Presto Precise 12-Quart Digital Pressure Canner

IMPORTANT SAFEGUARDS

To reduce the risk of personal injury or property damage when using electrical appliances, basic safety precautions should always be followed, including the following:

- Read all instructions. Improper use may result in bodily injury or property damage.

- Before each use, check both the vent pipe (Fig. A, page 3) and vent filter (Fig. F, page 3) to be certain they are free of any blockage. Remove the filter and clean any debris from both the vent pipe and filter (see “Disassemble Canner Parts for Cleaning” instructions on page 3).

- Always check the air vent/cover lock to be sure it moves freely before use.

- To protect against electrical shock, do not immerse cord, plug, or canner body in water or other liquid.

- Do not let children handle or put electrical cords or plugs in their mouths.

- Always attach plug to appliance first, then plug cord into the wall outlet. To disconnect, press and hold (the cancel button) for 3 seconds, then remove plug from wall outlet.

- Unplug cord from unit and outlet when not in use and before cleaning. Allow unit to cool before putting on or taking off parts and before cleaning.

- Do not operate any appliance with a damaged cord or plug or in the event the appliance malfunctions or has been damaged in any manner. Return the appliance to the Presto Service Department for examination, repair, or electrical or mechanical adjustment.

- WARNING! Contents are hot and can cause serious burns. Keep appliance and cord away from children. Do not let cord hang over edge of counter or table, or touch hot surfaces.

- To guard against electrical shock, can only in the removable pot provided.

- The use of accessory attachments not recommended by the appliance manufacturer may cause injuries. Use only genuine Presto® accessories and replacement parts

GETTING ACQUAINTED

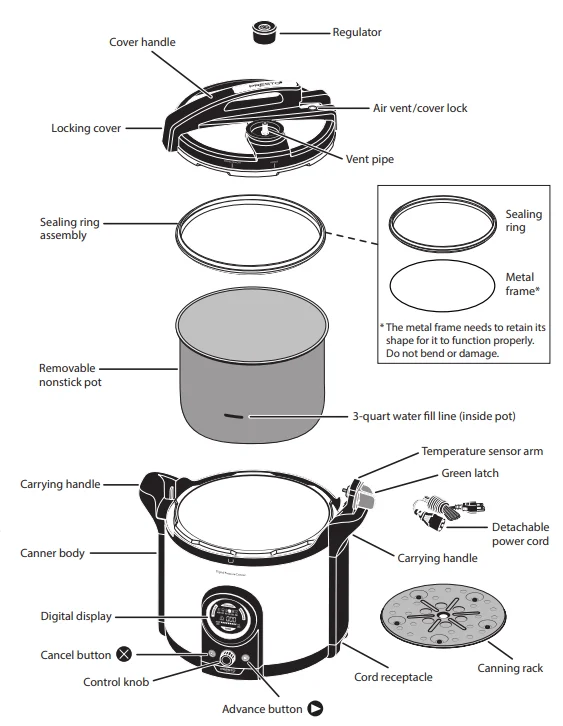

As received, your digital canner will be fully assembled. Disassemble and clean the canner parts (Fig. A) as directed below. Read all instructions carefully. If you are new to canning or need some refresher training, refer to the “Canning Basics” section on pages 5 and 6.

Remove the Canner Cover

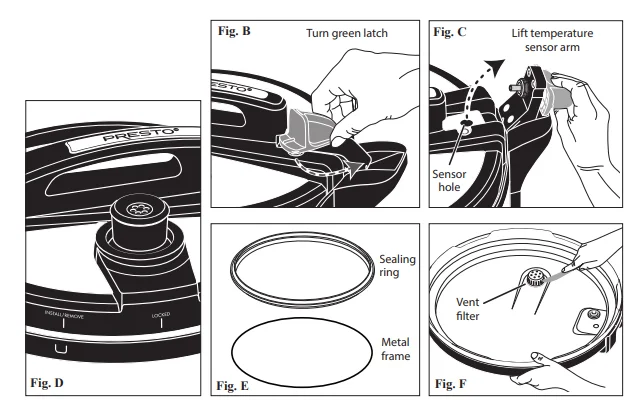

- Before removing the cover, you will need to unlock the green latch. Begin by positioning the canner so the digital display faces you. To unlock the latch, grasp the sides of the latch and turn it counterclockwise until it stops (Fig. B). Lift the temperature sensor arm out of the sensor hole in the cover (Fig. C).

