WEN AP6092 6-Gallon Air Compressor

INTRODUCTION

Thanks for purchasing the WEN Air Compressor. We know you are excited to put your tool to work, but first, please take a moment to read through the manual. Safe operation of this tool requires that you read and understand this operator’s manual and all the labels affixed to the tool. This manual provides information regarding potential safety concerns, as well as helpful assembly and operating instructions for your tool.

![]() Indicates danger, warning, or caution. The safety symbols and the explanations with them deserve your careful attention and understanding. Always follow the safety precautions to reduce the risk of fire, electric shock, or personal injury. However, please note that these instructions and warnings are not substitutes for proper accident prevention measures.

Indicates danger, warning, or caution. The safety symbols and the explanations with them deserve your careful attention and understanding. Always follow the safety precautions to reduce the risk of fire, electric shock, or personal injury. However, please note that these instructions and warnings are not substitutes for proper accident prevention measures.

NOTE: The following safety information is not meant to cover all possible conditions and situations that may occur. WEN reserves the right to change this product and specifications at any time without prior notice.

At WEN, we are continuously improving our products. If you find that your tool does not exactly match this manual, please visit wenproducts.com for the most up-to-date manual or contact our customer service at 1-847-429-9263. Keep this manual available to all users during the entire life of the tool and review it frequently to maximize safety for both yourself and others.

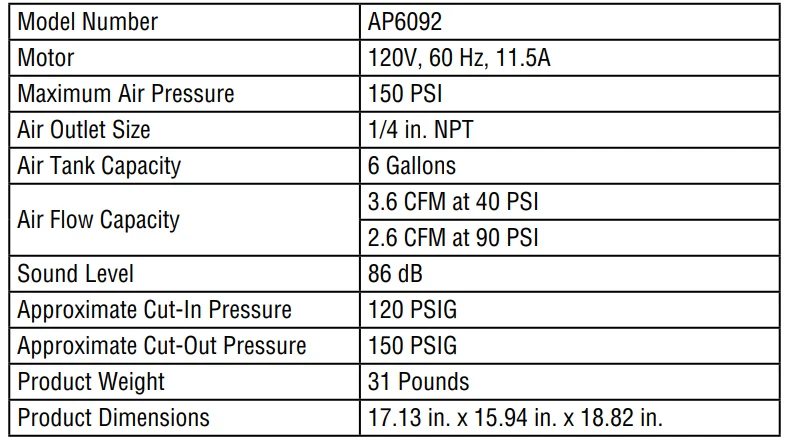

SPECIFICATIONS

GENERAL SAFETY RULES

WORK AREA SAFETY

- Keep the work area clean and well-lit. Cluttered or dark areas invite accidents.

- Do not operate power tools in explosive atmospheres, such as in the presence of flammable liquids, gases, or dust. Power tools create sparks, which may ignite the dust or fumes.

- Keep children and bystanders away while operating a power tool. Distractions can cause you to lose control.

ELECTRICAL SAFETY

- Power tool plugs must match the outlet. Never modify the plug in any way. Do not use any adapter plugs with earthed (grounded) power tools. Unmodified plugs and matching outlets will reduce the risk of electric shock.

- Avoid body contact with earthed or grounded surfaces such as pipes, radiators, ranges, and refrigerators. There is an increased risk of electric shock if your body is earthed or grounded.

- Do not expose power tools to rain or wet conditions. Water entering a power tool will increase the risk of electric shock.

- Do not abuse the cord. Never use the cord for carrying, pulling, or unplugging the power tool. Keep the cord away from heat, oil, sharp edges, or moving parts. Damaged or entangled cords increase the risk of electric shock.

- When operating a power tool outdoors, use an extension cord suitable for outdoor use. Use of a cord suitable for outdoor use reduces the risk of electric shock.

- If operating a power tool in a damp location is unavoidable, use a ground fault circuit interrupter (GFCI) protected supply. Use of a GFCI reduces the risk of electric shock.

PERSONAL SAFETY

- Stay alert, watch what you are doing, and use common sense when operating a power tool. Do not use a power tool while you are tired or under the influence of drugs, alcohol, or medication. A moment of inattention while operating power tools may result in serious personal injury.

- Use personal protective equipment. Always wear eye protection. Protective equipment, such as a respiratory mask, non-skid safety shoes, and hearing protection, used for appropriate conditions, will reduce the risk of personal injury.

- Prevent unintentional starting. Ensure the switch is in the off position before connecting to a power source and/or battery pack, picking up, or carrying the tool. Carrying power tools with your finger on the switch or energizing power tools that have the switch on invites accidents.

