Adexa 6G-TRM60 Commercial Gas Pasta Boiler

General information

- The appliance is equipped with a stainless steel tubular burner. It has flame failure protection function, thermostatic control function, pilot flame standby function, and pulse ignition function.

- Before installing the appliance, please read the instructions in this manual carefully, as they contain important information on how to install, use, and service the appliance safely, properly, and effectively.

- Keep this manual in a safe place so that it can be used as a reference by other operators of the appliance.

- This appliance should be installed following the instructions provided by the manufacturer and in compliance with all applicable local regulations. This appliance should be connected to the gas supply by qualified personnel only.

- All personnel in charge of using this appliance should be specifically trained in its operation.

- In the event of failure or malfunction, switch off the appliance. The periodic functional checks requested in this manual should be carried out according to the instructions. Have the appliance serviced by a technically qualified person duly authorised by the manufacturer who uses genuine spare parts.

- Failure to comply with the above may jeopardise the appliance’s safety.

Attention

- The appliance is only for commercial use, not for home use.

- When the appliance finishes work or the operator is not available to the appliance, please switch off the appliance and cut off the gas supply.

- Never use a water jet to flush the appliance in case of damage to the control components of the appliance.

- Please clean the stainless steel surface of the appliance periodically.

Warning

- The appliance is only suitable for gas with low pressure. When supplying LPG, it must use low pressure relief valve. It is prohibited to use any medium or high-pressure relief valve.

- Any refitting and wrong installation, adjustment and maintenance can cause property loss and casualty. Please contact the supplier if you need to adjust or maintain the appliance. And all these operations should be done by authorised professionals.

- Do not put flammable liquid, gas or other incendiary objects around the appliance for your safety’s sake.

- Do not change the positions of the air inlet port and flue gas outlet port.

- If there is a gas leakage from the appliance, please shut off the main gas valve immediately. Don’t press any electronic on/off button, and use any phones inside. Go outside and call the service centre to ask the professional staff to maintain it.

- The appliance can not be used empty. Ensure to fill water before the operation. Never ignite without water in the tank. Please watch the temperature of the water. No dry combustion, so as to avoid an incident!

Instructions for installation

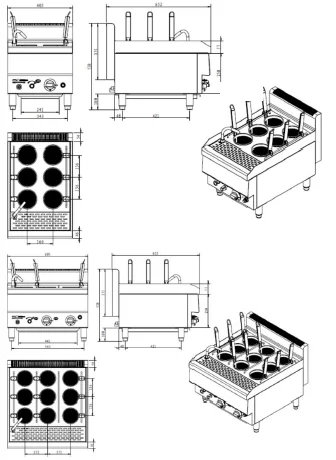

Installation drawings

Installation

- Before installing the product, verify that the type of gas (natural or propane) agrees with the specifications on the naming plate, which is located at the rear part of the unit.

- If a gas cylinder is used, please choose according to the local standard. The max diameter is 40cm, the max length is 1.2 meters. Put it in a dry, cool position.

- The appliance can be installed as a countertop type. Also, you can dismantle the 4 legs, and then screw the body to the cabinet, but first you should have a matched cabinet.

- The appliance should be both installed and serviced in accordance with all applicable regulations and standards in force.

- The appliance should be connected to a potable water supply in accordance with national regulations.

- Installing the appliance should be in accordance with EN1717 and national water regulations in force.

- The appliance is not suitable for built-in installation. Because the appliance will be working without enough oxygen supplying due to the restricted space, and the combustion products cannot be discharged from the kitchen immediately and completely, which is very harmful to the operators’ health.

- The appliance cannot be installed on an inflammable floor or other combustible objects. If the appliance is installed with its sides next to the walls, please keep a minimum clearance of 10cm away from the walls.

- The appliance should be installed in a well-ventilated area, if possible under a vent hood, in compliance with all applicable regulations in force. This will ensure that all burnt gases produced during the combustion process are completely exhausted.

- Prior to installation, remove all packaging materials from the appliance. Certain parts are wrapped up in adhesive film, which should be carefully removed. Remove any glue traces left on the appliance thoroughly using non-flammable solvents. It is forbidden to use abrasive substances.

- Check that the appliance is pre-set to use the gas family available at the place of installation. Make sure the supply gas is the same as the gas that the appliance allows us.

- If the available gas is different from the gas that the appliance requires to use, please don’t connect it, and mark the gas pipe with a yellow colour mark.

