Harbor Freight 98199 Sliding Compound Miter Saw

Important SAFETY Information

- KEEP GUARDS IN PLACE and in working order.

- REMOVE ADJUSTING KEYS AND WRENCHES. Form the habit of checking to see that keys and adjusting wrenches are removed from the tool before turning it on.

- KEEP WORK AREA CLEAN. Cluttered areas and benches invite accidents.

- DON’T USE IN DANGEROUS ENVIRONMENT. Don’t use power tools in damp or wet locations, or expose them to rain. Keep the work area well-lit.

- KEEP CHILDREN AWAY. All visitors should be a safe distance from the work area.

- MAKE WORKSHOP KID PROOF with padlocks, master switches, or by removing starter keys.

- DON’T FORCE TOOL. It will do the job better and safer at the rate for which it was designed.

- USE THE RIGHT TOOL. Don’t force a tool or attachment to do a job for which it was not designed.

- USE PROPER EXTENSION CORD. Make sure your extension cord is in good condition. When using an extension cord, be sure to use one heavy enough to carry the current your product will draw. An undersized cord will cause a drop in line voltage, resulting in loss of power and overheating. Table A shows the correct size to use depending on cord length and nameplate ampere rating. If in doubt, use the next heavier gage. The smaller the gauge number, the heavier the cord.

- WEAR PROPER APPAREL. Do not wear loose clothing, gloves, neckties, rings, bracelets, or other jewelry that may get caught in moving parts. Nonslip footwear is recommended. Wear a protective hair covering to contain long hair.

- ALWAYS USE SAFETY GLASSES. Also, use a face or dust mask if the cutting operation is dusty. Every day eyeglasses only have impact-resistant lenses; they are NOT safety glasses.

- SECURE WORK. Use clamps or a vise to hold work when practical. It’s safer than using your hand and it frees both hands to operate the tool.

- DON’T OVERREACH. Keep proper footing and balance at all times.

- MAINTAIN TOOLS WITH CARE. Keep tools sharp and clean for the best and safest performance. Follow instructions for lubricating and changing accessories.

- DISCONNECT TOOLS before servicing; when changing accessories, such as blades, bits, cutters, and the like.

- REDUCE THE RISK OF UNINTENTIONAL STARTING. Make sure the switch is in the off position before plugging in.

- USE RECOMMENDED ACCESSORIES. Consult the owner’s manual for recommended accessories. The use of improper accessories may cause risk of injury to persons.

- NEVER STAND ON A TOOL. Serious injury could occur if the tool is tipped or if the cutting tool is unintentionally contacted.

- CHECK DAMAGED PARTS. Before further use of the tool, a guard or other part that is damaged should be carefully checked to determine that it will operate properly and perform its intended function – check for alignment of moving parts, binding of moving parts, breakage of parts, mounting, and any other conditions that may affect its operation. A guard or other part that is damaged should be properly repaired or replaced.

- DIRECTIONS OF FEED. Feed work into a blade or cutter against the direction of rotation of the blade or cutter only.

Save these instructions.

Components of the Miter Saw

Specifications

Unpacking

When unpacking, check to make sure that the item is intact and undamaged. If any parts are missing or broken, please call Harbor Freight Tools at the number shown on the cover of this manual as soon as possible.

List of contents

Read the entire Important Safety Information section at the beginning of this manual, including all text under subheadings therein, before setting up or using this product.

WARNING: To prevent serious injury from accidental operation: Turn the Power Switch of the tool to its “OFF” position and unplug the tool from its electrical outlet before assembling or making any adjustments to the tool.

Note: For additional information regarding the parts listed in the following pages, refer to the Assembly Diagram near the end of this manual.

Assembly

- Attaching the Extension Supports and Miter Lock Handle

Insert the ends of the Extension Supports into the holes in the sides of the Base. Tighten the Wing Screws to hold the Extensions in place. The upper edge of the Extensions will be level with the surface of the saw. This provides a wider base for the work material to rest on.

Thread the Miter Lock Handle into the 2. Plate until securely in place. - Attaching the Dust Collection Bag

The Dust Collection Bag slips over the Dust Outlet behind the Blade Housing Assembly. Sawdust created by cutting is captured in the bag.

Mounting the Saw

The Miter Saw must be mounted on a support before use. This may be a commercially available support or a homemade saw table. There are bolt holes provided in each of the four legs of the base. These should be firmly mounted using bolts (not included) to your saw stand or saw table (not included). This will help prevent tipping or movement of the saw, preventing injury. Also, the use of a saw table will make it easier to efficiently handle work materials and make more accurate cuts.

Operating Instructions

Work Piece and Work Area Set Up

- Designate a work area that is clean and well-lit. The work area must not allow access by children or pets to prevent injury and distraction.

