Overhead Door Legacy 800 Garage Door Opener

OPENER FEATURES

CODEDODGER® Access Security System

An electronic access code system that enhances the security of the door opener by continuously changing the access code each time the remote control is used. The door opener responds to each new code only once. An access code copied from a working system and tried again will not control the door opener.

Lighted Wall Button

Operates door opener from inside garage. (Refer to section 3)

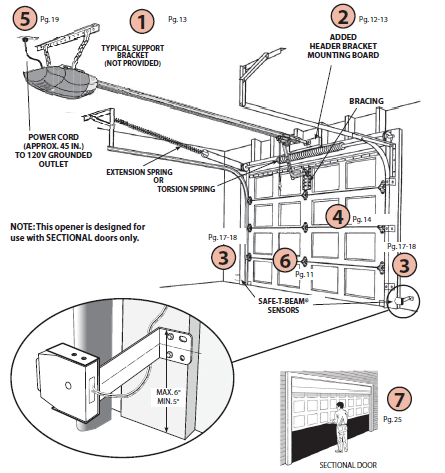

TYPICAL SECTIONAL DOOR INSTALLATION

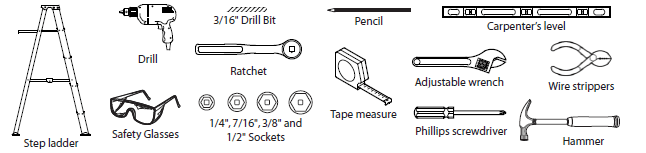

RECOMMENDED TOOLS

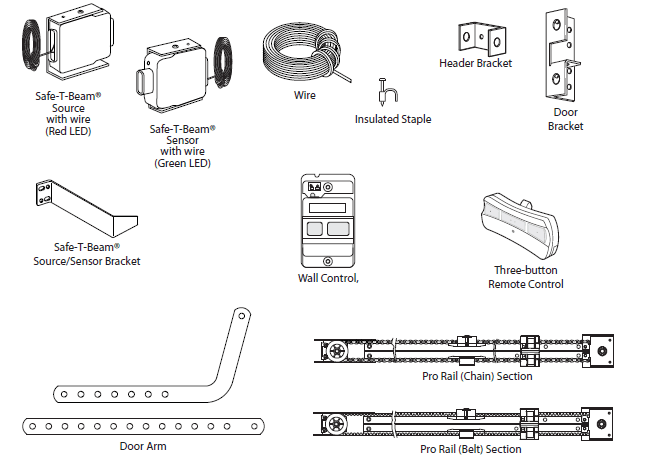

PARTS IDENTIFICATION

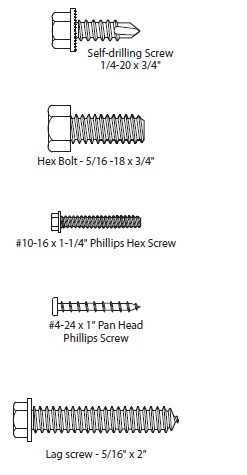

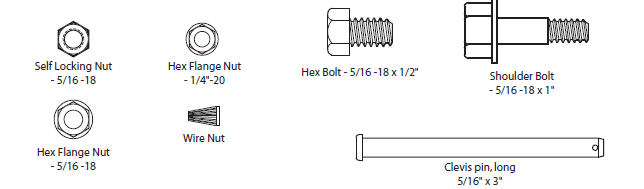

FASTENERS

| BAG NO. | DESCRIPTION | QUANTITY |

| 1 | BOLT – 5/16-18 x 1/2″ | 3 |

|

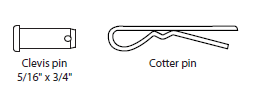

2 | CLEVIS PIN, LONG – 5/16″ x 3″ | 1 |

| COTTER PIN | 1 | |

| HEADER BRACKET | 1 | |

| LAG SCREW – 5/16″ x 2″ | 2 | |

| 3 | HEX BOLT – 5/16-18 x 3/4″ | 5 |

| HEX FLANGE NUT – 5/16-18 | 5 | |

| LAG SCREW – 5/16″ x 2″ | 2 | |

| 4 | SELF DRILLING SCREW – 1/4″-20 x 3/4″ | 3 |

| DOOR BRACKET | 1 | |

|

5 | HEX BOLT – 5/16-18 x 3/4″ | 3 |

| SELF LOCKING NUT – 5/16-18 | 1 | |

| HEX FLANGE NUT – 5/16-18 | 2 | |

| CLEVIS PIN – 5/16″ x 3/4″ | 1 | |

| COTTER PIN | 1 | |

| 6 | WALL CONTROL BUTTON ASSEMBLY | 1 |

