Ingersoll-Rand TS5 Bare Air Compressor

RECEIPT & INSPECTION

Ensure adequate lifting equipment is available for unloading and moving the compressor to the installation site. Use suitable lifting equipment (i.e., forklift) to lift and transport the compressor to the installation site. Ensure the lifting equipment, straps, etc., are capable of supporting the weight of the unit.

Lifting Equipment and Straps

Before signing the delivery receipt, inspect for damage and missing parts. If damage or missing parts are apparent, make the appropriate notation on the delivery receipt, then sign the receipt. Immediately contact the carrier for an inspection. All material must be held in the receiving location for the carrier’s inspection. Delivery receipts that have been signed without a notation of damage or missing parts are considered to be delivered “clear.” Subsequent claims are then considered to be concealed damage claims.

Settle damage claims directly with the transportation company. If you discover damage after receiving the compressor (concealed damage), the carrier must be notified within 15 days of receipt, and an inspection must be requested by telephone with confirmation in writing. On concealed damage claims, the burden of establishing that the compressor was damaged in transit reverts to the claimant. Read the unit nameplate to verify it is the model ordered, and read the motor nameplate to verify it is compatible with your electrical conditions. Make sure electrical enclosures and components are appropriate for the installation environment.

INSTALLATION

SELECTING A LOCATION

For most electric motor units, select a relatively clean and dry, well-lighted indoor area with plenty of space for proper ventilation, cooling air flow, and accessibility. Provide 1,000 cubic feet of fresh air per 5 horsepower. Locate the unit at least 15 inches (38 cm) from walls, and make sure the main power supply is clearly identified and accessible.

Unless the electrical components of the unit are specially protected for outdoor use, do not install an electric motor unit outdoors or in an area that will expose the electrical components to rain, snow, or sources of appreciable moisture.

AMBIENT TEMPERATURE CONSIDERATIONS

Ideal operating temperatures are between 32°F and 100°F (0°C and 37.8°C). If temperatures consistently drop below 32°F (0°C), install the compressor in a heated area. If this is not possible, you must protect safety/relief valves and drain valves from freezing. If temperatures are consistently below 40°F (4.4°C), consider installing an external crankcase heater kit, especially if the compressor has difficulty starting.

HUMID AREAS

In frequently humid areas, moisture may form in the pump and produce sludge in the lubricant, causing running parts to wear out prematurely. Excessive moisture is especially likely to occur if the unit is located in an unheated area that is subject to large temperature changes.

Two signs of excessive humidity are external condensation on the pump when it cools down and a “milky” appearance in petroleum lubricant. You may be able to prevent moisture from forming in the pump by increasing ventilation, operating for longer intervals, or installing an external crankcase heater kit.

NOISE CONSIDERATIONS

Consult local officials for information regarding acceptable noise levels in your area. To reduce excessive noise, use vibration isolator pads or intake silencers.

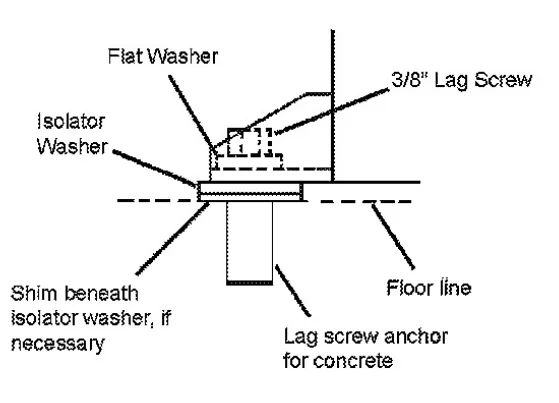

MOUNTING

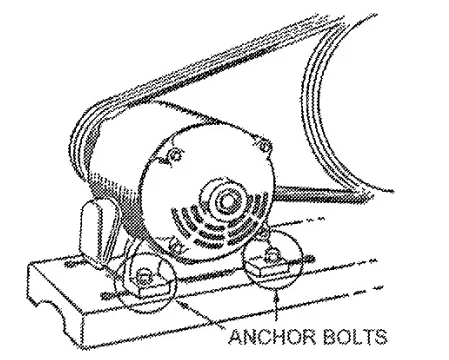

Bolt the unit to a firm, level foundation (such as a concrete floor). Do not bolt uneven feet tightly to the foundation, as this will cause excessive stress on the receiver tank. Use metal shims under the “short” feet if necessary.

