 degrees the room air blower will stop operating; the exhaust blower and the bottom auger will cease to operate when the temperature drops to 90 degrees. The red light will now shut off and the unit will be completely down. Keep in mind that the hotter the unit is operating, the longer it will take for the stove to complete the shutdown cycle.

Note: If the room temperature stays above 70 degrees, the unit will remain in the shutdown mode for 54 minutes, regardless of the temperature at the heat sensor. If the stove stays on this long and you are sure the fire is out, the cord can be unplugged from the outlet. After approximately 10 seconds the unit can be connected to the power source and the board will be reset.

DAILY OPERATION

Refueling the Unit

Always press the “OFF” pad before refueling. This unit has a 80-pound hopper and should be filled when the hopper level drops to three or four inches (3” or 4”).

Note: The hopper will be warm; therefore, you should always use some type of hand protection. Never place your hand near the auger while the stove is in operation.

Note: Be sure to close the hopper securely before re-firing.

Power Outage

Important: This stove is equipped with a vacuum safety switch. If the power to your stove is interrupted for more than three minutes, but less than 18 minutes, the unit will shut down and an error code will show in the “Heat Range” window of the Control Board. At this point, you may press the “On” button and the unit will automatically resume operation; however, if the power is off for more than 18 minutes, the unit will have to be re-started completely (see “Start-Up Procedure).

NOTE: The unit will also shut down in the event of Combustion Blower failure; if this is the case, the unit will not re-start and you must contact Customer Service at (800) 245-6489. It is very important for the unit to be vented properly (outside air), as the natural draft is needed to clear the smoke from the stove.

Also, do not open the hopper lid. This may cause fire to burn in the hopper. If the power is off for more than 18 minutes, use a poker or a scooper to place burning pellets in the sides of the firebox and remove them from the burn pot. When power is restored, press the “ON” button and let the unit run for approximately 5 minutes, then press the “OFF” button – this will remove any pellets from the upper and lower auger systems. After the unit has cooled, use a vacuum to remove all remaining pellets from the firebox and burn pot area; you may then restart your unit.

Fire Outage

If the fire in the burn pot goes out, the stove will automatically go into the shutdown mode.

Fuel Outage

If the unit should run out of pellets or the pellets happen to bridge in the hopper, the temperature of the heat chamber will fall below 90 degrees and the stove will go into the shutdown mode.

ASH REMOVAL AND DISPOSAL

Daily Ash Maintenance

If there is fuel in the hopper, press the “OFF” pad and allow the unit to burn for approximately five (5) minutes in the shutdown mode prior to opening the front door. Use a long-handled screwdriver or a long-handled putty knife to scrape off any build-up or crust in the burn pot area. This can be pushed to the left or right into the ash storage area until the weekly ash removal.

Weekly Ash Removal

Shut the unit down by pressing the “OFF” pad and allowing the unit to go through the complete shutdown cycle. Allow the unit to completely cool down and then remove the ashes by pushing them into the ash pan and dumping them. {NOTE: The 3” x 9” Ash Dump Door (the flat, rectangular piece of steel with a handle that is located directly above the ash pan) must be pulled out so the ashes from the burn pot area can be dropped into the ash pan. Remember to replace it after dumping the ash pan and before restarting the stove.} The ashes should be placed in a non-combustible container with an airtight lid and should always be placed on a non-combustible surface or on the ground until completely cooled and free of hot cinders.

Once the ash is removed, the burn pot should be given a thorough inspection. Remove the burn pot wear plate and check for any build-up in the front of the burn area. Clean out all air holes (if necessary a 1/8” drill can be used) — these air holes should be kept clean, as they supply combustion air under and around the pellet fuel.

Monthly Ash Removal

The large baffle plate (13” x 13”) that hangs behind the fire should be removed monthly. This can be done by lifting up the plate and pulling it out. The area behind this plate should be cleaned thoroughly and then the plate placed back in its original position. The burn pot assembly should also be thoroughly cleaned, and the wear plate should be removed and cleaned. Before replacing the worn plate, clean the burn box thoroughly.

