AEM 30-0300 X-Series Wideband UEGO AFR Sensor Controller Gauge

Features

- X-Digital Technology

- Free air or resistor trim calibration modes

- Fast response, 20ms typical

- 2-1/16″ / 52mm outer diameter mounting

- 8.0:1 to 20.0:1 AFR / 0.55 to 2.00 Lambda

- Configurable 3 or 4 digit precision display mode

- Lambda, AFR, O2 % display modes with reversible faceplate

- Black bezel/faceplate supplied; Silver/white available as an optional purchase

- Locking connectors

- Supports vehicle/system voltages up to 16V

- Supports Bosch LSU4.9 Sensor

- 0-5V Analog Output

- AEMnet (CAN bus) Output

- Serial RS-232 Output

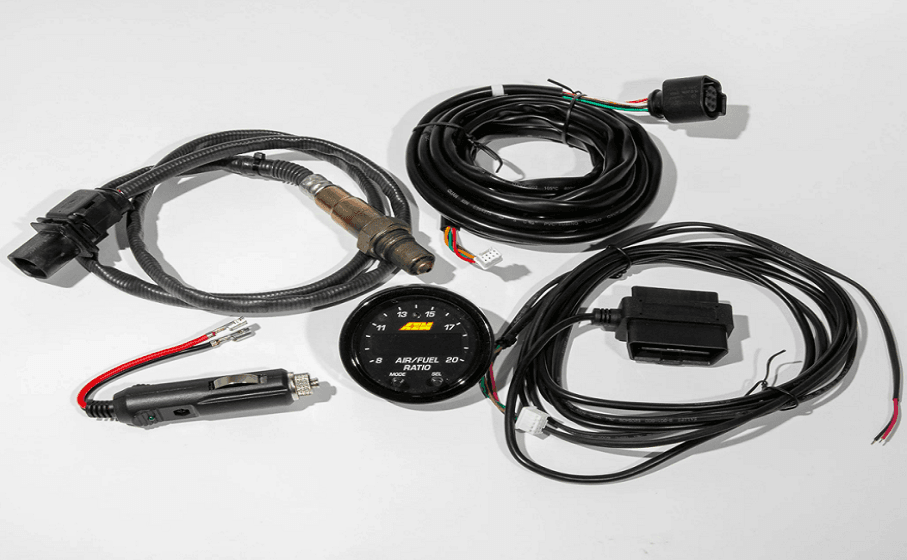

| KIT CONTENTS | |

| PN | Description |

| 10-0300 | INST, X-SERIES UEGO GAUGE |

| 35-0300 | GAUGE ASSY, X-SERIES AFR GAUGE |

| – | RED INSULATED BUTT CONNECTORS (4) |

| 35-4005 | WELD-IN BUNG,02 SENSOR 1214 MILD STEEL |

| 35-8618 | NUT, KNURLED, M4x0.7 (2) |

| 35-8614 | BRACKET, X-SERIES GAUGE |

| 35-3430 | PWR/IO CABLE, X-SERIES GAUGE |

| 35-3427 | SENSOR CABLE, X-SERIES GAUGE LSU4.9 |

| 35-8617 | RUBBER BAND, X-SERIES GAUGE |

| 35-2004 | SENSOR, WIDEBAND UEGO BOSCH LSU 4.9 |

| *OPTIONAL* ACCESSORIES | |

| PN | Description |

| 30-0300-ACC | BEZEL, X-SERIES GAUGE SILVER FACEPLATE, X-SERIES AFR WHITE |

| 30-2355-200 | NO WELD UEGO CLAMP KIT, 1.75″ to 2.00″ |

| 30-2355-250 | NO WELD UEGO CLAMP KIT, 2.25″ to 2.50″ |

| 30-2355-300 | NO WELD UEGO CLAMP KIT, 2.75″ to 3.00″ |

| 30-2355-350 | NO WELD UEGO CLAMP KIT, 3.25″ to 3.50″ |

