Husky HU80722 Pressure Washer

PRODUCT SPECIFICATIONS

- Engine…Honda GCV160

- Fuel Tank Capacity.….48 gal (1.8 liters)

- Maximum Pounds Per Square Inch Pressure…. 2,600 psi

- Maximum Gallons Per Minute.….2.3 gpm

- Maximum Inlet Water Temperature…..104˚F

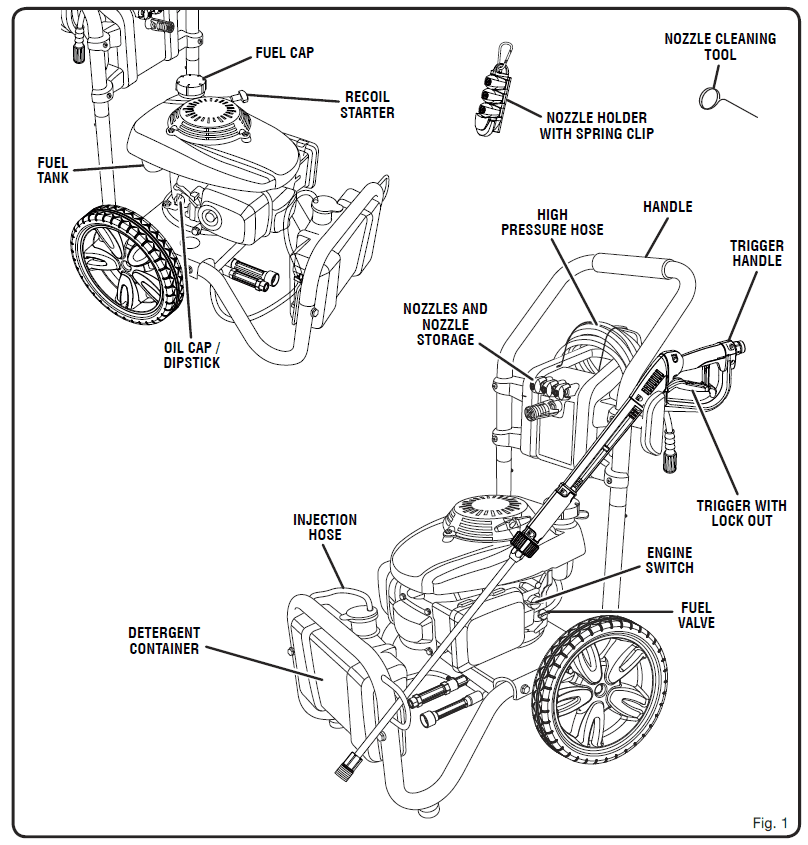

KNOW YOUR PRESSURE WASHER

- See Figure 1.

- The safe use of this product requires an understanding of the information on the tool and in this operator’s manual as well as a knowledge of the project you are attempting. Before using this product, familiarize yourself with all operating features and safety rules.

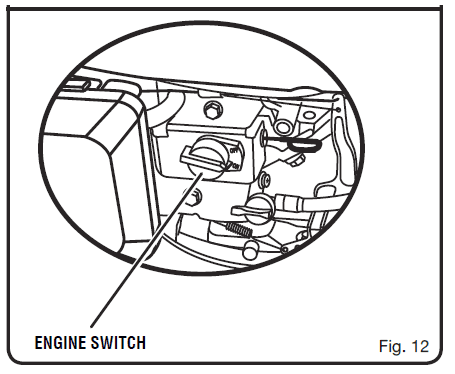

- Engine Switch

- The engine switch is used in combination with the recoil starter grip to start the engine. It is also used to turn the engine off.

- Fuel tank

- This fuel tank has a maximum capacity of .48 gal. (1.8 liters). Use unleaded automotive gasoline in the engine.

- HONDA GCV160 ENGINE

- This Honda engine enables the pressure washer to achieve 2,600 psi (pounds per square inch) at a rate of 2.3 gpm (gallons per minute). Please read the engine manual included with this product.