Annual Cleaning

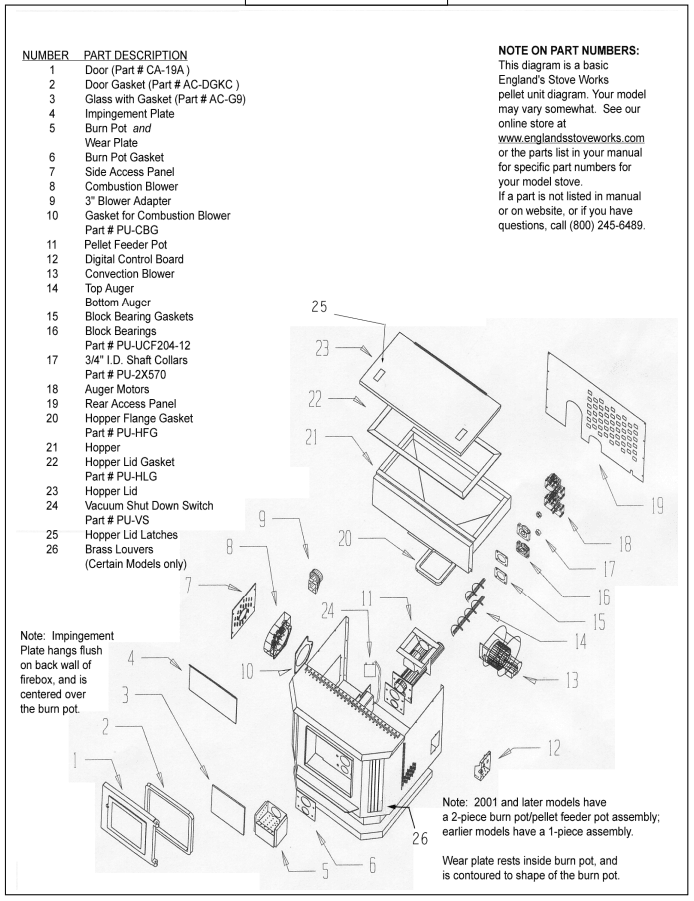

The stove and the flue system should be given a complete cleaning at the end of the heating season. Remove the burn pot assembly, clean it thoroughly, and re-install it (refer to Exploded View); this will require a new gasket for the burn pot. Be sure to tighten the set screws when you replace them, but do not over-tighten. In addition to the cleaning mentioned earlier, the exhaust blower should be removed annually and the blower tube vacuumed of any ash build-up. When cleaning or replacing the blower a new gasket (Part # PU-CBG) should be added between the blower flange and the steel exhaust tube.

Soot and Fly ash: Formation and Need for Removal – The products of combustion will contain small particles of fly ash. The fly ash will collect in the exhaust venting system and restrict the flow of flue gases. Incomplete combustion, such as occurs during startup, shutdown, or incorrect operation of the room heater will lead to some soot formation which will collect in the exhaust venting system. The exhaust venting system should be inspected at least once every year to determine if cleaning is necessary.

THE FUNCTION OF THE ADD-ON FURNACE

The Add-On Furnace is designed to be a supplemental hot air heating system that will connect to your existing heating system. The furnace will operate independently of your existing system while using the same hot air ducts that your present furnace uses. The furnace comes standard with an 850 CFM blower that pushes hot air up both sides and across the top of the unit through an inner duct chamber built around the firebox. The heated air exits the unit through a six-inch outlet located on the top, near the front of the furnace. The six-inch pipe connected at this exit will route the heated air into your duct system.

HOT AIR HOOK-UP

You first need to position your unit as close to the flue connector as possible and install your flue pipe. Once this is done, you may hook your hot air outlet into your ductwork. Located on the top, near the front of the unit is a six-inch opening for the mounting of the flue collar. When mounting this part be absolutely sure it is fastened securely to the opening, as this will be the hot air exit. Thirty gauges or thicker pipe should run from the top of the furnace to the hot air trunk line of your existing hot air system. Using the least possible amount of pipe will help the heat transfer to your duct system. Cut a six-inch diameter hole in the main trunk line of the furnace duct, which is usually located on the top of the central furnace. Slide the six-inch pipe from the wood furnace into the hole and seal the connection with duct tape.

Thirty gauge or thicker black pipe should be used for the first two feet and then thirty gauges or thicker galvanized pipe can be used to connect to the existing furnace duct. Sheet metal screws should be used to secure each joint of pipe and an aluminum heat-resistant tape can be wrapped around each joint to give an airtight seal.

NOTE: This versatile, all-purpose heater can also be used, for example, in a garage or shop environment without ductwork – simply attach a 6” elbow directly to the hot air outlet of the furnace, and point the elbow in the direction you wish to direct the air flow.

Installation Notes

NOTE:

- If 3” flue pipe exceeds 15’ in length, increase to 4” flue pipe for remaining flue connections.

- Total flue length should not exceed 35’.

- Horizontal run not to exceed 4’.

- Floor protector required: Min. size 36” x 36”.

- Outside Air is Mandatory.

Recommended Heat Ranges:

- Low Burn: Heat Range setting: 1 …………..Room Air Blower setting: 1

- Medium Low: Heat Range setting: 2 – 3……….. Room Air Blower setting: *

- Medium High: Heat Range setting: 5 – 8…….. Room Air Blower setting: *

- High Burn: Heat Range setting: 9………… Room Air Blower setting: 9

* NOTE: Blower Speed should match Heat Range.