| 30-4008 | WELD-IN FINNED BUNG, O2 LONG, STAINLESS STEEL |

| 35-4001 | BUNG PLUG,02 SENSOR |

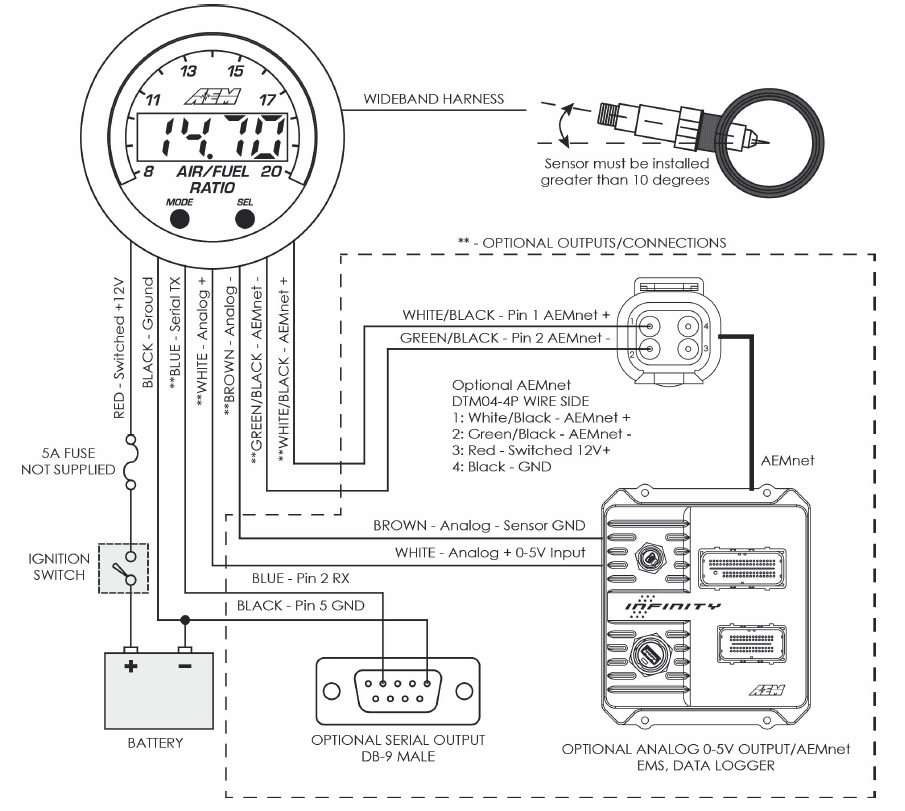

Wiring Installation Diagram

Gauge Connections

- The X-Series UEGO gauge is supplied with a Power/IO wiring harness (A) and a UEGO sensor harness (B); the harnesses are connected to the gauge as shown below. The UEGO sensor harness simply needs to be routed to the UEGO sensor whereas the Power/IO harness will require further integration into the vehicle. The minimum Power/IO connections required to operate the gauge are switched 12V (5A fuse) and ground. Please reference the diagrams and information on the provided for further detail

Important Notes on Wiring

- Route harnesses carefully to avoid chafing or undue strain.

- Secure wiring to vehicle with wire ties paying special attention to the sensor harness routing beneath the vehicle and/or in the engine compartment.

- Take care when routing sensor harness near hot exhaust components.

- Apply strain reliefs and wire coverings as necessary.

- Use a 5A inline fuse on the switched 12V power supply line (Pin 1 – Power/IO).

- Avoid cutting or extending the sensor harness.

- Use appropriate gauge wire (20 AWG or thicker) when extending wires, especially Pins 1(Switched 12V) or 2(Ground) of the Power/IO harness.

- Ensure all connections are secure and insulated from shorts to adjacent wires and the vehicle structure. Utilize proper crimping and solder/heatshrink techniques.

