Carrier 24ABC Comfort Air Conditioner

Installation Instructions

GENERAL

NOTE: In some cases, noise in the living area has been traced to gas pulsations from improper installation of equipment.

- Locate the unit away from windows, patios, decks, etc. where unit operation sound may disturb customers.

- Ensure that vapor and liquid tube diameters are appropriate for unit capacity.

- Run refrigerant tubes as directly as possible by avoiding unnecessary turns and bends.

- Leave some slack between structure and unit to absorb vibration.

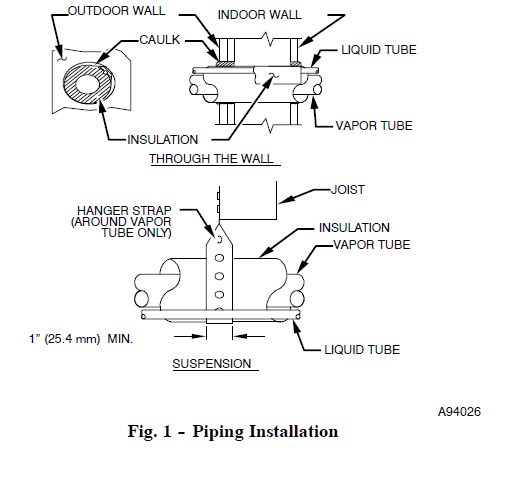

- When passing refrigerant tubes through the wall, seal the opening with RTV or other pliable silicon-based caulk. (See Fig. 1.)

- Avoid direct tubing contact with water pipes, duct work, floor joists, wall studs, floors, and walls.

- Do not suspend refrigerant tubing from joists and studs with a rigid wire or strap that comes in direct contact with the tubing. (See Fig. 1.)

- Ensure that tubing insulation is pliable and surrounds the vapor tube.

- When necessary, use hanger straps that are 1 in. (25.4 mm) wide and conform to the shape of the tubing insulation. (See Fig. 1.)

- Isolate hanger straps from insulation by using metal sleeves bent to conform to the shape of the insulation.

The outdoor unit contains a system refrigerant charge for operation with a rated indoor unit when connected by 15 ft. (4.57 m) of field-supplied or factory accessory tubing. For proper unit operation, check the refrigerant charge using the charging information located on the control box cover and/or in the Check Charge section of this instruction.

The outdoor unit contains a system refrigerant charge for operation with an AHRI-rated indoor unit when connected by 15 ft. (4.57 m) of the field supplied or factory accessory tubing. For proper unit operation, check the refrigerant charge using the charging information located on the control box cover and/or in the Check Charge section of this instruction.

INSTALLATION

Check Equipment and Job Site

UNPACK UNIT

Move to the final location. Remove the carton taking care not to damage the unit.

Inspect Equipment

File a claim with the shipping company before installation if the shipment is damaged or incomplete. Locate the unit rating plate on the unit corner panel. It contains information needed to properly install the unit. Check the rating plate to be sure the unit matches job specifications.

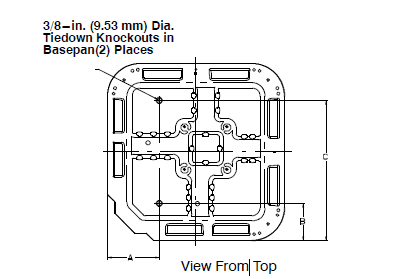

Install on a Solid, Level Mounting Pad

If conditions or local codes require the unit to be attached to a pad, tie-down bolts should be used and fastened through knockouts provided in the unit base pan. Refer to the unit mounting pattern in Fig. 2 to determine the base pan size and knockout hole location.

For hurricane tie-downs, contact the local distributor for details and PE (Professional Engineer) certification, if required by local authorities. On rooftop applications, mount on a level platform or frame. Place the unit above a load-bearing wall and isolate the unit and tubing set from the structure. Arrange supporting members to adequately support the unit and minimize transmission of vibration to the building. Consult local codes governing rooftop applications.

Roof-mounted units exposed to winds may require wind baffles. Consult the Application Guideline and Service Manual . Residential Split System Air Conditioners and Heat Pumps for wind baffle construction.