TYPICAL PERMANENT MOUNTING (CUSTOMER SUPPLIED HARDWARE)

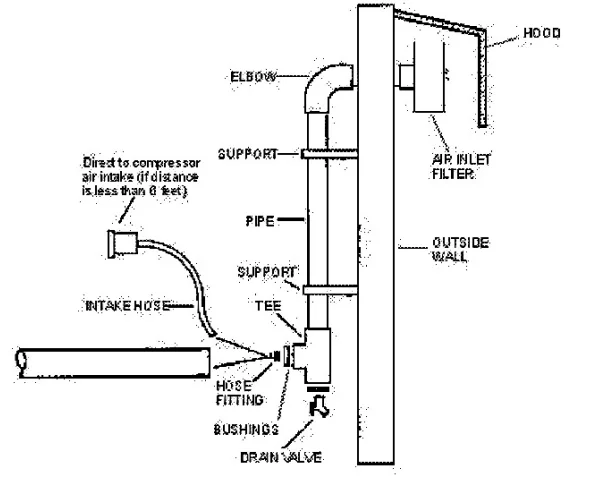

INSTALLING REMOTE AIR INLET PIPING

CAUTION: Do not operate the unit without air inlet filtration.

If the air around the unit is relatively free of dirt, install the air inlet filter at the inlet connection at the pump. If the air is dirty, pipe the filter to a source of clean air. Use PVC plastic tubes for remote inlet piping. Do not use black pipe or galvanized pipe, as these promote sweating and rust. Consider installing an in-line type filter for ease of cleaning and replacement.

Make the line as short and direct as possible and as large, or larger, than the diameter of the inlet connection on the pump. Do not install piping with a diameter lower than that of the pump intake. Increase the pipe diameter one size for every 10 feet (3 m) of length or every 90° bend. Make sure the piping is adequately braced. If you pipe the filter outdoors, cover it with a hood to prevent the entrance of rain or snow. Heavy-duty filter elements and filtration equipment are available for fine airborne dust, such as cement and rock dust.

TYPICAL REMOTE AIR INLET PIPING

INSTALLING DISCHARGE PIPING

SYNTHETIC COMPRESSOR LUBRICANT MATERIAL COMPATIBILITY LIST

SUITABLE: FKM (Fluoroelastomer), PTFE, Epoxy (Glass Filled), Oil Resistant Alkyd, Fluorosilicone, Fluorocarbon, Polysulfide, 2-Component Urethane, Nylon, POM (Polyoxymethylene/Polyacetal), High Nitrile Rubber (Buna N, NBR more than 36% Acrylonitrile), Polyurethane, Polyethylene, Epichlorohydrin, Polyacrylate, Melamine, Polypropylene, Baked Phenolics, Epoxy, Modified Alkyds (® indicates trademark of DuPont Corporation).

NOT RECOMMENDED: Neoprene, Natural Rubber, SBR Rubber, Acrylic Paint, Lacquer, Varnish, Polystyrene, PVC, ABS, Polycarbonate, Cellulose Acetate, Low Nitrile Rubber (Buna N, NBR less than 36% Acrylonitrile), EPDM, Ethylene Vinyl Acetate, Latex, EPR, Acrylics, Phenoxy, Polysulfones, Styrene Acrylonitrile (SAN), Butyl.

NOTICE: All compressed air systems generate condensate, which accumulates in any drain point (e.g., tanks, filters, drip legs, aftercoolers, dryers). This condensate contains lubricating oil and/or substances that may be regulated and must be disposed of in accordance with local, state, and federal laws and regulations.

GENERAL REQUIREMENTS

The piping, fittings, air receiver tank, etc., must be certified safe for at least the maximum working pressure of the unit. Use hard-welded or threaded steel or copper pipes and cast iron fittings that are certified safe for the unit’s discharge pressure and temperature. DO NOT USE PVC PLASTIC IN THE COMPRESSED AIR DISCHARGE LINE. Use pipe thread sealant on all threads, and make up joints tightly to prevent air leaks.