- The appliance should be connected to the gas supply by means of metal pipes –either rigid or flexible– having an adequate diameter. Any flexible hose or tubing that may be used for supplying gas can not exceed 1.5m

- The used gas supply tube or hose shall comply with the national requirement in form. The user should examine the gas tube periodically. If necessary, replace the tube or hose in time.

- When joining pipe fittings, never use oakum or Teflon, as their residues could get to the valve and jeopardise its operation. Instead, interpose a seal gasket suitable for use in gas systems. Do not forget to fit a shutoff valve on the gas supply line upstream of the appliance, which should be closed whenever the appliance is not in operation.

- A 3/4″ male BSP line for the gas connection is located near the lower right rear corner of the product. The serial plate indicates the type of gas the unit is equipped to burn (natural gas or propane). The product should be connected ONLY to the type of gas for which it is equipped.

- An adequate gas supply is imperative. Undersized or low-pressure lines will restrict the volume of gas necessary for satisfactory performance. A combination gas valve and pressure regulator, which is provided with each unit, is set to maintain a 2.0kPa manifold pressure for natural gas or a 2.75kPa/3.7kPa/5.0kPa manifold pressure for propane gas. Fluctuations of more than 25% on natural gas or10% on propane gas will create problems and affect burner operating characteristics.

- The available gas pressure should be the same as that indicated on the naming plate. If the gas pipe pressure is higher or lower than the rated pressure by 15%, please install a pressure regulator to adjust the gas pressure.

- After connecting the appliance to the gas system, check for leaks at joints and pipe fittings; to do so, use soapy water or a specific leak detector (spray).

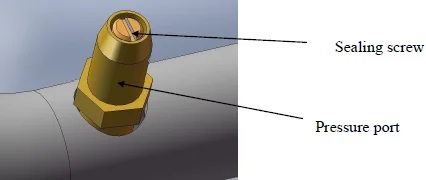

- Checking gas supply pressure after installation. Gas supply pressure can be measured with a liquid-filled pressure gauge (for example, a U-shaped pressure gauge, minimum scale division 0.1 mbar) or a digital gauge. Procedure as follows:

- Remove the panel, unscrew the screw on the pressure port (picture 2)

- Place the pressure gauge.

- Start up the appliance by following the instructions in the user’s manual.

- Check supply pressure.

- After the check, remove the pressure gauge.

- Replace the sealing screw

The appliance can not be used empty. Ensure to fill water before the operation.

The rear side of the vessel carries a permanently punched mark indicating the maximum and minimum operating level of filling. Fill Water till the level is between the maximum and minimum marks. If the water is below the minimum mark, fill the water.

Ignition

- Prior to lighting, check all joints in the gas supply line for leaks. Use a soap and water solution. Do not use an open flame.

- After piping has been checked for leaks, fully purge the gas pipes to remove air.

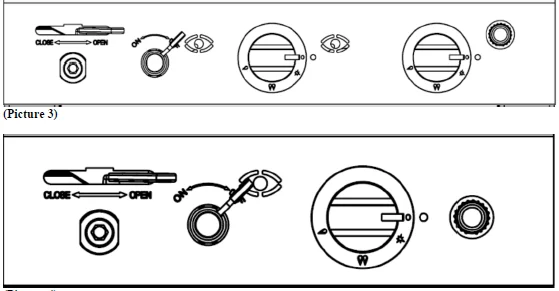

- Rotate the knob counter-clockwise; make sure the mark

on the knob is pointing to position 0.

on the knob is pointing to position 0. - Then push the knob, and press the impulse ignition device at the same time. (picture 6) ( It may take several times to ignite the flame, because there will be air in the pipe, only after air comes out, then gas flows in, and ignition can work.)

- When the pilot flame is ignited, after 20 seconds, please release your hand from the knob.

- Rotate the control knob to the position

, the burner is operating at maximum power.

, the burner is operating at maximum power. - Rotate the control knob to the position

, the burner is operating at minimum power.

, the burner is operating at minimum power.

Extinguish fire.

- Switch off the knob.

- Shut off the gas valve to cut off the gas supply to the burner.