Clearance Requirements

When installing, allow sufficient space for airflow clearance, wiring, refrigerant piping, and service. Allow 24 in (609.6 mm) clearance to service end of unit and 48 in. (1219.2 mm) (above unit. For proper airflow, a 6–in. (152.4 mm) clearance on 1 side of the unit and 12–in. (304.8 mm) on all remaining sides must be maintained. Maintain a distance of 24 in. (609.6 mm) between units or 18 in. (457.2 mm) if no overhang within 12 ft. (3.66 m) Position so water, snow, or ice from the roof or eaves cannot fall directly on the unit.

NOTE: The 18” (457.2 mm) clearance option described above is approved for outdoor units with wire grille coil guard only. Units with louver panels require 24” (609.6 mm) between units. On rooftop applications, locate the unit at least 6 in. (152.4 mm) above the roof surface.

Operating Ambient

The minimum outdoor operating ambient in cooling mode without accessories is 55 _F (12.78 _C), and the maximum outdoor operating ambient in cooling mode is 125 F (51.67 _C).

Make Piping Connections

| UNIT BASE PAN Dimension in. (mm) | TIEDOWN KNOCKOUT LOCATIONS in. (mm) | ||

| A | B | C | |

| 23 —1/2 X 23 —1/2 (596.9 X 596.9) | 7 —13/16 (198.4) | 4–7/16 (112.7) | 18–1/16 (458.8) |

| 26 X 26 (660.4 X 660.4) | 9–1/8 (231.8) | 4–7/16 (112.7) | 21–1/4 (539.8) |

| 31–1/2 X 31–1/2 (800.1 X 800.1) | 9–1/8 (231.8) | 6–9/16 (166.7) | 24–11/16 (627.1) |

| 35 X 35 (889 X 889) | 9–1/8 (231.8) | 6–9/16 (166.7) | 28–7/16 (722.3) |

Fig. 2 -Tiedown Knockout Locations

Outdoor units may be connected to the indoor section using an accessory tubing package or field supplied refrigerant grade tubing of the correct size and condition. Rated tubing diameters shown in Table 1 are recommended up to 80 ft. (24.38 m). See Product Data for acceptable alternate vapor diameters and associated capacity losses.For tubing requirements beyond 80 ft. (24.38 m), substantial capacity and performance losses can occur.

Following the recommendations in the Longline Guideline will reduce these losses. Refer to Table 1 for field tubing diameters. Refer to Table 5 for accessory requirements.There are no buried line applications greater than 36–in. (914.4 mm) allowed. If refrigerant tubes or indoor coils are exposed to the atmosphere, they must be evacuated to 500 microns to eliminate contamination and moisture in the system.

Outdoor Unit Connected to Factory Approved Indoor Unit

Outdoor unit contains correct system refrigerant charge for operation with factory approved AHRI rated indoor unit when connected by 15 ft. (4.57 m) of field–supplied or factory–accessory tubing, and factory supplied filter drier. Check refrigerant charge for maximum efficiency.

Refrigerant Tubing Connection Outdoor

Connect vapor and liquid tubes to fittings on vapor and liquid service valves (see Table 1.) Use refrigerant grade tubing

Sweat Connection

Use refrigeration grade tubing. Service valves are closed from factory and ready for brazing. After wrapping service valve with a wet cloth, braze sweat connections using industry accepted methods and materials. Consult local code requirements. Refrigerant tubing and indoor coil are now ready for leak testing. This check should include all field and factory joints.

Table 1 – Refrigerant Connections and Recommended Liquid and Vapor Tube Diameters (In.)

