Chicago Electric 80-Amp Inverter Arc Welder

Save This Manual

Keep this manual for the safety warnings and precautions, assembly, operating, inspection, maintenance, and cleaning procedures. Write the product’s serial number in the back of the manual near the assembly diagram (or the month and year of purchase if the product has no number). Keep this manual and the receipt in a safe and dry place for future reference.

IMPORTANT SAFETY INFORMATION

In this manual, on the labeling, and all other information provided with this product: This is the safety alert symbol. It is used to alert you to potential personal

injury hazards. Obey all safety messages that follow this symbol to avoid possible injury or death.

- DANGER indicates a hazardous situation which, if not avoided, will result in death or serious injury.

- WARNING indicates a hazardous situation which, if not avoided, could result in death or serious injury.

- CAUTION, used with the safety alert symbol, indicates a hazardous situation which, if not avoided, could result in minor or moderate injury.

- NOTICE is used to address practices not related to personal injury.

- CAUTION, without the safety alert symbol, is used to address practices not related to personal injury

General Safety Warnings

WARNING: Read all safety warnings and instructions. Failure to follow the warnings and instructions may result in electric shock, fire, and/or serious injury. Save all warnings and instructions for future reference.

1. Work area safety

- Keep the work area clean and well-lit. Cluttered or dark areas invite accidents.

- Do not operate welders in explosive atmospheres, such as in the presence of flammable liquids, gases, or dust. Welders create sparks that may ignite the dust or fumes.

- Keep children and bystanders away while operating a welder. Distractions can cause you to lose control.

2. Electrical safety

- Welder plugs must match the outlet. Never modify the plug in any way. Do not use any adapter plugs with grounded welders. Unmodified plugs and matching outlets will reduce the risk of electric shock.

- Avoid body contact with grounded surfaces such as pipes, radiators, ranges, and refrigerators. There is an increased risk of electric shock if your body is grounded.

Do not expose welders to rain or wet conditions. Water entering a welder will increase the risk of electric shock.

d. Do not abuse the cord. Never use the cord for carrying, pulling, or unplugging the welder. Keep the cord away from heat, oil, sharp edges, or moving parts. Damaged or entangled cords increase the risk of electric shock. - When operating a welder outdoors, use an extension cord suitable for outdoor use. Use of a cord suitable for outdoor use reduces the risk of electric shock.

- If operating a welder in a damp location is unavoidable, use a Ground Fault Circuit Interrupter (GFCI) protected supply. Use of a GFCI reduces the risk of electric shock.

3. Personal safety

- Stay alert, watch what you are doing, and use common sense when operating a welder. Do not use a welder while you are tired or under the influence of drugs, alcohol, or medication. A moment of inattention while operating welders may result in serious personal injury.

- Use safety equipment. Always wear ANSI-approved safety glasses and an arc-shaded, impact-safety full face shield. Safety equipment, such as a NIOSH-approved respirator, heavy-duty work gloves, non-skid safety shoes, and hearing protection, used in appropriate conditions, will reduce the risk of personal injuries.

- Prevent unintentional starting. Ensure the switch is in the off position before connecting to a power source or moving the welder. Carrying or energizing welders that have the switch on invites accidents.

- Do not overreach. Keep proper footing and balance at all times. This enables better control of the welder in unexpected situations.

- Only use safety equipment that has been approved by an appropriate standards agency. Unapproved safety equipment may not provide adequate protection. Eye protection must be ANSI-approved, and breathing protection must be NIOSH-approved for the specific hazards in the work area.

4. Welder use and care

- Do not use the welder if the switch does not turn it on and off. Any welder that cannot be controlled with the switch is dangerous and must be repaired.

Disconnect the plug from the power source before making any adjustments, changing accessories, or storing welders. Such preventive safety measures reduce the risk of starting the welder accidentally. - Store idle welders out of the reach of children and do not allow persons unfamiliar with the welder or these instructions to operate the welder. Welders are dangerous in the hands of untrained users.

- Maintain welders. Check for misalignment or binding of moving parts, breakage of parts, and any other condition that may affect the welder’s operation. If damaged, have the welder repaired before use. Many accidents are caused by poorly maintained welders.

- Use the welder and accessories in accordance with these instructions, taking into account the working conditions and the work to be performed. Use of the welder for operations different from those intended could result in a hazardous situation.

5. Service

- Have your welder serviced by a qualified repair person using only identical replacement parts. This will ensure that the safety of the welder is maintained.

