White 2037 Sewing Machine

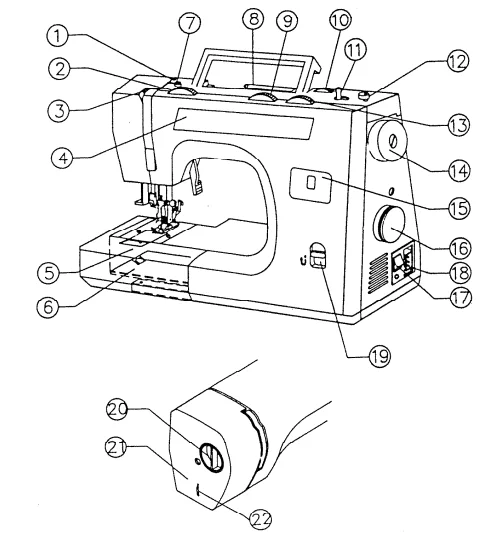

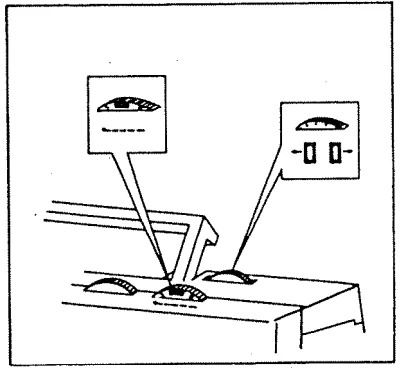

KNOW YOUR MACHINE

- Thread guide for upper thread

- Thread tension dial

- Thread take-up

- Stitch patterns

- Flat bed extension

- Feed the teeth lever

- Tension disk for bobbin winding

- Horizontal spool pin

- Stitch width dial

- Buttonhole density dial

- Bobbin winder spindle

- Bobbin winder stopper

- Stitch length dial

- Hand wheel

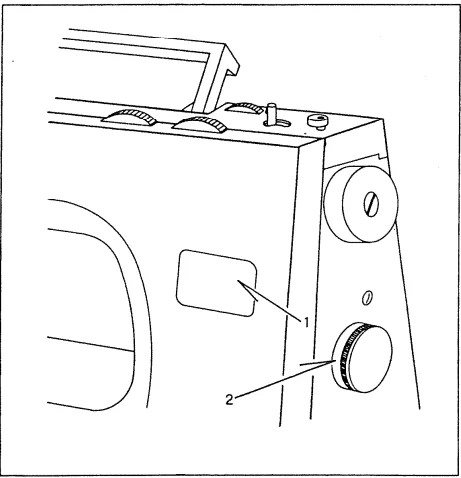

- Stitch selection window

- Stitch pattern selector dial

- On/off power and light switch

- Plug socket for power cord

- Reverse stitch lever

- Presser foot pressure dial

- Face cover plate

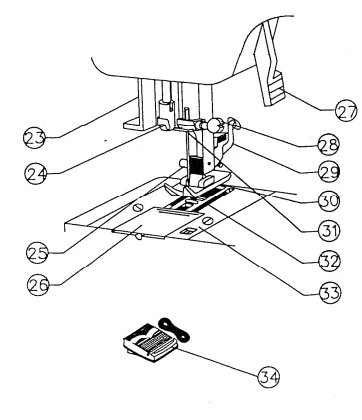

- Thread cutter

- Automatic needle threader

- Thread guide

- Presser foot screw

- Bobbin cover plate

- A lever to raise and lower the presser foot

- Needle clamp screw

- Lever to release the presser foot

- Presser foot

- Thread guide

- Feed teeth

- Needle plate

- Foot control.

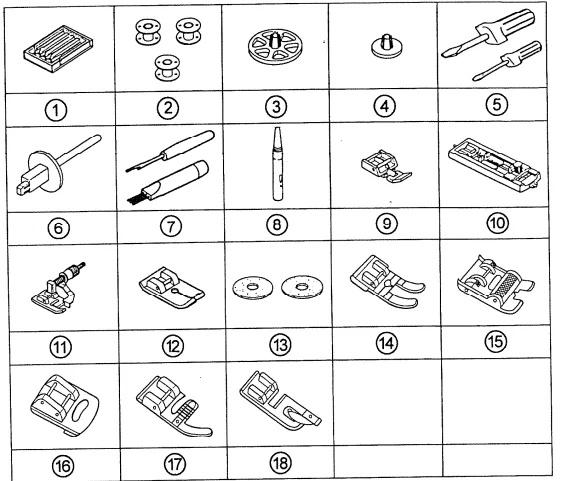

ACCESSORIES

- Needles

- Bobbins

- Spool pin cap for large thread spools

- Spool pin cap for small thread spools

- Screwdriver

- Spool pin

- Seam ripper/buttonhole cutter and brush

- Oil

- Zipper foot

- Buttonhole foot

- Blind hem foot

- Straight stitch foot

- Spool pin felt

- 1/4″ piecing foot

- Rolled hem foot

- Gathering foot

- Cording foot

- Ruler foot

Welcome to the wonderful world of sewing with your new White Sewing Machine. Be sure to watch the video and read through this instruction book for the basic information you’ll need to get started.