- Replacement pins are JST P/N SPUD-001T-P0.5 terminals for 22-26 AWG wire

Connector A – Power / IO

| Pin | Color | Description |

| 1 | RED | Switched 12V Power (5A Fuse) |

| 2 | BLACK | Power Ground |

| 3 | GREEN/BLACK | AEMnet- / CANL (Optional) |

| 4 | WHITE/BLACK | AEMnet+ / CANH (Optional) |

| 5 | BLUE | Serial / RS-232 Output (Optional) |

| 6 – 8 | – | Not Used |

| 9 | WHITE | 0-5V Analog Output Positive+ (Optional) |

| 10 | BROWN | 0-5V Analog Output Negative- (Optional) |

Connector B – Bosch LSU4.9UEGO Sensor

| Pin | Color | Description |

| 1 | GREEN | Trim Resistor |

| 2 | WHITE | Heater Negative- |

| 3 | ORANGE | COM |

| 4 | – | Not Used |

| 5 | RED | Pump Current |

| 6 | BLACK | Sense |

| 7 | – | Not Used |

| 8 | BROWN | Heater Positive+ |

Operation

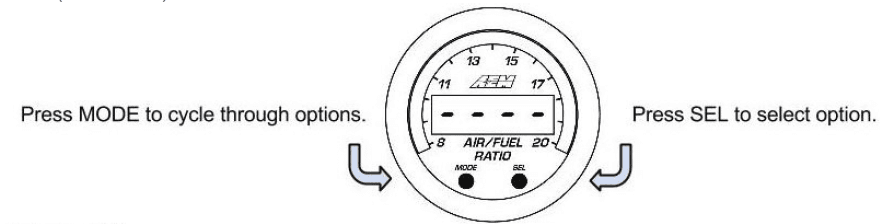

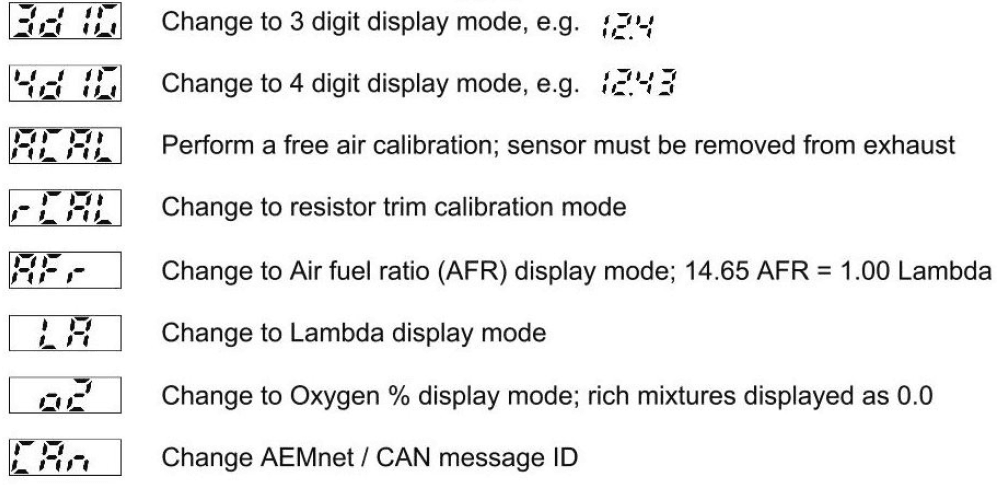

- Mode (MODE) and select (SEL) buttons are located on the face of the gauge for configuration; refer to the diagram below for the available options and their function. Note that the faceplate is two-sided and reversible. If the display mode is changed to lambda, the faceplate may be flipped to display the corresponding lambda scaling. Please reference the Faceplate/Bezel Installation section in this manual for instruction on this process. The oxygen percentage display mode may be selected but the outer “needle” LEDs will be non-functional and, thus, there is no corresponding faceplate for this mode. The center display will indicate the current sensor reading numerically or four dashes “—-” if the current mixture is full lean (> 20:1 AFR).

Calibration

Calibration

- Calibration

- The supplied UEGO sensor is factory calibrated via a trim resistor, integral to the sensor connector, and requires no further calibration. The ability to perform a free air calibration is provided for users that wish to do so. A free air calibration can be used as a sensor ages, however, new sensors should use the resistor calibration for best accuracy.