- Once you have released the temperature sensor arm from the cover, rotate the cover counterclockwise until the INSTALL/REMOVE vertical mark is within the mark on the canner body (Fig. D). Then lift the cover straight up off the canner body

Disassemble Canner Parts for Cleaning

It is recommended that the canner parts be thoroughly washed before first use to remove any manufacturing residue.

- Take the sealing ring assembly off the removable pot rim (Fig. A). Then, lift the canning rack and removable pot out of

the canner body. - Detach the sealing ring from the metal frame (Fig. E).

- Remove the vent filter for cleaning. To remove the filter, place the inverted cover on the counter, then rest a table knife on the rim of the cover and insert the knife tip into one of the filter slots (Fig. F); gently lift the filter up.

- Wash the sealing ring, metal frame, vent filter, canning rack, and removable pot in warm, soapy water. Rinse and dry thoroughly. The canning rack is dishwasher safe. Do NOT wash any of the other parts in the dishwasher.

- Clean the canner cover with a damp, soapy cloth. Do NOT immerse the canner cover in water or wash it in the dishwasher.

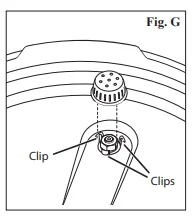

- After cleaning the cover, reattach the vent filter. Be sure to place the vent filter over all 3 clips (Fig. G), then push it into place. If placed correctly, you will hear a snap as the clips grip the filter. The filter should fit tightly.

- Reattach the sealing ring to the metal frame. Use your thumbs and index fingers to gently push it around the frame. The sealing ring is properly positioned when the metal frame is seated in the ring’s inner groove.

INTRODUCTION

The Presto Precise® Digital Pressure Canner is both a pressure canner and boiling water canner in one. Use the control knob to set the desired canning method. The LED display icons will then guide you through each step of the process. Each time you use the canner, complete the preparation steps on pages 6 and 7. Then follow the instructions for Pressure Canning on pages 7 to 9 or for Boiling Water Canning on pages 18 and 19. There is no altitude adjustment necessary when pressure canning; however, when using the boiling water canning method, you must increase the processing time. Refer to the altitude chart on page 20 for recommended times.

CANNING BASICS

- The key to successful canning is to understand the acidity and spoilage factor of the food you wish to can, as well as the acceptable canning methods to process those foods. There are invisible microorganisms present all around us. Fruits, vegetables, and meat contain these microorganisms naturally; and yet, they are not a problem unless food is left to sit for extended periods of time, causing food spoilage. This is nature’s way of telling us when food is no longer fit to eat.

- There are four basic agents of food spoilage—enzymes, mold, yeast, and bacteria. Canning interrupts the natural spoilage cycle so food can be preserved safely. Molds, yeast, and enzymes are destroyed at temperatures below 212°F, the temperature at which water boils (except in mountainous regions). Therefore, boiling water processing is sufficient to destroy those agents.

- Foods naturally high in acid and acidified foods having a pH of 4.6 or less may be safely processed using the boiling water method.

- Step-by-step instructions for Boiling Water Canning begin on page 18.

- Bacteria, however, are not as easily destroyed. The bacteria Clostridium botulinum produces a spore that makes a poisonous toxin which causes botulism. This spore is not destroyed at 212°F. In addition, the bacteria thrive on low-acid foods in the absence of air.

- According to the United States Department of Agriculture (USDA), pressure canning is the only safe method of processing low-acid foods (vegetables, meats, poultry, fish, and seafood).

- In pressure canning, some of the water in the canner is converted to steam, which creates pressure within the canner.

- This pressure is what allows the canner to reach temperatures above boiling. At 240°F, this pressurized heat destroys the potentially harmful bacterial spores. Step-by-step instructions for Pressure Canning begin on page 7.