| PAN HEAD PHILLIPS SCREW – #4-24 x 1″ | 2 | |

| 7 | 13 MM INSULATED STAPLE | 30 |

| 8 | Safe-T-Beam® SOURCE/SENSOR BRACKET | 2 |

| PHILLIPS HEX SCREW – #10-16 x 1- 1/4″ | 4 | |

| WIRE NUT (GREY) | 4 | |

| NO NUMBER | REMOTE WITH BATTERY | 1 |

| NO BAG | Safe-T-Beam® SOURCE/SENSOR & WIRE SET | 1 |

| NO NUMBER | LIGHT COVER – WHITE | 2 |

PIECE RAIL ASSEMBLED VIEW

OPENER ASSEMBLY

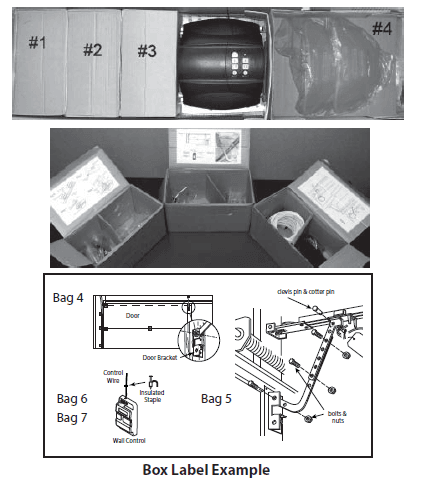

Clear a workspace area to unpack and organize box and contents for assembly.

- There are 4, or more, boxes inside the carton. Each box is numbered 1 – 4. Note that some openers will contain the same parts and be packaged with fewer boxes. Carefully remove the three internal boxes (Labeled #1, 2, and 3) and place them on the floor for easy access (Fig. 1-1). These boxes contain assembly parts and the contents are organized by assembly tasks. For quick reference inside the lid of each box there is a label illustrating the components inside.

- Remove the motor power head and place it on the floor for later use. Remove box #4 and place it on the floor for later use.

FIG. 1-1 Internal boxes

FIG. 1-1 Internal boxes

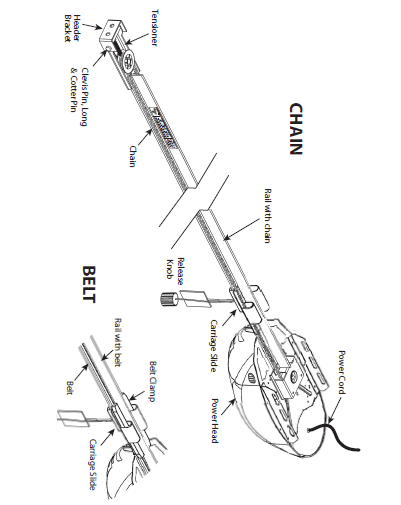

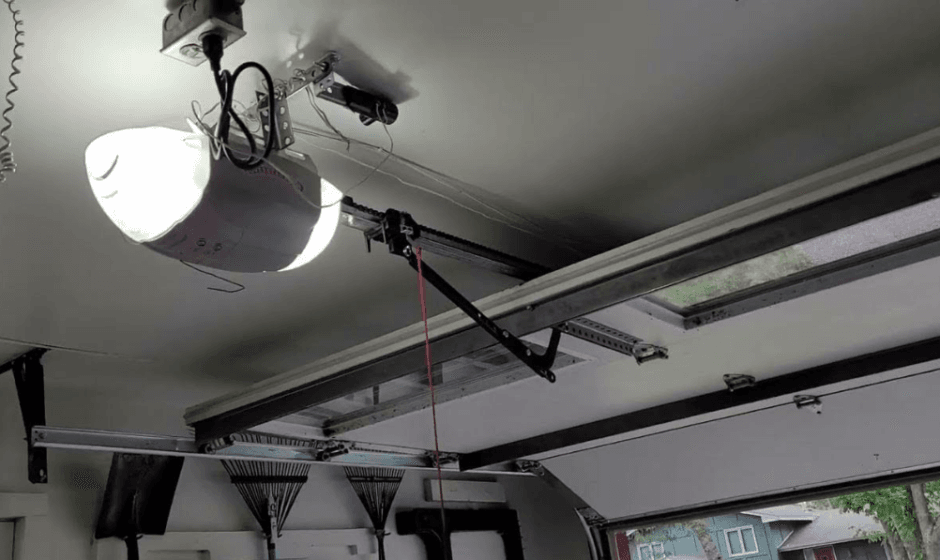

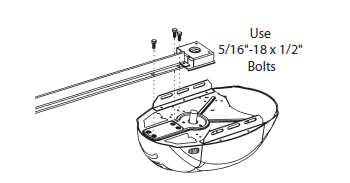

POWER HEAD & CHAIN DRIVE RAIL ASSEMBLY

- Attach rail assembly to power head by aligning the sprocket onto the motor shaft. Use (3) bolts, 5/16 -18 x 1/2″ (Fig. 1-2).