- Resistor Trim Calibration Mode (rCAL)

- This is the X-Series UEGO controller’s default mode as shipped from the factory. It is the recommended calibration mode and, for most users, no further action or calibration is required.

- Free Air Calibration Mode (ACAL)

- Refer to the Operation section of this manual for instruction on how to navigate to the menu selection ACAL. The sensor MUST be removed from the exhaust for this procedure. The free air calibration process begins once the ACAL menu option selection is confirmed. The calibration will take approximately ten to fifteen seconds during which the sensor must be placed in a “fresh” air environment, i.e. an area without lingering exhaust or chemical fumes. The process will complete and the gauge will report PASS or FAIL on the display. If the gauge reports FAIL then the sensor detected too low a level of oxygen; this is typically indicative of a sensor being left in the exhaust pipe or in an environment with excess exhaust/chemical fumes.

Faceplate / Bezel Installation

- The gauge kit is supplied assembled with a black faceplate and black bezel. An accessory kit is available (for purchase through AEM dealers) which includes an optional silver bezel and white faceplate. Please reference the Optional Accessories section earlier in the document for the appropriate part numbers. Contact your dealer or visit www.aemelectronics.com for more information.

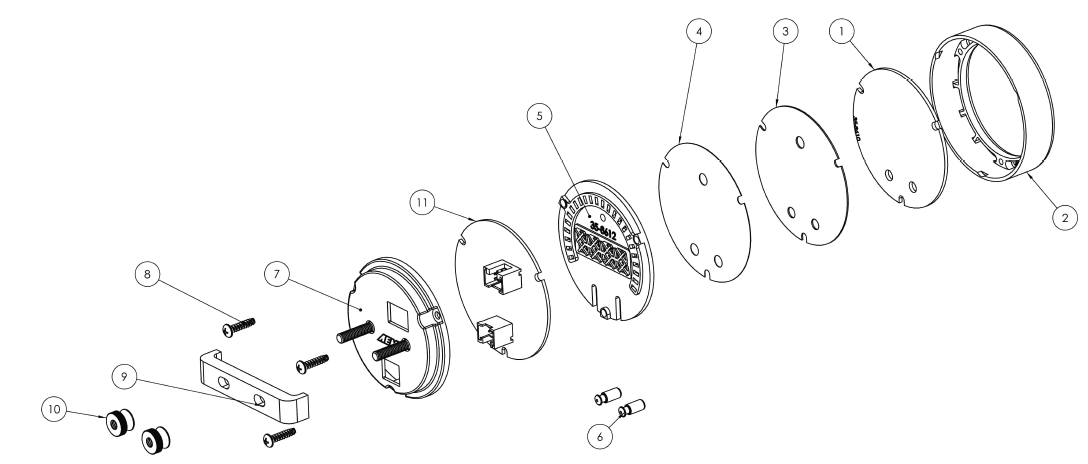

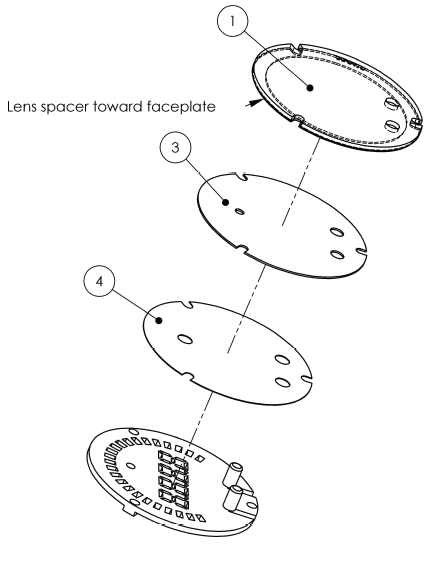

- The faceplate may be reversible, displaying alternative scalings on either side. Reference the Operation section of this manual for details on how to switch the display mode when reversing the faceplate. Disassembly is required to change the faceplate, flip/reverse the faceplate, or change the bezel of the gauge. The following diagram will provide familiarization with the major components of the gauge prior to beginning the procedure.