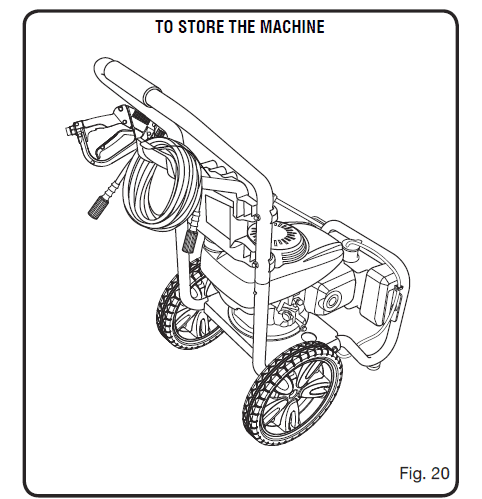

- HOSE Storage

- Once the high-pressure hose is rolled, hang it on the back of the machine using the stretch strap to secure it in place.

ASSEMBLY

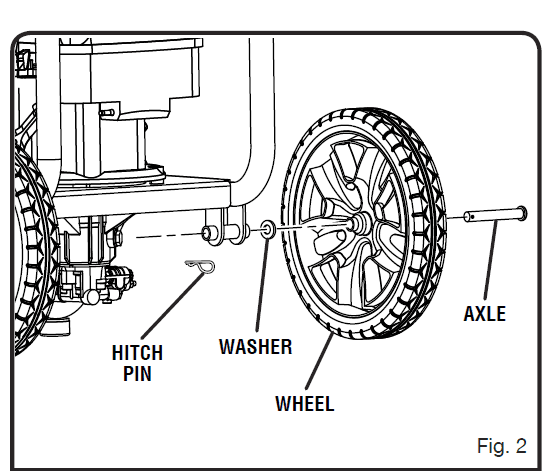

Attaching the wheel assembly

- See Figure 2.

To attach the wheels to the pressure washer base:

- Locate the axle, hitch pins, washers, and wheels. Remove the hitch pin from the axle.

- Slide the axle through the hole in the center of the wheel.

- Slide the washer onto the axle.

- Lift the machine and slide the axle into the wheel mounting hole in the machine base as shown.

- Push the hitch pin into the hole on the end of the axle to secure the wheel assembly.

- NOTE: The hitch pin should be pushed into the axle until the center of the pin rests on top of the axle.

- Repeat with the second wheel.

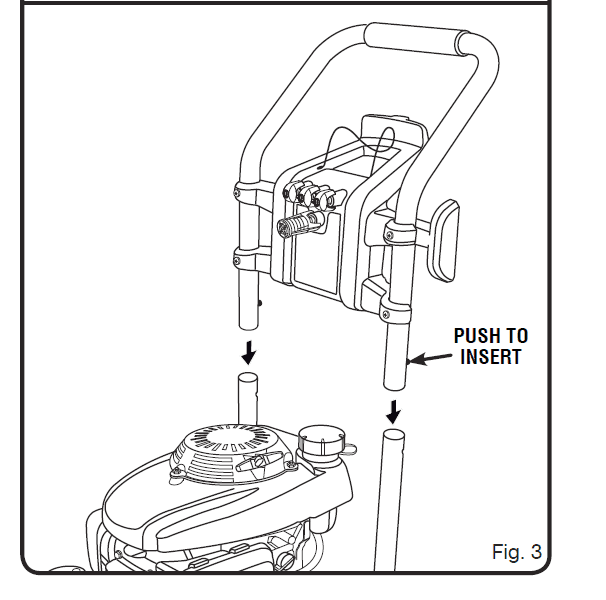

Installing the handle

- See Figure 3.

To install the handle:

- Push and hold the button on the handle as you slide the handle into the holes in the frame.

- NOTE: Before use, pull the handle up until the lock button snaps through the locking slot to secure the handle in place.