- As jars cool after processing (by either the boiling water or pressure canning method), a vacuum is formed, sealing food within and preventing any new microorganisms from entering and spoiling the foods.

Before Beginning

Selecting a recipe

To produce home-canned food that is safe for storage at room temperature, it is necessary to use a tested canning recipe. Recipes that have been handed down through the years or those found on the web are oftentimes unreliable and usually do not include the scientifically-tested processing procedures vital to a successful and safe canning project. Canning information published prior to 2015 may be incorrect and could pose a serious health risk. A tested canning recipe has been evaluated to determine the accurate processing method (boiling water canning or pressure canning) as well as the processing time. Do NOT can leftovers; it is not safe. Always choose recipes from a reliable resource, such as the National Center for Home Food Preservation (nchfp.uga.edu), your local Cooperative Extension Service, or this instruction book.

Selecting Jars

- Glass home canning jars, sometimes referred to as Mason jars, are the only jars recommended for safe home canning.

- They can withstand the heat of a pressure canner, are durable, and can be reused time after time. They are available in standard sizes (halfpint, pint, and quart jars) and other non-standard sizes. The diameter of Mason jars may vary from one manufacturer to another.

- When canning with a research-tested recipe, a smaller jar size may be used than what is specified in the recipe.

- However, you must follow the processing time for the smallest jar size listed in the recipe. Never use a larger jar than what is listed.

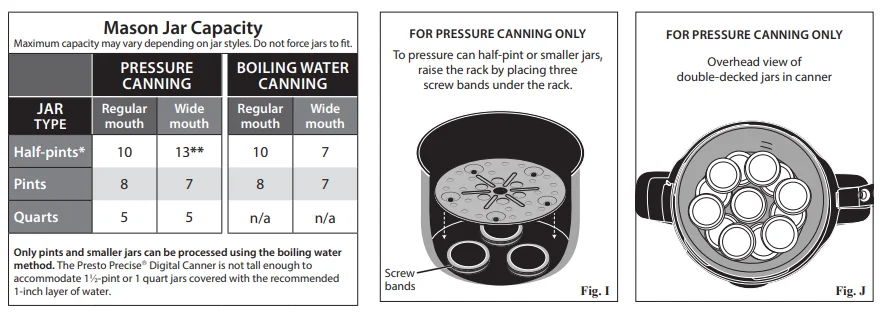

- Before filling Mason jars, test load your canner. When pressure canning, it will be necessary to double-deck half-pint wide mouth jars to reach the maximum capacity, as indicated in the chart on page 4. To double-deck, stagger the jars by placing one jar on top of two (Fig. J, page 4). Jars may touch. Do not double-deck jars for the boiling water method.

- The canning rack which accompanied your canner must be placed on the bottom of the removable pot to prevent jar breakage.

- Although it is not necessary to use a rack between layers of jars, if you wish to do so, a rack can be ordered from the Presto Consumer Service Department (see page 32).

Canning Lids and Bands

The two-piece vacuum cap (lid and band) is the recommended closure for home canning. It consists of a flat metal lid with a sealing compound on the outer edge and a separate metal screw band that secures the lid during processing. The flat lid is for one use only while the bands can be used repeatedly if they remain in good condition. Do not use dented or rusty bands. Use only jars, lids, and screw bands in perfect condition so an airtight seal may be obtained. Bands should be removed prior to storage.

Measuring Headspace

Headspace is the air space between the top of the food or its liquid and the lid. Leaving too much headspace can result in

underprocessing because it may take too long to release the air from the jar. Leaving too little headspace will trap food between the jar and the lid and may result in an inadequate seal. As a general rule, allow ¼-inch headspace for jams and jellies; ½-inch for fruits and tomatoes; 1-inch for vegetables, meats, and seafood; and 1¼-inch for poultry. All recipes will indicate the amount of headspace necessary for the food being canned.

Removing Air Bubbles

After food has been packed in jars, any air bubbles must be removed. Trapped air bubbles may rise to the top during processing, causing too much headspace. Work quickly to remove air bubbles that have become trapped between the pieces of food by moving a clean, nonmetal spatula around the jar between the food and side of the jar.