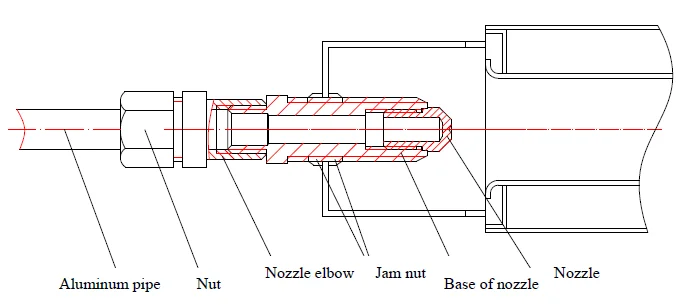

Replace the main burner nozzle, adjust the air inlet, and replace the pilot nozzle

Note: Layman is not allowed to replace the nozzle. (picture 5)

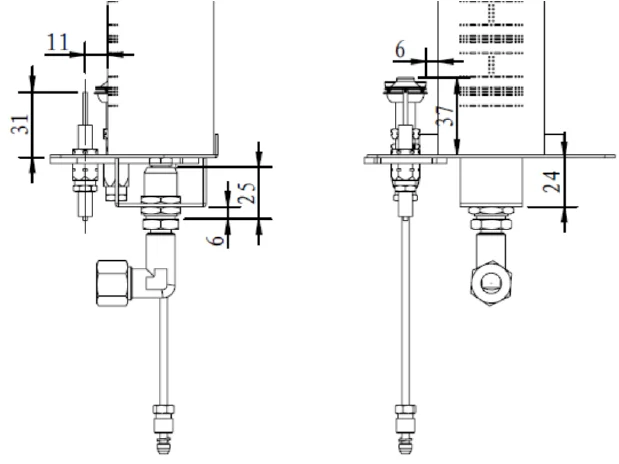

Move the base of the nozzle left and right to adjust the primary air

Adjust the orifice to the desired position. In the picture below, you can find the suggested position. The distance is between the burner base and the orifice.

Replace the nozzle of the main burner

- Prepare one Phillips screwdriver and two proper open spanners

- Dismantle the control panel, and then remove the nut and aluminium pipe, dismantle the joint of the nozzle, unscrew the jam nut, remove the nozzle and replace a new proper nozzle.

- Screw the two jam nuts, and fit all the dismantled parts again. Finally, fit the control panel.

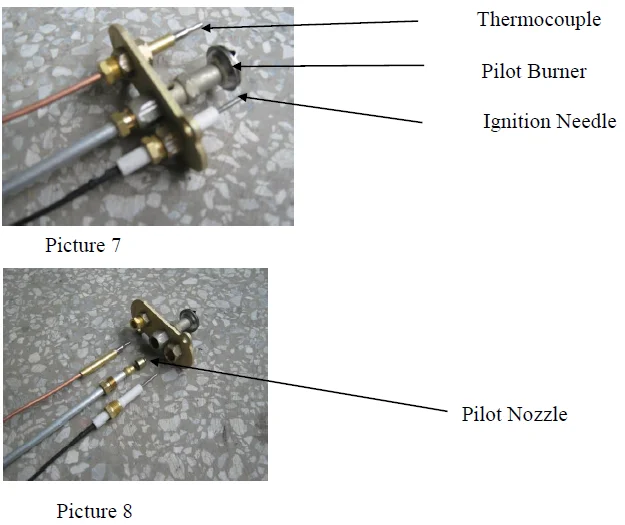

Replace the pilot nozzle

Use a proper spanner on the nut of the nozzle to balance the torsional stress. Then unscrew the screw of the thermocouple and the aluminium pipe, and dismantle the thermocouple and the aluminium pipe. Remove the pilot nozzle, and then replace a new proper one. There is no need to adjust the primary air.

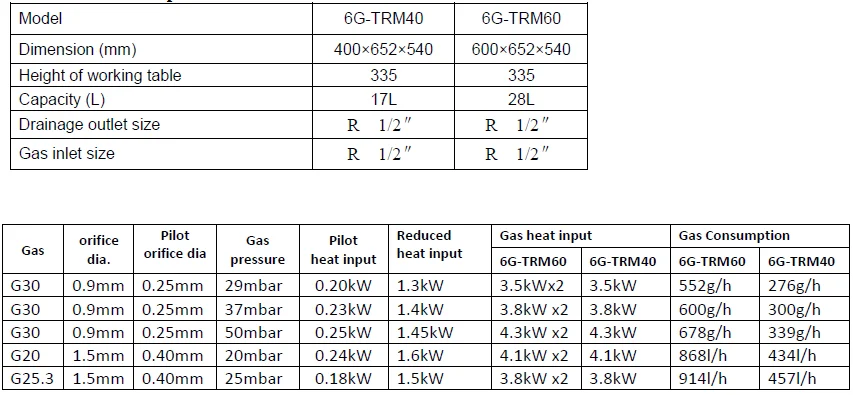

Technical specifications table

Use and Maintenance

Attention to use

- The appliance is designed to cook pasta. Any other usages are not permitted.

- Before using, please clean the water tank first:

- Use the towel to wash it clean with neutral detergent, and finally rinse it with water.