Specifications

Operating Instructions

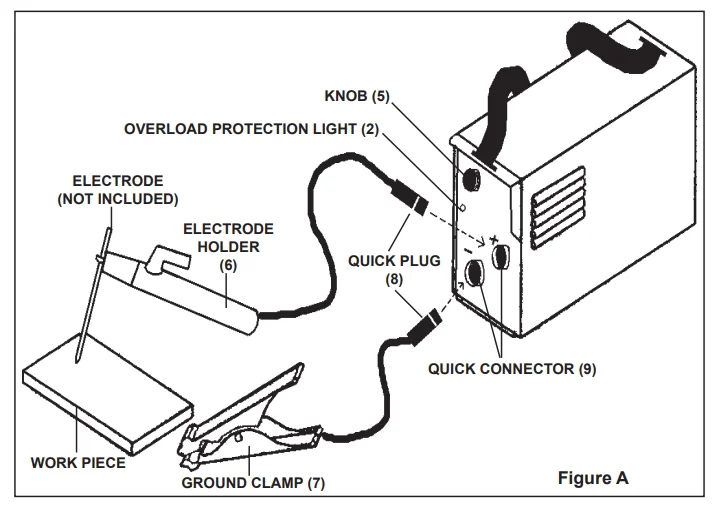

NOTE: For additional references to the parts listed in the following pages, refer to the Assembly Diagram and Figure A.

Warning: Prior to performing any assembly procedures, make sure the power cord of the Inverter Arc Welder is unplugged from its electrical outlet.

- Connect the Quick Plug (8) to the negative (-) Quick Connector (9) on the Inverter Arc Welder. Also, connect the Ground Clamp (7) to the work piece or to a metal welding table where the work piece will be placed.

- Connect the Electrode Holder (6) to the positive (+) Quick Connector on the front of the Inverter Arc Welder. Install an electrode (not included) into the Electrode Holder by squeezing the Holder while positioning the electrode at the desired angle.

- Plug the Power Cord (16) into the nearest 120-volt grounded electrical outlet. WARNING! Wear ANSI-approved safety glasses under a properly shaded welding helmet.

- Hold the Electrode Holder (6) away from all objects. Then position the Knob (5) to about mid-range to start.

- To begin welding, position the electrode at about a 60º angle and touch the tip of it to the workpiece. Once the arc is stable, move the electrode along the workpiece and down as the welding process consumes the electrode. Replace the electrode as needed to complete the job.

- If necessary, adjust the Knob (5) to increase or decrease the electrical current output to achieve the desired performance and weld results. NOTE: The Inverter Arc Welder is equipped with an automatic “Hot Start.” This feature momentarily surges the current output, which makes starting the electrode easier. Should the electrode stick to the workpiece, usually a quick twist of the Electrode Holder (6) will break the electrode free. If the electrode is not broken loose, shut down the Inverter Arc Welder and physically remove the electrode from the Electrode Holder and work piece. CAUTION! The electrode and metal are hot.

- When the job is completed, turn the Knob (5) to its “OFF” position and unplug the Power Cord (16) from its electrical outlet. Then remove the Ground Clamp (7) from the workpiece or metal table.

Ratings listed above are estimates and will vary depending on electrode coating and electrode manufacturer. When possible, use the manufacturer’s recommended amperage setting instead.

Inspection, Maintenance, and Cleaning

Make sure the Knob (5) is in its “OFF” position. Unplug the Power Cord (16) from its electrical outlet and allow the Inverter Arc Welder and discharge electrode to completely cool before performing any inspection, maintenance, or cleaning procedures.

- Before each use, inspect the general condition of the Inverter Arc Welder. Check for damaged electrical wiring, loose connections, cracked, burnt, or broken parts, and any other condition that may affect its safe operation. If abnormal noise or vibration occurs, have the problem corrected before further use. Do not use damaged equipment.

- Before each use, clean or, if necessary, replace the electrode.

- To clean, use a shop vacuum cleaner or compressed air.

- When storing, make sure to store the Inverter Arc Welder in a safe, clean, and dry location.

Troubleshooting Guide

1. The Inverter Arc Welder will not turn on.

- Make sure the Power Cord (16) is plugged in.

- Make sure the Quick Plugs (8) are properly plugged into the Quick Connectors (9).

2. The Inverter Arc Welder is turned on but will not strike an arc.

- Make sure the electrode is securely attached to the Electrode Holder (6).

- Make sure the Quick Plugs (8) are properly plugged into the Quick Connectors (9).

- Make sure the Ground Clamp (7) is securely attached to the work piece or metal table on which the work piece is placed, and that the point of attachment is clean from rust, paint, or any other material that would insulate the connection.

3. The Inverter Arc Welder is not working, and the Overload Protection Light (2) is on.

- When the Inverter Arc Welder overheats, it will automatically shut down temporarily. When this happens, stop welding but leave the welder on until it cools down. As soon as the Overload Protection Light goes off, you may continue welding.