After Processing

Cooling Jars

After processing, remove jars to a dry towel on countertop away from drafts. Leave 1 to 2 inches of space between jars to allow for even cooling. Do not retighten bands. Do not invert jars or cover with a cloth. Allow jars to cool naturally. Check seals no earlier than 12 hours, but no later than 24 hours. Bubbles often appear in the jar after removal from the canner because food is still boiling in the jar. Ordinarily bubbles do not appear once the product has been allowed to thoroughly cool.

PREPARATION STEPS BEFORE CANNING

- Place the electric canner on a dry, level surface. Always place a protective heat-resistant material (such as a large cutting board) between the canner and the countertop surface to avoid heat damage. To prevent steam damage to cabinets, position the canner so the vent pipe and air vent/cover lock are not directly under cabinets.

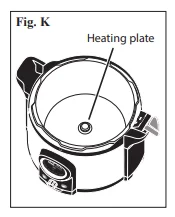

- Be sure the bottom of the removable pot and the heating plate within the canner body (Fig. K) are free of debris before placing the pot in the canner body

- Check both the vent pipe and vent filter to be sure they are clear and do not contain any debris. In order to check the vent pipe, you will need to remove the regulator from the cover (Fig. A, page 3). Then hold the cover up to a light and make sure you can see light coming through the vent pipe. If you cannot, remove the vent filter (see page 3) and clean the vent pipe with a small brush or pipe cleaner to remove the blockage. Reattach the vent filter to

the cover.

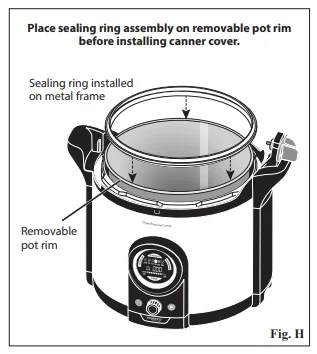

- Ensure the sealing ring is properly positioned on the metal frame. Also, verify the sealing ring assembly is seated on the removable pot rim before installing the canner cover (Fig. H, page 4).

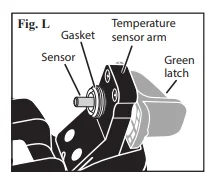

- Always make sure the gasket is positioned on the sensor (Fig. L).

- Check Mason jars for nicks, cracks, and sharp edges. Check screw bands for dents or rust. Use only jars, lids, and screw bands in perfect condition so an airtight seal may be obtained.

- Wash and rinse jars, lids, and screw bands. Follow closure manufacturer’s directions for preparing lids.

PRESSURE CANNING

GETTING READY

- Complete “Preparation Steps Before Canning” on page 6 and at the top of this page. Select the canning recipe (see pages 10 to 17 or use a tested canning recipe) and gather the needed supplies.

- Begin preparing the food that will be used for filling the jars in step 12.

- Place the removable pot in the canner body. Put the canning rack in the pot, feet side down.

- Pour 3 quarts of hot tap water into the pot, up to the fill line (Fig. A, page 3).

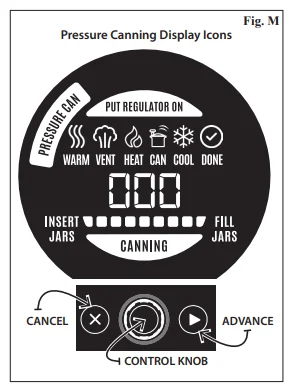

- Attach the power cord to the canner body, making sure to fully insert it in the receptacle. Then plug into a 120VAC wall outlet. The default icon PRESSURE CAN will flash in the display window (Fig. M). Press the control knob to select the PRESSURE CAN mode. The PRESSURE CAN icon will remain illuminated for the duration of the canning process.

- Rotate the knob to set the time for the specific canning recipe and jar size being used. The time adjusts in 5-minute

increments up to 180 minutes - Press . INSERT JARS will light up. Fill the canning jars half full with hot tap water and place them on the canning rack.