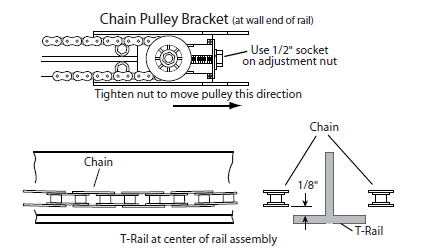

- Tighten the chain by turning the adjustment nut clockwise. The chain adjustment nut is located in the Chain Pulley Bracket (opposite rail end from the power head) (Fig. 1-3).

- Tighten chain until chain is approximately 1/8 inch above the base of the rail at midpoint on the rail (Fig. 1-3). Do not over tighten chain.

FIG. 1-2 Rail – Power head assembly

FIG. 1-3 Chain adjustment

FIG. 1-3 Chain adjustment

Set assembled power head and rail aside. Begin with Section 2 INSTALLATION. FIG. 1-4 Belt adjustment

FIG. 1-4 Belt adjustment

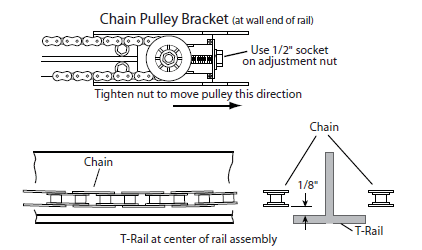

FIG. 1-5 Disable garage door lock

FIG. 1-5 Disable garage door lock

POWER HEAD & BELT DRIVE RAIL ASSEMBLY

- Attach rail assembly to power head by aligning the sprocket onto the motor shaft. Use (3) bolts, 5/16 -18 x 1/2″ (Fig. 1-2).

- Tighten the belt by turning the adjustment nut clockwise. The belt adjustment nut is located in the Belt Pulley Bracket (opposite rail end from the power head) (Fig. 1-4).

- Tighten belt until belt is approximately 1/8 inch above the base of the rail at midpoint on the rail (Fig. 1-4). Do not over tighten belt. Set assembled power head and rail aside. Begin with Section 2 INSTALLATION.

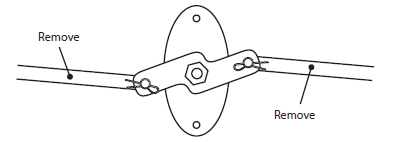

FIG. 2-1 Final height mark

FIG. 2-1 Final height mark

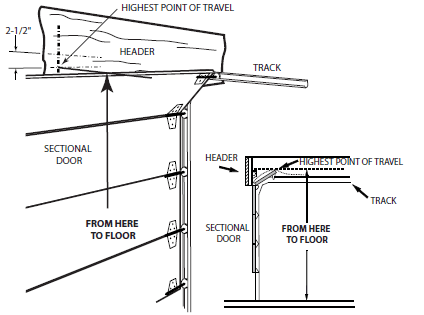

- Finding header bracket mounting location.

- Close garage door.

- Use a pencil and level.

- a) Mark center of garage door (one-half overall width) on the wall with 6″ vertical line at top edge of door.

- b) Continue this line on wall above door for about 12″ (Fig. 2-1, a).

- Raise garage door until top edge of door reaches its maximum height (Fig. 2-2).

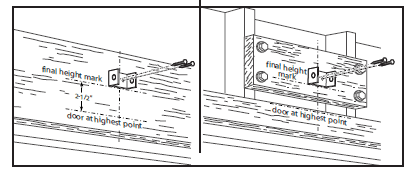

- With door at highest point.

- Measure height from top edge of door to floor (Fig. 2-2).

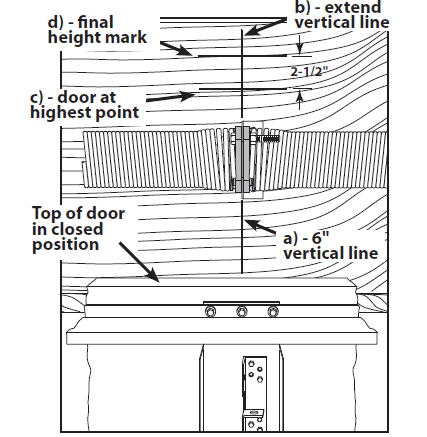

FIG. 2-2 Finding highest point of travel

FIG. 2-2 Finding highest point of travel - Close door again.

- Mark height measurement on wall above door (Fig. 2-1, c).

- Make your mark across vertical line made earlier.

- Add 2-1/2″ to height mark just made on wall. This is location for header bracket (Fig. 2-1, d).

