Gilbarco PAM 5000 Veeder-Root Pump

Tools Required for Installation

- Large Slotted Screwdriver

- Small (max 5.mm) Slotted Screwdriver

- Drill & Fasteners (to secure PAM 5000 to the wall)

System Overview

This Launch Package is to help familiarize you with the Gilbarco PAM 5000. This document should not be used as a replacement for parts, service, or installation manuals. In this Launch Package you will find a list of documents (Manual References listed above) related to the Gilbarco PAM 5000 that should be used for reference should more information be needed. These documents should be used when performing service work of any kind on this product. All of the listed documents can be found on the Gilbarco website GOLD on the Gilbarco Extranet (www.gilbarco.com). Always use the most current documentation when servicing this product.

What is a Gilbarco PAM 5000?

The PAM 5000 is a system based on the Gilbarco PAM 1000 Controller. It will be able to replace the old system with full compatibility. The PAM POS protocol is based on the PAM 1000 software version 32.1.60 and the PAM 1000 Interface specification.

The PAM 5000 will support the PAM protocol using different communication speeds (300-19200 baud rate) and different protocol options (24 or 36 Pump support). The physical serial interface to the POS is based on Hardware Interface Module (HIM) DSB 500 supporting RS232/RS422 or CL 45mA passive, selectable at the wiring time. By default, the PAM 5000 basic system will handle up to 16 fueling positions. For sites swapping out the PAM 1000 for the PAM 5000 and the D/Box is reused, the default can be changed to 12 fueling positions per PAM port. An extra CL hardware interface module would be needed if the number of fueling points is higher than 12. For new sites, the default will be 16 fueling points per PAM port with the third board then supporting 4 fueling points if needed.

The physical connection is made with a Gilbarco HIM module DSB492 (maximum of eight dispensers or 16 fueling positions per module). The system will come with the necessary DSB500 and DSB492 modules per the site’s configuration. If the site has more than 16 fueling positions then another DSB492 module will be needed. The system would just need a simple setup change to the PAM configuration and no software upgrade would be necessary. The PAM 5000 is replacing the PAM 1000 because parts for the PAM 1000 are going to end-of-life and will become obsolete by the summer of 2008.

Features/Benefits of the PAM 500

- Better performance

- Simple & easy to expand

- Ethernet connection and Service port (RS-232) with TCP/IP available for remote service and monitoring

- Built-in web server

- Easy software update to flash memory

- No jumpers are needed. All changes made via the web, locally, or remote

- Local display for service and status monitoring

- Devices can be monitored on the local display or via the web

- Port statistics (errors) can be monitored

- Transaction and device status monitoring

- Port communication log (Can see which ports are communicating)

- Adds remote diagnostics to troubleshoot POS to PAM issues

- Allows elimination of the Distribution Box

Commissioning the Equipment

Before leaving the site you must commission the equipment so that the warranty can start. Failure to do so will cause problems with attempting to open/close service and calls and getting paid for work completed thereafter. Please call 1-888-800-7498 listen to the menu and select the Commissioning option.

Parts/Descriptions for the PAM 5000

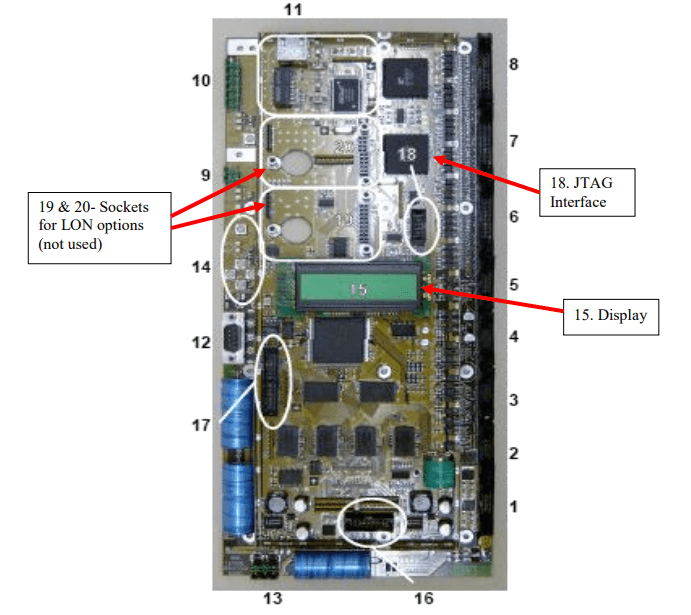

Central Processor Board (CPB509) Part # M08037B010

- Port 11 DSB- This port is used for connecting to the PAM

- Port 12 DSB- This port is used for pump loop #1 (FP1-16 default or 1-12)

- Port 13 DSB- This port is used for pump loop #2 (FP17-32 default or 13-24)

- Port 14 DSB- This port is used for pump loop #3 (FP33-36)

- Port 15 DSB- Not used

- Port 21 DMB- This port is used to supply power for CRIND loop #1

- Port 22 DMB- Not Used

- Port 23 DMB- Not Used

- Port 31 LON- Not Used

- Port 32 LON- Not Used

- Port 41 Ethernet- This port has an Ethernet cable connecting to it, which leads to an external Ethernet port. That is used for downloading software to the CPB.