- Position the sealing ring assembly on the removable pot rim (Fig. N).

- REMOVE THE REGULATOR if it is on the canner cover. It will not be needed until step 16 of the venting phase.

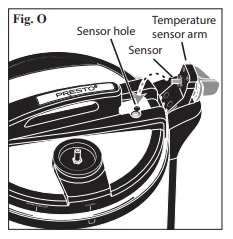

- Place the cover on the canner body, aligning the INSTALL/REMOVE vertical mark within the mark on the canner body (Fig. D, page 3). Rotate the cover clockwise until it stops. The canner cover is properly installed when the LOCKED vertical mark is within the mark on the canner body (Fig. O). Keep the temperature sensor arm in the upright, unlocked position.

- Press . WARM will light up and the progress bar will begin scrolling from left to right, indicating the unit is heating.

Jar warming will take about 20 minutes. During this time, complete any necessary food preparation. - When the canner beeps twice and FILL JARS lights up, the jars are preheated and ready for filling. The canner will continue to keep the jars warm until you are ready to fill them. Unlock and remove the canner cover. Lift the cover toward you to keep any steam away from you.

- Verify the sealing ring assembly is on the removable pot rim (Fig. N).

- Place the cover back on the canner and lock it on. Lower the temperature sensor arm and insert the sensor into its hole in the cover (Fig. O). It may be necessary to rotate the cover slightly so the hole aligns with the sensor. Then, grasp the green latch and, using a slight downward pressure, turn the latch clockwise until it aligns with the handle (Fig. P).

- Once the proper temperature is reached, the canner will proceed to the vent phase; VENT and I0 will light up. The venting timer will begin counting down. During venting, air/steam will release from the vent pipe and air vent/cover lock. This will be noticeable. You will hear boiling throughout the venting and canning phases. Depending on the number and size of the jars, the air vent/cover lock may lift during venting. The smaller the load, the more likely the air vent/cover lock will lift.

- When the time expires, the unit will start beeping and PUT REGULATOR ON will light up. Place the regulator on the vent pipe (Fig. Q). The regulator will fit loosely on the vent pipe. Press to advance to the canning phase. The beeping will stop. If the air vent/cover lock did not lift during venting, air/steam will continue to release from the air vent/cover lock until it lifts (Fig. R).

- CAN will light up and the processing time programmed in step 6 will appear in the display. The progress bar will continue to scroll as the canner heats.

- Once the required canning temperature is reached, the unit will beep twice and CANNING will light up. The canner is now processing and the timer will start to count down. The progress bar will stop scrolling and begin to light up in segments, increasing in length as the processing time counts down (e.g., if 15 minutes of a 20 minute processing time have elapsed, 75% of the bars will be illuminated).

- When the processing time expires, the canner will beep 4 times and COOL will light up. This is the final canning phase.

The length of the cool-down period will depend on the canner load and may take about 1½ hours. I0 will light up in the display. The unit will start to count down when cooling is almost done. The progress bar will scroll from right to left to indicate the unit is cooling. - When the time expires, the unit will beep 10 times and DONE will light up. Press and hold for 3 seconds. If the air vent/cover lock remains in the up position when the display indicates DONE, wait for it to drop. Remove the regulator, unlock the green latch, and lift the temperature sensor arm. Then unlock and remove the canner cover. Lift the cover toward you to keep any steam away from you.

- Using a jar lifter, remove jars by lifting them straight up. Be careful not to tilt the jars, which causes liquid to siphon out. Food particles may also get between the jar rim and the lid and prevent the jar from sealing. Place jars upright on a board or dry towel, away from drafts. Do not retighten bands. Allow jars to cool naturally. Check seals no earlier than 12 hours, but no later than 24 hours. See page 6 for “After Processing” information.

- When processing consecutive batches: Before warming the next batch of jars, allow the water in the canner to cool or

replace with 3 quarts of fresh hot tap water. NOTICE: Placing jars immediately in the water from the previous batch can result in thermal shock to the glass jars that may in turn cause cracks and breakage. If reusing the water, check the water level in the canner. Add water, if necessary, to keep water at the 3-quart fill mark (Fig. A, page 3). - To can additional jars, repeat steps 6 to 22.