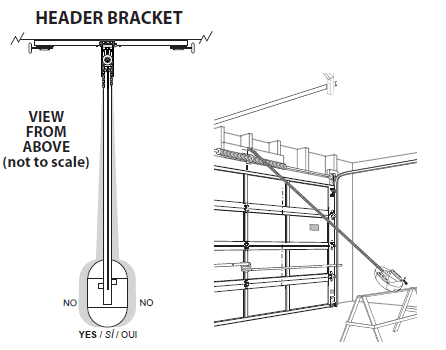

- Mounting the header bracket.

- Hold header bracket against wall (Fig. 2-3).

- Position bracket as shown.

- Place center on vertical line.

- Bottom edge on final height line.

- Mark screw hole locations on wall.

- Drill 3/16″ pilot holes at each screw hole mark.

- Fasten header bracket with 2 lag screws (provided) (Fig. 2-3).

FIG. 2-3 Header bracket mounting (on header & above header)

MOUNTING THE OPENER

- Getting started

- Position assembled rail on wall next to header bracket (Fig. 2-4).

FIG. 2-4 Position assembly and align

FIG. 2-4 Position assembly and align - Place material on floor under power head to protect from scratching. (A box, stool, or similar device may be needed to clear a torsion spring.)

- Position assembled rail on wall next to header bracket (Fig. 2-4).

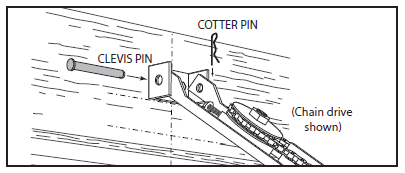

- Mounting the assembly

- Attach rail to header bracket using clevis pin and cotter pin.

- Support power head on step-ladder to prevent interference with header mounted (torsion) spring (Fig. 2 5).

FIG. 2-5 Rail mounting to Header bracket

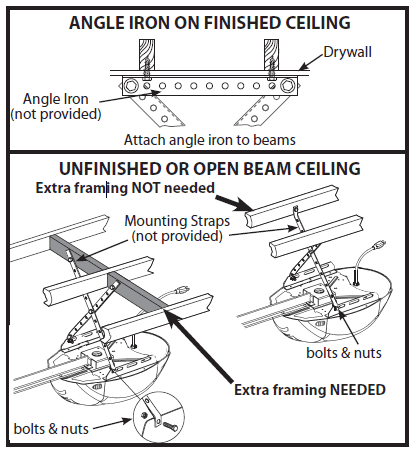

FIG. 2-5 Rail mounting to Header bracket - Attach mounting straps to ceiling using lag bolts (Fig. 2-6).

- Set height of power head to following: (Fig. 2-6).

FIG. 2-6 Mounting the power head

FIG. 2-6 Mounting the power head - a) Rail must clear door at door’s highest point of travel.

- b) Be level or power head slightly below level.

- Securely tighten power head mounting bolts and nuts.

- Carefully raise and lower door manually. Ensure door does not contact any section of power head or rail.

- Check that rail clamp bolts and nuts are tight.

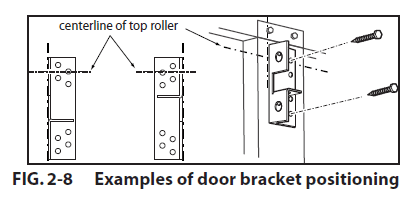

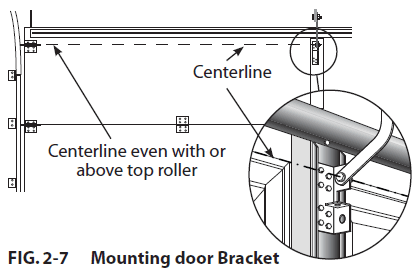

- Finding door bracket mounting location.

- Door bracket is mounted as high on door as possible along vertical centerline and NO LOWER THAN top set of rollers (Fig. 2-7).

- Mounting the door bracket.

- Proper bracing should be verified at this point.

- Align door bracket centered on your vertical centerline (Fig. 2-8).

- Attach using 3 self-drilling screws for sheet metal or other light weight material.

- Use lag screws (not provided) for solid wooden sectional doors.

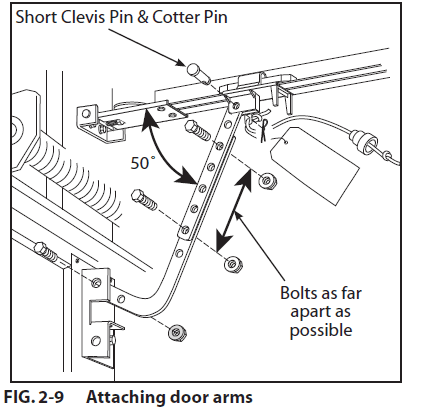

- Attach the arms

- Fasten short branch of curved door arm to door bracket using bolt and locking nut (Fig. 2-9).

