Echo SRM-210 Grass Trimmer

SAFE OPERATION

- Keep A Firm Grip

- Hold the front and rear handles with both hands with thumbs and fingers encircling the handles

- Keep A Solid Stance

- Maintain footing and balance at all times. Do not stand on slippery, uneven or unstable surfaces. Do not work in odd positions or on ladders. Do not overreach

- POWER HEAD – Includes the Engine, Clutch, Fuel System, Ignition System, and Recoil Starter.

- GRIP – Rear (right-hand) handle.

- THROTTLE TRIGGER LOCKOUT – This lever must be held during starting. Operation of the throttle trigger is prevented unless the throttle trigger lockout lever is engaged.

- STOP SWITCH – “SLIDE SWITCH” mounted on top of the Throttle Trigger Housing. Move the switch FORWARD to RUN, BACK to STOP.

- FRONT HANDLE – The Front (loop) handle is loosely assembled to the Drive Shaft assembly and must be positioned for proper cutting attitude and operator comfort.

- DRIVE SHAFT ASSEMBLY – Includes the Gear Housing assembly, flex drive cable, and Safety Decal.

- NYLON CUTTER HEAD – Contains replaceable nylon trimming lines.

- CUT-OFF KNIFE – Trims line to the correct length (5 in.). If the trimmer is operated without a cut-off knife the line may be too long – more than (5 in.) – the operating speed will slow, the engine overheat and performance will suffer.

- PLASTIC DEBRIS SHIELD ASSEMBLY – Included in plastic bag (co-pack). MUST be installed on the unit before use, see . The shield assembly includes the Cut-Off Knife. Mounts on the Gear Housing Assembly just above the cutting attachment. Helps protect the operator by deflecting debris produced during the trimming operation. This shield must be replaced with a steel shield for blade use.

- THROTTLE TRIGGER – Spring loaded to return to idle when released. During acceleration, press the trigger gradually for the best operating technique.

- SPARK PLUG – Provides spark to ignite fuel mixture.

- TOP GUARD – Protects arm from the hot engine.

- SPARK ARRESTOR – CATALYTIC MUFFLER / MUFFLER -The muffler or catalytic muffler controls exhaust noise and emission. The spark arrestor screen prevents hot, glowing particles of carbon from leaving the muffler. Keep the exhaust area clear of flammable debris.

- FUEL TANK – Contains fuel and fuel filter.

- RECOIL STARTER HANDLE/ROPE – Pull recoil starter handle/rope using light pulling force, approximately 2/3 (2 ft.) of rope length. Two (2) to Six (6) pulls are required to properly tension the starter spring prior to automatic engine engagement. DO NOT let the handle snap back or damage to the unit will occur.

- FUEL TANK CAP – Covers and seals fuel tank opening.

- PRIMER BULB – Pumping the primer bulb before starting the engine draws fresh fuel from the fuel tank priming the carburetor for starting. Pump the primer bulb until the fuel is visible and flows freely in the clear fuel tank return line. Pump the bulb an additional 4 or 5 times.

- AIR CLEANER – Contains replaceable filter element.

- CHOKE – The choke control is located on the top of the air filter case. Move the choke lever to “Cold Start” to close the choke for a cold start. Move the choke lever to the “Run” position to open the choke.

- SAFETY VIDEO – (Not included with the unit) P/N 99922202540 English version and P/N 99922203508 Spanish version are available at a cost of $5.00 from ECHO, INC. or any authorized ECHO dealer. The video overviews safety precautions and proper operating techniques and is supplemental to the Safety Manual. Read and understand the Safety Manual for complete information on safe operation.

ASSEMBLY

PLASTIC SHIELD INSTALLATION

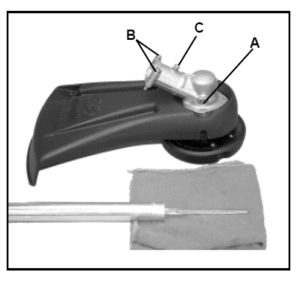

- Remove the plastic sleeve and upper plate (A) from the PTO shaft.

- Install the shield on the bottom of the bearing housing flange.

- Place shield plate (B) on the shield, align holes and install three (3) 5×16 mm screws.

- Install upper plate (A).

NYLON LINE HEAD INSTALLATION

- Align the hole in the upper plate with the notch in the edge of the gear housing and insert the head locking tool (C). Remove the plastic sleeve from the PTO shaft.

- Be sure the upper plate (A) remains on the PTO shaft.

- Place line head onto PTO shaft. Followed by a large metal washer.

- Thread the L.H. nut on PTO shaft. Tighten securely.

- Install new split pin.

- Remove the locking tool (C).

FRONT HANDLE INSTALLATION

Tools Required: Screwdriver.

