Homdox WD3800 Electric Pressure Washer

PRECAUTIONS FOR GASOLINE ENGINES/ELECTRIC MOTORS

Follow all safety precautions, operating procedures, and maintenance listed in your engine operator’s manual, which came with the pressure cleaner. This manual may be obtained from your local small engine repair center.

- DO NOT fill the engine with gasoline when the engine is running, hot, or near an open flame. DO NOT SMOKE.

- DO NOT run power washers in an enclosed area. Exhaust fumes contain poisonous carbon monoxide gas. Breathing exhaust gases can cause serious illness or death.

- DO NOT touch or come in contact with hot mufflers, cylinders, cooling fins, or hot exhaust gases, as this may result in severe burns. Never tamper with the governor spring, governor links, or other components that may increase the speed (RPM) of the engine.

- DO NOT operate pressure cleaners in the presence of flammable vapors or gases. When servicing pressure cleaning equipment, be sure to properly dispose of any flammable materials.

- DO NOT make adjustments to your equipment without first removing the spark plug.

- When transporting pressure cleaners, the fuel shut-off valve must be in the closed position to prevent fuel from spilling out.

- A circuit dedicated only to the electric pressure washer is recommended. This circuit should be installed by a licensed electrician and checked to supply adequate voltage under load. If the distance from the panel is too long, the wire size is too small, or the voltage is initially too low, this will cause the GFCI or Thermal overload to trip. If the GFCI trips or the thermal overload on the motor trips, consult the factory. Plug your cord into the receptacle. DO NOT USE EXTENSION CORD! USE ONLY THE FACTORY-SUPPLIED POWER CORD.

INITIAL SETUP AND OPERATION OF YOUR NEW PRESSURE WASHER

Inspection for freight damage

- When you receive your commercial pressure washer, be sure you check for concealed freight damage. Any damage should be noted with the delivering carrier. If you have any questions related to freight, call your selling dealer.

Inspection of oil levels

- Check all oil levels in the pump or engine if applicable. Failure to check all levels could result in pressure washer damage. Most pumps are shipped with oil from the factory, and the crankcases are sealed. You may have to remove a shipping plug and install a dipstick in the pump. Oil type is stated on the pump breakdown and in the engine manual.

Water Supply

- Your water supply must provide water to the equipment that exceeds the Gallon Per Minute (GPM) rate of your machine. You can check your GPM by using a 5-gallon bucket and a timer. If your machine is 5 GPM or less and the bucket fills in less than a minute, you have an adequate supply. Some water supply systems are affected by things like washing machines, livestock watering systems, and flushing toilets. Be sure the supply is still adequate when these operations are taking place. The water temperature cannot exceed 145°F on the standard models and 180°F on the high temperature models, and the pressure should not exceed 60 PSI. Failure to secure an adequate water supply to your commercial pressure washer will result in pump damage. DO NOT RUN PUMP DRY.

Water Quality

- Your water should not contain particles larger than 80 microns. Although there are small filters installed on power washers that filter the water, they can only filter poor-quality water for a short period of time before they clog. This would result in damage to the machine. Therefore, you should ensure that no sand or scale particles are present in the water supply.

Supply Hose

- Hook a garden hose from the faucet to the machine. When doing this, be sure to check the inlet water filter or screen. This hose should be at least 5/8″ in diameter and a length of at least 15 feet. This 15′ length helps isolate the water supply from pulsations from the pump. Many states require a Vacuum Break or backflow preventer to be installed at the faucet, before the garden hose, to ensure the water source cannot be contaminated. Be sure to check local and state regulations upon installation.

Purge Air

- Turn on the water supply and open the trigger gun. This will purge all the air from the system. Look for water leaks and stop any leaks found. Leaks can cause erratic pump behavior.

Pump

- Prior to turning on the power switch or starting the engine, check the oil level in the pump. The pump oil should be changed after the first 50 hours of operation, then every 3 months or 300 hours of operation thereafter for average service or more frequently for extensive use or hostile environments (dusty or high moisture).

Turn on Power

- Turn on the power switch. Pull the trigger gun and check for adequate pressure.

Filters

- Water filters, hoses, and fittings should be checked prior to every operation for cleanliness, leaks, and repair needs. Repair or replace as needed.

The Unloader Valve

- Pressure cleaners are built with one of two types of unloaders: The Trapped Pressure Unloader or the Flow Actuated Unloader. After the pump is filled with water, the direction of water flow must be controlled with the unloader or regulating valve. A positive displacement pump is always delivering a specific volume of water, whether the spray gun is open or closed; therefore, a device is needed to control the direction of flow, either to the open spray gun or to redirect the flow back to the inlet side of the pump when the spray gun is closed. Without an unloader valve, dangerously high pressure will be produced when the spray gun is closed because the water being forced out of the pump has no place to go. The unloader is used as a safety device to guard against the failure of component parts and the development of dangerously high pressures.