- Fasten straight arm to carriage using clevis pin and cotter pin (Fig. 2-9)

- Connecting the arms

- Slide carriage back and forth to adjust arm length.

- Position the straight arm 50º down from the rail.

- With the arms arranged in this position, fasten arms together using bolts and nuts spaced as far apart as possible (Fig. 2-9)

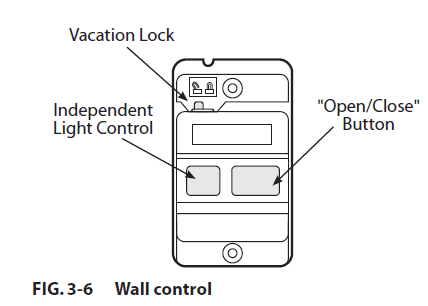

WALL CONTROL INSTALLATION

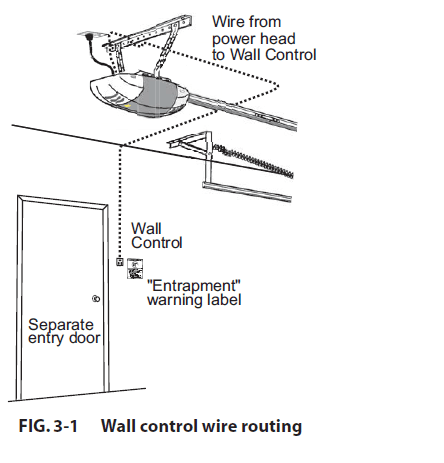

- Wall Control location

- Wall Control location should be in direct sight of door.

- It should be at least five feet (5’) above floor to prevent small children from operating door.

- It must be away from any moving parts. (You should NOT be able to reach the garage door while standing at wall control.)

- Wall Control board screw connections are polarized, (+) positive and (-) negative.

- a. Wiring (If pre wired)

- Locate wall control pre-wired wire ends (Fig. 3-1). (They should be located within the guidelines mentioned above.)

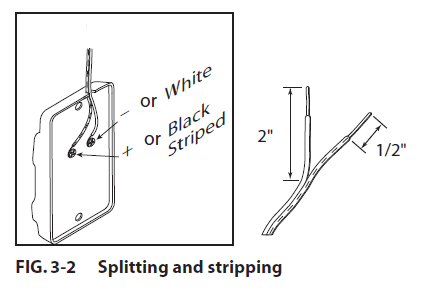

- Split and strip ends of wire (Fig. 3-2).

- Fasten wire to wall control board screws on back of wall control.

- Striped wire to the + (plus) terminal.

- White wire to the – (minus) terminal.

- 2a. Wiring (If NOT pre-wired)

- Pick a convenient location for mounting wall control using the guidelines mentioned above (Fig. 3-1).

- Run wire from wall control to power head (Fig. 3-1).

- Split and strip ends of wire (Fig. 3-2).

- Fasten wire to control board screws on back of wall control button.

- Striped wire to the + (plus) terminal.

- White wire to the – (minus) terminal.

- Locate wall control pre-wired wire ends (Fig. 3-1). (They should be located within the guidelines mentioned above.)

- Securely fasten wires

- Securely fasten wires to ceiling and wall using insulated staples provided.

- Use insulated staples.

- Staples should be snug only.

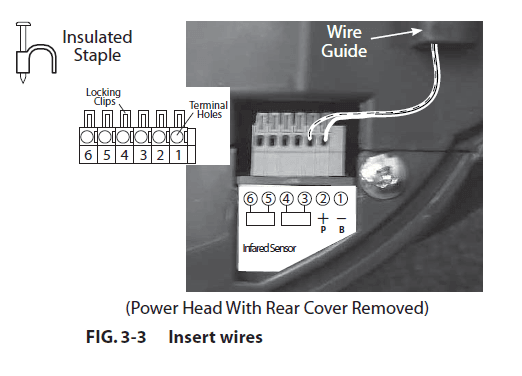

- If rear cover is attached to power head, remove it.

- On power head.

- Route wall control wires through wire guide.

- Split and strip ends of wire (Fig. 3-2 on previous page).

- Insert wire into terminal holes and lightly press in the orange locking clips above each terminal hole. (You can use a pencil or small screwdriver to comfortably press in locking clips.) The white wire into #1 terminal hole and striped wire into the #2 terminal hole.

- Confirm wire lock by lightly tugging on the wire. The wire should remain in the terminal hole.

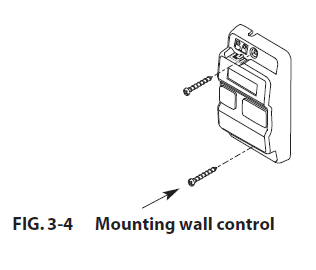

- Mounting

- Fasten wall control to wall with 2 screws (provided) (Fig. 3-4).