- Position the front handle for comfortable operation and secure screws.

PRE – OPERATION

OPERATION WITH BLADES

Preparing the Trimmer/Brush Cutter for Blade Use

Light-Duty Use – Plastic, Nylon, or Metal Blades:

- Install Blade Conversion Kit, P/N 99944200415 – Includes metal shield (A), barrier bar (B), and shoulder harness (C).

- NOTE

- The Barrier Bar is NOT A HANDLE and should not be gripped when using or carrying the unit.

Choosing the Correct Blade

- Plastic/Nylon Blades may be used wherever the nylon line head is used. DO NOT use this blade for heavy weeds or brush

- 8 Tooth Weed/Grass Blade P/N 69600120331 is designed for grass, garden debris, and thick weeds. DO NOT use this blade for brush or heavy woody growth, 19 mm (3/4 in.) diameter or larger.

- Brush/Clearing Blade P/N 69500120331 is designed for cutting brush and woody growth up to 76 mm (3 in.) in diameter.

- During blade operation, the same fatigue reduction is achieved. Safety for the operator is also enhanced by preventing blade contact with the operator’s hands and feet by restricting trimmer movement.

- NOTE

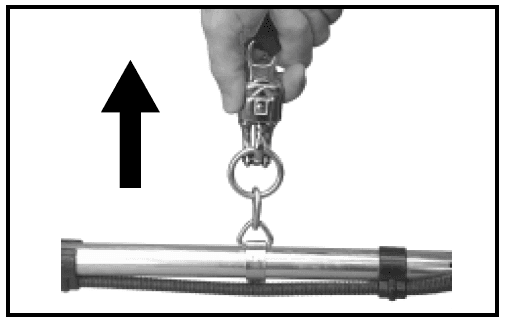

- In case of Emergency, pull up on the Quick Release Collar to disconnect the trimmer from the harness

FUEL

Fuel Requirements

- Gasoline – Use 89 Octane [R+M/2] (mid-grade or higher) gasoline or gasohol known to be good quality. Gasohol may contain up to 10% Ethyl (grain) alcohol or 15% MTBE (methyl tertiary-butyl ether). Gasohol containing methyl (wood) alcohol is NOT approved.

- Two-Stroke Oil – A two-stroke engine oil meeting ISO-L-EGD (ISO/CD 13738) and J.A.S.O. FC Standards, must be used. Echo brand Premium 50:1 oil meets these standards. Engine problems due to inadequate lubrication caused by failure to use an ISO-L-EGD and J.A.S.O. FC certified oil, such as Echo Premium 50:1 Two-stroke Oil, will void the two-stroke engine warranty. (Emission-related parts only are covered for two years, regardless of two-stroke oil used, per the statement listed in the Emission Defect Warranty Explanation.)

OPERATION

STARTING COLD ENGINE

- Stop Switch

Move the stop switch button (A) forward away from the STOP position. - Choke

Move the choke lever (B) to the Cold Start Position ( ).

).

- Primer

Pump primer bulb (C) until the fuel is visible and flows freely in the clear

fuel tank return line. Pump the bulb an additional 4 or 5 times.- NOTE

- Energy is stored in the starter spring each time the handle/rope is pulled. Generally, two to six pulls, using light pulling forces, will store enough energy to engage the starter and spin the engine. Do not pull the rope out to the end stop.

- Recoil Starter

Lay the unit on a flat, clear area. Firmly grasp the right-hand grip and throttle trigger lockout with the left hand, and fully depress the throttle trigger to wide open position. Gently pull the starter handle/rope (D) until the engine fires or 2 to 3 engine engagements.

- Choke

After the engine fires or 2 to 3 engine engagements, move the choke lever (B) to Run position ( ). Hold the throttle trigger and throttle trigger lockout fully depressed, and pull the starter handle/rope until the engine starts and runs. Release the throttle trigger and allow the unit to warm up at idle for several minutes.

). Hold the throttle trigger and throttle trigger lockout fully depressed, and pull the starter handle/rope until the engine starts and runs. Release the throttle trigger and allow the unit to warm up at idle for several minutes. - After the engine warms up, gradually depress the throttle trigger to increase the engine RPM to the operating speed

STARTING WARM ENGINE

- The starting procedure is the same as Cold Start except DO NOT close the choke, and do not depress the throttle trigger to wide wide-open position

- STARTING WARM ENGINE

The starting procedure is the same as Cold Start except DO NOT close the choke, and do not depress the throttle trigger to wide wide-open position

- Primer

Pump primer bulb (C) until the fuel is visible and flows freely in the clear fuel tank return line. Pump the bulb an additional 4 or 5 times

MAINTENANCE

- Your ECHO trimmer is designed to provide many hours of trouble-free service. Regularly scheduled maintenance will help your trimmer achieve that goal. If you are unsure or are not equipped with the necessary tools, you may want to take your unit to an ECHO Service Dealer for maintenance. To help you decide whether you want to DO IT YOURSELF or have the ECHO Dealer do it, each maintenance task has been graded. If the task is not listed, see your Echo Dealer for repairs.