SETTING UP YOUR WHITE SEWING MACHINE

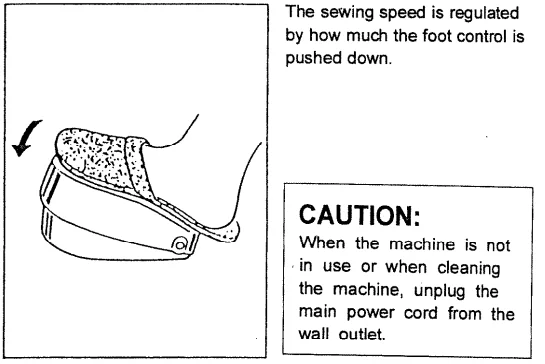

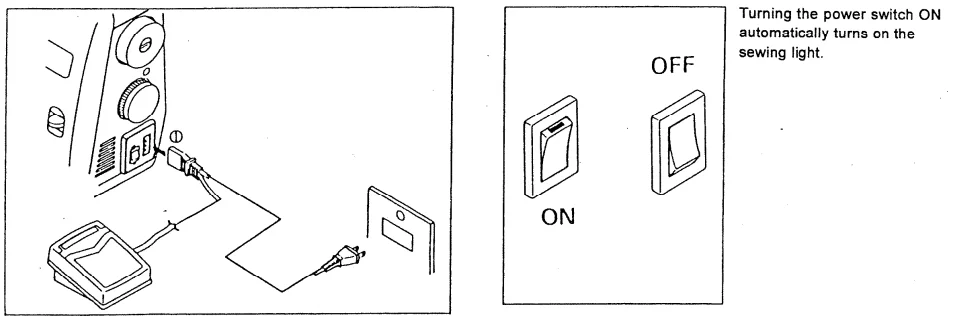

ELECTRICAL CONNECTION

- Connect the foot control to the machine by inserting the 3-hole plug into the socket located on the right side of the sewing machine.

- Plug the power cord into a wall outlet.

- Turn the power on/off switch on the right side of the machine to the on position.

POLARIZED PLUG INFORMATION

This machine has a polarized plug (one blade is wider than the other). To reduce the risk of electric shock, this plug is intended to fit in a polarized outlet only one way. If the plug does not fit fully into the outlet, reverse the plug. If it still does not fit, contact a qualified electrician to install the proper outlet. Do not modify the plug in any way.

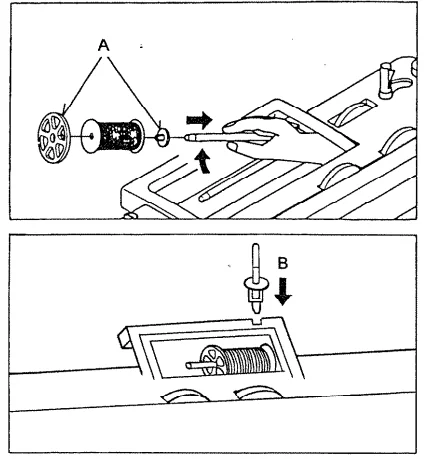

SPOOL PINS

Place a spool of thread on the spool pin. Secure it with the spool cap (A), leaving a gap between the spool cap and the thread so the spool can rotate freely. Use the large spool cap for large spools of thread and the small spool cap for smaller spools. The second spool pin (B) can be inserted into the square hole on the handle to use a second spool of thread.

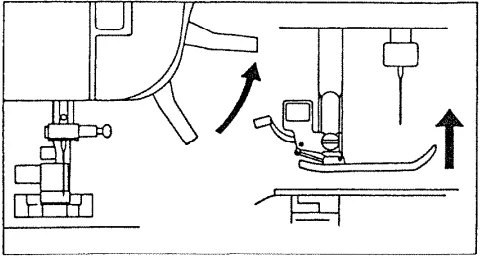

PRESSER FOOT LEVER

There are three positions for your presser foot:

- Lower the presser foot to sew.

- Raise the presser foot lever to the middle position to insert or remove fabric.

- Lift the presser foot lever to the highest position to insert or remove thick fabrics or to change the presser foot.