- When canning is complete, unplug the cord from the wall outlet and then from the canner base. Allow canner to cool

completely, empty water from removable pot, and clean according to the instructions on page 30.

PRESSURE CANNING Tomatoes and Tomato Products

Tomatoes and tomato products may be safely processed using the boiling water method or pressure canning method. Tomatoes have a pH close to 4.6, which means it is necessary to take precautions to can them safely. First, carefully choose the tomatoes for canning. Use only tomatoes that are disease-free, preferably vine-ripened, and firm.

Second, an acid must be added to tomatoes whether they are processed using the boiling water method or pressure canning method. To ensure the safety of whole, crushed, or juiced tomatoes, add 1 tablespoon bottled lemon juice (not natural juice) or ¼ teaspoon citric acid per pint jar; for quarts, add 2 tablespoons bottled lemon juice or ½ teaspoon citric acid.

TROUBLESHOOTING

CARE AND MAINTENANCE

- When not in use, store the electric canner in a dry place at temperatures above freezing. Exposure to temperatures below freezing may damage the canner. The canner should be completely dry before storing. To prevent unpleasant odors from lingering, store the canner with the cover inverted on the canner body.

- Do not use metal utensils as they may scratch the nonstick surface.

- Do not strike the rim of the pot with any utensil. This could damage the rim which may allow steam to escape and prevent the canner from sealing.

- Periodically check the air vent/cover lock gasket and sensor gasket. Replace these parts when they become hard, deformed, cracked, or torn.

- Also check the sealing ring occasionally. The sealing ring is silicone and may stretch over time. If stretched, it may not fit properly on the metal frame and should be replaced. If it is not replaced, you may notice steam escaping and/or receive an error code when processing.

- The air vent/cover lock gasket and the sensor gasket deteriorate over time (become hard, deformed, cracked, torn with normal use). If you begin to notice steam escaping or receive an error code, these parts may need to be replaced.

- Replacement of the sealing ring, air vent/cover lock gasket, and sensor gasket is considered routine maintenance and not covered under the warranty.

- Periodically check the vent pipe nut for looseness. If necessary, retighten with a ½ʺ wrench.

- If for any reason the canner cannot be opened, contact the Consumer Service Department in Eau Claire, WI at 1-800-877-0441 for assistance.

- Any maintenance required for this product, other than normal household care and cleaning, should be performed by National Presto Industries, Inc. (see page 32).

FOR MORE MANUALS BY PRESTO, VISIT MANUALSLIBRARYY

Presto Precise 12-Quart Digital Pressure Canner-FAQs

How do I use my Presto pressure canner?

Wash and heat your jars. Fill the canner with 2–3 inches of water and place the rack at the bottom. Add jars, secure the lid, heat until steam vents, then process according to the recipe.

How many jars fit in a 12-quart canner?

It holds 10 half-pint jars, 8 pint jars, or 5 quart jars (regular mouth).

How much water should I use in the canner?

Use about 3 quarts of water, regardless of the number of jars.

Can I use it on a glass-top stove?

Yes, current Presto pressure canners work on electric coil, gas, and smooth-top ranges.

What is the difference between a pressure cooker and a pressure canner?

Pressure cookers cook food quickly but cannot safely preserve low-acid foods. Pressure canners can do both cooking and safe canning.

Can I stack jars in the canner?

Only stagger jars in one layer on the rack. Avoid stacking directly to prevent breakage.

How do I know if a jar is sealed properly?

After cooling, the lid should be concave (curved down) and not pop when pressed.

Can I leave jars in the canner overnight?

No, jars must cool gradually. Leaving them in the canner can cause spoilage or flat sour.

What foods must be pressure canned?

Low-acid foods like vegetables (beans, corn, carrots), meats, poultry, and seafood must be pressure canned to prevent botulism.

Can I cook food directly in the canner?

Yes, it functions like a large pressure cooker, but water amounts and processing times differ from pressure cooking.