CONDENSATE DISCHARGE PIPING

If installing a condensate discharge line, the piping must be at least one size larger than the connection, as short and direct as possible, secured tightly, and routed to a suitable drain point or waste container. Condensate must be disposed of in accordance with local, state, and federal laws and regulations.

INSTALLING ELECTRICAL WIRING

GENERAL

The motor rating, as shown on the motor nameplate, and the power supply must have compatible voltage, phase, and hertz characteristics.

WIRE SIZE

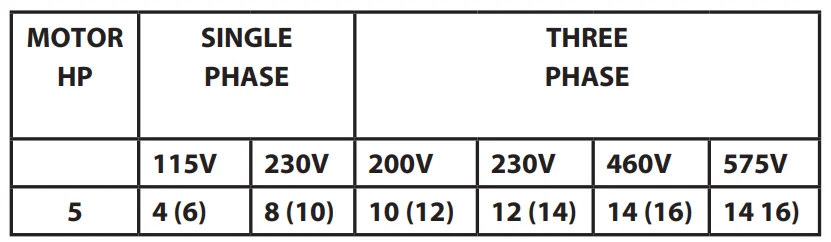

The electrical wiring between the power supply and electric motor varies according to motor horsepower and other factors. Install adequately sized power leads to protect against excessive voltage drop during start-up. Refer to the National Electric Code (NEC) for information on selecting the proper wire size and securing electrical connections.

If you connect additional electrical equipment to the same circuit, consider the total electrical load when selecting the proper wire size. DO NOT USE UNDERSIZED WIRE. If wire size information is not available, the wire sizes shown in the following wire selection chart can be used as a safe guide if the distance does not exceed 50 feet (15.3 m). For longer distances, consult an electrical contractor or the local electric company for recommendations.

Wire sizes shown in AWG (SWG):

- AWG = American Wire Gauge

- SWG = British Imperial Standard Wire Gauge

MAGNETIC STARTER

If the motor installed on your unit has a motor reset button, it does not require a magnetic starter. If the motor does not have this button and the unit does not have a factory-installed starter, install a magnetic starter with thermal overload protection. Follow the manufacturer’s instructions for installation. Ingersoll Rand cannot accept responsibility for damages arising from failure to provide adequate motor protection.

FUSES

Refer to the NEC to determine the proper fuse or circuit breaker rating required. When selecting fuses, remember that the momentary starting current of an electric motor is greater than its full load current. Time-delay or “slow-blow” fuses are recommended.

PRESSURE SWITCH

On units without a factory-installed pressure switch, wire a pressure switch in accordance with the appropriate wiring schematic in the DIAGRAMS section of this manual. Mount the pressure switch in accordance with the manufacturer’s recommendations. The connecting line to the receiver tank must be as short and direct as possible, and certified safe for at least the maximum working pressure of the unit.

COMPRESSOR LUBRICATION

CAUTION: Do not operate without lubricant or with inadequate lubricant. Ingersoll Rand is not responsible for compressor failure caused by inadequate lubrication.

SYNTHETIC COMPRESSOR LUBRICANT

Ingersoll Rand recommends All-Season Select synthetic lubricant from the start-up. See the WARRANTY for extended warranty information.

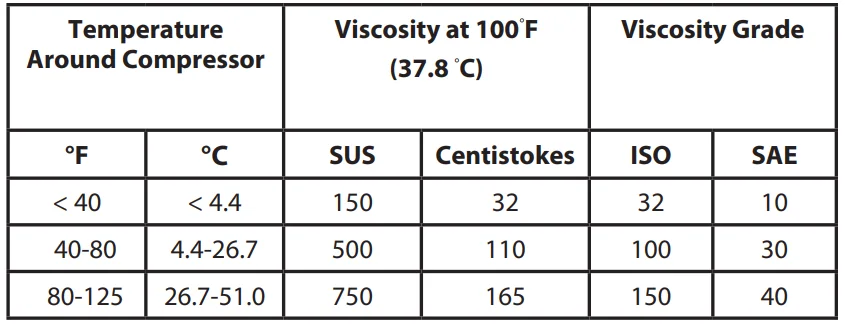

ALTERNATE LUBRICANTS

You may use XL-300 or a comparable petroleum-based lubricant that is premium quality, does not contain detergents, contains only anti-rust, anti-oxidation, and anti-foam agents as additives, has a flashpoint of 440°F (227°C) or higher, and has an auto-ignition point of 650°F (343°C) or higher. See the petroleum lubricant viscosity table below. The table is intended as a general guide only. Heavy-duty operating conditions require heavier viscosities. Refer specific operating conditions to Ingersoll Rand for recommendations.