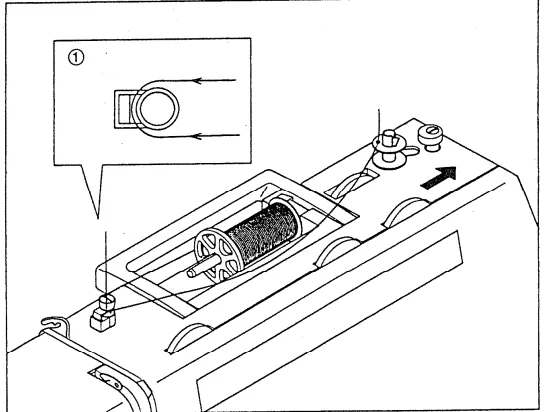

BOBBIN WINDING

- Place the thread spool on the spool pin and bring the thread around the bobbin winding tension disc as illustrated.

- Put the end of the thread through the hole in the bobbin as shown.

- Push the bobbin winder spindle to the left position and place the bobbin onto the spindle with the thread end coming from the top of the bobbin. Push the bobbin winder spindle to the right until it clicks. Hold the thread end.

- Press the foot control to start winding the bobbin. Stop and cut the thread end. Press again to continue winding. It will stop when full. Push the spindle to the left and remove the bobbin.

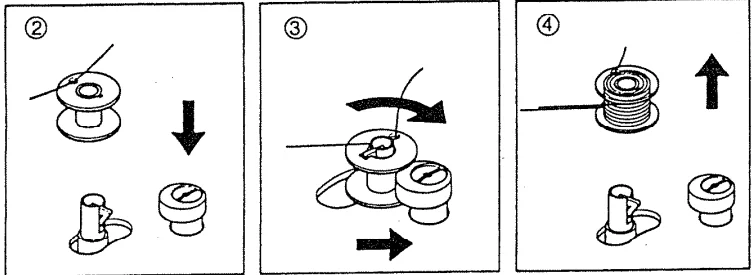

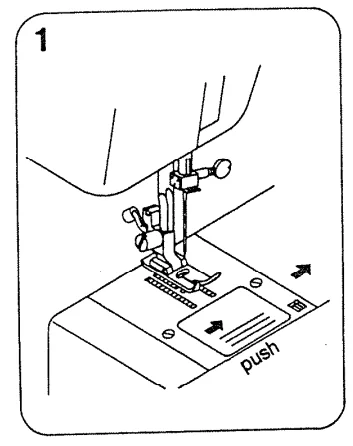

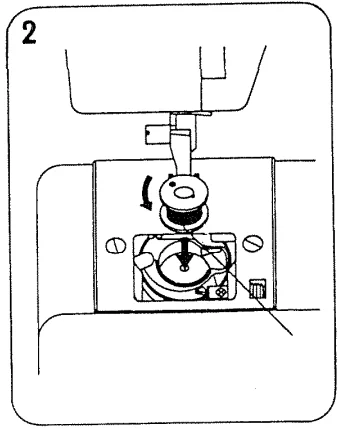

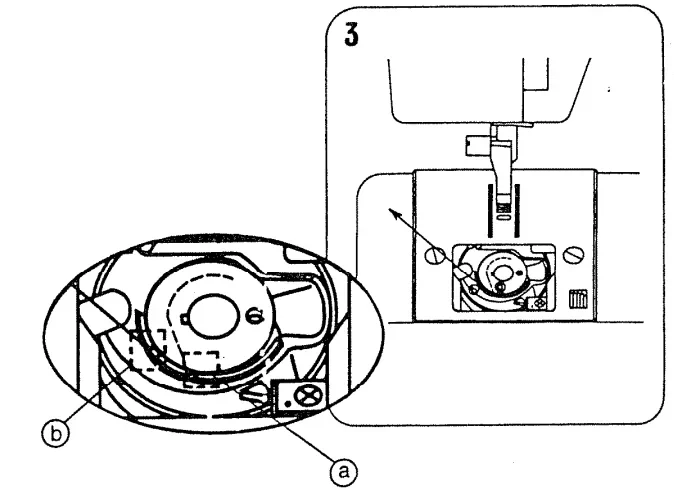

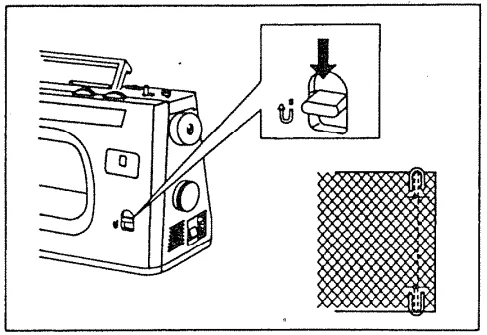

INSERTING THE BOBBIN

- To remove the bobbin cover, push the black button to the right while pushing on the left front of the cover (where it says push). Lift the cover off.

- Hold the bobbin with the thread coming off the left side and drop it into the bobbin case. Hold the bobbin with your left index finger to keep it from turning, and pull the thread end into the tension slot (A) up to the left (B).

- Pull out about 5 inches of thread (there should be tension on the thread, and the bobbin should turn counterclockwise) and replace the bobbin cover.