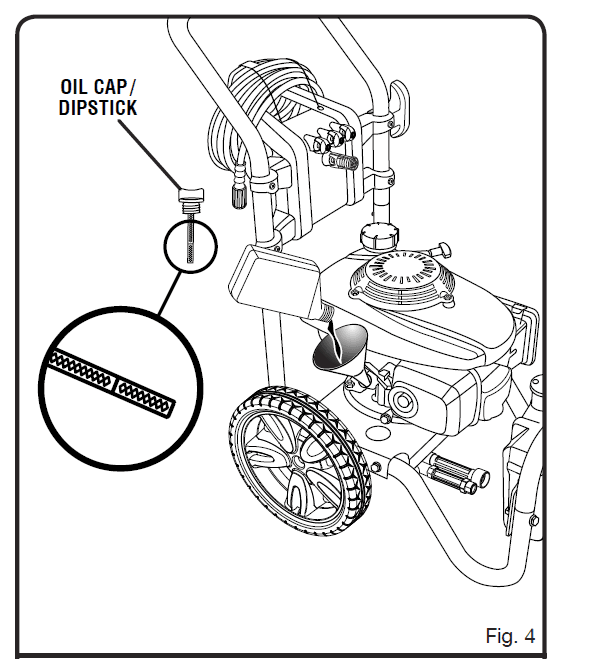

Adding Lubricant to the engine

- See Figure 4.

- NOTE: This machine has been shipped with approximately 2 oz. of lubricant in the engine from testing. You must add lubricant to the engine before starting it the first time.

- Place the pressure washer on a flat, level surface.

- Unscrew the oil cap/dipstick by turning counterclockwise.

- Using 4-stroke engine lubricant (SAE 30 or SAE 10W30), fill to the upper level of the oil filter neck (18 oz., 4-cycle engine lubricant provided).

- Replace the oil cap/dipstick and securely tighten it.

- NOTE: This engine has a total lubricant capacity of 20 oz. (.6 liters).

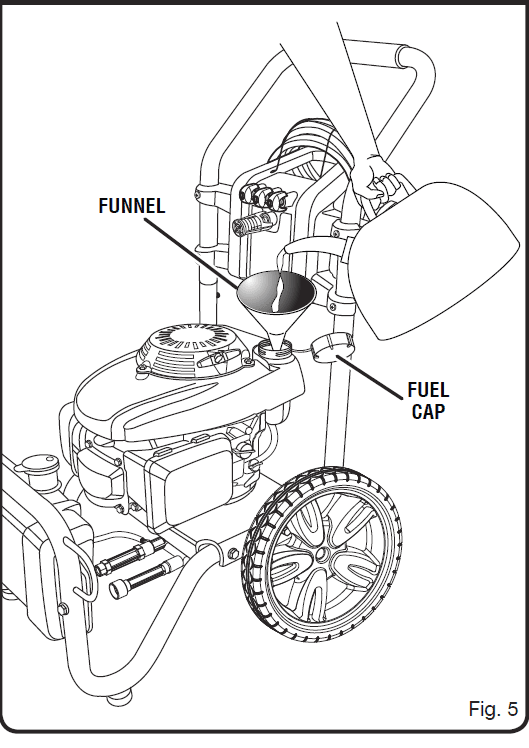

Adding gasoline to the fuel tank

- See Figure 5.

When adding gas to the pressure washer, make sure the unit is sitting on a flat, level surface. If the engine is hot, let the pressure washer cool before adding gas. Always fill the fuel tank outdoors with the machine turned off.

- NOTE: Use unleaded gas only. Do not mix lubricant with gas.

- Before removing the fuel cap, clean the area around it. Remove the fuel cap.

- Insert a clean funnel into the fuel tank then slowly pour gasoline into the tank. Fill the tank to approximately 1-1/2 in. below the top of the tank neck (this allows for fuel expansion).

- Replace the fuel cap and tighten it until the cap “clicks”.