SKILL LEVELS

- Level 1 = Easy to do. Most required tools come with a unit.

- Level 2 = Moderate difficulty. Some specialized tools may be required.

- Level 3 = Experience required. Specialized tools are required. ECHO recommends that the unit be returned to your ECHO dealer for servicing. ECHO offers REPOWERTM Maintenance Kits and Parts to make your maintenance job easier. Below each task heading are listed the various part numbers required for that task. See your ECHO dealer for these parts

MAINTENANCE INTERVALS

| COMPONENT/ SYSTEM | MAINTENANCE PROCEDURE | REQ’D SKILL LEVEL | DAILY OR BEFORE USE | EVERY REFUEL | 3 MONTHS OR 90 HOURS | 6 MONTHS OR 270 HOURS | YEARLY 600 HOURS |

| Recommended Echo Dealer Maintenance Procedures | |||||||

| Cylinder Exhaust Port | Inspect/Clean/Decarbon | 3 | I / C | ||||

| Do-It-Yourself Maintenance Procedures | |||||||

| Air Filter | Inspect/Clean/Replace | 1 | I / C | R* | |||

| Choke | Inspect/Clean | 2 | I / C | ||||

| Fuel Filter | Inspect/Replace | 1 | I | I / R * | |||

| Fuel System, leaks | Inspect/Replace | 1 | I * | I | I | ||

| Cooling System | Inspect/Clean | 2 | I / C | ||||

| Muffler Spark Arrestor | Inspect/Replace | 2 | I / R * | ||||

| Drive Shaft (Flex Cable Models) | Grease | 2 | I (1) | ||||

| Gear Housing | Grease | 2 | I (2) | ||||

| Recoil Starter Rope | Inspect/Clean | 1 | I / C * | ||||

| Spark Plug | Inspect/Clean | 2 | I / C | R * | |||

| Screws/Nuts/Bolts | Inspect/Tighten/Replace | 1 | I / R * | ||||

| MAINTENANCE PROCEDURE LETTER CODES: I = INSPECT, R = REPLACE, C = CLEAN IMPORTANT NOTE – Time intervals shown are maximum. Actual use and your experience will determine the frequency of required maintenance. MAINTENANCE PROCEDURE NOTES: (1) Apply ECHO LUBETM every 25 hours of use. ® (2) Apply ECHO LUBETM every 50 hours of use. ® * All recommendations to replace are based on the finding of damage or wear during inspection.. | |||||||

AIR FILTER

Level 1.

Tools required: 25 – 50 mm (1 – 2 in.) Cleaning Brush

Parts required: 90008 REPOWERTM AIR & FUEL FILTER KIT.

- Close choke (Cold Start Position). This prevents dirt from entering the carburetor’s throat when the air filter is removed. Brush accumulated dirt from the air cleaner area.

- Remove the air cleaner cover. Clean and inspect the element for damage. If the element is fuel-soaked and very dirty, replace it.

- If an element can be cleaned and reused, be certain it:

- still fits the cavity in the air cleaner cover.

- Is installed with the original side out.

COOLING SYSTEMS CLEANING

Level 2.

- Tools required: Cross-head screwdriver, 3 and 4 mm hex wrench, pointed wood stick, 25 – 50mm (1 – 2 in.) medium bristle paintbrush.

- Parts Required: None if you are careful.

Overheating and engine seizure can occur when:

- Air intakes are blocked, preventing cooling air from reaching the cylinder.

- Dust and grass build up on the outside of the cylinder. This build-up insulates the engine and prevents the heat from leaving. Removal of cooling passage blockages or cleaning of cooling fins is considered “Normal Maintenance”. Any failure attributed to lack of maintenance is not warranted

- Disconnect the spark plug lead from the spark plug.

- Release stored energy in the power spring by removing the spark plug.

- Remove three (3) screws (A) from the starter assembly and remove the starter.

- NOTE

- DO NOT disassemble the starter assembly.

- Remove the four screws that retain the engine cover. Two at the inside top of the mounting plate (B), one on the top guard (C), and one at the muffler cover (D).

- Disengage the heat deflector tabs (E) under the muffler from the slots in the engine/muffler cover.

- Lift the cover from the engine.

LUBRICATION

Level 1.

- Tools required: 8 mm Open End Wrench, Screwdriver, Clean rag

- Parts Required: ECHO® LUBETM 8 oz. (P/N 91014) or Lithium Base Grease.