- Route the power cord along a safe route to reach the work area without creating a tripping hazard or exposing the power cord to possible damage. The power cord must reach the work area with enough extra length to allow free movement while working.

- Use a saw table, saw stand, or other means to support the workpiece. The Miter Saw must be mounted in such a way that the surface is level to the ground, and supports used must provide a surface on the same level as the saw table. If the work surface and any work material supports are not level and on the same level, unwanted bevel angles will appear in the cuts, resulting in poor joinery.

- Work pieces may be secured to the saw table using the Hold Down Clamp or other clamping devices (not included). Securing the workpiece will provide safety by preventing kickback and by removing the need to hold workpieces near the blade by hand. Clamping the workpiece will also improve cutting accuracy by preventing the workpiece from moving during the cutting operation.

- When using this saw, work pieces are often quite long. Allow room on both the left and right of the saw for extended work pieces.

General Operating Instructions

- When the Handle is lowered, the 1. Blade Guard raises automatically. When the Handle is raised, the Blade Guard returns to its safety position. Keep your hands clear of the Blade when the Handle is lowered. Never interfere with the proper movement of the Blade Guard.

- There are locking mechanisms for the miter angle and the Slides. Unlock the Table to set the miter angle, then re-lock it before making the cut. Unlock the Slide using the Slide Lock Wing Screw before cutting if the work material is too wide to “chop”.

- To rotate the Table, press down the Miter Thumb Lever, rotate the Table to the desired angle, then release the Miter Lock Lever. Notches are machined into the Base of the tool, which will lock the Table into several often-used miter angles. These angles are 0º (centered), 15º, 22.5º, 30º, and 45º, both left and right cut.

- On wider pieces, you will have to slide the blade while cutting. To unlock the Slide, loosen the Slide Lock Wing Screw at the back of the saw.

- To make a bevel cut, release the Bevel Lock Lever, rotate the blade assembly to the desired bevel angle, then lock the blade assembly in place using the Bevel Lock Lever. Making bevel cuts is discussed in more detail later in this manual.

- This saw is provided with a Kerf Board. The Kerf Board helps to prevent tear-out on the bottom side of the work material. The Kerf Board is factory adjusted prior to shipment of this tool, so the blade does not contact the Kerf Board during normal operation, including bevel cuts. Adjustment of the Kerf Board and techniques to prevent tear-out are discussed later in this booklet.

- Before starting work, check the accuracy of the Guide Fence, miter angle, and bevel angle. Instructions for checking and adjusting these angles are discussed later in this booklet.

- The work 8. material must be properly supported before cutting. The material must be level on the Table. The material must be supported on both ends. Using the Work Piece Extension Supports is discussed in the next section.

Using the Work Piece Extension Supports

- The Work Piece Extension Supports are inserted into each side of the Table, and locked in place using the Wing Screws.

- When properly installed, the upper face of the Work Piece Extension Supports is level with the Table and provides a wider support surface for the workpiece.

- Always support the workpiece to be level with the table, so that after the cut is made, the cut-off pieces will not fall. You may need to use saw horses or other supports (not included) to support the workpiece.

- If the workpiece is not level, you will make an unintentional bevel cut in the material. If the workpiece is not supported, it will bind the blade and may cause the material to kick back, potentially causing injury.

Adjusting the Miter Angle

- A miter cut is one that is at an angle across the horizontal surface of the material. You will commonly make 45º miter cuts to join two pieces in a right-angle corner. A 30º cut is often used for a scarf joint or to make a chamfered end.

- To make a miter cut, loosen the Miter Lock the Knob by turning it approximately 1/4 turn counterclockwise. Press down the Thumb Lever to unlock the Table. While holding the Thumb Lever down, move the Table to the desired angle. The Miter Angle Indicator will indicate the selected angle. The table will lock into place at often-used miter angles, including 22.5º, 30º, 45º, and 90º on both left and right sides.

- With the Table adjusted to the desired angle, place the workpiece flush against the Fence, secure it with the Hold Down Clamp, and make the cut.

Adjusting the Bevel Angle

- A bevel cut is one that is at an angle to the vertical plane of the material.

- Bevel cuts can be used to miter relatively wide and thin material. Bevel cuts can be used in combination with a miter cut to form a compound angle. Compound angle cuts are often used in crown moldings, picture frames, and similar trim materials.

- To set the bevel angle, loosen the Bevel Lock Handle at the rear of the saw. To do this, press the Lock Button and rotate the Handle 1/2 turn counterclockwise. Move the blade assembly to the desired angle. You can read the angle on the Bevel Angle Indicator. Lock the blade assembly into position by pressing in the Lock Button and rotating the Bevel Lock Handle clockwise. Tighten firmly but not over-tight.

- Make a sample cut in a piece of scrap and check to be sure the bevel angle is correct. If it is not, correct the angle before cutting your work material.