- Remove protective backing from “Entrapment” warning label (Fig. 3-5). The “Entrapment” label is located in the center of this manual.

- Stick label on wall near wall control.

- Fasten wall control to wall with 2 screws (provided) (Fig. 3-4).

SAFE-T-BEAM® SYSTEM INSTALLATION

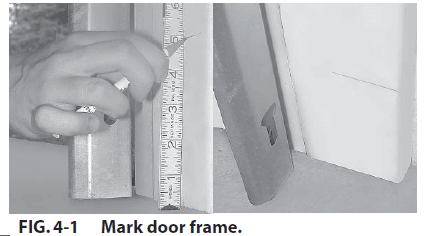

- Mounting brackets

- Mark both sides of garage door frame or wall no higher than 6″ and no lower than 5″ above floor (Fig. 4 1).

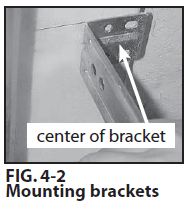

- Hold bracket against door frame or wall.

- Check if brackets extend out from wall far enough, so tongue of bracket is beyond door, tracks or any door hardware.

- If not:

- a) Mounting bracket extensions are available through an authorized Overhead Door dealer.

- b) Blocks of wood, etc. may be substituted for extensions.

- Locate top of bracket on your mark (Fig. 4-2).

- Fasten each with 2 screws (Fig. 4-2).

- Mark both sides of garage door frame or wall no higher than 6″ and no lower than 5″ above floor (Fig. 4 1).

- Mounting Safe-T-Beam® Source (Red LED) and Sensor (Green LED)

- If garage has only one garage door.

- Determine which side of garage receives most direct sunlight (Fig. 4-4).

- Red LED should always be on sunny side whenever possible (Fig. 4-4).

- For multiple doors.

- Preventing crossed signals is critical.

- Place source and sensor modules on adjacent doors facing in opposite directions (Fig. 4-4).

- Slide source/sensor onto tongue of bracket until it clicks into place (Fig. 4-3).

- Wiring (If NOT pre-wired)

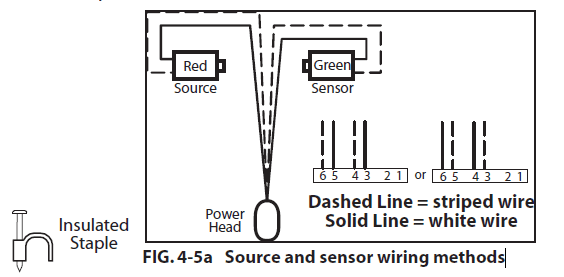

- Route wire from Safe-T-Beam® sensors to power head using method shown in (Fig. 4-5a).

- Securely fasten wires to wall and ceiling as you go (Fig. 4-6 on next page).

- Use insulated staples.

- Staples should be snug only.

- Route wire from Safe-T-Beam® sensors to power head using method shown in (Fig. 4-5a).

CONTACT REVERSE TEST

The force adjustments and limit switch settings MUST BE COMPLETED before testing.

- Testing

- Open garage door using Wall Control.

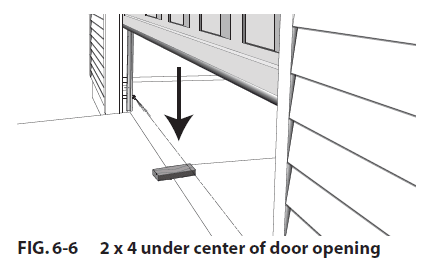

- Place a 2″ x 4″ board (laid flat) under center of garage door opening (Fig. 6-6).

- Close garage door using Wall Control.

- When door contacts board, the door must stop (within 2 seconds) and reverse direction returning to open position.

- Adjustment

- If the door does not properly reverse.

- Check to see if door has “close” limit programmed. It should not have reached its “close” limit before hitting board.

- If the door STOPS but does not reverse, decrease “CLOSE FORCE” CLOSE control setting slightly (turn it counter-clockwise).

- Test again. Repeat as necessary until door reverses upon contacting board.

PROGRAMMING REMOTE CONTROLS

- Single Button Remote Programming.

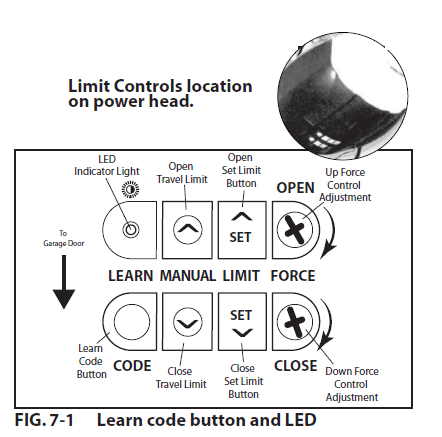

- Locate learn code button and indicator LED on the power head (Fig. 7-1).