- Don’t use hard detergent, steel wire or sharp tools to scrape the surface of the appliance, in case of damage to it.

- Don’t use a water jet to directly flush the body of the appliance, and don’t use a detergent that contains corrosive substances, such as hydrochloric acid, to wash the surface of the appliance.

- Don’t change the air inlet port and flue gas outlet port of the appliance in case of serious accidents occurring.

- If the appliance will remain idle for a certain period of time, clean it and wipe it dry first, and then apply a film of a suitable product (such as vaseline oil spray or similar products) to protect it. Shut off the gas and power supply upstream of the appliance.

- Only qualified personnel are allowed to carry out service and maintenance operations. The following maintenance operations should be performed at least once a year:

Checking for proper operation of all control and safety devices;

Checking burner combustion, i.e.:

- ignition;

- combustion safety;

- checking for proper operation throughout the entire HIGH-to-LOW control range.

- All packaging materials must be disposed of in compliance with applicable local regulations in force where the appliance is being installed. Packaging materials should be separated according to their types and delivered to specific collection sites. Ensure compliance with environmental protection regulations.

Scald Warning

- When the appliance is working, don’t directly touch the surface of the appliance with your hands in case of scald.

Troubleshooting

Cannot ignite the pilot flame:

- The installation or the connection of the igniter is wrong. Please install the ignitor correctly.

- The igniter’s plug or the wire of the plug is broken. Please replace a new one.

- The gas pressure is not enough. Adjust the relief valve to get a proper pressure.

- The nozzle is blocked. Please unblock the nozzle.

- The connection of the thermocouple is not good. Please fasten the connection.

- The thermocouple is damaged. Replace a new one.

- The gas control valve has a problem. Ask the professional people to repair or replace a new one.

The pilot flame is on, but the main burner can not be ignited.

- The gas pressure is not enough. Adjust the relief valve to get a proper pressure.

- The nozzle of the main burner is blocked. Unblock the nozzle.

- The gas control valve has a problem. Ask the professional people to repair or replace a new one.

Turn off the gas valve, and it has a lit-back sound.

- The diameter of the nozzle does not match the gas source. Please adjust the nozzle diameter.

- The gas pressure is too low. Adjust the relief valve.

It has red flame and black smoke.

- The diameter of the nozzle does not match the gas source. Please adjust the nozzle diameter.

- The gas is nearly used out. Replace the gas.

- Reduce the gas flow.

ADEXA DIRECT LIMITED

Unit 1, Swift Point, Cosford Lane, Swift Valley Industrial Estate, Rugby, CV21 1QN, UK

T:+44 1788 222 410

For more Manuals by Adexa, visit ManualsLibraryy

Adexa 6G-TRM60 Commercial Gas Pasta Boiler-FAQs

What is a pasta boiler?

A pasta boiler is a commercial kitchen appliance designed to boil large quantities of pasta quickly and efficiently. It is durable, easy to clean, and ideal for heavy-duty use in restaurants.

How does a commercial pasta boiler work?

The boiler heats a water tank using gas burners (or electricity in some models) until it reaches boiling temperature. Baskets are used to submerge pasta for fast, even cooking.

What can I cook in the Adexa pasta boiler besides pasta?

Besides pasta, you can boil vegetables, eggs, rice, noodles, dumplings, and other foods that require hot water cooking.

What is the purpose of a pasta machine and how is it different?

A pasta machine rolls and cuts dough to make fresh pasta sheets or shapes. A pasta boiler, like the Adexa 6G-TRM60, is for boiling pasta, not making dough.

What materials or equipment are commonly used in commercial cooking?

Commercial kitchens use stainless steel appliances such as burners, stock pots, grills, ovens, tandoors, and boilers—made for durability and hygiene.

What is the basic working principle of a boiler?

A boiler heats water by burning fuel. Heat transfers from the flame to the water tank, producing boiling water or steam for cooking.

How do I cook pasta properly in a commercial boiler?

Fill the tank, heat the water to a rolling boil, add salt, place pasta-filled baskets into the water, stir occasionally, cook until al dente, then lift and drain.

How do I drain water from the pasta boiler?

Most commercial pasta boilers have a built-in drain valve. Allow the unit to cool slightly, open the valve carefully, and let the water flow into a safe drainage area.

How much water should I use in a pasta boiler?

Fill the tank to the marked maximum level. Overfilling or underfilling affects boiling performance and safety.

How do I clean a pasta boiler?

After turning it off and cooling, drain the water, remove food residue, scrub the tank and baskets with warm soapy water, rinse thoroughly, and dry before next use.