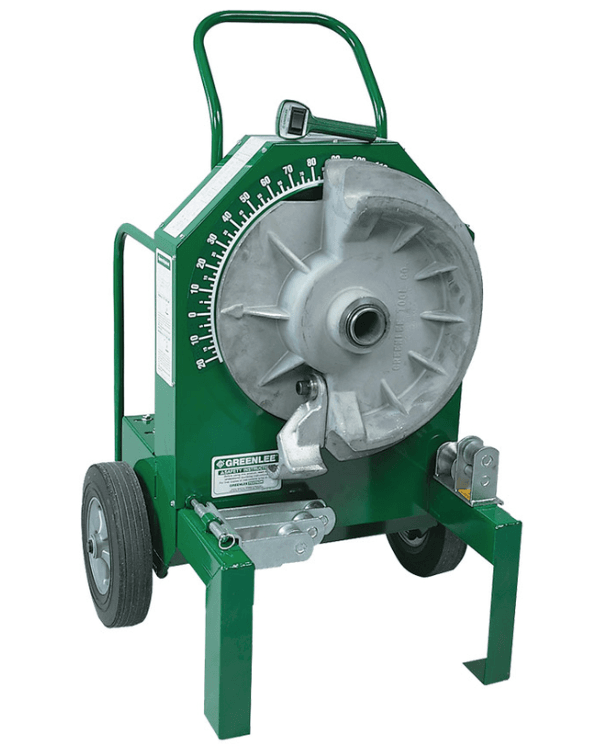

Greenlee 555 Electric Conduit Bender

IMPORTANT SAFETY INFORMATION

WARNING:

Extension cords:

- Use only three-wire, 12-AWG extension cords that have three-prong grounding-type plugs and

three-hole receptacles that accept the tool’s plug. - Do not use extension cords that are longer than 30 m (100′).

- Repair or replace damaged extension cords. Failure to observe these warnings could result in severe injury or death.

Make sure that the handle is properly installed and secured with the safety spring clips and snap pins before lifting or moving the bender. An improperly installed handle could allow the bender to fall, injuring nearby personnel. Failure to observe this warning could result in severe injury or death.

Pinch points: Keep hands away from bending shoe, rollers and conduit when bender is in use. Failure to observe this warning could result in severe injury or death.

Unplug the bender before changing accessories. Accidental startup could result in serious injury.

CAUTION:

Conduit moves rapidly as it is bent. The path of the conduit must be clear of obstructions. Be sure clearance is adequate before starting the bend.

- Do not operate the bender while wearing loose clothing. Loose clothing can get caught in moving

parts. - Inspect the bender before use. Replace worn, damaged or missing parts with Greenlee replacement parts. A damaged or improperly assembled component could break and strike nearby personnel.

- Some bender parts and accessories are heavy and may require more than one person to lift and

assemble. - Use only accessories and attachments recommended by Greenlee.

- Do not stand on the bender; the bender may tip over.

- Do not leave the tool running unattended. Do not leave the tool until it comes to a complete stop. Turn the power off and unplug the tool after use.

- Ensure that all bystanders are away from the work area when operating the bender.

- Ensure that the work area is clean, dry, uncluttered, and well-lit.

- Use this tool for the manufacturer’s intended purpose only. Use other than that which is instructed in this manual can result in injury or property damage. Failure to observe these precautions may result in injury or property damage.

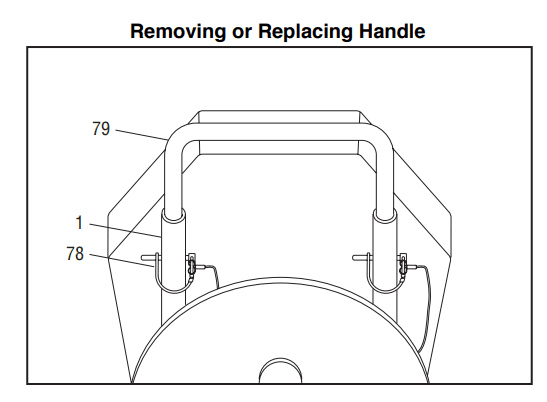

Handle Removal and Replacement

The handle of the 555 is designed to be removable. This feature is convenient when performing complex bending, and makes it easy to replace a damaged handle.

Removal

- Place the bender in the upright position.