- Clean up any spills before starting the engine

Attaching the injection hose

- See Figure 6.

Before detergent can be used with this machine, the injection hose must be attached.

- Open the cap from the detergent container.

- From the top of the cap, slide the injection hose through the hole in the cap.

- Push the injection hose filter onto the end of the injection hose and pull enough hose through the cap so the injection hose filter will rest at the bottom of the detergent container (or detergent bottle).

- Close the cap on the detergent container.

- Push the open end of the clear injection hose securely over the fitting as shown in figure 6.

- NOTE: Keep the injection hose away from hot surfaces by pushing the hose into the clip in the frame.

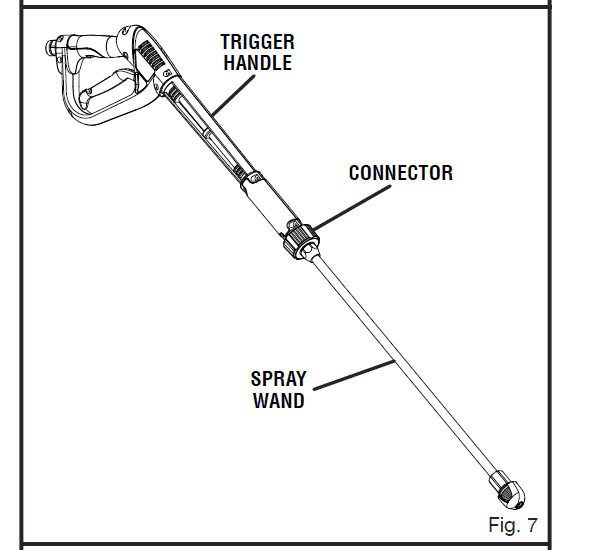

Assembling the trigger handle

- See Figure 7.

- To attach the spray wand:

- Place the threaded end of the spray wand in the connector on the end of the trigger handle.

- Turn the connector clockwise until it stops. This secures the spray wand in place.

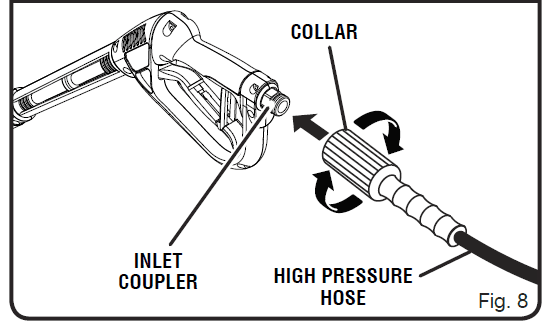

Connecting high-pressure hose to trigger handle

- See Figure 8.

- Screw the collar on the high-pressure hose into the trigger handle inlet coupler by turning the hose collar clockwise.

- Pull on the hose to be certain it is properly secured.

Connecting the high-pressure hose to the pump

- See Figure 9.

- After the high-pressure hose has been uncoiled and attached to the spray wand:

- Align the collar on the threaded nipple on the pump.

- Insert the nozzle on the end of the high-pressure hose collar into the threaded nipple.

- Turn the collar clockwise to tighten the hose securely to the pump.

- Pull on the hose to be certain it is properly secured.

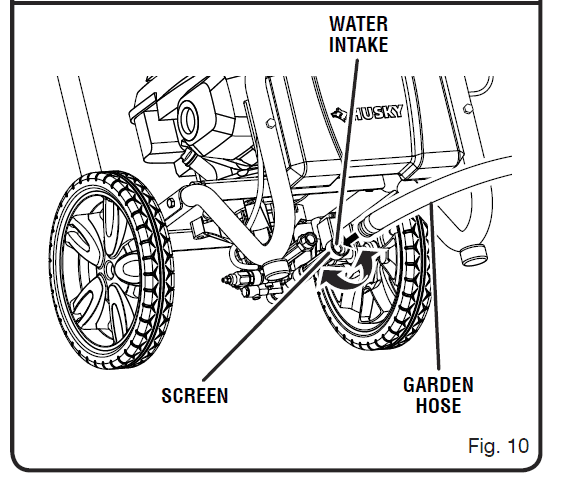

Connecting the garden hose to the pressure washer

- See Figure 10.