| 24ABB3 | |||

UNIT SIZE | LIQUID | RATED VAPOR* | |

| Connection & Max. Tube Diameter | Connection Diameter | Tube Diameter | |

| 18, 24 | 3/8 | 3/4 | 3/4 |

| 30 | 3/8 | 3/4 | 3/4 |

| 36 | 3/8 | 7/8 | 7/8 |

| 42, 48 | 3/8 | 7/8 | 7/8 |

| 60 | 3/8 | 7/8 | 1 —1/8 |

| 24ABC6 | |||

UNIT SIZE | LIQUID | RATED VAPOR* | |

| Connection & Max. Tube Diameter | Connection Diameter | Tube Diameter | |

| 18, 24 | 3/8 | 3/4 | 3/4 |

| 30 | 3/8 | 3/4 | 3/4 |

| 36 | 3/8 | 7/8 | 7/8 |

| 42, 48, 49 | 3/8 | 7/8 | 7/8 |

| 60, 61 | 3/8 | 7/8 | 1 —1/8 |

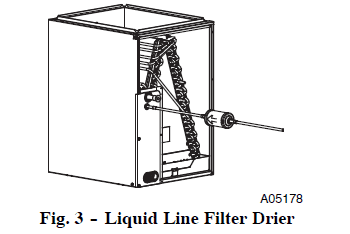

Install Liquid Line Filter Drier Indoor

Refer to Fig. 3 and install the filter drier as follows:

- Braze 5-in. liquid tube to the indoor coil.

- Wrap the filter drier with a damp cloth.

- Braze filter drier to above 5-in. (127 mm) liquid tube. The flow arrow must point toward the indoor coil.

- Connect and braze the liquid refrigerant tube to the filter drier.

Evacuate Refrigerant Tubing and Indoor Coil

Refrigerant tubes and indoor coil should be evacuated using the recommended deep vacuum method of 500 microns. The alternate triple evacuation method may be used (see triple evacuation procedure in the service manual). Always break a vacuum with dry nitrogen.

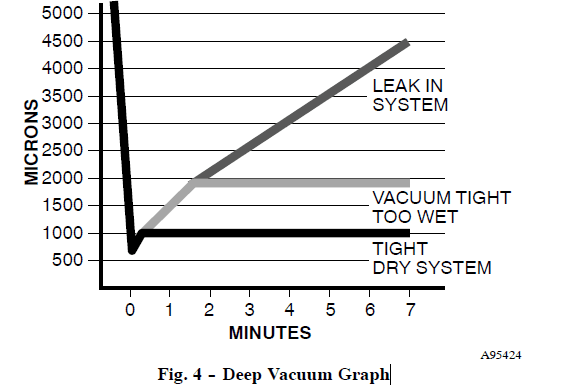

Deep Vacuum Method

The deep vacuum method requires a vacuum pump capable of pulling a vacuum of 500 microns and a vacuum gauge capable of accurately measuring this vacuum depth. The deep vacuum method is the most positive way of assuring a system is free of air and liquid water. A tight dry system will hold a vacuum of 1000 microns after approximately 7 minutes. See Fig. 4.

Final Tubing Check

IMPORTANT: Check to be certain factory tubing on both indoor and outdoor units has not shifted during shipment. Ensure tubes are not rubbing against each other or any sheet metal or wires. Pay close attention to feeder tubes, making sure the wire ties on the feeder tubes are secure and tight.

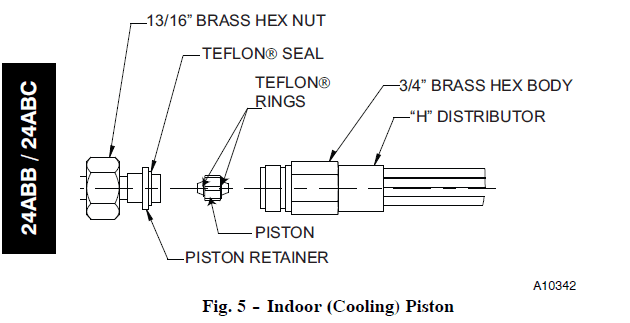

Installing with Indoor Piston

Outdoor Unit Connected to Factory-Approved Indoor Unit Check the piston size shipped with the indoor unit to see if it matches the required indoor piston size. If it does not match, replace the indoor piston with the correct piston size.

NOTE: Correct pistons are shipped with outdoor units in the accessory bag and are only qualified for piston fan coils. Example fan coils with piston: FB4C and FY5B (1.5 through 4 ton) When changing the indoor piston, use a backup wrench. Hand tighten the hex nut, then tighten with the wrench 1/2 turn. Do not exceed 30 ft−lbs. The indoor piston contains a Teflon ring (or seal) which is used to seat against the inside of the distributor body and must be installed properly to ensure proper seating. See Fig.

Units with Cooling Mode TXV

Units installed with cooling mode TXV require charging by the subcooling method.