- Release the spring clip on the safety snap pin (78).

- Remove the pin from the handle (79) and the sleeve of the frame (1).

- Repeat Steps 1 through 3 for the other end of the handle.

- Lift the handle to remove.

Replacement

- Insert the handle (79) into the sleeves of the frame (1).

- Align the holes in the handle with the holes in the sleeves.

- Insert the safety snap pin (78). Ensure that the pin goes through the handle and the sleeve on the frame (1).

- Engage the safety spring clip over the end of the pin. Ensure that the loop on the clip is completely around the pin.

- Repeat Steps 2 through 4 for the other end of the handle.

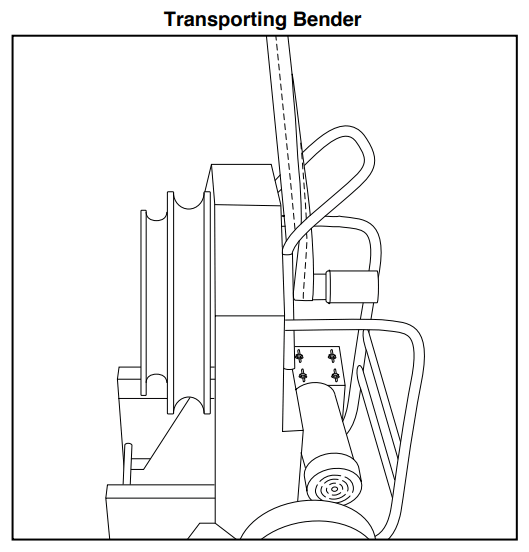

Transportation

WARNING: Make sure that the handle is properly installed and secured with the safety spring clips and snap pins before lifting or moving the bender. An improperly installed handle could allow the bender to fall, injuring nearby personnel. Failure to observe this warning could result in severe injury or death.

The only proper way to lift this bender is by attaching a nylon or polyester sling around the storage spindle. The sling should extend between the handle and the main frame of the bender so that the handle acts as a guide for the sling, as shown.

Make sure that all components used to lift this bender are properly rated for the 167 kg (368 lb) weight. Use a ramp to load and unload from a truck or other vehicle that is not equipped with a lift gate.

Maintenance

There is no need for periodic flushing and replacing of lube in the bender gearbox since it is sealed and locked tight. However, if the box is opened for repair and the lube is lost or contaminated by dirt, then the box and parts should be flushed out and filled with 26 fluid ounces of Mobil® 634 synthetic oil. Flushing should be accomplished with kerosene, which is a petroleum hydrocarbon that does not affect seals.

Note: Aromatic hydrocarbons such as benzine, chlorinated solvents such as carbon tetrachloride, and

ketones such as acetone should never be used for flushing as they are solvents for rubber. They are also

harmful to the environment.

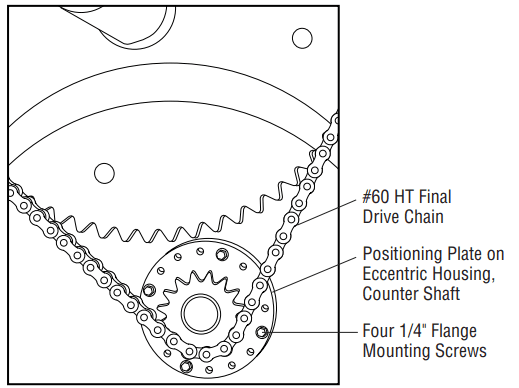

Chain Adjustment

Both chains have to be adjusted if the final drive #60 chain is to be reset. Refer to the Exploded View and

Parts List.

- Remove the front cover (38) and upper rear guard (37).

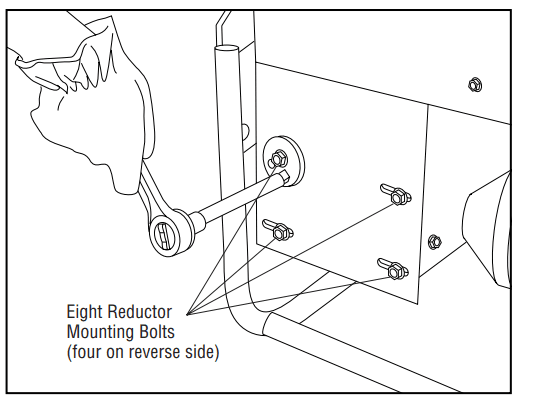

- Loosen the eight mounting bolts for the reductor (19). Remove the eccentric cam and move the

reduction to create chain slack. - Remove the four retaining screws for eccentric adjustment. Rotate to remove slack from the chain