Hoses and Couplers

- Factory-supplied hoses are sized in length and diameter for best operational performance and size within the pressure capabilities. Additional hose added to the machine may change the performance of the machine. Consult the factory if you have any questions. When replacing or disconnecting the quick couplers, be sure the machine is shut off and relieve the pressure from all hoses.

During Operation

- The pressure was set at the factory during the testing procedure; no adjustments to the machine should be required for operation. During operation, do not leave the machine running for more than 2 minutes without the trigger gun being pulled. Although your machine has a bypass valve on it and may have a thermal relief system, this can cause extensive pump damage. If the machine will not be discharging water for more than 2 minutes, shut the machine off.

TIP STYLES

Chemical injector use with interchangeable tips

- Your pressure washer is supplied with a downstream chemical injector. The 1/4″ clear vinyl tube is to be inserted into the desired chemical to apply. Be sure to use the black, low-pressure nozzle to inject the chemical. The chemical injector will only open up and allow chemical into the line when this tip is used. This tip enables the pressure to drop to approximately 250 PSI to draw chemical. Some injectors can be shut on and off, or the rate of injection can also be set by turning the knob that the clear vinyl tube attaches to. See calibration below. Be sure to flush the injection system with clear water after use.

Multi-Reg (Adjustable) Tip

- If your machine is supplied with an adjustable tip, the spray pattern can be changed by rotating the outer shell of the nozzle. The nozzle will also move forward and backward. The nozzle must be pulled back toward the gun for high-pressure rinse. When the nozzle is moved forward, you will have low pressure, and the soap injector will start to draw chemical.

Chemical injector use with multi-reg tip

- Move the outer shell of your tip forward (away from the gun). This will lower your pressure and allow the injector to start to draw chemical. Chemical will only be drawn in the low-pressure setting. Pull the nozzle back for a high-pressure rinse.

Calibration

- If an accurate injection rate is desired, use this formula: (GPM x 128) ÷ (ounces drawn in 1 minute) = x:1. IE, If a 2.0 GPM machine draws 8 ounces of chemical in 1 minute, (2×128)/8 = 32:1

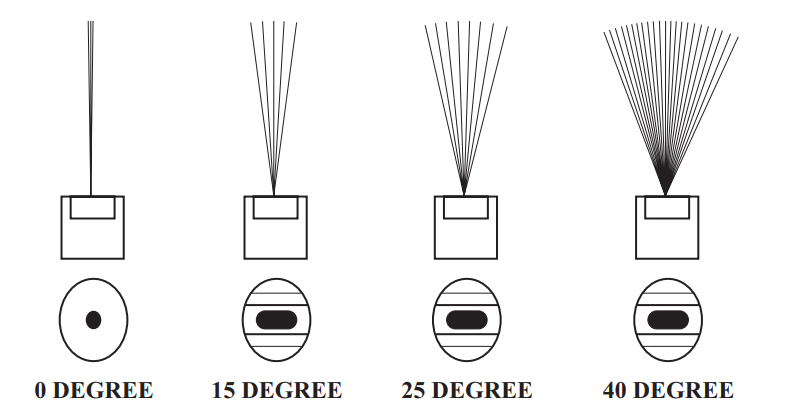

NOZZLE SELECTION GUIDE

- Spray nozzle can be identified by the nozzle “number”, a five or six-digit number that is stamped on the nozzle, which indicates the spray angle and orifice size. In most cases, the second and third digits of the nozzle number indicate the spray angle in degrees. EXAMPLE: 00 is 0 degrees, 15 is 15 degrees, and 40 is 40 degrees. The last two numbers of the nozzle number indicate the orifice size, a standard industry designation. EXAMPLE: 60 is a 6.0 orifice, 55 is a 5.5 orifice. These numbers correspond to the actual dimensions, giving the size of the orifice. They do not, however, directly indicate gallons per minute, flow rate, or inches in diameter of the orifice. Some power washers come with an adjustable nozzle, which is fixed to the end of the wand. The fan spray may be adjusted by turning the nozzle, and chemicals may also be applied by pulling outward on the nozzle.

STANDARD SPRAY NOZZLE APPLICATIONS

A. 0 DEGREE – BLASTING

- Removing caked-on mud from heavy construction, farm, or lawn equipment.

- Cleaning tar, glue, or stubborn stains from concrete.

- Cleaning overhead areas.