- Operate the unit for a minimum of 15 minutes before checking the charge.

- Measure liquid service valve pressure by attaching an accurate gauge to the service port.

- Measure liquid line temperature by attaching an accurate thermistor type or electronic thermometer to the liquid line near the outdoor coil.

- Refer to the unit rating plate for the required subcooling temperature.

- Refer to Table 2 – Rating Plate (required) Subcooling Temperature. Find the point where the required subcooling temperature intersects the measured liquid service valve pressure.

- To obtain the required subcooling temperature at a specific liquid line pressure, add refrigerant if the liquid line temperature is higher than indicated or reclaim refrigerant if the temperature is lower. Allow a tolerance of plus-minus 3 degree (plus minus 1.7_C).

Units with Indoor Piston

Units installed with indoor pistons require charging by the superheat method. The following procedure is valid when indoor airflow is within plus or minus 21 percent of its rated CFM.

- Operate the unit for a minimum of 15 minutes before checking the charge.

- Measure suction pressure by attaching an accurate gauge to the suction valve service port.

- Measure suction temperature by attaching an accurate thermistor type or electronic thermometer to the suction line at the service valve.

- Measure outdoor air dry bulb temperature with a thermometer.

- Measure indoor air (entering indoor coil) wet–bulb temperature with a sling psychrometer.

- Refer to Table 3 — Superheat Charging — AC Only. Find the outdoor temperature and evaporator entering air wet-bulb temperature. At this intersection, note superheat. Where a dash (—-) appears on the table, do not attempt to charge the system under these conditions or refrigerant slugging may occur. The charge must be weighted in, adding, or removing 0.6 oz/ft of 3/8 liquid line above or below 15 feet (4.6m) respectively.

- Refer to Table 4 — Required Suction–Line Temperature. Find superheat temperature (from #6 above) and suction pressure. At this intersection, note the suction line temperature.

- If the unit has a higher suction line temperature than the charted temperature, add refrigerant until the charted temperature is reached.

- If a unit has a lower suction line temperature than the charted temperature, reclaim the refrigerant until the charted temperature is reached.

- When adding refrigerant, charge in liquid form into the suction service port using a flow-restricting device.

- If outdoor air temperature or pressure at the suction valve changes, charge to the new suction line temperature indicated on the chart.

- Optimum performance will be achieved when the operating charge produces 10_F suction superheat at suction service valve with 95_F (35_C) outdoor ambient and 80_F (27_C) dry bulb (67_F / 19_C) wet bulb) indoor temperature (DOE “A” test conditions) at rated airflow.

Table 2 – Rating Plate (required) Subcooling Temperatures

| Measure Liquid Pressure (psig) | R – 410A Required Liquid Line Temperature _F (_C) | |||||||||||