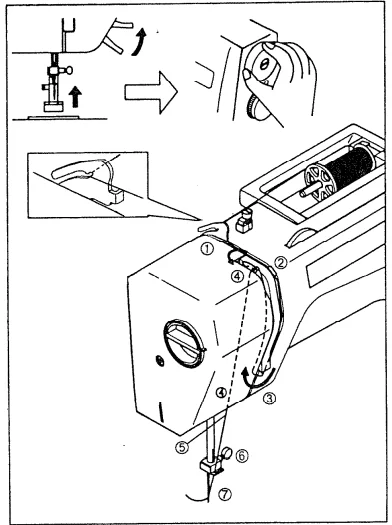

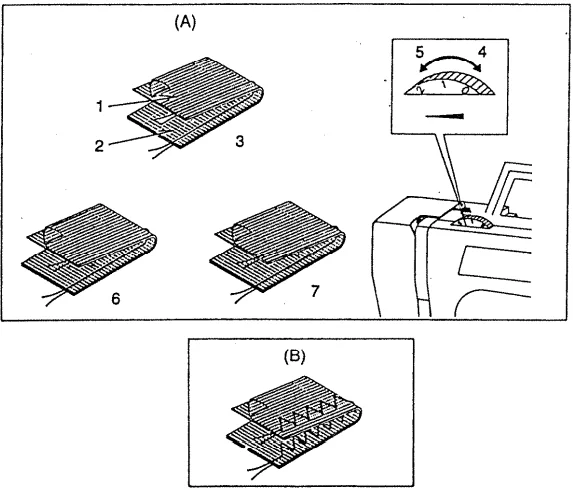

THREADING THE TOP THREAD

- Raise the presser foot lever to the up position. Be sure to thread with the presser foot up so the tension is released.

- Raise the needle to the highest position by turning the hand wheel toward you.

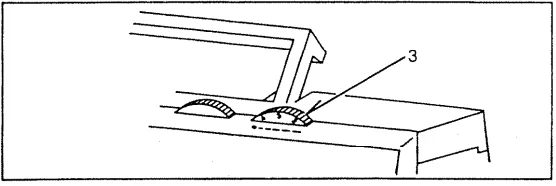

- Thread the machine in the following order: bring the thread across the first guide (1), across the top of the machine to the tension disk (2). Bring the thread straight down under the guide (3) and back up to the thread take-up (4). Drop the thread into the take-up lever from right to left and down to guide (5). Then place the thread behind the guide (6) and through the needle from front to back (see page 15 to use the built-in needle threader).

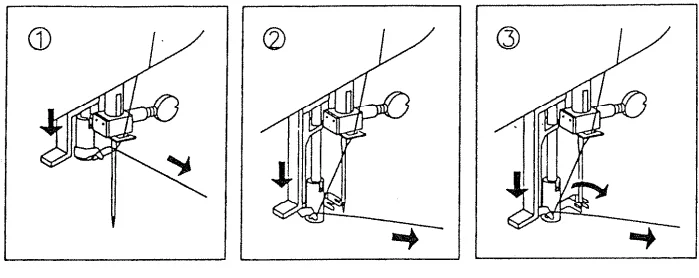

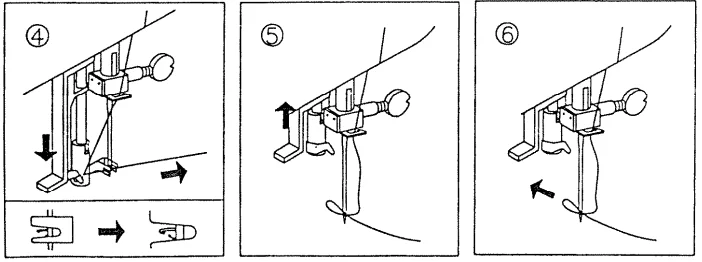

AUTOMATIC NEEDLE THREADER

Raise the needle to the highest position by turning the hand wheel toward you.

- Hook the thread around the thread guide on the left as illustrated.

- Pull down the lever holding the end of the thread.

- Hold the lever as far down as it will go.

- Guide the thread into the hook that is coming through the eye of the needle, and hold it upward and to the right.

- Release the lever, and a loop of thread will be pulled through the needle.

- Grasp the loop and pull the thread through the needle eye.

Note: It is recommended to set the machine to a center needle straight stitch when using the needle threader.