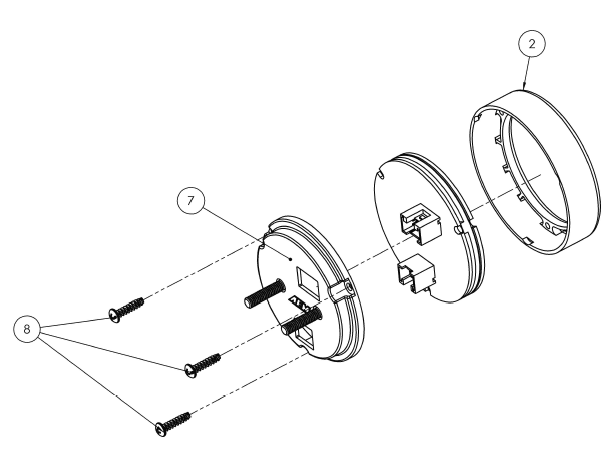

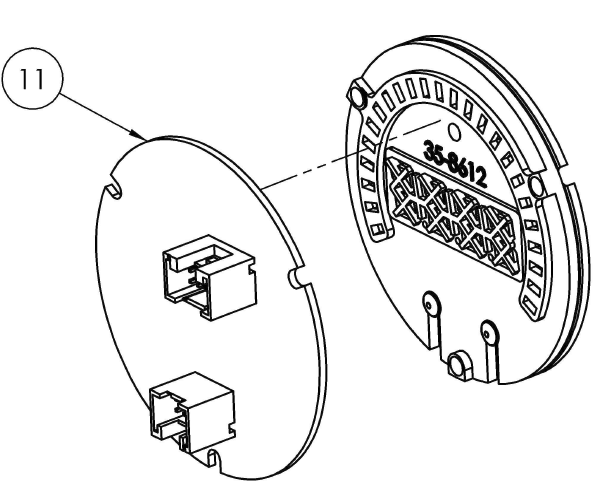

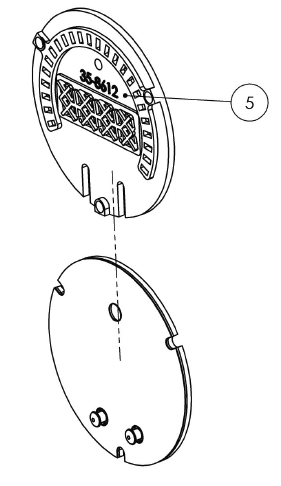

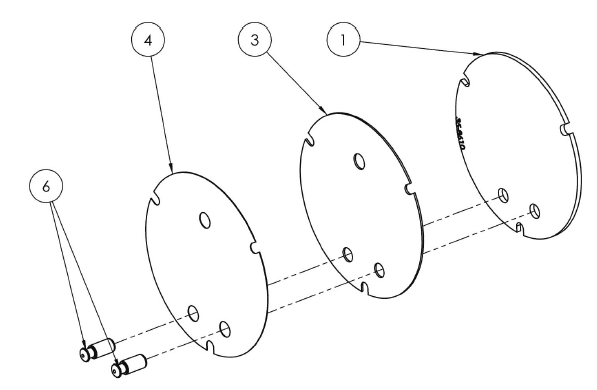

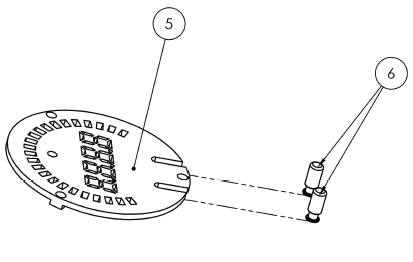

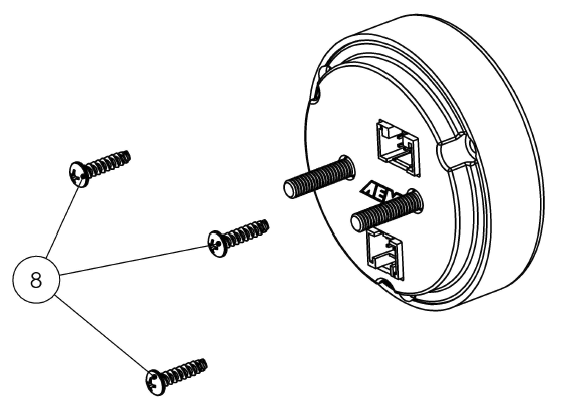

Item Qty Description 1 1 Lens 2 1 Bezel 3 1 Faceplate 4 1 Diffuser 5 1 Light Guide 6 2 Button 7 2 Mounting Stud (M4 x 0.7) 8 3 Assembly Screw 9 1 Mounting Bracket 10 2 Brass Thumb Screw (M4 x 0.7) 11 1 Printed Circuit Board (PCB)

Gauge Disassembly

- STEP 1 – Remove the three assembly screws (8) using a #1 Phillips head screwdriver. Separate the bezel (2) and cup (7) from the rest of the assembly. If you have purchased the optional accessory kit, the silver bezel may be replaced for the existing bezel at this time

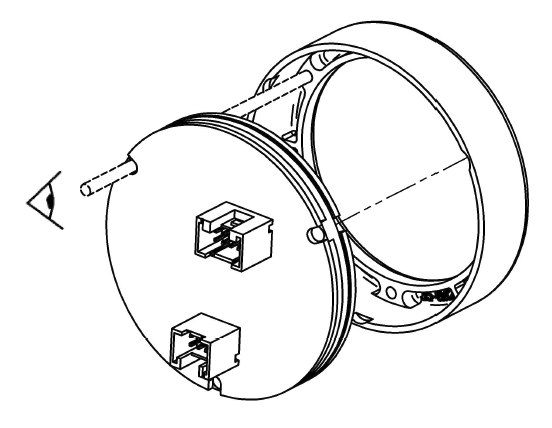

- STEP 2 – Separate the PCB (11) from the remaining components

- STEP 3 – Slide the light guide (5) upward to remove it, the buttons may fall out at this time – take care not to lose them

- STEP 4 – As you separate the remaining components, diffuser (4), faceplate (3), lens (1), note the order in which they were assembled. The faceplate (3) may now be reversed to display an alternate scaling or replaced for a different color as included in the optional accessory kit

Gauge Assembly

- STEP 1 – Place the light guide (5) on a flat surface (black side up) and slide the buttons (6) into the slots

- STEP 2 – Stack the diffuser (4), faceplate (3), and lens (1) in order, over the buttons, and on to the light guide

- STEP 3 – Reassemble the PCB and display stack with the bezel, making sure screw holes are aligned through the entire assembly

- STEP 4 – Reassemble and tighten screws to 2 in-lb (previously assembled bezel) or 3 in-lb (new bezel). Do not over-tighten!