If you use a petroleum-based compressor lubricant at start-up and decide to convert to All-Season Select later on, the pump must be decarbonized and flushed before conversion. Contact Ingersoll Rand for more information.

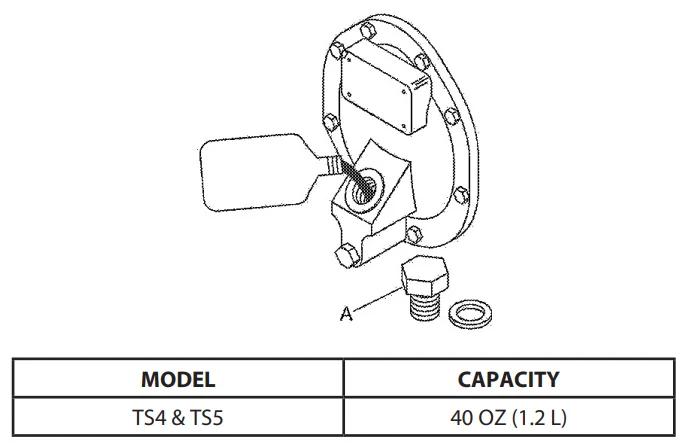

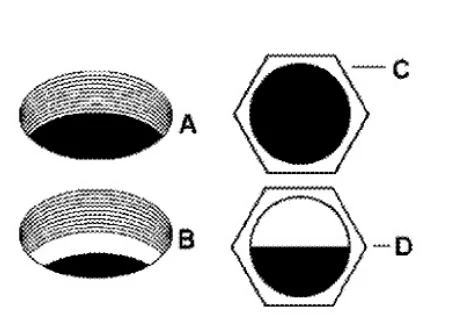

FILLING PROCEDURES:

- Unscrew and remove the oil fill plug.

- Fill the crankcase with lubricant.

- Replace the oil fill plug HAND TIGHT ONLY.

Use one of the following methods illustrated to determine when the crankcase is full.

- A = FULL level at the bottom thread of the oil fill opening on units without a sight glass.

- B = ADD level below the bottom thread of the oil fill opening on units without a sight glass.

- C = FULL level on units with a sight glass.

- D = ADD level on units with a sight glass.

LOW OIL LEVEL SWITCH

A float-activated low oil level switch may be installed to protect your unit against damage due to insufficient compressor oil level. Low oil level in the compressor crankcase causes the switch contacts to open, thus shutting the unit down until the proper oil level has been restored. Proper protection against low oil levels depends on proper adjustment of the low oil level switch.

During the initial run, stop the unit and drain one quart of oil from the compressor crankcase into a suitable clean container. Listen for the switch to click or check the switch with a continuity tester. The float sometimes gets cocked or stuck during shipping. If the float is cocked or stuck, open the disconnect switch, drain the remaining oil, remove the crankcase cover, and then free the float. Reassemble and then reuse the same oil.

OPERATION

START-UP

The Pressure Switch is pre-set at the required pressure. The range and differential settings are not adjustable. The Pressure Switch should not be tampered with in any way, and no attempt should be made to adjust the pressure settings, as this could damage the switch to the point of failure and/or void any warranty for the Pressure Switch.

- Close the service valve.

- Release any remaining tank pressure by slowly opening the manual drain valve.