- Port 1/Service Port- This is an RS-232 connection that can also be used for downloading software to the CPB. It can also be used for Servicing and Diagnostics

- Power Supply Connector- A 3-Pin connector from the Transformer connects here

- Keyboard- The CPB has a 5-key keyboard called a local service panel that is used to access some programming if a laptop is not available. * Does not access all programming

- Display- The display is used in conjunction with the keyboard so programming options can be seen

- Test Connector- This connector is not used

- BDM Connector- This connector is not used

- JTAG Interface- This connector is not used at this time

- & 20- Sockets for LON options (These are not used at this time)

The CPB is a microprocessor-based controller for use in the PAM 5000 forecourt controller system. It is equipped with the following:

- 5 DSB ports

- 3 DMB ports

- 1 Ethernet interface

- 2 LON interfaces (add-on options)

- 16MB Flash memory for application software

- 4MB SRAM for data memory

A keyboard consisting of 5 keys together with a 32-character LCD display makes it possible to adjust and monitor several parameters without the need for connecting an external PC. A battery is used for data and a real-time clock in case of a power failure.

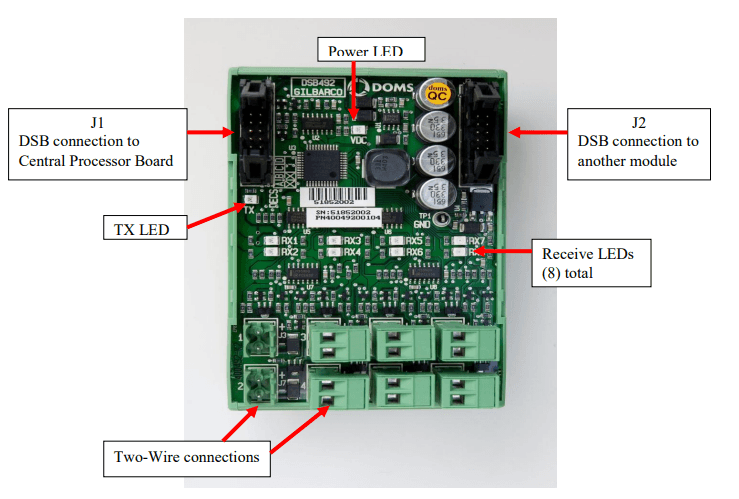

Current Loop Interface Module (DSB 492)

Part # M08037B001S

The Current Loop Interface Board connects to the DIN rail and the Central Processor Board. The Central Processor Board provides the voltage and communication information to the Current Loop Interface Board via a ribbon cable. The Current Loop Interface Board uses ports 12 through 14, which are located on the Central Processor Board. Each board is equipped with 8 LEDs for status indications. It supports the required 45ma needed, and 8 dual or 16 single dispensers for a total of 16 fueling positions.

LEDs

- Yellow = Power (VDC)

- Green = Transmit

- Red = Receive (8 LEDs)

VDC indicates power is present. TX is flashing when data is transmitted from the DSB 500 and the RX is flashing if data is received from the connection. The DSB492 drives a total load of 5.0-volt idle voltage. This voltage makes the sum of the idle pump load, the connection wire drop, and the noise margin.