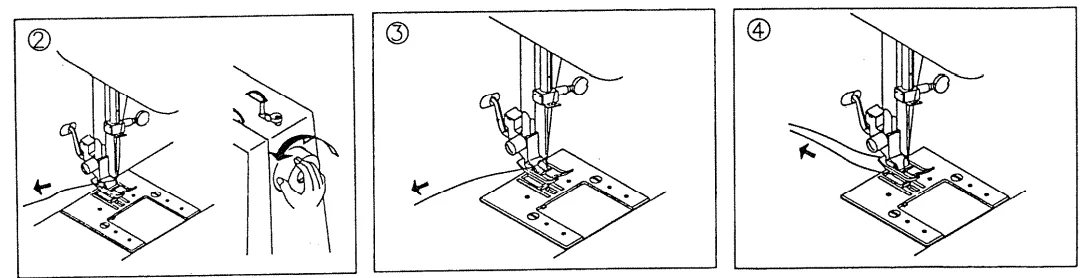

BRINGING UP BOBBIN THREAD

- Raise the presser foot lever.

- Hold the needle thread loosely with your left hand and turn the hand wheel toward you until the needle goes down into the needle plate and back up to the highest position.

- Lightly pull the top thread upward until a loop of bobbin thread comes up.

- Grasp the bobbin thread and pull both top and bobbin threads under the presser foot and to the back, leaving about 5 inches of thread.

ADJUSTING TOP THREAD TENSION

A balanced stitch is determined by the tension of both top and bobbin threads. The tension is correct when these two threads lock in the middle of the fabric layers. Set the tension dial at about 3 for normal sewing. If the stitch is irregular, rethread the machine. Be sure the presser foot is up when you thread. If tension is still irregular, adjust the top tension by turning the dial one number at a time and sew a sample to check the stitch.

ZIG ZAG STITCHING

The top thread may appear on the underside of the fabric depending on the thread type, fabric, stitch, and sewing speed, but the bobbin thread should not appear on the top of the fabric. Illustration A: Straight stitching

- Underside

- Top side

- Well-balanced tension

- Decrease top tension – set dial to a lower number

- Increase top tension – set dial to a higher number

- The top stitch is too tight

- The top stitch is too loose

Illustration B: Zig-zag stitching

BOBBIN TENSION

The bobbin tension has been correctly set at the factory, so you should not need to adjust it.

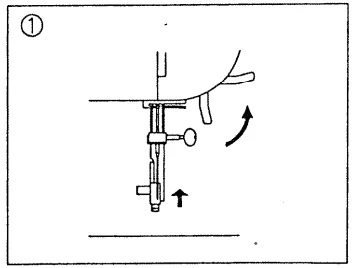

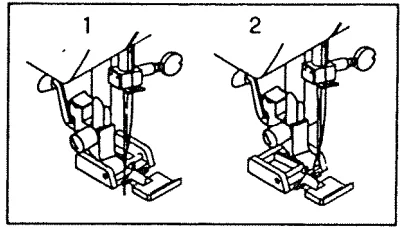

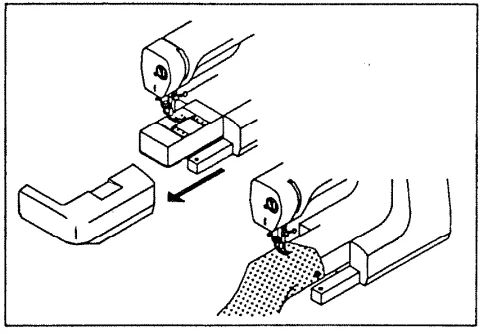

CHANGING PRESSER FEET

Be sure the needle is in the highest position. Raise the presser foot lever.

- Push the foot release lever (at the back of the foot) up to remove the presser foot.

- Place the desired foot on the needle plate and lower the ankle/shank until it lines up with the bar on the presser foot and snaps in place.

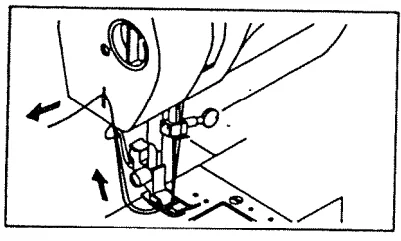

FEED TEETH LEVER

The feed teeth move the fabric under the presser foot as it is sewn. The feed teeth should be up for all general sewing. Lower the feed teeth for free-motion darning, embroidery, monogramming, and stipple quilting. When the feed teeth are lowered, you must move the fabric as you sew. To lower the feed teeth, push the lever in and to the right. To return them to the up position, push the lever to the front.

STITCH PATTERN SELECTOR AND INDICATOR

The stitch patterns are pictured on the front of the machine.

- To select a stitch, be sure the needle is out of the fabric in the highest position.

- Turn the stitch selector dial until the desired stitch is indicated by the red symbol on the indicator panel. Two numbers will appear in the window.

To stitch the upper number, set the stitch length between 0 and 5. To stitch the lower number, set the stitch length to the green “S”.

STITCH LENGTH AND STRETCH STITCH SETTING

Stitch length is adjusted according to the thickness and type of fabric. Stitch length settings will be suggested for each stitch. You can adjust the length to your fabric and technique. Stretch stitch patterns are selected by turning the stitch length dial to the green “S”.