| _F | (_C) | _F | (_C) | _F | (_C) | _F | (_C) | _F | (_C) | _F | (_C) | |

| 6 | 3 | 8 | 4 | 10 | 6 | 12 | 7 | 14 | 8 | 16 | 9 | |

| 251 | 78 | 26 | 76 | 24 | 74 | 23 | 72 | 22 | 70 | 21 | 68 | 20 |

| 259 | 80 | 27 | 78 | 26 | 76 | 24 | 74 | 23 | 72 | 22 | 70 | 21 |

| 266 | 82 | 28 | 80 | 27 | 78 | 26 | 76 | 24 | 74 | 23 | 72 | 22 |

| 274 | 84 | 29 | 82 | 28 | 80 | 27 | 78 | 26 | 76 | 24 | 74 | 23 |

| 283 | 86 | 30 | 84 | 29 | 82 | 28 | 80 | 27 | 78 | 26 | 76 | 24 |

| 291 | 88 | 31 | 86 | 30 | 84 | 29 | 82 | 28 | 80 | 27 | 78 | 26 |

| 299 | 90 | 32 | 88 | 31 | 86 | 30 | 84 | 29 | 82 | 28 | 80 | 27 |

| 308 | 92 | 33 | 90 | 32 | 88 | 31 | 86 | 30 | 84 | 29 | 82 | 28 |

| 317 | 94 | 34 | 92 | 33 | 90 | 32 | 88 | 31 | 86 | 30 | 84 | 29 |

| 326 | 96 | 36 | 94 | 34 | 92 | 33 | 90 | 32 | 88 | 31 | 86 | 30 |

| 335 | 98 | 37 | 96 | 36 | 94 | 34 | 92 | 33 | 90 | 32 | 88 | 31 |

| 345 | 100 | 38 | 98 | 37 | 96 | 36 | 94 | 34 | 92 | 33 | 90 | 32 |

| 364 | 104 | 40 | 102 | 39 | 100 | 38 | 98 | 37 | 96 | 36 | 94 | 34 |

| 374 | 106 | 41 | 104 | 40 | 102 | 39 | 100 | 38 | 98 | 37 | 96 | 36 |

| 384 | 108 | 42 | 106 | 41 | 104 | 40 | 102 | 39 | 100 | 38 | 98 | 37 |

| 395 | 110 | 43 | 108 | 42 | 106 | 41 | 104 | 40 | 102 | 39 | 100 | 38 |

| 406 | 112 | 44 | 110 | 43 | 108 | 42 | 106 | 41 | 104 | 40 | 102 | 39 |

| 416 | 114 | 46 | 112 | 44 | 110 | 43 | 108 | 42 | 106 | 41 | 104 | 40 |

| 427 | 116 | 47 | 114 | 46 | 112 | 44 | 110 | 43 | 108 | 42 | 106 | 41 |

| 439 | 118 | 48 | 116 | 47 | 114 | 46 | 112 | 44 | 110 | 43 | 108 | 42 |

| 450 | 120 | 49 | 118 | 48 | 116 | 47 | 114 | 46 | 112 | 44 | 110 | 43 |

| 462 | 122 | 50 | 120 | 49 | 118 | 48 | 116 | 47 | 114 | 46 | 112 | 44 |

| 474 | 124 | 51 | 122 | 50 | 120 | 49 | 118 | 48 | 116 | 47 | 114 | 46 |

Table 3 – Superheat Charging — AC Only

| OUTDOOR TEMP (_F) | EVAPORATOR ENTERING AIR TEMPERATURE (_F WB) | |||||||||||||

| 50 | 52 | 54 | 56 | 58 | 60 | 62 | 64 | 67 | 68 | 70 | 72 | 74 | 76 | |

| 55 | 9 | 12 | 14 | 17 | 20 | 23 | 26 | 29 | 32 | 35 | 37 | 40 | 42 | 45 |

| 60 | 7 | 10 | 12 | 15 | 18 | 21 | 24 | 27 | 30 | 33 | 35 | 38 | 40 | 43 |

| 65 | — | 6 | 10 | 13 | 16 | 19 | 21 | 24 | 27 | 30 | 33 | 36 | 38 | 41 |

| 70 | — | — | 7 | 10 | 13 | 16 | 19 | 21 | 24 | 27 | 30 | 33 | 36 | 39 |

| 75 | — | — | — | 6 | 9 | 12 | 15 | 18 | 21 | 24 | 28 | 31 | 34 | 37 |

| 80 | — | — | — | — | 5 | 8 | 12 | 15 | 18 | 21 | 25 | 28 | 31 | 35 |

| 85 | — | — | — | — | — | — | 8 | 11 | 15 | 19 | 22 | 26 | 30 | 33 |