Using the Depth Stop

- If you want to make a kerfing or rabbet cut that does not cut through the workpiece, you can use the Depth Stop Screw to control the depth of the cut.

- To limit blade assembly travel, turn the Depth Stop Screw clockwise. The further you screw down the Depth Stop Screw, the shallower the cut will be.

- After the desired cut has been made, return the Depth Stop Screw to its open position by turning it counterclockwise.

Making a Cut

- Observe all safety and planning items discussed in this booklet. Detailed instructions on each of the following steps are discussed in this booklet. Do not make any cuts until you have read this entire booklet and are familiar with the operation of this tool.

- Release the Locking Pin to allow the blade assembly to come up. Check to be sure the Table is fixed in place at the desired miter angle. Check to be sure the slide lock is released to allow the blade assembly to slide freely.

- Blow any sawdust or debris away from the Fence. Place the work material against the Fence.

- Make any necessary miter or bevel adjustments.

- Align the marked location of the cut on the work material with the saw blade. Be aware that the Saw Blade will remove material from the cut equal to the width of the blade. This is the “kerf”. To prevent your workpiece from being cut too short, align the edge of the blade with your measured mark, keeping the kerf on the waste side of the cut.

- Hold the work material in place using the Hold Down Vise. Ensure that the work material is level and supported securely, using saw horses or supports if necessary.

- Grip the Saw Handle and squeeze the Trigger to start the Blade turning.

- Pressing down lightly, move the Blade smoothly across the work material to cut it. With narrow material, you can press straight down, “chopping” the material. With wider material, you must move the Blade across the material to cut it. Do not bear down on the material; use light downward pressure. If the material binds the blade, release the trigger. Keep your hands away from the Blade.

- When the cut is completed, raise the blade assembly, wait for the Blade to stop turning, release the Hold Down Vise, and remove the work material from the saw.

Maintenance And Servicing

WARNING To prevent serious injury from accidental operation, turn the Power Switch of the tool to its “OFF” position and unplug the tool from its electrical outlet before performing any inspection, maintenance, or cleaning procedures.

To prevent serious injury from tool failure: Do not use damaged equipment. If abnormal noise or vibration occurs, have the problem corrected before further use.

Cleaning, Maintenance, and Lubrication

- BEFORE EACH USE, inspect the general condition of the tool. Check for loose screws, misalignment or binding of moving parts, cracked or broken parts, damaged electrical wiring, and any other condition that may affect its safe operation.

- After Use,, clean the external surfaces of the tool with a clean, moist cloth. To prevent accidents, turn off the tool and disconnect its power supply after use. Clean, then store the tool indoors out of children’s reach.

- If the blade has become dirty, use a 3-blade cleaner (not included) to clean it. Dirty blades will bind more easily, and will more often overheat and burn the wood as it cuts. Overheated blades dull more easily.

- If the Blade has become dull, replace it. Dull blades will cause increased tear-out and ragged edges on the cuts.

- Occasionally, clean the Slides, rotating Table components and other moving parts. Use a good quality dry lubricant (not included) which will not attract dust.

- WARNING If the supply cord of this power tool is damaged, it must be replaced only by a qualified service technician.

Replacing the Blade

- Unplug the tool from its power source.

- Lock the blade assembly in the raised position by pushing in the Locking Pin.

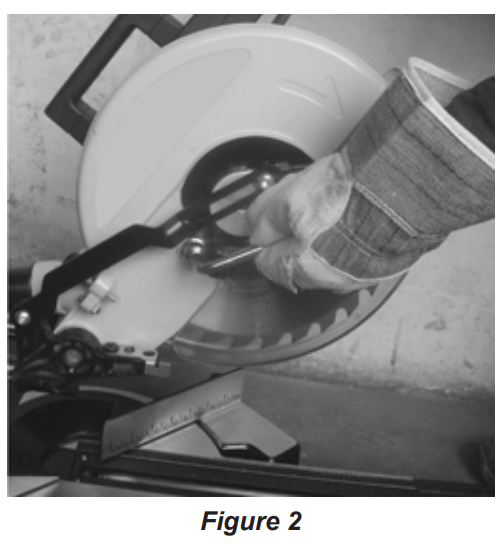

- Use the supplied Wrench to remove the Center Cover Fixing Bolt holding the Center Cover in place by turning it counterclockwise. (See Figure 2.)

- Remove the Safety Screw. (See Figure 3.)

- Raise the Blade Guard and Center Cover. (See Figure 4.)

- While holding in the Arbor Lock Button, use the Wrench to loosen the Arbor Bolt by turning it clockwise. (See Figure 5.)

- Remove the Arbor Bolt, Outer Flange, and Saw Blade by pulling them straight off the Arbor.