REVERSE STITCH LEVER

Sewing in reverse at the beginning and end of seams will reinforce the seam and keep the ends from coming unstitched. To sew in reverse, push down on the reverse lever. The machine will sew backward as long as you hold the lever down.

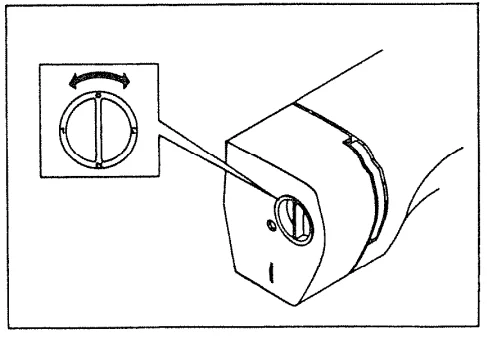

PRESSER FOOT PRESSURE DIAL

This dial regulates how hard the presser foot pushes down on the fabric. Too little pressure may cause poor feeding of the fabric, skipped stitches, or difficulty in guiding the fabric as you sew. Too much pressure may result in one layer feeding ahead of another or feed teeth or presser foot marks on the fabric. For most fabrics, set the dial at 2. For thicker fabric, increase to 3; for thin fabric, decrease to 1.

STITCH WIDTH DIAL

The stitch width dial sets the needle to swing from side to side as in a zig-zag stitch. The higher the number set for stitch width, the wider the stitch. Most stitches recommend a stitch width of 3, but you can vary the setting for narrower or wider stitches.

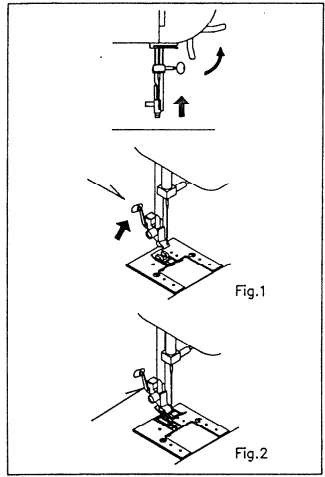

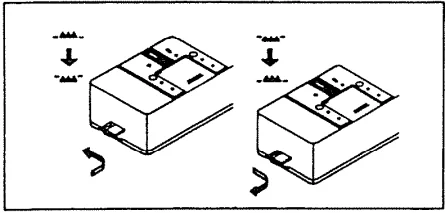

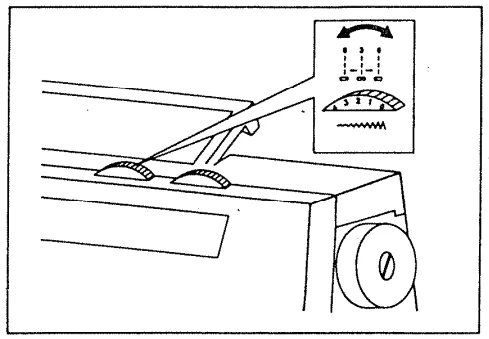

FREE ARM SEWING

Your White Sewing Machine can be used with a flat bed or a free arm. Slide on the flat bed extension for a larger working surface. Slide the flat bed extension to the left to remove it for free arm sewing on smaller projects, sleeves, hems, and children’s clothes.

STRAIGHT STITCH #4

The center needle straight stitch is the most used stitch for sewing. Set the stitch, then select the stitch length best for your project.

- Straight stitch, center needle position

- Stitch Selector Dial – Stitch 4

- Stitch Width 3

- Stitch Length 2-3 for normal sewing

- Straight stitch, left needle position

- Stitch Selector Dial – Stitch 4

- Stitch Width 6

- Stitch Length 2-3

STARTING TO SEW

Before placing the fabric under the presser foot, turn the hand wheel to bring the needle to the highest position. Place about 5 inches of top and bobbin threads under the presser foot and toward the back. Place your finger on the thread ends and hold them in place as you begin to sew. Begin sewing about 3/8 inch from the edge of the fabric, and then press the reverse lever to sew in reverse to the fabric edge and lock the beginning of the seam. Release the reverse lever and sew the seam. Reverse at the end to lock the stitch.

REMOVING FABRIC

When you have reached the end of a seam, stop sewing and turn the hand wheel toward you to bring the needle to the highest position. Raise the presser foot and pull the fabric out from under the foot to the back of the machine. Cut the threads in the thread cutter on the left side of the machine.

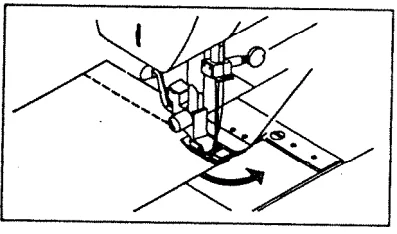

STITCH A CORNER / PIVOTING

To stitch or pivot around a corner, sew to 5/8 inch from the fabric edge (stop sewing with the fabric edge at the corner guideline), and stop sewing with the needle in the fabric. Raise the presser foot and turn the fabric. The edge of the fabric will align with the 5/8 inch seam guideline on the needle plate. Lower the presser foot and sew.