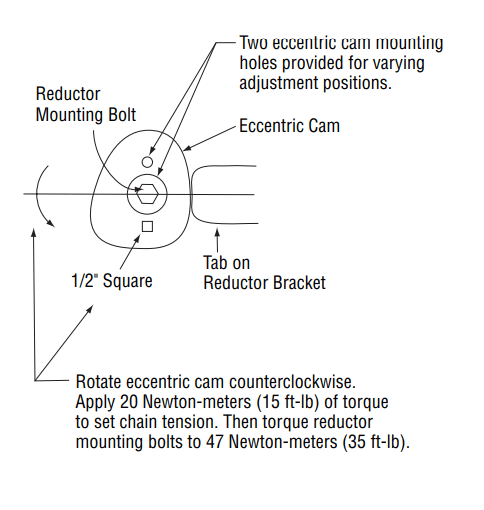

and align with one of the two sets of holes in the frame. Remount the eccentric with the four bolts. - Slide the reduction in slotted mounting holes to the retention chain. Set tension with the eccentric cam.

With the eight reduction mounting bolts (22, 24) loose, rotate the eccentric cam with a 1/2″ square drive to tension the chain. Torque the eight reduction mounting bolts to 47 Newton meters (35 ft-lb).

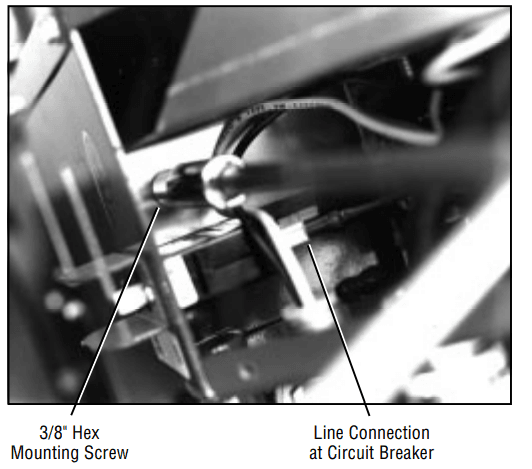

Electrical Control Unit Removal

- Remove the cover retained by ten 5/16″ hex screws.

- Disconnect the pendant switch plug from the circuit board and remove it through the cord grip.

- Remove two hex mounting screws, one on each side.

- Remove the motor leads, power cord ground wire, and neutral wire before the control unit can be totally removed from the bender.

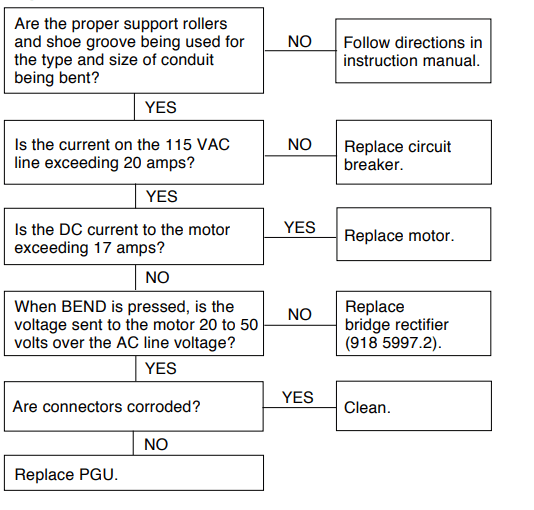

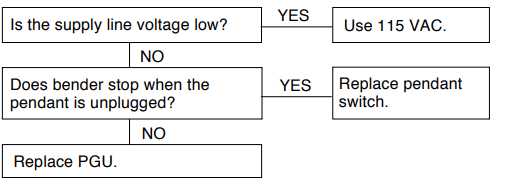

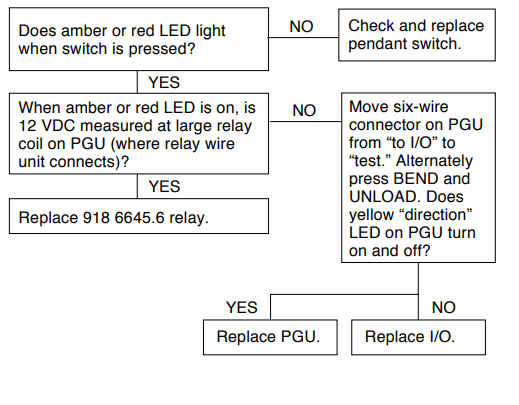

Troubleshooting

The following flow charts show the suggested troubleshooting procedures for some bender problems. They by no means encompass all possible problems or solutions.