| 90 | — | — | — | — | — | — | 5 | 9 | 13 | 16 | 20 | 24 | 27 | 31 |

| 95 | — | — | — | — | — | — | — | 6 | 10 | 14 | 18 | 22 | 25 | 29 |

| 100 | — | — | — | — | — | — | — | — | 8 | 12 | 15 | 20 | 23 | 27 |

| 105 | — | — | — | — | — | — | — | — | 5 | 9 | 13 | 17 | 22 | 26 |

| 110 | — | — | — | — | — | — | — | — | — | 6 | 11 | 15 | 20 | 25 |

| 115 | — | — | — | — | — | — | — | — | — | — | 8 | 14 | 18 | 23 |

Table 4 – Required Suction–Line Temperature

| SUPERHEAT TEMP (_F) | SUCTION PRESSURE AT SERVICE PORT (PSIG) | ||||||||

| 107.8 | 112.2 | 116.8 | 121.2 | 126 | 130.8 | 138.8 | 140.8 | 145.8 | |

| 0 | 35 | 37 | 39 | 41 | 43 | 45 | 47 | 49 | 51 |

| 2 | 37 | 39 | 41 | 43 | 45 | 47 | 49 | 51 | 53 |

| 4 | 39 | 41 | 43 | 45 | 47 | 49 | 51 | 53 | 55 |

| 6 | 41 | 43 | 45 | 47 | 49 | 51 | 53 | 55 | 57 |

| 8 | 43 | 45 | 47 | 49 | 51 | 53 | 55 | 57 | 59 |

| 10 | 45 | 47 | 49 | 51 | 53 | 55 | 57 | 59 | 61 |

| 12 | 47 | 49 | 51 | 53 | 55 | 57 | 59 | 61 | 63 |

| 14 | 49 | 51 | 53 | 55 | 57 | 59 | 61 | 63 | 65 |

| 16 | 51 | 53 | 55 | 57 | 59 | 61 | 63 | 65 | 67 |

| 18 | 53 | 55 | 57 | 59 | 61 | 63 | 65 | 67 | 69 |

| 20 | 55 | 57 | 59 | 61 | 63 | 65 | 67 | 69 | 71 |

| 22 | 57 | 59 | 61 | 63 | 65 | 67 | 69 | 71 | 73 |

| 24 | 59 | 61 | 63 | 65 | 67 | 69 | 71 | 73 | 75 |

| 26 | 61 | 63 | 65 | 67 | 69 | 71 | 73 | 75 | 77 |

| 28 | 63 | 65 | 67 | 69 | 71 | 73 | 75 | 77 | 79 |

| 30 | 65 | 67 | 69 | 71 | 73 | 75 | 77 | 79 | 81 |

| 32 | 67 | 69 | 71 | 73 | 75 | 77 | 79 | 81 | 83 |

| 34 | 69 | 71 | 73 | 75 | 77 | 79 | 81 | 83 | 85 |

| 36 | 71 | 73 | 75 | 77 | 79 | 81 | 83 | 85 | 87 |

| 38 | 73 | 75 | 77 | 79 | 81 | 83 | 85 | 87 | 89 |

| 40 | 75 | 77 | 79 | 81 | 83 | 85 | 87 | 89 | 91 |

Make Electrical Connections

Be sure field wiring complies with local and national fire, safety, and electrical codes, and that voltage to system is within limits shown on the unit rating plate. Contact the local power company for correction of improper voltage. See unit rating plate for recommended circuit protection device.

Route Ground and Power Wires

Remove the access panel to gain access to the unit wiring. Extend wires from the disconnect through the power wiring hole provided and into the unit control box.

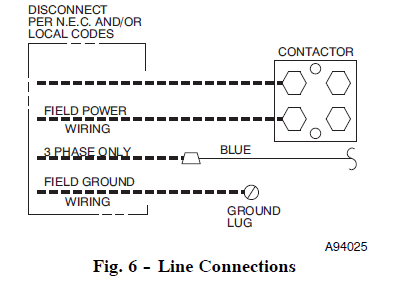

Connect Ground and Power Wires

Connect the ground wire to the ground connection in the control box for safety. Connect the power wiring to the contactor as shown in Fig. 5.