- Remove any adjusting key or wrench before turning the power tool on. A wrench or a key left attached to a rotating part of the power tool may result in personal injury.

- Do not overreach. Keep proper footing and balance at all times. This enables better control of the power tool in unexpected situations.

- Dress properly. Do not wear loose clothing or jewelry. Keep your hair and clothing away from moving parts. Loose clothes, jewelry, or long hair can be caught in moving parts.

- If devices are provided for the connection of dust extraction and collection facilities, ensure these are connected and properly used. The use of dust collection can reduce dust-related hazards.

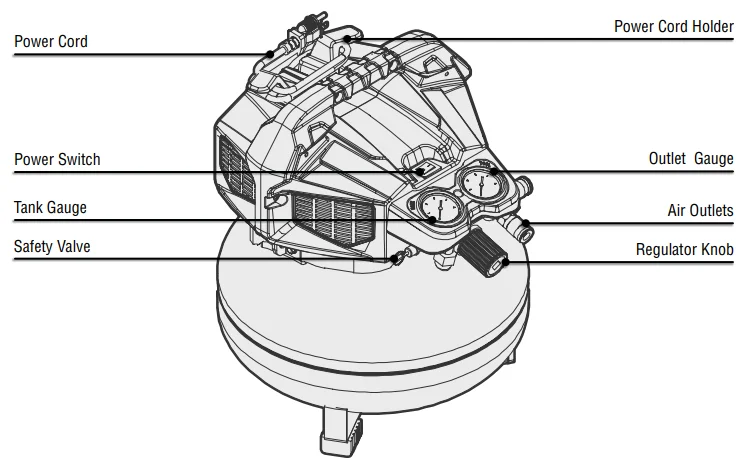

KNOW YOUR AIR COMPRESSOR

ASSEMBLY & ADJUSTMENTS

BREAKING IN THE AIR COMPRESSOR

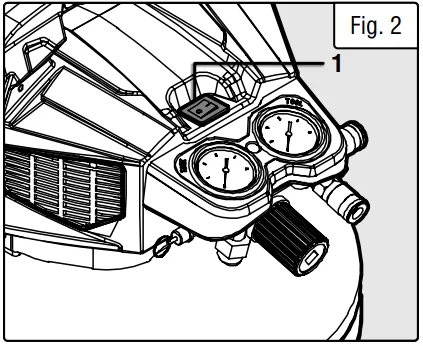

- Turn the power switch (Fig. 2 – 1) to the OFF position and unplug the power cord (Fig. 2 – 2).

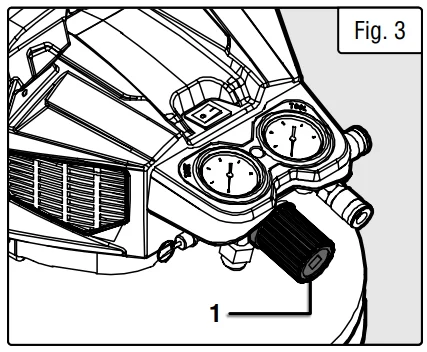

- Turn the regulator knob (Fig. 3 – 1) to the “+” position to fully open the pressure regulator valve.

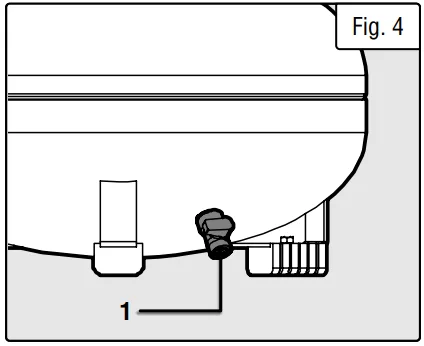

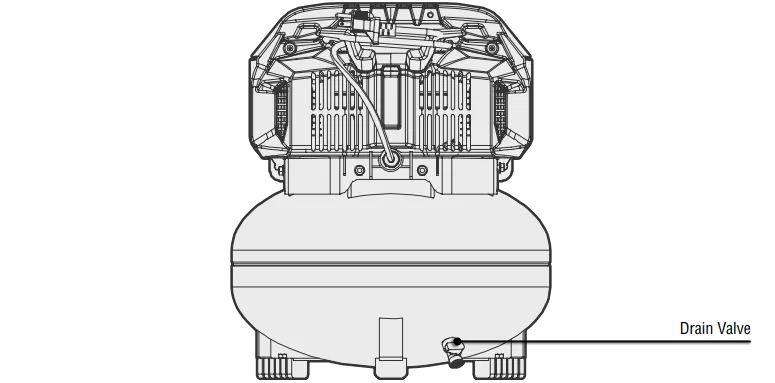

- Fully open the drain valve (Fig. 4 – 1).