- Press and release learn code button.

- Indicator LED will blink RED at a rate of twice per second.

- Within 30 seconds, push remote control button once.

- Indicator LED will stop blinking and stay ON.

- Press remote control button again.

- Red LED will go out. Remote is now programmed and ready for use.

- 1b. Multi Button Remote Programming

- Locate learn code button and indicator LED on the power head (Fig. 7-1).

- Operating.

- Press remote button once. Door will move.

- Press button again. Door will stop.

- Press button again. Door will move in opposite direction.

REMOTE CONTROL BATTERY REPLACEMENT AND VISOR CLIP INSTALLATION

- Battery replacement

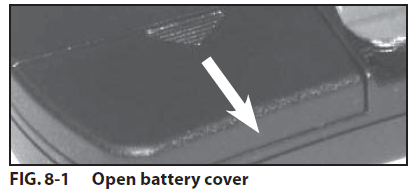

- To open, gently push straight out on battery cover lock tab as shown. (Fig. 8-1).

- Slide open battery cover.

- Remove old battery.

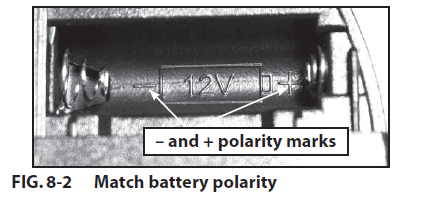

- Make sure new battery is facing proper direction (Match battery polarity with symbols inside battery housing) (Fig. 8-2).

- Recommended replacement battery type: Alkaline A23, 12 volt.

- To open, gently push straight out on battery cover lock tab as shown. (Fig. 8-1).

- Visor clip

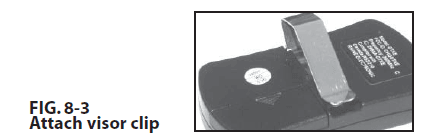

(The visor clip may come already installed.) You will have to install the visor clip if you choose to attach our remote to the car visor.- Slide visor clip into back of remote control.

- It will snap into place (Fig. 8-3).

LIGHT BULB/LENS INSTALLATION

- Light bulb

- Recommendations.

- Do NOT use a short neck bulb.

- Light bulbs should be no more than 60 Watts.

- Use a heavy duty service bulb for longer life.

- Screw 1 bulb into each socket.

- Lens

- Select a white (lamp) cover.

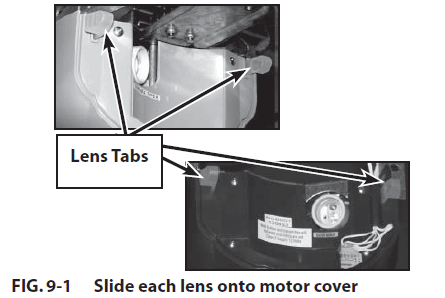

- On the power head end nearest the garage door, line up lamp lens tabs on power head with corresponding slots in lens (Fig. 9-1).

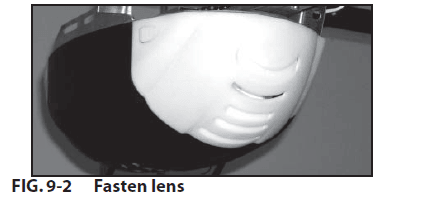

- Slide lens onto power head. Make sure the tabs are fully engaged into lens slots (Fig. 9-2).

- Repeat for rear lens on power head.

- Plug power cord back into electrical outlet.

- Test lamp operation.