BASTING

Sew a basting straight stitch or temporary stitching. This is an easy stitch to pull out later.

- Stitch Selector 4

- Stitch Width 3

- Stitch Length 4

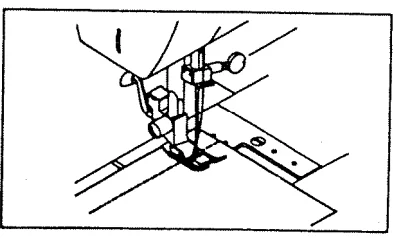

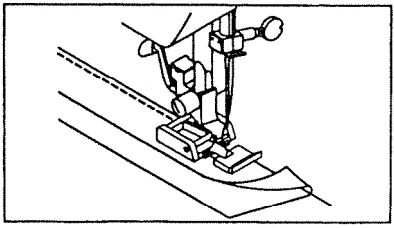

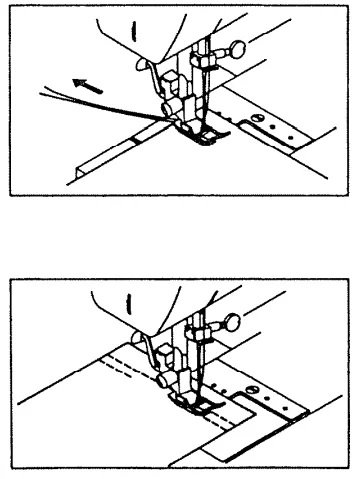

INSERT ZIPPERS AND PIPING

ZIPPERS

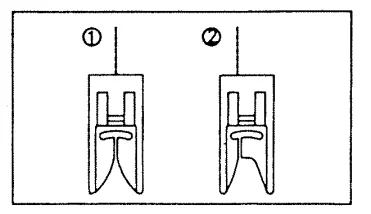

Attach the zipper foot (see page 16), which can be snapped on to the right or left of the foot, so you can stitch close to the zipper on the right or left side. Illustration

- Needle to the left of the foot

- Needle to the right of the foot

- Stitch Selector 4

- Stitch Width 3

- Stitch Length 2-3

To insert zippers, consult the zipper package for instructions on how to prepare the zipper placket and place the zipper. To sew close to the zipper on the right side, snap the zipper foot onto the ankle on the left side so the needle passes through the opening on the left side of the foot. Snap the foot onto the ankle on the other side of the foot to sew close to the left side of the zipper.

PIPING

- Stitch Selector 4

- Stitch Width 3

- Stitch Length 3

To insert piping, purchase pre-made piping or cover cording with a bias strip of fabric using the zipper foot snapped onto the left side of the ankle. Place the piping between two layers of fabric. Stitch with the piping next to the foot so the stitching is tight against the cord.

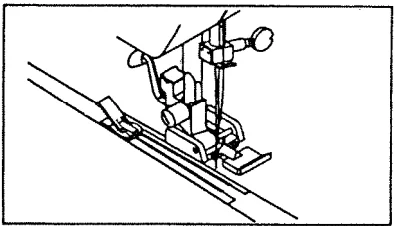

MACHINE QUILTING / PIECING

- Stitch Selector 4

- Stitch Width 3

- Stitch Length 2

To sew fabric pieces together for a quilt (quilt piecing), attach the 1/4 inch foot. Place the fabric edge aligned with the edge of the foot as you stitch.

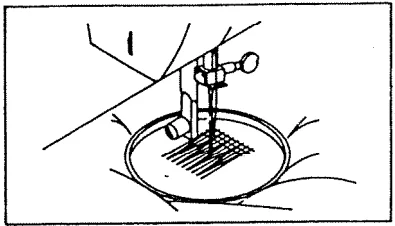

FREE-MOTION STIPPLING

- Stitch Selector 4

- Stitch Width 3

- Stitch Length 0

The stippling technique is a free-motion stitch for quilting. Lower the feed teeth. Remove the presser foot and ankle. Set the presser foot pressure to 0. Hoop the quilt or fabric. Move the fabric under the needle to create a wavy straight stitch quilting.

DARNING

- Stitch Selector 4

- Stitch Width 3

- Stitch Length 0

With this free-motion stitch, you can sew over holes and tears. Lower the feed teeth and remove the presser foot and ankle. Set presser foot pressure to 0. Hoop the fabric and move it back and forth to stitch over the area needing darning.

REINFORCED STRAIGHT STITCH

- Stitch Selector 22

- Stitch Width 3

- Stitch Length S+

The reinforced straight stitch is stronger than a regular straight stitch and will stretch with the fabric. Use it to seam stretch fabrics and to sew and mend crotch seams and other areas of garments that are subject to strain in both stretch and woven fabrics.