Gear Housing

- Clean all loose debris from the gearbox.

- Remove plug (A) and check the level of grease.

- Add grease if necessary, DO NOT overfill.

Drive Shaft

- Loosen two (2) screws (B) and remove the center locating screw (C). Pull the gearbox and shield from the drive shaft housing.

- Pull the flexible cable from the drive shaft housing, wipe clean, and recoat with a thin coating [15 ml (1/2 oz.)] of grease.

- Slide the flexible cable back in the drive housing. DO NOT get dirt on the flex cable.

- Install the gear housing and shield assembly.

TROUBLESHOOTING

| ENGINE PROBLEM TROUBLESHOOTING CHART | ||||

| Problem | Check | Status | Cause | Remedy |

|

Engine cranks – starts hard/ doesn’t start | Fuel at carburetor | No fuel at carburetor | Fuel strainer clogged Fuel line clogged Carburetor | Clean or replace Clean or replace See your Echo dealer |

| Fuel at cylinder | No fuel at the cylinder | Carburetor | See your Echo dealer | |

| Muffler wet with fuel | Fuel Mixture too rich | Open choke Clean/replace air filter Adjust carburetor See your Echo dealer | ||

| Spark at end of plug wire | No spark | Stop switch off Electrical problem Interlock switch | Turn the switch to ON See your Echo dealer See your Echo dealer | |

| Spark at plug | No spark | Spark gap incorrect Covered with carbon Fouled with fuel Plug defective | Adjust to 0.70mm (0.026 in.) Clean or replace Clean or replace the plug | |

|

The engine runs, but dies or does not accelerate properly | Air filter | Air filter dirty | Normal wear | Clean or replace |

| Fuel filter | Fuel filter dirty | Contaminants/residues in fuel | Replace | |

| Fuel vent | Fuel vent plugged | Contaminants/residues in fuel | Clean or replace | |

| Spark Plug | Plug dirty/worn | Normal wear | Clean and adjust or replace | |

| Carburetor | Improper adjustment | Vibration | Adjust | |

| Cooling System | The cooling system is dirty/plugged | Extended operation in dirty/dusty locations | Clean | |

| Spark Arrestor Screen | The spark arrestor screen plugged | Normal wear | Replace | |

| Engine does not crank | N/A | N/A | Internal engine problem | See your Echo dealer |

STORAGE

Long Term Storage (over 30 days)

Do not store your unit for a prolonged period of time (30 days or longer) without performing protective storage maintenance which includes the following:

- Store the unit in a dry, dust-free place, out of the reach of children.

- Place the stop switch in the “STOP” position.

- Remove accumulation of grease, oil, dirt, and debris from the exterior of the unit.

- Perform all periodic lubrication and services that are required.

- Tighten all the screws and nuts.

- Drain the fuel tank completely and pull the recoil starter handle several times to remove fuel from the carburetor

For more manuals by Echo visit, ManualsLibraryy

Echo SRM-210 Grass Trimmer-FAQs

What is the correct fuel mixture for the Echo SRM-210?

The Echo SRM-210 requires a fuel-to-oil mixture of:

1. 25:1 or 32:1 when using Echo-brand oil

2. 50:1 when using Echo-approved special oil

Always use regular-grade gasoline with a high-quality air-cooled two-stroke engine oil.

Why did my Echo trimmer stop working?

A common cause is a clogged fuel filter due to old fuel left in the trimmer. Over time, fuel can thicken and block the filter, preventing the engine from starting. Regular fuel replacement and filter maintenance can help prevent this issue.

What is the engine displacement of the Echo SRM-210?

The Echo SRM-210 has a 21.2cc engine displacement and meets an emission compliance period of 300 hours.

Is Echo a reliable trimmer brand?

Yes, Echo trimmers are known for their durability, lightweight design, and easy starting mechanism. Many users consider Echo products highly reliable for long-term use.

What is the spark plug gap for the Echo SRM-210?

The proper spark plug gap for the Echo SRM-210 is 0.6–0.7 mm (0.024–0.028 inches). Make sure to inspect the electrode for wear during maintenance.

What should I do if my trimmer stops working?

Check for hair, dirt, or debris stuck inside the trimmer. Clean the cutting unit and remove any blockages. If issues persist, refer to the user manual for detailed troubleshooting steps.

How do I remove the trimmer head on the Echo SRM-210?

1. Align the locking hole in the upper plate with the notch on the bearing housing.

2. Insert the locking tool above the cutting head.

3. Use a 9/16-inch (14.5mm) wrench to turn the nut counterclockwise and remove the cutting head.

What is the fuel/oil ratio for the Echo SRM-210?

A 50:1 fuel-to-oil ratio is recommended when using 89–93 octane fuel with oil that is ISO-L-EGD and JASO M345 FD certified.