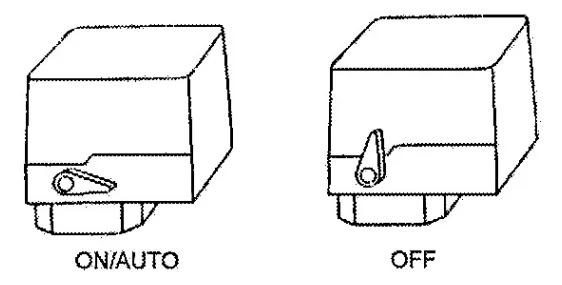

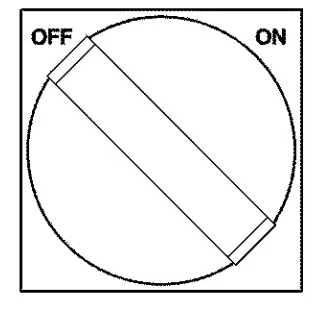

- Close the manual drain valve and apply power to the compressor. If the pressure switch is equipped with an “ON/AUTO-OFF” lever, flip the switch to the “ON/AUTO” position. If the unit is equipped with a control panel “ON/OFF” switch, move the switch to the “ON” position.

- TYPICAL PRESSURE SWITCH LEVER (IF EQUIPPED)

- TYPICAL CONTROL PANEL SWITCH (IF EQUIPPED)

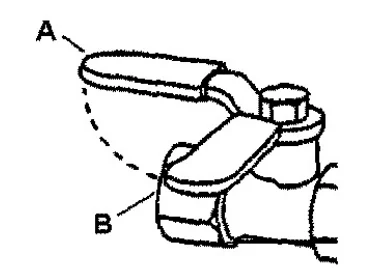

- Slowly open the service valve.

- TYPICAL SERVICE VALVE (A = OPEN, B = CLOSED)

OIL CONSUMPTION CHECK

A rule of thumb in determining a “passing grade” for oil consumption is to consider consumption at or above 50 horsepower-hours per ounce to be acceptable. The formula is as follows:

- Horsepower × Hours of Operation = Horsepower Hours

- Horsepower Hours ÷ Ounces of Oil Used = Hours per Ounce

To apply this formula, consider the size of the machine. In the following example, a 5-horsepower compressor uses 2 ounces of oil every 20 hours of operation.

- 5 Horsepower × 20 Hours of Operation = 100 Horsepower Hours

- 100 Horsepower Hours ÷ 2 Ounces of Oil Used = 50 Horsepower Hours per Ounce

The compressor in the example passes the oil consumption test.

MAINTENANCE

FILTER INSPECTION & CLEANING

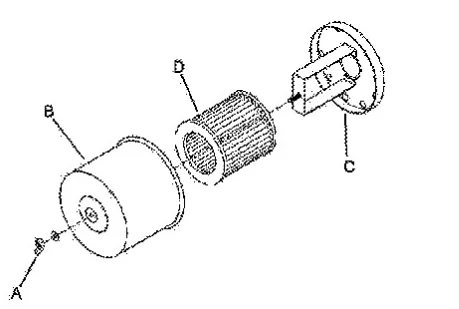

- Unscrew and remove the wing nut (A) securing the filter housing (B) to its base (C).

- Remove the filter housing and withdraw the old filter element (D). Clean the element with a jet of air or vacuum.

- Replace the filter element and housing, securing it in place with the wing nut previously removed.

OIL CHANGE

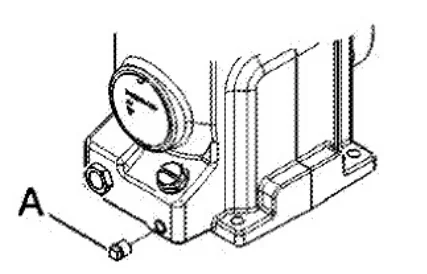

- Remove the oil drain plug (A) and allow the lubricant to drain into a suitable container.

- Replace the oil drain plug.

- Follow the filling procedures in the OPERATION section.

BELT ADJUSTMENT

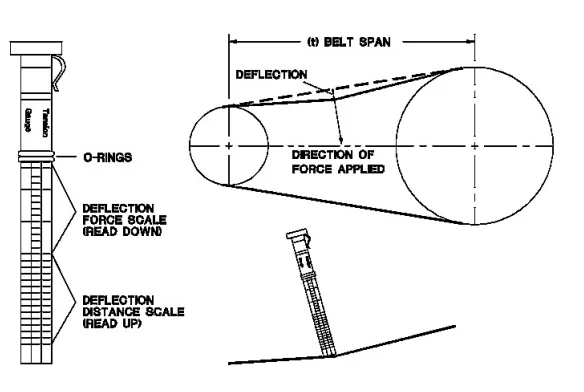

CHECKING BELT TENSION

Check belt tension occasionally, especially if looseness is suspected. New belts must also be properly tensioned upon installation.