What is a UEGO Wideband Sensor?

- A Universal Exhaust Gas Oxygen (UEGO) oxygen sensor, also known as a wideband or lambda sensor, measures the proportion of oxygen (O2) in the exhaust of a running engine. An air to fuel ratio (AFR) or lambda value can be calculated from this measurement. Typically, when calibrating or “tuning” the fuel delivery system of an engine, a specific AFR can be targeted to achieve maximum power, economy, or emissions. The output from a UEGO sensor controller can be used to adjust a carburetor or fuel injection system to reach this target.

- UEGO sensors are one of the more sophisticated sensors found in today’s vehicles. The sensing element is made of a zirconium dioxide ceramic with a thin platinum coating and has an integrated heating element. An electronic controller, such as is contained in AEM’s X-Series UEGO Gauge or Inline Controller, is required to use a UEGO oxygen sensor. The controller connects to the sensor via multiple wires (up to 6) carrying sensitive voltages and electrical currents to process and calculate an AFR value. This value may be read directly from a gauge face or data-log as recorded by an ECU or logger via several methods as discussed elsewhere in this manual.

Interpreting Wideband Sensor Readings

- An internal combustion engine runs on air (which contains ~20% oxygen) and fuel. The ratio of air to fuel (AFR) that, when combusted, perfectly consumes 100% of both the oxygen and fuel is called the stoichiometric ratio. This ratio is different for every fuel. Ratios lower than stoichiometric have more fuel and are considered “rich”; ratios higher than stoichiometric have less fuel and are considered “lean.”