- Removing rust from steel and oxidation from aluminum.

B. 15 DEGREE – STRIPPING

- Removing paint from wood, masonry, or metal.

- Removing grease or dirt from equipment.

- Removing heavy mildew stains.

- Removing marine growth from boats and marine equipment.

- Removing rust from steel and oxidation from aluminum.

C. 25 DEGREE – CLEANING

- General cleaning of dirt, mud, and grime.

- Cleaning roofs, gutters, and downspouts.

- Removing light, mildew stains.

- Removing algae and bacteria buildup from pools.

- Rinsing surfaces in preparation for painting.

D. 40 DEGREE – WASHING

- Light cleaning and washing.

- Washing and rinsing of automobiles and boats.

- Leaning roofs, windows, patios, and driveways.

SHUT-DOWN PROCEDURE

STORAGE

- Turn off the power switch on the commercial pressure washer.

- Relieve pressure on the line by pulling the trigger gun.

- Shut off the water supply and disconnect the garden hose.

- Be sure to check for water leaks or oil leaks that should be repaired before the next operation.

- If you are going to store the machine for extended periods of time in cold climates, be sure to antifreeze the equipment. A 50% anti-freeze solution may be drawn in through the inlet of the pump using a short remnant of garden hose. This fluid should be run through the pump. When the fluid is discharged from the pump discharge, your machine is winterized. Do not allow the machine to freeze.

- Fuel stabilizer for gas if the unit is to be stored for 30–90 days. If storing the unit for over 90 days, drain the fuel tank, shut off the fuel valve, and run the unit until it stops.

PREVENT DAMAGES AND EXCESSIVE WEAR

- Avoid extending hoses across high-traffic areas while using power washers, and never leave the hose where it may be run over by vehicles of any type.

- Never pull on the hose to move the pressure washer.

- Never pull your pressure hose around a tight corner or force it into a small loop. The wire braid hose has a minimum bend radius of 5″, and should not be forced into any small bend.

- Wrap up the pressure washer hose when finished cleaning and store it on a hose hook, hanger, reel, or other safe location.

- Check oil levels (pump & engine) at every fueling to prevent low oil damage.

- Inspect the inlet water filter for cleanliness and damage. If soiled or dirty, rinse with fresh water. If damaged, replace with a new filter.

- When lifting or transporting power washers, secure and lift only with appropriate lifting handles.

PRESSURE WASHER CARE

- Follow the recommended service instructions in the owner’s manual for the engine.

- Change oil in the pump after the first 50 working hours (break-in period) and then every 3 months or 300 hours of operation. The oil drain bolt is located on the bottom side of the pump. When refilling or adding oil to your pump, the pressure cleaner should be on level ground. Most pressure cleaners have a sight glass located on the side of the pump; the oil level must be in the center of the sight glass. See the pump manufacturer’s specification sheet for proper lubrication.

- Prevent the pump from freezing during freezing conditions. Flush the pump with 1 to 1 mixture of automobile anti-freeze and water. This will also act as a lubricant.

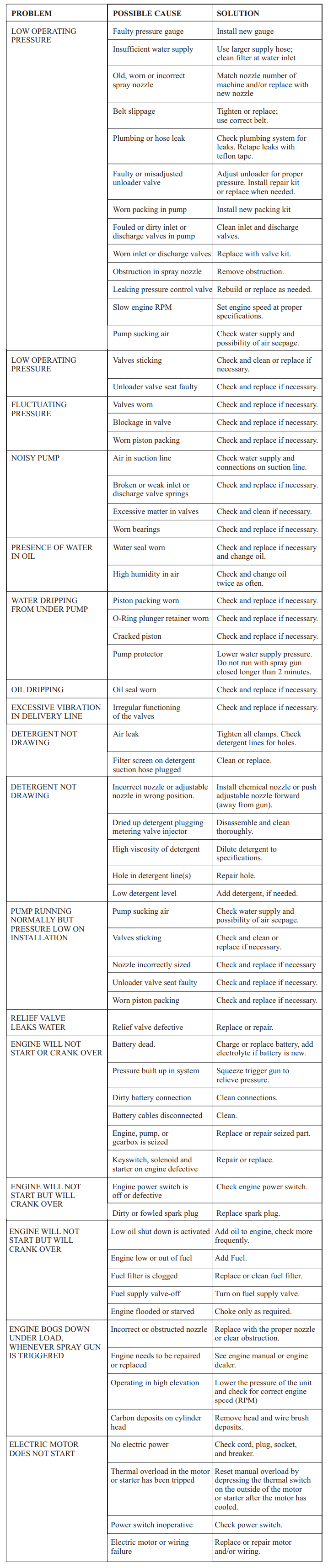

TROUBLESHOOTING — COMMON PROBLEMS AND SOLUTIONS

Low Nozzle Pressure

Low nozzle pressure is a common complaint. In a majority of instances, low nozzle pressure is generally caused by one of the following:

- Obstructed or clogged nozzle tip.