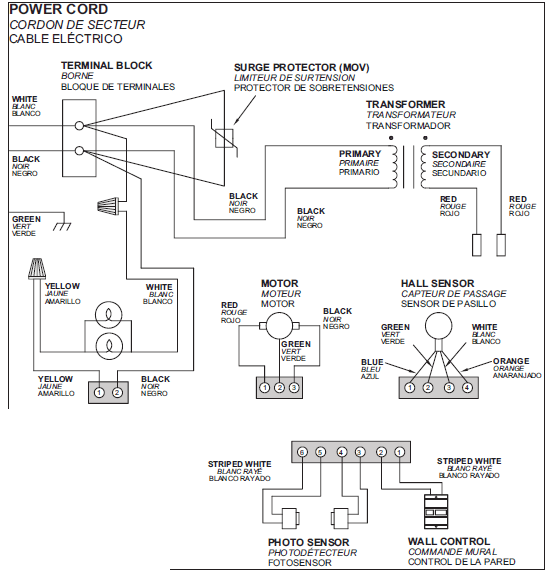

CIRCUIT WIRING DIAGRAM

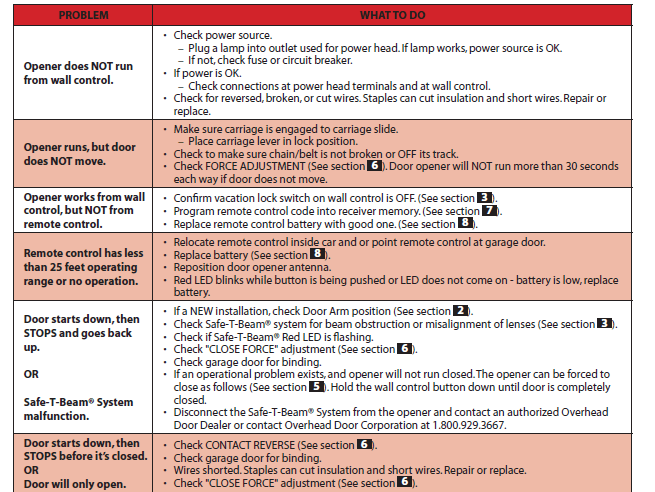

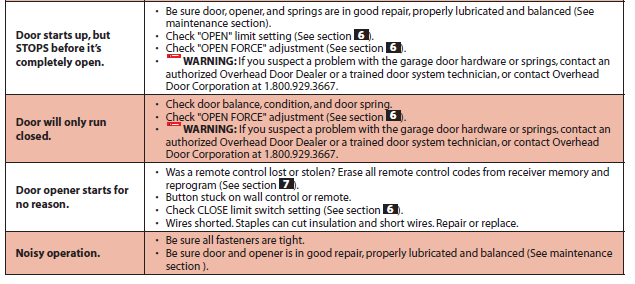

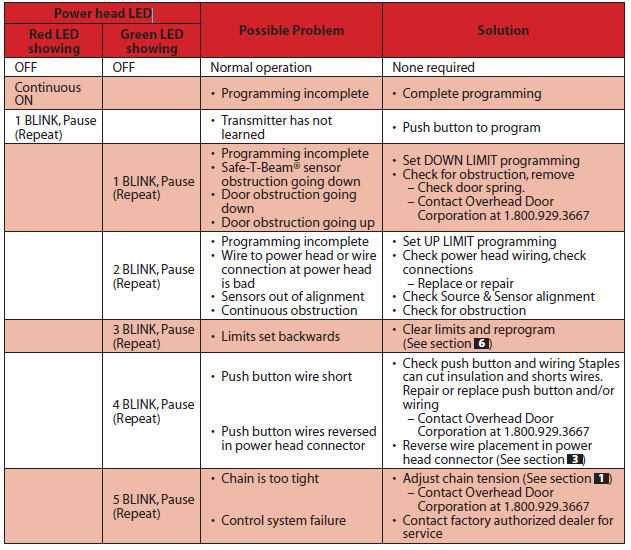

TROUBLESHOOTING GUIDE

For more manuals by Overhead Door visit, ManualsLibraryy

Overhead Door Legacy 800 Garage Door Opener-FAQs

How do you reset a Legacy garage door opener?

Press the learn button on the control unit (don’t hold it down). Then press and hold the Homelink buttons on your remote while someone presses the built-in Homelink button in your car. Release after you hear a click to complete the process.

What frequency does the Legacy garage door opener use?

The opener operates on both 315 MHz and 390 MHz frequencies, ensuring reliable performance even in areas with interference.

How do I program an overhead door opener?

1. Press the Learn Code button once (red LED will blink).

2. Enter your PIN.

3. Press the button with the arrow up/down triangles three times to complete the programming.

What is a keyless entry garage door?

A keyless entry system uses a keypad or wireless remote to operate the garage door. The keypad is installed near the door, and you can enter a code or use the remote for access.

Does Overhead Door have an app?

Yes, the OHD Anywhere™ app can be downloaded from your device’s app store for remote operation of your garage door.

How do I clear an Overhead Door remote?

To reset to factory settings:

1. Press and hold button #3 on the remote.

2. While holding #3, press button #4 four times.

3. The blue LED will blink and then turn off, indicating a reset.

Can I change the frequency of my garage door opener?

No, the frequency is built into the logic board of the motor unit and cannot be changed.

Does the Legacy 850 have Wi-Fi?

Wi-Fi is an optional feature available through OHD Anywhere™.

What frequency does the SD800 remote use?

The SD800 remote operates at 433 MHz.

How does an overhead garage door work?

The door uses torsion springs mounted horizontally above the door. As the door lowers, cables wind the springs to store energy. When the door opens, the springs unwind, releasing energy to assist in lifting the door.

FIG. 2-2 Finding highest point of travel

FIG. 2-2 Finding highest point of travel

FIG. 2-4 Position assembly and align

FIG. 2-4 Position assembly and align FIG. 2-5 Rail mounting to Header bracket

FIG. 2-5 Rail mounting to Header bracket FIG. 2-6 Mounting the power head

FIG. 2-6 Mounting the power head