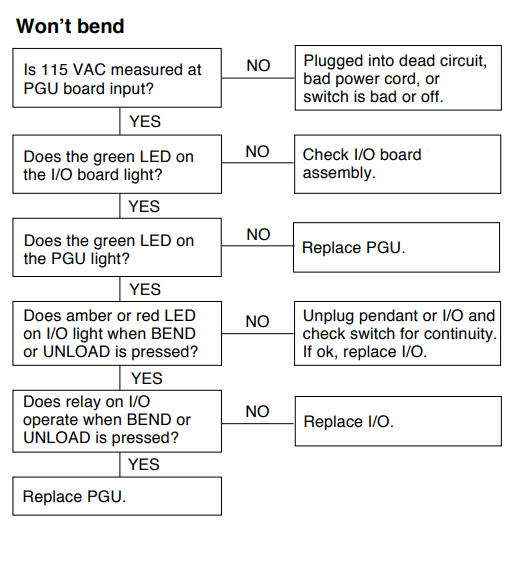

Won’t bend

Trips circuit breaker

Won’t stop

Bender only runs in one direction

Quick diagnostics for electronic problems

- With the bender unplugged, switch the six-wire connector on PGU from “To I/O” to “Test.”

- Plug the unit in.

- Press BEND. The contactor on I/O will activate.

- If not, check for 12 VDC at the contactor coil— If 12 VDC is present, replace contactor 918 6645.6—else replace I/O

- If Bender runs, replace PGU.

- On PGU near the “test” connector:

- Green “Power” LED is ON

- Yellow “Direction” LED is OFF

- The red “PWM” LED slowly turns dimly on If not, replace I/O.

- Press UNLOAD. The contactor on I/O will activate.

- If not, check for 12 VDC at the contactor coil — If 12 VDC is present, replace contactor 918 6645.6—else replace I/O

- On PGU near the “test” connector:

- Green “Power” LED is ON

- Yellow “Direction” LED is ON

- The red “PWM” LED slowly turns dimly on

- If not, replace I/O.

- Press BEND. With the insulated object, carefully press the black button “S1” on PGU. Bender will run slowly. If not, replace PGU.

For more manuals by Greenlee, visit ManualsLibraryy

Greenlee 555 Electric Conduit Bender-FAQs

What is the largest conduit size the Greenlee 555 bender can handle?

The Greenlee 555 can bend 3/4″ Rigid (using the 1” Rigid or 1” EMT shoe grooves) and 1” to 2” Rigid, EMT, or IMC conduit. It features smart sensors that automatically account for spring-back.

What is a 555 bender?

The Greenlee 555 bender is an electrically-powered device designed to reshape pipes or tubes to precise angles or curves for various applications.

How many bends are allowed in a conduit run?

A conduit run can have a maximum of four quarter bends, equivalent to 360° total, between pull points such as boxes or conduit bodies.

What are the common conduit bend angles?

The most common configurations are a 45° center bend with two 22-1/2° outer bends, or a 60° center bend with two 30° bends. The same calculation method applies to both configurations.

What is the function of a conduit bender?

A conduit bender reshapes pipes or tubes to specific angles, making them suitable for various plumbing, electrical, and construction applications.

Why is it called a “bender”?

The term “bender” likely originates from the act of bending pipes or possibly from the phrase “getting bent out of shape.”

What is the strongest type of bending?

In specialized contexts like fiction, “bloodbending” is considered the strongest. In real-world applications, the strength of a bender depends on its design and the material it is bending, with electric-powered benders like the Greenlee 555 being highly efficient.

How many degrees is a quarter bend?

A quarter bend equals 90°.

What is the conduit rule?

In general conduit guidelines, bends must not exceed 360° between pull points. In other contexts, like HIPAA’s Conduit Exception Rule, it refers to entities that transmit data without storing or accessing it.