- Plug in the power cord and turn the power switch to the ON position.

- Let the unit run for 15 minutes. Air will expel freely through the drain valve.

- Turn the power switch to the OFF position, unplug the power cord, and close the drain valve.

WORK AREA SETUP

- Designate a work area that is clean and well-lit. Make sure that the air compressor is out of the reach of children.

- Place the air compressor on a flat, level surface to prevent damage to the unit. Keep at least 12” of space around the unit to allow for air circulation.

- Route the power cord from the air compressor to a grounded wall outlet along a safe path without creating a tripping hazard or exposing the power cord to possible damage.

AIR CONNECTION SETUP

- Connect a 1/4” air hose with an industrial (T-Style) or automotive (M-Style) plug (both sold separately) to the air outlet. The air hose must be long enough to reach the work area with enough extra length to allow free movement while working.

- Consult your pneumatic tool’s user manual for needed accessories.

BEFORE EACH USE

Inspect the general condition of the air compressor before each use. Check for:

- Loose hardware

- Misalignment or binding of moving parts

- Cracked or broken parts

- Damaged electrical wiring

- Any other condition that may affect its safe operation

OPERATION

WARNING! Read the entire important safety information section at the beginning of this manual, including all text under subheadings therein, before setup or use of this product.

- To prevent serious injury and death from explosion, do not adjust the internal pressure switch.

- Any change to the automatic pressure levels may cause excess pressure to accumulate, causing a hazardous situation.

- Do not use damaged equipment. If abnormal noises or vibrations occur, have the problem corrected before further use.

OPERATING THE AIR COMPRESSOR

- Make sure that the power switch is turned to the OFF position before making any adjustments.

- Close the drain valve.

- Turn the regulator knob to the “-” position to close the pressure regulator valve.

- Plug the power cord into a grounded 120V AC electrical outlet.

- Turn the power switch to the ON position.

- Allow the air compressor to build up pressure until it cycles off. NOTE: When using the air compressor for the first time, check for air leaks by applying soapy water to connection points while the air compressor is pumping and after the pressure cut-out. Look for air bubbles. If air bubbles are present at connection points, tighten the connections. Do not use the air compressor unless all connections are air-tight. The extra air leaking out will cause the air compressor to operate too often, increasing wear on the air compressor. NOTE: As long as the power switch is ON, the operation of the air compressor is automatic, controlled by an internal pressure switch. The air compressor will turn ON automatically when the air pressure drops to 120 PSI and will turn OFF automatically when the air pressure reaches 150 PSI.

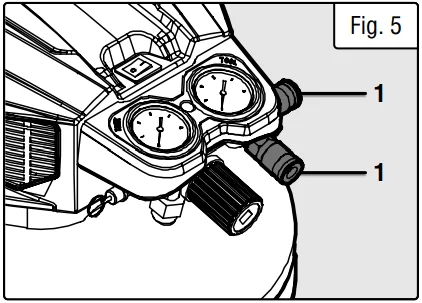

- Make sure the pneumatic tool’s throttle or switch is in the OFF position. Connect the air hose to the air outlet (Fig. 5 – 1) and connect the air tool to the air hose. NOTE: Two air outlets can be used simultaneously.

- Turn the regulator knob clockwise to increase the pressure and counter-clockwise to decrease the pressure. Adjust the pressure gradually while checking the outlet pressure gauge to set the pressure.

- Once the operation has completed, turn the power switch to the OFF position and unplug the air compressor.

- Bleed air from the pneumatic tool and then disconnect it from the air compressor.

- Clean and then store the air compressor indoors, in the upright position, and out of the reach of children.

EMERGENCY DEPRESSURIZATION

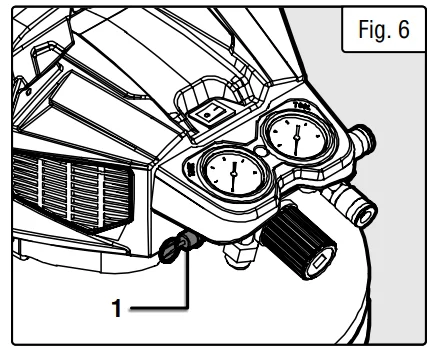

If it is necessary to quickly depressurize the air compressor, turn the power switch to the OFF position and pull on the ring on the safety valve (Fig. 6 – 1) to quickly release stored air pressure.