- Obstructed or clogged inlet filter.

- The unloader valve stuck open due to debris lodged under the check valve ball.

- Customer use of shutoff-type quick connectors.

- Plugged or obstructed hose.

- Insufficient flow in gallons per minute (not pressure) to the pump.

Why should I keep my nozzles clean?

- Clogged nozzles can increase pump back pressure and possibly damage the pump. Immediate attention is required.

How do I clean clogged nozzles?

- Always disconnect your spray wand from the gun before cleaning your nozzles!

- Clear the nozzle with a small, rigid piece of wire such as a paper clip.

- Flush the nozzle backwards with water.

- 4. Reconnect the wand to the gun.

- Restart the pressure washer and depress the trigger on the spray gun.

- If the nozzle is still plugged or partially plugged, repeat steps 1–4. If the previous procedure does not clear the nozzle, replace it with a new one.

Surging Operation

Another condition is that pressure surges. That is, when the trigger is pulled, pressure is satisfactory for a moment, then falls off. When the trigger is released, pressure builds up to normal levels. This is generally a sign that the water supply cannot provide the flow rate (gallons per minute) required by the pump. The following are some possible solutions:

- Make sure the supply is not restricted, that there are no undersized fittings, and that the inlet screen is unobstructed.

- Make sure the flow rate of the water supply is sufficient for the pump. First, find the capacity of your pump in gallons per minute (GPM). Then determine the flow rate of your supply by measuring the gallons that can be delivered in one minute. If your supply does not deliver the GPM your pump requires, do not use the pump. It will suck air, causing cavitations which can quickly damage pump components.

- Check for leaks in the supply fittings. Any leak will cause the pump to draw air and perform poorly.

Soap Injector Not Working Properly

When a soap injector is not working properly, the problem is generally fairly easy to isolate. Check the following:

- If you have interchangeable tips, make sure the black soap tip is installed. Soap injectors will not work when high-pressure nozzles are installed.

- Be sure that the soap injector valve is turned on, and turn the selector valve to the desired setting.

- A piece of debris may be caught in the injector valve, injector ball valve, or orifice. Disassemble and clean the injector.

- If you have an adjustable nozzle, be sure it is in the low-pressure position (away from the gun) to draw soap.

Notice

User maintenance procedures include replacing valves and seals. Unloader components are not user-serviceable. Repairs involving unloaders and crankcase components should be referred to the factory or a factory-authorized repair center.

For More Manuals By Homdox, Visit ManualsLibraryy.

Homdox WD3800 Electric Pressure Washer-FAQs

Q1. How do you properly operate an electric pressure washer?

Connect the garden hose to the washer, plug in the power cord, and turn on the water supply. Choose the correct nozzle, then press the power button. Always start spraying at a safe distance and adjust as needed.

Q2. Do you need a hose connected to start a pressure washer?

Yes. A steady water supply is required. Running the unit without water can damage the pump and motor.

Q3. Should the water be turned on before starting?

Yes. Always turn on the water first, then start the pressure washer. This ensures the pump is primed and prevents dry running.

Q4. What is a good PSI for an electric pressure washer?

For most household cleaning, 1300–2400 PSI is ideal. The Homdox WD3800 provides enough power for patios, cars, siding, and outdoor furniture.

Q5. What GPM (gallons per minute) should I look for?

A good balance is 1.2–2.5 GPM, which offers strong cleaning efficiency while conserving water.

Q6. How do I adjust the pressure on my washer?

You can use the pressure regulator knob (if available) or change to a different nozzle tip. Wide-angle nozzles lower pressure, while narrow tips increase it.

Q7. Which nozzle should I use for concrete cleaning?

The yellow 15° nozzle works best for heavy-duty jobs like cleaning concrete, driveways, or garage floors.

Q8. Can I use detergent with this washer?

Yes. Add detergent to the soap tank or siphon tube, but always dilute it (about 1:10 with water). Avoid bleach or harsh chemicals that may damage seals.

Q9. Can I use household items like dish soap or vinegar?

Yes, mild dish soap or diluted vinegar are safe options for light cleaning. Never use thick, corrosive, or oil-based cleaners.

Q10. How can I make an electric pressure washer more powerful?

You can’t increase PSI beyond design limits, but you can boost cleaning efficiency by using a turbo nozzle, proper detergent, and keeping nozzles unclogged