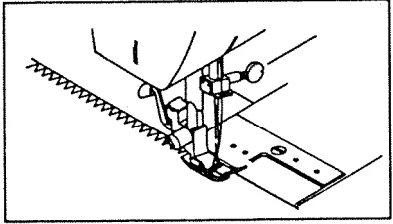

ZIG ZAG STITCH

- Stitch Selector 5

- Stitch Width 1-5 (the higher the number, the wider the zig-zag stitch)

- Stitch Length 2-4 (the lower the number, the closer together the zig-zag stitch)

The stitch length and width can be adjusted to create different sizes and types of zig-zag stitches. Begin sewing with stitch width 1 and turn the stitch length dial toward higher numbers as you sew. Set the stitch width dial to 1 and begin sewing. Turn the stitch width dial to higher numbers as you sew.

BUTTON SEWING

- Stitch Selector 5

- Stitch Width 3-5 (adjust as needed so zig-zag stitches fit in the holes of the button)

- Stitch Length 0

Lower the feed teeth. Tape the button onto the fabric with transparent tape. Use the zig-zag presser foot or no foot. Lower the presser foot lever and turn the hand wheel by hand carefully, and adjust the stitch width so the needle goes into the holes in the button. Sew 6 to 8 zig-zag stitches to secure the button. Set the stitch width to 0 and sew several stitches to lock the stitch.

APPLIQUE SATIN STITCH

- Stitch Selector 5

- Stitch Width 3-5

- Stitch Length – buttonhole setting

Stitch the applique in place with a satin stitch. Fuse the appliqué to the fabric with a fusible web. Place a tear-away stabilizer under the fabric. Try the stitch on a scrap of stabilized fabric before sewing on your project and adjust the stitch length as needed. For best results, thread the top with decorative rayon thread. Set the stitch width from 2-5. The larger the applique, the wider the width setting.

Set the stitch length to 1 and then begin to sew on your scrap. Turn the stitch length dial toward the buttonhole setting slowly until the zig-zag stitching is very close together and satiny. This is called a satin stitch. An open-toe applique foot, available as an optional accessory, will feed smoothly over the satin stitch thanks to a tunnel on the underside of the foot, and the open toe gives visibility as you sew around the applique.

MONOGRAM / FREE-MOTION EMBROIDERY

- Stitch Selector 5

- Stitch Width 5

- Stitch Length 0

Lower the feed teeth. Remove the presser foot and ankle. Draw the monogram or design on the fabric with a fabric marking pencil. Place the fabric in a hoop with stabilizer under it. Place the hooped fabric under the needle and follow the marked letter or design with the stitching. Move the hoop without turning it. You must move the fabric because the feed teeth are lowered.

For More Blogs, Visit ManualsLibraryy.

White 2037 Sewing Machine-FAQs

How do I operate the White 2037 sewing machine step by step?

Start with the needle raised and presser foot lifted. Place your fabric under the needle, lower the presser foot, and gently press the foot pedal to start sewing. Lock the beginning and end stitches by sewing a few reverse stitches. Guide your fabric smoothly, then lift the needle and presser foot to remove the fabric.

How do I thread an old White sewing machine?

Place the thread spool on the top pin, pull the thread through the upper guides and tension discs, then through the take-up lever. Next, pass the thread down through the needle bar thread guide and insert it through the needle eye from front to back. Finally, wind and insert the bobbin according to your model’s diagram.

What brand makes the White 2037 sewing machine?

The White Sewing Machine Company originally manufactured the 2037 model. The brand later became part of Electrolux and was eventually merged with the Husqvarna Viking brand in 2006.

How do I insert a needle into the White 2037 sewing machine?

Turn off the machine and loosen the needle clamp screw. Insert the needle with the flat side facing the back, then tighten the screw securely. Make sure the needle is pushed up as far as it will go before tightening.

How can I tell if my sewing machine is threaded correctly?

A properly threaded machine will sew smooth, even stitches without loops or tangles. If thread bunches under the fabric, recheck the upper thread path, bobbin placement, and tension settings.

What is the most common sewing machine problem and how can I fix it?

Thread bunching (or “birdnesting”) is the most common issue. To fix it, rethread both the upper thread and bobbin, replace a bent needle, and clean out any lint from the bobbin area.

What is the basic stitch length setting on the White 2037?

A standard stitch length is around 2.5 mm, ideal for general sewing. Shorter stitches (2.0 mm) are used for fine fabrics, and longer ones (3.0–4.0 mm) for basting or topstitching.

How do I clean and maintain my sewing machine?

Unplug the machine, remove the needle, bobbin, and plate, and use a small brush to clean out lint and thread. Apply one drop of oil to the hook area, replace all parts, and wipe down the exterior.