AUTOMATIC SHUT-OFF SYSTEM

- If the air compressor automatically shuts off before reaching its normal cutoff pressure:

- Shut OFF all tools.

- Turn the air compressor power switch to the OFF position.

- Unplug the air compressor.

- Wait until the air compressor cools down (about 10 minutes).

- Plug the air compressor back in.

- Turn the air compressor power switch to the ON position.

- Resume operation.

- Possible causes of repeated automatic shut-off of the air compressor are:

- Using an extension cord that is too long or narrow.

- An air leak or an open hose causes the air compressor to cycle too often and build up heat.

- Turning the air compressor ON and OFF too quickly.

- Correct any issues before further use to avoid damage to the air compressor.

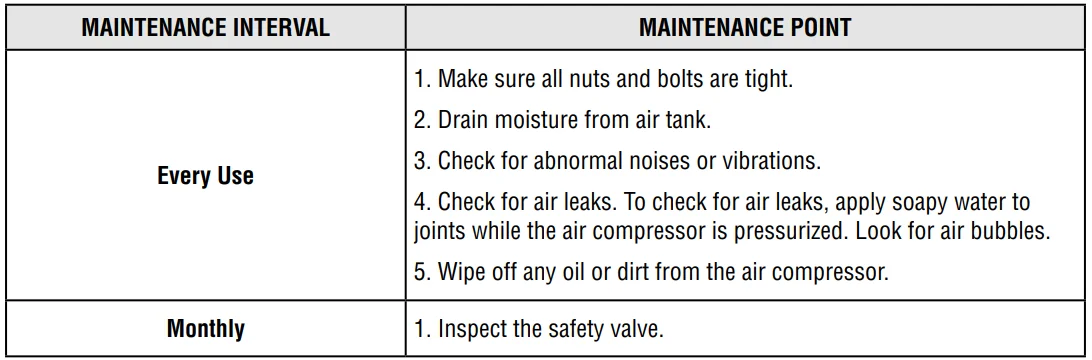

MAINTENANCE

WARNING! To avoid injury from accidental startups, be sure that the tool is switched OFF and disconnected from the power supply before inspecting the unit, making adjustments, changing accessories, or performing any maintenance.

AFTER EACH USE

Wipe all external surfaces of the air compressor with a clean cloth. Store the compressor indoors, in the upright position, and out of the reach of children.

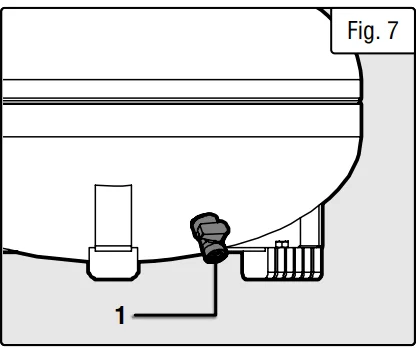

DRAINING MOISTURE FROM AIR TANK

The drain valve (Fig. 7 – 1) is located under the tank. It must be used every time to release all trapped air and moisture from the tank. Doing this will eliminate condensation and prevent tank corrosion.

- Turn the power switch to the OFF position.

- Unplug the air compressor.

- Tilt the compressor and turn the drain valve to open it.

- Once all pressure and moisture have been released, close the drain valve.

TESTING FOR LEAKS

Make sure all connections are tight and secure before testing for leaks. A small leak in any hoses or connectors will greatly reduce the abilities of the compressor. To locate a leak, simply spray a mixture of soap and water across the entire surface of both the tank and the hose, wherever the leak is believed to be. Bubbles will begin to appear if a leak is indeed present. Fix immediately. Try to avoid getting soapy water near any of the inlets on the tank or the pump.

STORAGE

Before storing the compressor, drain the tank by opening the tank drain valve on the underside of the compressor. This will drain the compressor to prevent moisture from collecting and rusting the inside of the tank. Pulling on the air release valve located next to the tank pressure gauge will quickly empty out the tank. Do not store in cold climates, as cold climates may create problems with the motor while possibly freezing water condensation.