- If the welder does not cool down as described above, check to see if the Fan (13) is operating. If the Fan is operating, check the side panel vents to see if anything is obstructing airflow from the Fan. If obstructions exist, remove them and wait for the welder to cool while observing the Overload Protection Light (2).

4. The current output is unstable and unable to produce a smooth welding bead.

- Make sure the Power Cord (16) is properly connected to its electrical outlet.

- Make sure the Quick Plugs (8) are securely connected to the Quick Connectors (9).

- Make sure the Ground Clamp (7) is securely attached to the work piece or metal table on which the work piece is placed, and that the point of attachment is clean from rust, paint, or any other material that would insulate the connection.

- Make sure the electrode is in good condition and that the welding current output is properly adjusted. (Increasing the current output usually improves this situation.)

Please Read the Following Carefully

The manufacturer and/or distributor has provided the parts list and assembly diagram in this manual as a reference tool only. Neither the manufacturer nor distributor makes any representation or warranty of any kind to the buyer that he or she is qualified to make any repairs to the product, or that he or she is qualified to replace any parts of the product.

In fact, the manufacturer and/or distributor expressly states that all repairs and parts replacements should be undertaken by certified and licensed technicians, and not by the buyer. The buyer assumes all risk and liability arising out of his or her repairs to the original product or replacement parts thereto, or arising out of his or her installation of replacement parts thereto.

Parts List

Assembly Diagram

Limited 90 Day Warranty

Harbor Freight Tools Co. makes every effort to assure that its products meet high quality and durability standards, and warrants to the original purchaser that this product is free from defects in materials and workmanship for the period of 90 days from the date of purchase. This warranty does not apply to damage due directly or indirectly to misuse, abuse, negligence, or accidents, repairs or alterations outside our facilities, criminal activity, improper installation, normal wear and tear, or lack of maintenance.

We shall in no event be liable for death, injuries to persons or property, or for incidental, contingent, special, or consequential damages arising from the use of our product. Some states do not allow the exclusion or limitation of incidental or consequential damages, so the above limitation of exclusion may not apply to you. This warranty is expressly instead of all other warranties, express or implied, including the warranties of merchantability and fitness.

To take advantage of this warranty, the product or part must be returned to us with transportation charges prepaid. Proof of purchase date and an explanation of the complaint must accompany the merchandise. If our inspection verifies the defect, we will either repair or replace the product at our election, or we may elect to refund the purchase price if we cannot readily and quickly provide you with a replacement. We will return repaired products at our expense, but if we determine there is no defect, or that the defect resulted from causes not within the scope of our warranty, then you must bear the cost of returning the product.

This warranty gives you specific legal rights, and you may also have other rights which vary from state to state.

3491 Mission Oaks Blvd. • PO Box 6009 • Camarillo, CA 93011 • 1-888-866-5797

Visit our website at: http://www.harborfreight.com.

Email our technical support at: [email protected]

For More Manuals By Chicago Electric, Visit ManualsLibraryy.

Chicago Electric 80-Amp Inverter Arc Welder-FAQs

Is arc welding AC or DC?

Arc welders can use either AC or DC. The Chicago Electric 80-Amp Inverter typically delivers DC output for stable performance and better arc control.

What is the “golden rule” of welding?\/;

Always prepare the joint properly, ensure the machine is set up correctly, and maintain a comfortable welding position to achieve a smooth, strong weld.

Which welding wire size is better – 0.8 mm or 0.9 mm?

Use 0.8 mm wire for thin materials and more control, while 0.9 mm wire suits thicker metals and higher welding speeds.

Can you weld aluminum with an inverter welder?

Yes, with the right settings and electrodes, inverter welders can weld aluminum effectively, especially in TIG or MIG modes.

What metals should not be welded?

Avoid welding dissimilar metals like copper and aluminum together, as their different thermal properties can cause cracks and weak joints.

What is the 35-foot rule in welding?

Keep all flammable materials at least 35 feet away from the welding area, or shield them properly to prevent fires from sparks or heat.

Why does my rod stick when arc welding?

The rod may stick if your amperage is too low, the electrode angle is incorrect, or you’re moving too slowly. Increasing amperage slightly often helps.

1Should beginners start with a MIG or ARC welder?

Beginners usually find MIG welding easier to learn due to its continuous wire feed, but ARC welding is better for outdoor work and thicker materials.

Can you weld 7018 electrodes on AC current?

Yes, but 7018 rods perform best on DC current. Some “7018AC” variants are specially designed for AC welders.