NOTE: The bottom 3 buttons are pre-set at the factory and do not need adjustment. Call Service at (800) 245-6489 if you have questions or problems.

THE CONTROL BOARD

The control board (PART #PU-CB98) is a digital read-out board. This board offers a wide variety of settings to operate the unit. Again, the bottom controls are preset at the factory and should not require any alteration on start-up of the unit (see “Unit Preparation” section for information on setting the Heat Range). This part can be removed from the unit by loosening the two screws on the outside of the stove, and then pulling it back to the inside of the stove. The rear access panel should be removed prior to removing the control board.

THERMOSTATS

REMOTE: There is now a Remote Thermostat (Part # AC-3001) available for your pellet stove. It comes with everything necessary for quick installation and has many features to allow remote control of your unit.

WALL: Also, an external wall thermostat (such as our Part # PU-DTSTAT) can be used on our pellet units as long as it is a 24-volt that works with millivolt systems. After unplugging the unit, locate the jumper wire (J-18) on the bottom of the control panel. The two screws should then be loosened and the jumper wire removed from the board. Next, the two thermostat lead wires should be slipped into these openings and the screws tightened; the jumper wire should be saved for future operation without a thermostat. The unit will operate differently once the wall thermostat is connected — we recommend the stove control board be set at a minimum of “5” on the Heat Range while using the thermostat. This will allow the stove to run around a medium setting and drop back to a lower setting when the thermostat is not calling for heat. Refer to the section on “Start-up Procedure” for information on cold starts.

Call (800) 516-3636 or log onto www.englandsstoveworks.com to inquire or order these.

Important: Hopper Lid Latches must be checked periodically and kept tight so the top is sealed to prevent back-burn.

LIMITED 5 YEAR WARRANTY FROM THE DATE OF PURCHASE TO THE ORIGINAL OWNER

The manufacturer extends the following warranties:

Five-Year Period:

- Carbon steel and welded seams in the firebox are covered for 5 years against splitting.

- The cast iron door and hinges are covered for 5 years against cracking.

One Year Period: - Component parts such as the hopper, auger burn pot, baffle plate, auger shafts, auger bearings, and fasteners are covered for 1 year against cracking, breakage and welded seams from separating.

- Electrical components, accessory items, glass and the painted surface are covered for 1 year from the date of purchase.

Procedure:

Purchaser must give notice of claim of defect within the warranty period and pay transportation to and from a service center designated by the factory. The dealer from which the unit was purchased or the factory, at our option, will perform the warranty service.

Other Rights:

This warranty gives you specific legal rights, and you may also have other rights, which may vary from state to state.

NOTE: THIS WARRANTY IS NULL AND VOID IF YOU DO NOT RETURN THE ATTACHED WARRANTY REGISTRATION WITH A COPY OF THE SALES RECEIPT WITHIN 30 DAYS FROM THE DATE OF PURCHASE. WARRANTY IS NOT TRANSFERABLE

Pellet Stove Exploded View

For more manuals by Warnock Hersey, visit ManualsLibraryy

Warnock Hersey 25-PAF wood and Pellet Stove-FAQs

What should I consider when installing a pellet stove?

Frequent use can lead to a buildup of dangerous particles, and improper maintenance may cause vent system failures, reducing air quality. Regular cleaning and upkeep are essential.

How much space does a pellet stove require?

Most pellet stoves need at least 3 inches of clearance from side walls and 1 inch from the back wall. They should be placed on a non-combustible surface like stone or tile that is at least 3/8 inch thick.

How much clearance is needed for a pellet stove?

The stove should be installed with at least 10 feet of clearance above a paved sidewalk or driveway on public property. Additionally, the non-combustible surface should extend at least 6 inches beyond the stove’s front, back, and sides.

How does a pellet stove vent exhaust?

A pellet stove can be vented vertically through the roof or horizontally through a side wall. A small vertical rise before a horizontal vent is recommended for better airflow.

How much electricity does a pellet stove use?

Pellet stoves typically consume around 100 kilowatt-hours (kWh) per month, costing about $9 in electricity. If the stove lacks a backup power source, a power outage will cause it to stop working.

Can I leave a pellet stove running overnight?

Yes, pellet stoves can safely operate overnight. Some users prefer to turn them off, but running them at a lower setting can maintain warmth without compromising safety.

Can a pellet stove work without electricity?

No, pellet stoves require electricity to power fans, controls, and pellet feeders. Without electricity, they won’t function unless connected to a backup power supply.

What can cause a pellet stove to explode?

Using poor-quality or damp pellets can slow ignition, causing the burn pot to overload with unburned pellets. If these suddenly ignite, a small explosion may occur inside the stove.

Where is the best place to install a pellet stove?

A central location is ideal for even heat distribution. Pellet stoves are typically installed a few inches from a rear wall, but they can be positioned further if needed.