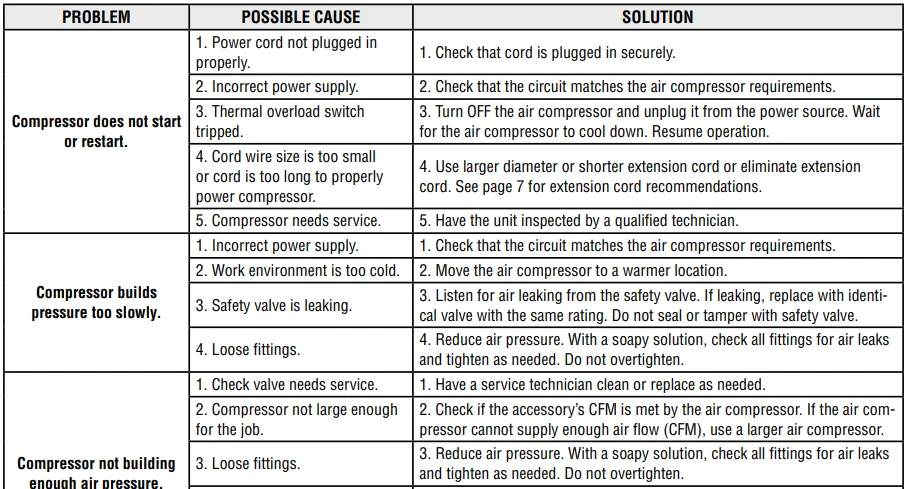

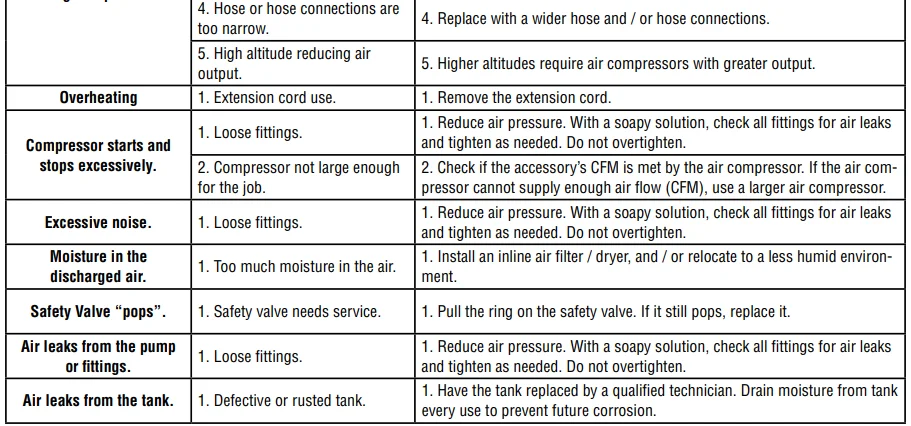

TROUBLESHOOTING GUIDE

WARNING! Stop using the air compressor immediately if any of the following problems occur, or risk serious personal injury. If you have any questions, please contact customer service at 1-847-429-9263 (M-F 8-5 CST) or email [email protected].

WARRANTY STATEMENT

WEN Products is committed to building tools that are dependable for years. Our warranties are consistent with this commitment and our dedication to quality.

LIMITED WARRANTY OF WEN PRODUCTS FOR HOME USE

GREAT LAKES TECHNOLOGIES, LLC (“Seller”) warrants to the original purchaser only that all WEN consumer power tools will be free from defects in material or workmanship during personal use for a period of two (2) years from the date of purchase or 500 hours of use, whichever comes first. Ninety days for all WEN products if the tool is used for professional or commercial use. The purchaser has 30 days from the date of purchase to report missing or damaged parts.

SELLER’S SOLE OBLIGATION AND YOUR EXCLUSIVE REMEDY under this Limited Warranty and, to the extent permitted by law, any warranty or condition implied by law, shall be the replacement of parts, without charge, which are defective in material or workmanship and which have not been subjected to misuse, alteration, careless handling, misrepair, abuse, neglect, normal wear and tear, improper maintenance, or other conditions adversely affecting the Product or the component of the Product, whether by accident or intentionally, by persons other than Seller.

To claim under this Limited Warranty, you must make sure to keep a copy of your proof of purchase that clearly defines the Date of Purchase (month and year) and the Place of Purchase. Place of Purchase must be a direct vendor of Great Lakes Technologies, LLC. Purchasing through third-party vendors, including but not limited to garage sales, pawn shops, resale shops, or any other secondhand merchant, voids the warranty included with this product.

Contact [email protected] or 1-847-429-9263 with the following information to make arrangements: your shipping address, phone number, serial number, required part numbers, and proof of purchase. Damaged or defective parts and products may need to be sent to WEN before the replacements can be shipped out.