The water supply must come from a water main. NEVER use hot water or water from pools, lakes, etc. Before connecting the garden hose to the pressure washer:

- Run water through the hose for 30 seconds to clean any debris from the hose.

- Inspect the screen in the water intake.

- If the screen is damaged, do not use the machine until the screen has been replaced.

- If the screen is dirty, clean it before connecting the garden hose to the machine.

OPERATION

- Before starting the engine:

- Connect all hoses.

- Check all fluids (lubricant and gas).

- Turn on the garden hose then squeeze the trigger to relieve air pressure; hold the trigger until a steady stream of water appears.

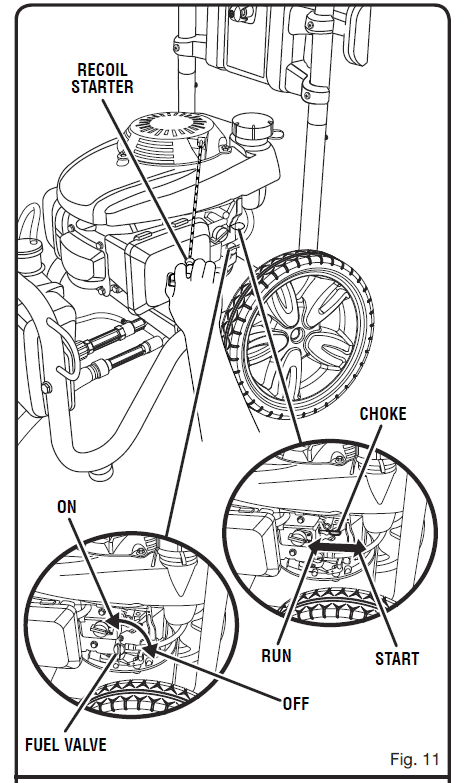

- To start the engine:

- Turn the fuel valve to the ON position.

- Put the engine switch in the ON position.

- Pull choke.

- Grasp the recoil starter and pull slowly until resistance is felt. Give the recoil starter a short, brisk pull to start the engine.

- NOTE: Do not allow the recoil starter to snap back after starting; return it gently to its original place.

- Let the engine run for several seconds, then push the choke in.

- To stop the engine:

- Put the engine switch in the OFF position.

- Turn the fuel valve to the OFF position.

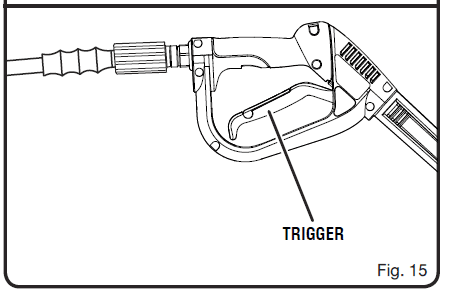

Using the spray wand trigger

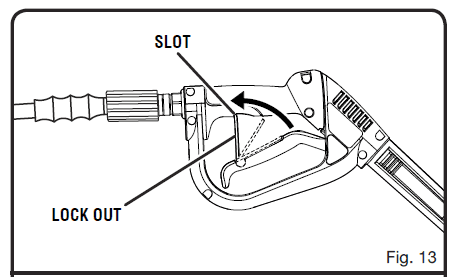

- See Figure 13.

For greater control and safety, keep both hands on the trigger handle at all times.

- Pull back and hold the trigger to operate the pressure washer.

- Release the trigger to stop the flow of water through the nozzle.

- To engage the lockout:

- Push up on the lockout until it clicks into the slot.

- To disengage the lockout:

- Push the lockout into its original position.