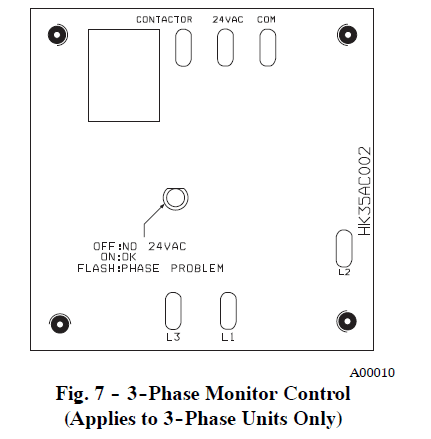

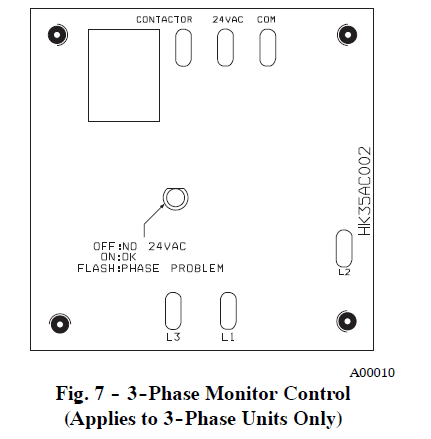

Connect Control Wiring

Route 24–v control wires through control wiring grommet and connect leads to control wiring (See Fig. 7). Refer to Installation Instructions packaged with thermostat. Use No. 18 AWG color-coded, insulated (35_C minimum) wire. If the thermostat is located more than 100 ft. (30.48 m) from the unit, as measured along the control voltage wires, use No. 16 AWG color-coded wire to avoid excessive voltage drop.

All wiring must be NEC Class 1 and must be separated from incoming power leads. Use furnace transformer, fan coil transformer, or accessory transformer for control power, 24v/40va minimum.

Final Wiring Check

IMPORTANT: Check factory wiring and field wire connections to ensure terminations are secured properly. Check wire routing to ensure wires are not in contact with tubing, sheet metal, etc.

Compressor Crankcase Heater

When equipped with a crankcase heater, furnish power to the heater a minimum of 24 hr before starting the unit. To furnish power to the heater only, set the thermostat to OFF and close the electrical disconnect to an outdoor unit. A crankcase heater is required if refrigerant tubing is longer than 80 ft. (24.38 m). Refer to the Residential Piping and Longline Guideline and Service Manual Longline Section–Residential Split–System Air Conditioners and Heat Pumps.

Install Electrical Accessories

Refer to the individual instructions packaged with kits or accessories when installing.

Follow these steps to properly start-up system:

- After the system is evacuated, fully open the liquid and vapor service valves.

- Unit is shipped with valve stem(s) front seated (closed) and caps installed. Replace stem caps after the system is opened to refrigerant flow. Replace caps finger–tight and tighten with wrench an additional 1/12 turn.

- Close electrical disconnects to energize the system.

- Set the room thermostat at the desired temperature. Be sure the set point is below the indoor ambient temperature.

- Set room thermostat to COOL and fan control to ON or AUTO mode, as desired. Operate the unit for 15 minutes. Check system refrigerant charge.

3-Phase Monitor

In 3–phase units a small circuit board is factory installed to monitor line voltage. A small LED will flash if a phase problem exists. See code descriptions on the monitor. If the LED is flashing, disconnect power to the unit and interchange 2 fields–wiring leads on unit contactor3–Phase Monitor In 3–phase units a small circuit board is factory installed to monitor line voltage. A small LED will flash if a phase problem exists. See code descriptions on the monitor. If the LED is flashing, disconnect power to the unit and interchange 2 fields–wiring leads on the unit contactor Table 5 – Three-PhaseMonitor LED Indicators

Table 5 – Three-PhaseMonitor LED Indicators

| LED | STATUS |

| OFF | No call for compressor operation |

| FLASHING | Reversed-phase |

| ON | Normal |

Sequence of Operation

Turn on power to indoor and outdoor units. The transformer is energized. On a call for cooling, the thermostat makes circuits R-Y and R-G. Circuit R-Y energizes the contactor, starting the outdoor fan motor and compressor circuit. R-G energizes the indoor unit blower relay, starting the indoor blower motor at high speed.

When the thermostat is satisfied, its contacts open, de-energizing the contactor and blower relay. The compressor and motors stop. If the indoor unit is equipped with a time-delay relay circuit, the indoor blower will run an additional 90 seconds to increase system efficiency.

Check Charge

Factory charge amount and desired subcooling are shown on the unit rating plate. The charging method is shown on the information plate inside the unit. To properly check or adjust the charge, conditions must be favorable for subcooling charging. Favorable conditions exist when the outdoor temperature is between 70_F and 100_F (21.11_C and 37.78_C), and the indoor temperature is between 70_F and 80_F (21.11_C and 26.67_C). Follow the procedure below:

Unit is factory charged for 15ft (4.57 m) of line set. Adjust charge by adding or removing 0.6 oz/ft of 3/8 liquid line above or below 15ft (4.57 m) respectively. For standard refrigerant line lengths (80 ft/24.38 m or less), allow the system to operate in cooling mode for at least 15 minutes. If conditions are favorable, check the system charge by the subcooling method. If any adjustment is necessary, adjust the charge slowly and allow the system to operate for 15 minutes to stabilize before declaring a properly charged system.