Upon the confirmation of a WEN representative, your product may qualify for repairs and service work. When returning a product for warranty service, the shipping charges must be prepaid by the purchaser. The product must be shipped in its original container (or an equivalent), properly packed to withstand the hazards of shipment. The product must be fully insured, with a copy of the proof of purchase enclosed. There must also be a description of the problem in order to help our repair department diagnose and fix the issue. Repairs will be made, and the product will be returned and shipped back to the purchaser at no charge for addresses within the contiguous United States.

THIS LIMITED WARRANTY DOES NOT APPLY TO ITEMS THAT WEAR OUT FROM REGULAR USAGE OVER TIME, INCLUDING BELTS, BRUSHES, BLADES, BATTERIES, ETC. ANY IMPLIED WARRANTIES SHALL BE LIMITED IN DURATION TO TWO (2) YEARS FROM THE DATE OF PURCHASE. SOME STATES IN THE U.S. AND SOME CANADIAN PROVINCES DO NOT ALLOW LIMITATIONS ON HOW LONG AN IMPLIED WARRANTY LASTS, SO THE ABOVE LIMITATION MAY NOT APPLY TO YOU.

IN NO EVENT SHALL SELLER BE LIABLE FOR ANY INCIDENTAL OR CONSEQUENTIAL DAMAGES, INCLUDING BUT NOT LIMITED TO LIABILITY FOR LOSS OF PROFITS, ARISING FROM THE SALE OR USE OF THIS PRODUCT. SOME STATES IN THE U.S. AND SOME CANADIAN PROVINCES DO NOT ALLOW THE EXCLUSION OR LIMITATION OF INCIDENTAL OR CONSEQUENTIAL DAMAGES, SO THE ABOVE LIMITATION OR EXCLUSION MAY NOT APPLY TO YOU.

THIS LIMITED WARRANTY GIVES YOU SPECIFIC LEGAL RIGHTS, AND YOU MAY ALSO HAVE OTHER RIGHTS WHICH VARY FROM STATE TO STATE IN THE U.S., PROVINCE TO PROVINCE IN CANADA, AND FROM COUNTRY TO COUNTRY.

THIS LIMITED WARRANTY APPLIES ONLY TO ITEMS SOLD WITHIN THE UNITED STATES OF AMERICA, CANADA, AND THE COMMONWEALTH OF PUERTO RICO. FOR WARRANTY COVERAGE WITHIN OTHER COUNTRIES, CONTACT THE WEN CUSTOMER SUPPORT LINE. FOR WARRANTY PARTS OR PRODUCTS REPAIRED UNDER WARRANTY SHIPPING TO ADDRESSES OUTSIDE OF THE CONTIGUOUS UNITED STATES, ADDITIONAL SHIPPING CHARGES MAY APPLY. For replacement parts and the most up-to-date instruction manuals, visit wenproducts.com.

For More Manuals By WEN Products, Visit ManualsLibraryy.

WEN AP6092 6-Gallon Air Compressor- FAQs

How does the WEN AP6092 air compressor work?

The compressor pulls in air, compresses it inside the tank, and stores it under pressure. This stored air is then released to power air tools when needed.

What can a 6-gallon air compressor be used for?

A 6-gallon compressor like the WEN AP6092 is ideal for inflating tires, powering nail guns, staplers, airbrushes, and handling light DIY or household tasks.

Can a 6-gallon air compressor run an impact wrench?

It can run small, low-CFM impact wrenches for short bursts, but it may not be suitable for continuous or heavy automotive use.

What PSI does the WEN AP6092 air compressor provide?

Most light-duty air compressors operate around 90 to 150 PSI, which is sufficient for common home and workshop applications.

How do I know if my air compressor needs oil?

If your compressor is oil-lubricated, check the oil level through the sight glass or dipstick. Low oil levels, loud operation, or overheating are signs it may need oil.

Do I need to lubricate the WEN AP6092 air compressor?

If your model is oil-free, no lubrication is required. Always check the manufacturer’s manual to confirm whether oil is needed.

How often should I drain the air compressor tank?

You should drain the tank after each use or daily to remove moisture buildup, which helps prevent rust and internal damage.

What safety precautions should I follow when using an air compressor?

Always wear eye and ear protection, never point compressed air at people, and ensure hoses and fittings are rated for the compressor’s pressure.

What are three things you should never do with compressed air?

Never aim it at yourself or others, never use it to clean clothes or hair, and never exceed the recommended pressure limits.