- For the most effective cleaning, the spray nozzle should be between 8 in. and 24 in. from the surface to be cleaned. If the spray is too close it can damage the cleaning surface.

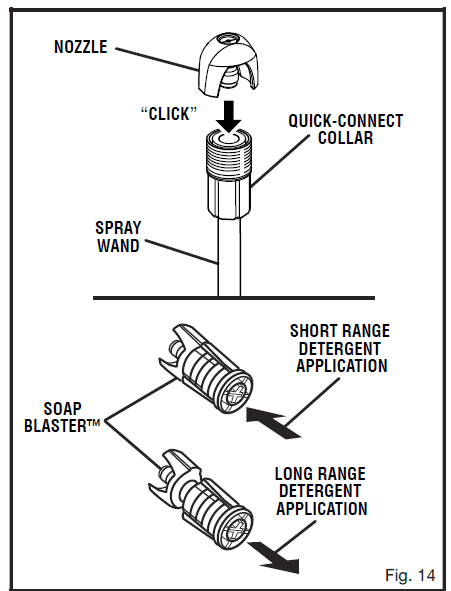

Selecting the right quick-connect nozzle for the job

- See Figure 14 – 15.

- Before starting any cleaning job, determine the best nozzle for the job. Each of the nozzles has a different spray pattern. The nozzle patterns are: 25˚ (for general purpose or large surfaces), 15˚ (for tough jobs), 0˚ (for spot cleaning or high-to-reach areas), and the Soap Blaster™ nozzle (for long and short-range detergent application).

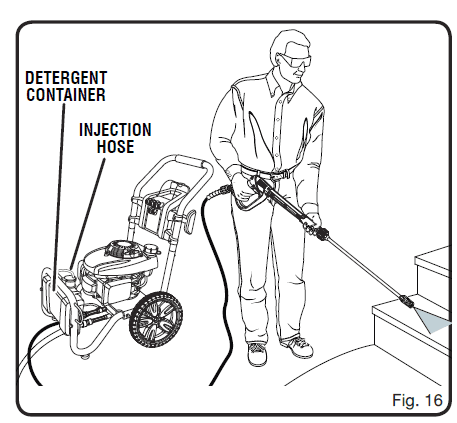

Washing with detergent

- See Figures 16 – 17.

- Use only detergents designed for pressure washers; household detergents, acids, alkalines, bleaches, solvents, flammable material, or industrial-grade solutions can damage the pump. Many detergents may require mixing prior to use. Prepare cleaning solution as instructed on the solution bottle.

- Remove the cap from the detergent container and pour detergent in the container. Replace cap on the container.

- Install the Soap Blaster™ nozzle on the spray wand.

- Spray the detergent on a dry surface using long, even, overlapping strokes. To prevent streaking, do not allow detergent to dry on the surface.

MAINTENANCE

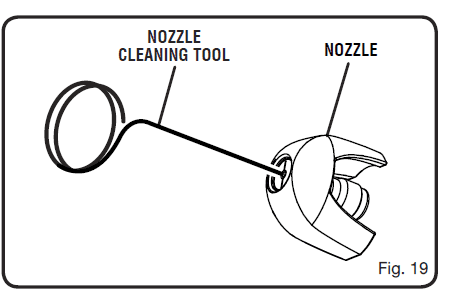

Nozzle maintenance

- See Figure 19.

- Excessive pump pressure (a pulsing sensation felt while squeezing the trigger) may be the result of a clogged or dirty nozzle.

- Turn off the pressure washer and shut off the water supply. Pull the trigger to release water pressure.

- Remove the nozzle from the spray wand.

NOTE: Never point the spray wand at your face. - Using the nozzle cleaning tool provided, free any foreign materials clogging or restricting the nozzle.

- Using a garden hose, flush debris out of the nozzle by back flushing (running the water through the nozzle backward or from the outside to the inside).

- Reconnect the nozzle to the spray wand.

- Turn on the water supply and start the engine

Preparing for use after storage

- Pull the recoil starter grip three or four times to clean the lubricant from the combustion chamber.