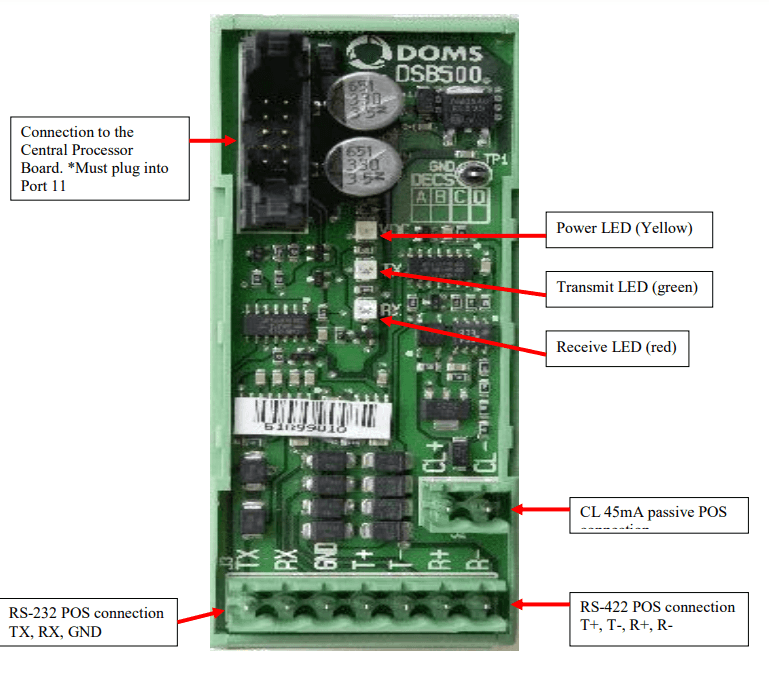

RS-232/RS-422/CL Interface Module (DBS 500)

Part # M08037B002S

This module is the interface between the POS and the Central Processor Board. It supports communication baud rates for the POS between 300 and 19200. This module supports RS-232 (any runs between the PAM 5000 and the POS longer than 50ft. require a line booster) as well as RS-422, current loop 45 mA, which if the POS supports it can run much longer distances without needing a line booster.

PAM 5000 Parts Breakdown

Gilbarco Part # DOMS Part # Description

| M08037B003 | 140718 | Fuse, slow blow, 5x20mm, 1A, IEC127-2/3 |

| M08037B004 | 138484 | Fuseholder, for insertion in AC inlet |

| M08037B005 | 141636 | PAM CRIND Cross Ribbon Cable DSMB no 42 |

| M08037B006 | 126678 | DSB-cable mini, 2.7“/ 7cm, DSB no 23 |

| M08037B007 | 135695 | DSB-cable 7.8” / 42cm, DSB no 33 |

| M08037B008 | 133088 | AC Filter without fuse holder (add M8037B004 to complete) |

| M08037B009 | 140109 | Power Supply Transformer, 120V/24V, 36VA, toroid |

| M08037B010 | 138552 | Central Processor Board (CPB509) |

| M08037B011 | 135547 | Internal Ethernet Cable, 25”/65cm (CBL311 type 001) |

| M08037B012 | 135391 | Ethernet Connection Board (DCB460) |

| M08037B002S | 141662 | RS232/RS422/CL interface module (DSB500) |

| M08037B001S | 140042 | Current Loop 45mA Interface Module, 8 connections (DSB492) |

| Q11121 02 | 141666 | Power Cord, grounded US plug NEMA 5-15, IEC320, 78” / 2m black |

| Q11736 03 | 138243 | Power Cord without a plug for wall end, IEC320, 59” /1.5m black PVC |

| R19000-02 | Pigtail for PAM to D-Box cable | |

| R19000-03 | Pigtail for POS to PAM cable | |

| R19000-04 | Pigtail for PAM to D/Box cable (CRIND Control) | |

| PA03820000 | PAM 5000 |

For more manuals by Gilbarco, visit ManualsLibraryy

Gilbarco PAM 5000 Veeder-Root Pump-FAQs

What does Gilbarco Veeder-Root do?

Gilbarco Veeder-Root provides fuel dispensers, point-of-sale systems, payment solutions, forecourt merchandising, and support services for fuel stations.

How do I fix error code 31 on Gilbarco pumps?

Error code 31 indicates a power issue, such as unplugging without turning off the battery, a dead battery, or a blown fuse. To fix this, perform a RAM reset using Command Code 6 in Level 1 Command Codes.

What does error code 4322 mean on Gilbarco pumps?

Error code 4322 means the nozzles were off during power-up. Turn off the power, raise or activate the nozzles, and then restore power. The error should clear.

What is the purpose of the Veeder-Root system?

The Veeder-Root system is an automatic tank gauge (ATG) that monitors storage tanks’ use, compliance, and performance, whether aboveground or underground.

What is the function of a fuel dispenser?

A fuel dispenser pumps various fuels like gasoline, diesel, CNG, LPG, ethanol, or biodiesel into vehicles at filling stations.

Why do gas station pumps sometimes flow slowly?

Slow fuel flow is often caused by clogged filters, which can occur due to age. Filters should generally be replaced annually to maintain efficiency.

What is a DP flow meter?

A differential pressure (DP) flow meter measures the flow of liquids, steam, or gases in pipes using Bernoulli’s principle.

What is the Gilbarco protocol?

The Gilbarco Two-Wire Protocol is a standard communication protocol for fuel dispensers, ensuring secure and efficient data exchange between the dispenser and the POS system.

How do I resolve error code 12 on a Gilbarco pump?

Error code 12 indicates a keylock option change. Reprogram the Keylock Option using Command Code 4, Function Code 2, then power down, turn off the battery, and power up again.