TENSIONING BELTS

Belt tensioning can be achieved by loosening the motor anchor screws, pushing the motor away from the pump, and retightening the motor anchor screws. The motor can be easily moved by placing a prying tool beneath it. A commercially available spreader or other belt tensioning device can also be helpful.

Follow the procedures outlined below to correctly set and measure belt tension. Refer to the following illustration for a visual representation.

- Lay a straight edge across the top outer surface of the belt drive from pulley to sheave.

- At the center of the span, perpendicular to the belt, apply pressure to the outer surface of the belt with a tension gauge. Force the belt to the deflection indicated in the BELT TENSION TABLE in the DIAGRAMS & TABLES section. Compare the reading on the tension gauge to the table.

Ensure the pulley and sheave are properly aligned, and the motor anchor screws are adequately retightened before restarting the compressor. To prevent these problems from occurring, ensure the pulley and sheave are aligned, and the belt tension is satisfactory after installing new belts or tensioning existing belts.

TANK INSPECTION

The life of an air receiver tank is dependent upon several factors, including, but not limited to, operating conditions, ambient environments, and the level of maintenance. The exact effect of these factors on tank life is difficult to predict; therefore, Ingersoll Rand recommends that you schedule a certified tank inspection within the first five years of compressor service. To arrange a tank inspection, contact Ingersoll Rand. If the tank has not been inspected within the first 10 years of compressor service, the receiver must be taken out of service until it has passed inspection. Tanks that fail to meet requirements must be replaced.