- Remove the spark plug from the cylinder. Wipe the lubricant from the spark plug and return it to the cylinder.

- Reconnect the spark plug wire.

- Refuel the machine as described earlier in the operator’s manual

Troubleshooting

| PROBLEM | CAUSE | SOLUTION |

| The engine fails to start | 1. No fuel in the tank 2. Spark plug shorted or fouled 3. The spark plug is broken (cracked porcelain or electrodes broken) 4. The ignition lead wire shorted, broken, or disconnected from the spark plug 5. Ignition inoperative | 1. Fill tank 2. Replace spark plug 3. Replace spark plug

4. Replace the lead wire or attach to the spark plug 5. Contact the authorized service center |

| Engine hard to start | 1. Water in gasoline

2. Weak spark at spark plug | 1. Drain the entire system and refill it with fresh fuel 2. Contact the authorized service center |

| Engine lacks power | 1. Dirty air filter | 1. Clean or replace air filter |

| The detergent fails to mix with the spray | 1. The detergent injection hose is not properly submerged 2. High-pressure nozzle attached | 1. Insert the injection hose into a detergent container or detergent bottle 2. Use a low-pressure nozzle (black) to apply detergent |

| The pump doesn’t produce pressure | 1. Low pressure nozzle installed 2. Inadequate water supply 3. Trigger handle or spray wand leaks

4. Nozzle is clogged 5. Pump is faulty 6. Air in line | 1. Replace with high-pressure nozzle 2. Provide adequate water flow 3. Check connections and/or replace the trigger handle or spray wand 4. Clean nozzle 5. Contact the authorized service center 6. Squeeze the trigger on trigger handle to remove air from the line |

| The machine doesn’t reach high pressure | 1. The diameter of garden hose is too small 2. Water supply is restricted

3. Not enough inlet water 4. Wrong nozzle is attached | 1. Replace with 3/4 in. garden hose

2. Check garden hose for kinks, leaks, and blockages 3. Open water source full force 4. Attach the high-pressure nozzle |

For more manuals by Husky visit, ManualsLibraryy

Husky HU80722 Pressure Washer-FAQs

Can a pressure washer run without water?

No, a pressure washer cannot operate without water. Water is essential for pressurizing and ejecting to clean surfaces.

How does a pressure washer work?

A pressure washer uses a water pump powered by a fuel engine, electric motor, or air pressure. The pump pressurizes water and forces it through a high-pressure hose to the spray gun for cleaning.

What powers the Husky HU80722 pressure washer?

The pressure washer is powered by a fuel engine, which drives the water pump system.

What happens if a pressure washer overheats?

Overheating can damage internal components, leading to costly repairs or replacements. It’s important to prevent overheating by ensuring proper operation and adequate water supply.

How much water does a pressure washer use?

Residential pressure washers typically use 1.5 to 2.5 gallons per minute (GPM), while commercial models may use 2.2 to 10 GPM or more, depending on the application.

What PSI is recommended for a pressure washer?

Medium-duty pressure washers with 1900-2788 PSI are ideal for home use, including cleaning siding, fences, patios, and decks. Commercial units start at 3100 PSI for heavy-duty tasks.

How do nozzles work on a pressure washer?

Nozzles contain small openings (orifices) that control the fluid flow and shape of the spray. The design of the orifice determines the spray’s pattern and pressure.

What should I do if my pressure washer overheats?

Turn off the pressure washer, let it cool down, and check for any blockages or issues with water flow. Avoid running it for extended periods without breaks.

How does water flow affect pressure washing?

Water flows from regions of higher hydraulic head to lower, creating pressure gradients. Proper water flow ensures optimal cleaning performance and prevents overheating.

What is the typical hydraulic gradient in pressure washers?

The hydraulic gradient measures the change in hydraulic head along a water flow path, which directly affects the pressure and cleaning efficiency of the washer.