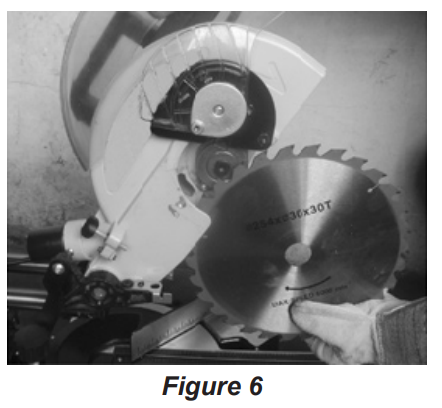

- Reinstall a new Blade on the Arbor. (See Figure 6.) Be sure to match the direction marked on the new blade with the direction marked on the saw Blade Housing.

- Replace the Outer Flange and Arbor 9. Bolt. Tighten the Arbor Bolt securely using the Wrench by turning it counterclockwise.

- Rotate the Center Cover back into place and tighten the Center Cover Fixing Bolt using the Wrench by turning it clockwise.

- Release the Locking Pin.

Adjusting or Replacing the Kerf Board

- If the Kerf Board becomes damaged, it must be replaced.

- Remove the four screws holding the Kerf Board in place.

- Install a new Kerf Board. Replace the four screws and tighten them slightly.

- To adjust the Kerf Board, lower the Saw Blade and lock it down with the Locking Pin. Adjust the Kerf Board 0 the right side of the Blade slightly clears the edge of the Kerf Board. Loosen the Bevel Lock and set the Bevel Angle at 45° left. Ensure that the left side of the Blade clears the Kerf Board. Tighten the four screws holding the Kerf Board in place.

Cleaning and Lubricating the Miter Saw

- Observe the Dust Bag while using the saw. Empty the sawdust into an appropriate container when the bag is full.

- Occasionally, wipe or blow off sawdust that accumulates on the saw. Sawdust on the Fence can cause you to make inaccurate cuts.

- Keep the Slides free of sawdust. Wipe or blow them off as required. Use a dry lubricant or wax on the slides. Do not use an oil or grease lubricant, as this will attract dust.

- Occasionally, lubricate the pivot point of the Table as well as other moving parts with a dry lubricant.

Troubleshooting

PLEASE READ THE FOLLOWING CAREFULLY

THE MANUFACTURER AND/OR DISTRIBUTOR HAS PROVIDED THE PARTS LIST AND ASSEMBLY DIAGRAM IN THIS MANUAL AS A REFERENCE TOOL ONLY. NEITHER THE MANUFACTURER NOR DISTRIBUTOR MAKES ANY REPRESENTATION OR WARRANTY OF ANY KIND TO THE BUYER THAT HE OR SHE IS QUALIFIED TO MAKE ANY REPAIRS TO THE PRODUCT, OR THAT HE OR SHE IS QUALIFIED TO REPLACE ANY PARTS OF THE PRODUCT. IN FACT, THE MANUFACTURER AND/OR DISTRIBUTOR EXPRESSLY STATES THAT ALL REPAIRS AND PART REPLACEMENTS SHOULD BE UNDERTAKEN BY CERTIFIED AND LICENSED TECHNICIANS, AND NOT BY THE BUYER. THE BUYER ASSUMES ALL RISK AND LIABILITY ARISING OUT OF HIS OR HER REPAIRS TO THE ORIGINAL PRODUCT OR REPLACEMENT PARTS THERETO, OR ARISING OUT OF HIS OR HER INSTALLATION OF REPLACEMENT PARTS THERETO.

For moe manuals by Harbor Freight, visit ManualsLibraryy

Harbor Freight 98199 Sliding Compound Miter Saw-FAQs

What is a sliding compound miter saw used for?

It is used to make precise crosscuts, bevel cuts, miter cuts, and compound cuts on wood, trim, molding, and with the right blade, some plastics or metals.

What is the difference between a miter saw and a sliding miter saw?

A sliding miter saw has a sliding feature that allows it to cut wider materials than a standard miter saw.

What types of cuts can this saw make?

It can make crosscuts, miter cuts, bevel cuts, and compound cuts for angled joints.

What size materials can it cut?

The sliding feature increases cutting capacity, allowing thicker and wider boards than a non-sliding saw.

What safety precautions should I follow?

Keep hands at least 6 inches from the blade, wear safety glasses, avoid cutting warped or small pieces, and always let the blade stop completely before removing scrap.

Can I use it to cut laminate flooring?

Yes, it works well for precise cuts on laminate flooring and other long boards when placed on a stable surface.

What are common mistakes to avoid?

Avoid cutting small pieces by hand, never remove safety guards, and don’t rush the cut. Always secure your workpiece.

How should I position the saw for best results?

Place it on a stable surface with enough clearance around for the blade to swing freely. Use the detent stops for common angles.

What is a bevel cut?

A bevel cut is an angled cut along the thickness of the wood, where the top surface is not perpendicular to the edges.