Fuel Stoichiometric AFR Lambda Unleaded Gasoline 14.65: 1 1.00 Methanol 6.47: 1 1.00 Ethanol 9.00: 1 1.00 Propane 15.67: 1 1.00 CNG 17.20: 1 1.00

Sensor Placement

The location at which the sensor is installed in the vehicle’s exhaust system is critical to its performance and longevity. Please review the following placement guidelines:

- 18 inches (45cm) downstream of the cylinder head’s exhaust port or turbocharger

- Upstream of any catalytic converters or emission control devices

- Downstream of any turbochargers or large contributors to exhaust pressure

- As far as possible from the exhaust exit (tailpipe) to avoid scavenging fresh air in low exhaust flow conditions such as idling

- AEM’s X-Series UEGO controller is a very sensitive device and, thus, it is important to have a completely leak-free exhaust

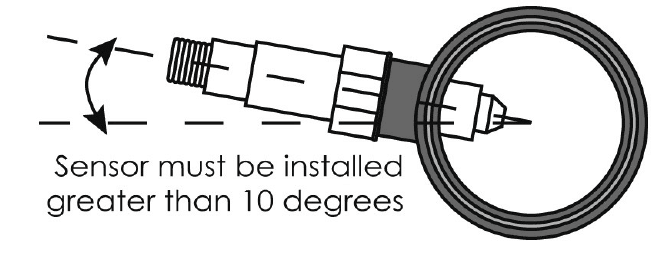

Sensor Bung

- The supplied mild steel sensor bung must be welded into the vehicle’s exhaust. An optional stainless steel sensor bung is available for purchase from AEM dealers and may be useful in specific installation scenarios. The taller geometry of this bung helps bring the sensing element further out of the exhaust stream when used in small diameter tubing such as header primaries. In addition, the finned body helps dissipate heat when used in extreme applications. As an alternative to welding, users may purchase a P/N 30-2355-XXX No Weld UEGO Clamp Kit.

- P/N 35-4001 Mild Steel Sensor Bung

- The bung should be welded in such a way that the installed sensor orientation is greater than ten degrees from horizontal to allow any condensation to properly drain from the sensor. In addition, it is recommended to avoid a completely vertical sensor orientation to prevent overheating the sensor. Failure to heed these recommendations may result in premature sensor failure

0-5V Analog Output

- WHITE WIRE = Analog Positive +

- BROWN WIRE = Analog Negative –

0-5V Analog Output Scaling Formulas AFR = (2.3750 * Volts) + 7.3125 Lambda = (0.1621 * Volts) + 0.4990 - The 0-5V analog output is suitable for output to devices such as loggers or ECUs. This differential output requires special care to ensure proper operation. The WHITE signal wire should be connected to the positive of the analog input of the logging device or ECU; the BROWN wire must be connected to the negative of the analog input of the logging device or ECU. If the logging device or ECU does not have a differential analog input (both a dedicated positive and negative terminal for the analog input) then connect the BROWN wire to the shared signal ground. If the device does not have a dedicated signal ground then as a last course of action, connect it to the power ground of the logging device.

0-5V Analog Output Scaling Table Volts Lambda AFR (Gasoline) <0.50 SENSOR NOT READY 0.50 0.58 8.50 0.75 0.62 9.09 1.00 0.66 9.69 1.25 0.70 10.28 1.50 0.74 10.88 1.75 0.78 11.47 2.00 0.82 12.06 2.25 0.86 12.66 2.50 0.90 13.25 2.75 0.94 13.84 3.00 0.99 14.44 3.25 1.03 15.03 3.50 1.07 15.63 3.75 1.11 16.22 4.00 1.15 16.81 4.25 1.19 17.41 4.50 1.23 18.00 >4.50 SENSOR ERROR

AEMnet (CAN Bus) Output

- WHITE WIRE WITH BLACK STRIPE = AEMnet+ / CANH

- GREEN WIRE WITH BLACK STRIPE = AEMnet- / CANL

- The AEMnet output is suitable for output to AEM devices such as the AQ-1 data logger or Infinity ECU. The following CAN configuration and message definition information is provided below to facilitate interface with third-party devices.