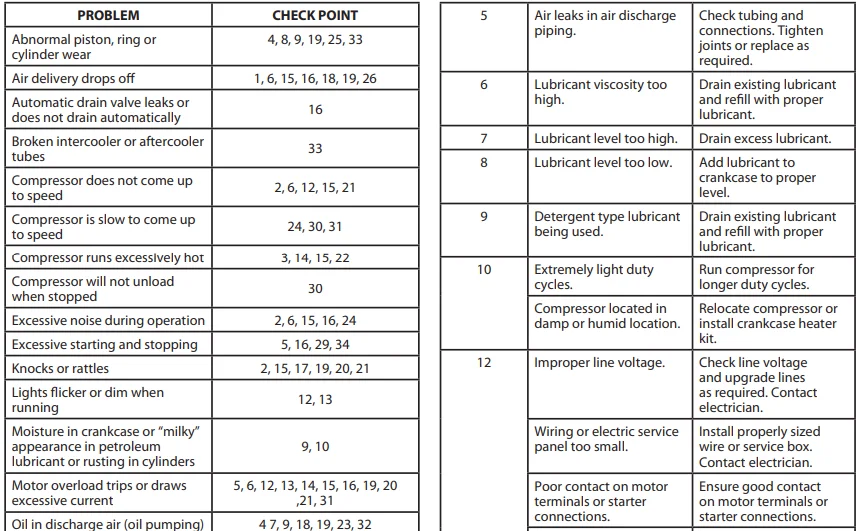

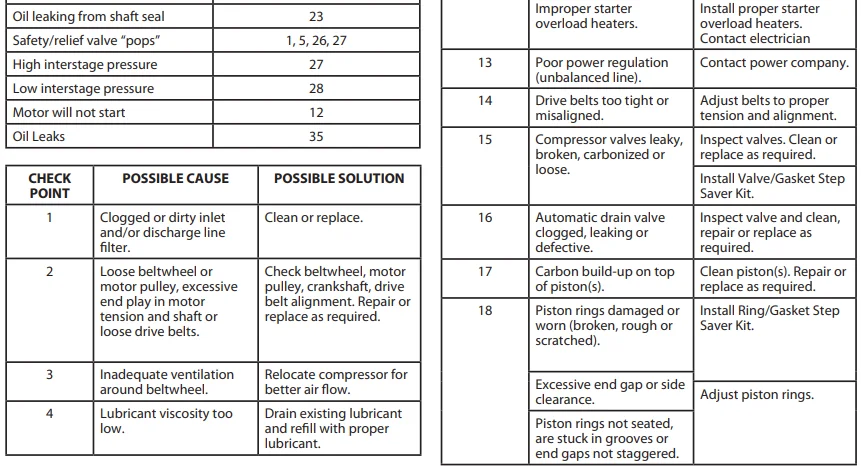

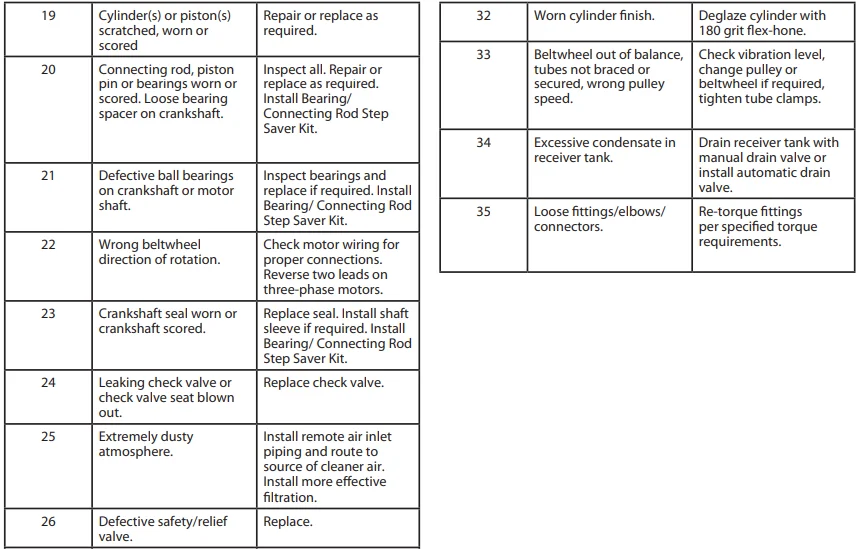

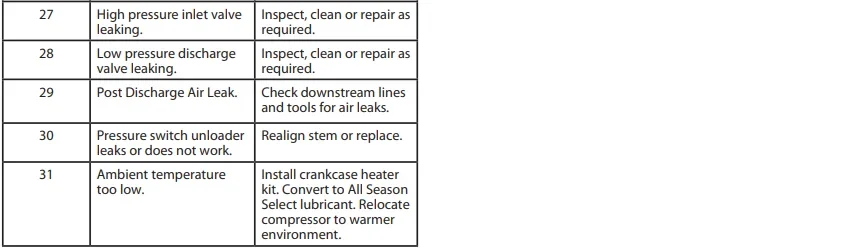

TROUBLESHOOTING

Visit ingersollrandproducts.com for more details.

For More Manuals By Ingersoll-Rand, Visit ManualsLibraryy.

Ingersoll-Rand TS5 Bare Air Compressor -FAQS

How does the Ingersoll-Rand TS5 air compressor work?

The TS5 compressor draws air into the compression unit, compresses it using rotating components, and stores the pressurized air in a tank for powering pneumatic tools and equipment.

What is the basic working principle of an air compressor?

An air compressor increases air pressure by reducing its volume, converting electrical or mechanical energy into stored compressed air energy.

What is the first step in troubleshooting an air compressor failure?

Start by checking the power supply to ensure the unit is plugged in and the circuit breaker has not tripped. Also inspect the air filter for blockages.

What is the most common cause of air compressor failure?

Lack of regular maintenance, overheating, and electrical problems are the most frequent reasons for compressor failure.

How can I diagnose a fault in my air compressor?

Inspect circuit breakers, fuses, wiring connections, pressure switches, and look for air leaks or overheating signs.

What does CFM mean in air compressors?

CFM (Cubic Feet per Minute) measures how much air the compressor delivers, which determines what tools it can support.

What are common air compressor problems?

Common issues include low pressure output, air leaks, clogged filters, overheating, electrical faults, and pressure switch failures.

What pressure does an Ingersoll-Rand air compressor typically operate at?

Operating pressure varies by model, but industrial Ingersoll-Rand compressors can reach very high pressure levels depending on configuration.

Can the pressure switch on an Ingersoll-Rand compressor be adjusted?

Yes. The cut-in and cut-out pressure settings can be adjusted carefully following safety procedures and manufacturer guidelines.