If the indoor temperature is above 80_F (26.67_C), and the outdoor temperature is in the favorable range, adjust the system charge by weight based on line length and allow the indoor temperature to drop to 80_F (26.67_C) before attempting to check the system charge by the subcooling method as described above.

If the indoor temperature is below 70 (21.11_C), or the outdoor temperature is not in the favorable range, adjust the charge for line set length above or below 15ft (4.57 m) only. The charge level should then be appropriate for the system to achieve rated capacity. The charge level could then be checked at another time when both indoor and outdoor temperatures are in a more favorable range.

Final Checks

IMPORTANT: Before leaving the job, be sure to do the following:

- Ensure that all wiring is routed away from tubing and sheet metal edges to prevent rub–through or wire pinching.

- Ensure that all wiring and tubing are secure in the unit before adding panels and covers. Securely fasten all panels and covers.

- Tighten service valve stem caps to 1/12–turn past finger tight.

- Leave the Owner’s Manual with the Owner. Explain system operation and periodic maintenance requirements outlined in the manual.

- Fill out the Dealer Installation Checklist and place it in the customer file.

CARE AND MAINTENANCE

For continuing high performance and to minimize possible equipment failure, periodic maintenance must be performed on this equipment. The frequency of maintenance may vary depending on geographic areas, such as coastal applications. See Owner’s Manual for information.

Table 6 – Accessory Usage

| ACCESSORY | REQUIRED FOR LOW-AMBIENT COOLING APPLICATIONS (Below 55°F/12.8_C) | REQUIRED FOR LONG LINE APPLICATIONS* | REQUIRED FOR SEA COAST APPLICATIONS (Within 2 miles/3.22 km) |

| Ball Bearing Fan Motor | Yes{ | No | No |

| Compressor Start Assist Capacitor and Relay | Yes | Yes | No |

| Crankcase Heater | Yes | Yes | No |

| Evaporator Freeze Thermostat | Yes | No | No |

| Hard Shut — Off TXV | Yes | Yes | Yes |

| Liquid Line Solenoid Valve | No | No | No |

| Motor MasterÒ or Low – ambient Pressure Switch | Yes | No | No |

| Support Feet | Recommended | No | Recommended |

| Winter Start Control | Yes | No | No |

For more manuals by Carrier visit, ManualsLibraryy

Carrier 24ABC Comfort Air Conditioner-FAqS

What is included in the Carrier 24ABC Comfort Air Conditioner installation?

The installation includes mounting the outdoor unit, connecting refrigerant lines, wiring the unit, and configuring it to work with the indoor system.

What is the required clearance for proper installation?

Ensure a minimum clearance of 24 inches on all sides and 60 inches above the unit for proper airflow and maintenance access.

How do I connect the refrigerant lines?

Connect the refrigerant lines following the manufacturer’s instructions. Be sure to evacuate the system to remove air and moisture before charging it with refrigerant.

What type of wiring is needed for the unit?

Use the specified electrical wiring as outlined in the manual. Ensure proper grounding and follow local electrical codes during installation.

Can I install the Carrier 24ABC unit indoors?

No, this unit is designed for outdoor use only. Installing it indoors will cause poor performance and may damage the unit.

How should the unit be leveled?

Install the unit on a level surface, such as a concrete pad, to ensure proper drainage and operation.

What size circuit breaker is recommended?

Refer to the product specifications in the manual for the recommended circuit breaker size, which depends on the unit’s model and capacity.

How do I ensure proper airflow around the unit?

Keep the area around the unit clear of obstructions, such as furniture, plants, or debris, to maintain efficient airflow and performance.

Do I need professional installation for this air conditioner?

Yes, professional installation is highly recommended to ensure the unit operates safely and efficiently while adhering to all local codes and regulations.

How do I check for leaks in the refrigerant lines?

Perform a pressure test and use a leak detector or soap solution to identify any leaks before charging the system with refrigerant.

What maintenance is required after installation?

Regular maintenance includes cleaning the coils, checking the refrigerant levels, and inspecting electrical connections to keep the unit operating efficiently.