- Message ID

- If multiple gauges are connected to the same CAN bus then they must each be configured to have unique message IDs using the gauge’s menu system. Depress the MODE button to navigate to the CAN submenu, press the SEL button until the desired ID is displayed, then wait 3 seconds to accept setting; DONE will appear to confirm your selection. The options “ID 1”, “ID 2”, …, “ID 16” correspond to the 29-bit identifiers 0x0000180, 0x0000181, 0x0000180, …, 0x000018F.

FAQ / Troubleshooting

What are the minimum wiring connections needed to use the gauge?

- Switched/fused 12V (RED) and power ground (BLACK) must be supplied to the 10 pin connector. Any unused wires may be secured and fastened away for future use. The 8 pin sensor harness must also be connected between the gauge and sensor.

When should I use free air calibration mode?

- The sensor that is supplied is laboratory calibrated using the integral trim resistor; this is the preferred and recommended calibration mode. If you feel your sensor has been extremely contaminated or damaged and requires re-calibration, then it is suggested that you purchase a new sensor. Alternatively, performing a free air calibration may be helpful.

The gauge displays “bAtt” when I key-on or crank the engine.

- The gauge requires a minimum supply voltage to properly drive the UEGO sensor heater and will display “bAtt” if a low voltage condition is detected. Please ensure the vehicle’s battery is in good condition, e.g. >12V engine off, >13.8V engine running.

I installed my gauge correctly and the display just shows four dashes, “- – – -“

- Four dashes means the sensor is detecting a very lean, high oxygen content higher than 20:1 AFR. This is completely normal behavior in conditions such as engine off, decel fuel cutoff, or when the sensor is outside of an exhaust in open air. It may also be indicative of an exhaust leak upstream of the sensor, or a sensor installed too close to an open air source, especially if this occurs only at idle and light loads.

I performed a free air calibration but the gauge reported “FAIL”

- The sensor must be removed from the exhaust to perform a free air calibration. Remove the sensor from the exhaust to a fresh air environment that is free from exhaust or chemical/solvent fumes

For more manuals by AEM Electronics visit ManualsLibraryy

AEM 30-0300 X-Series Wideband UEGO AFR Sensor Controller Gauge-FAQs

What is the purpose of the AEM Wideband?

The AEM Wideband Controller enhances air-fuel ratio (AFR) tuning by reducing deadtime, which is the delay between exhaust gas changes and sensor readings. This leads to better vehicle performance.

What voltage does the AEM 30-0300 support?

It is compatible with vehicle voltages up to 16V and provides 0-5V and RS232 outputs for data logging, feedback control, and CANbus communication.

What is the output voltage range of the AEM Wideband?

The analog output varies from 0.5V at 8.5:1 AFR to 4.5V at 18.0:1 AFR, enabling integration with data loggers and engine management systems like the AEM EMS.

How do AFR gauges work?

AFR gauges measure oxygen levels in exhaust gases using the Nernst equation, generating a voltage signal that corresponds to the air-to-fuel ratio (AFR).

Can AEM gauges be daisy-chained?

Yes, AEM gauges support AEMnet CAN-bus connectivity, allowing multiple units to be daisy-chained for use with Infinity ECU, Series 2 EMS, AQ-1 Data Logger, and other compatible systems.

What does UEGO stand for?

UEGO (Universal Exhaust Gas Oxygen) sensor detects air-to-fuel ratios in an engine by analyzing exhaust gas composition.

What voltage is required for an AEM fuel pump?

The AEM fuel pump operates best at 13.5V, though most vehicle electrical systems range from 13.2V to 14.2V. A minimum of 10 amps is required for optimal performance.

What does AEM stand for?

In the context of this gauge, AEM refers to Advanced Engine Management, specializing in performance electronics for tuning and monitoring engines.