Amana NED4655EW Front Load Electric Dryer

INSTALLATION REQ1AZSsUIREMENTS

Tools and Parts

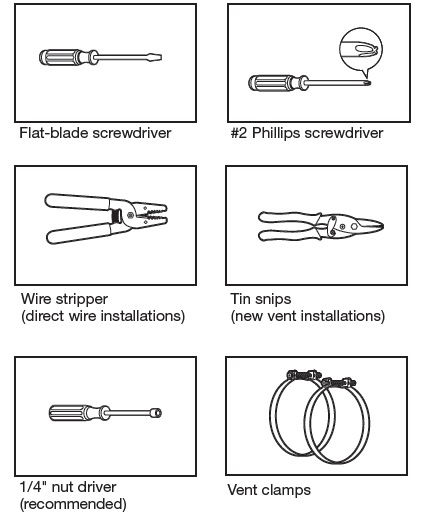

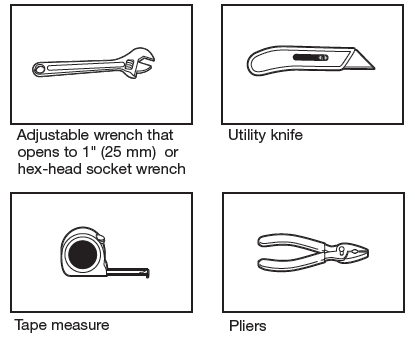

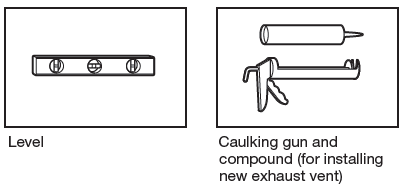

Gather the required tools and parts before starting installation. Read and follow the instructions provided with any tools listed here.

Tools needed

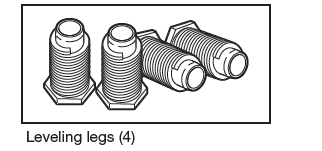

Parts supplied (all models)

The parts package is located in the dryer drum. Check that all parts are included.

Parts needed

Check local codes. Check existing electrical supply and venting, and read “Electrical Requirements” and “Venting Requirements” before purchasing parts. Mobile home installations require metal exhaust system hardware, available for purchase from the dealer from whom you purchased your dryer. For further information, please reference the “Assistance or Service” section of the “Use and Care Guide”.

If using a power supply cord

Use a UL-listed power supply cord kit marked for use with clothes dryers. The kit should contain:

- A UL-listed 30-amp power supply cord, rated 120/240 volt minimum. The cord should be type SRD or SRDT and be at least 4 ft. (1.22 m) long. The wires that connect to the dryer must end in ring terminals or spade terminals with upturned ends.

- A UL-listed strain relief.

Location Requirements

You will need

- A location allowing for proper exhaust installation. See “Venting Requirements.”

- A separate 30 amp circuit.

- If you are using a power supply cord, a grounded electrical outlet is located within 2 ft. (610 mm) of either side of the dryer. See “Electrical Requirements.”

- A sturdy floor to support the total weight (dryer and load) of 200 lbs. (90.7 kg). The combined weight of a companion appliance should also be considered.

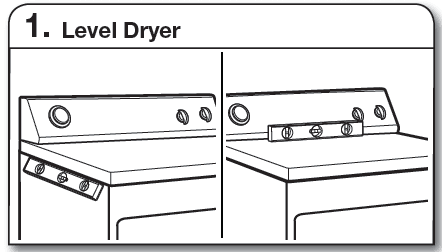

- Level floor with a maximum slope of 1″ (25 mm) under the entire dryer. (If the slope is greater than 1″ [25 mm], install Extended Dryer Feet Kit, Part Number 279810.) If not level, clothes may not tumble properly and automatic sensor cycles may not operate correctly. Do not operate your dryer at temperatures below 45°F (7°C). At lower temperatures, the dryer might not shut off at the end of an automatic cycle. Drying times can be extended. The dryer must not be installed or stored in an area where it will be exposed to water and/or weather. Check code requirements. Some codes limit or do not permit, the installation of the dryer in garages, closets, mobile homes, or sleeping quarters. Contact your local building inspector.

Installation clearances

The location must be large enough to allow the dryer door to open fully.

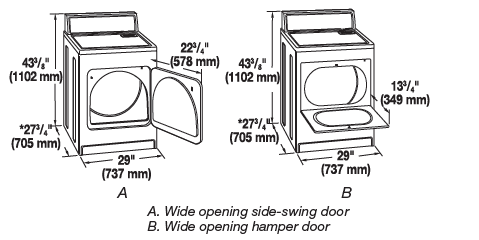

Dryer Dimensions

The parts package is located in the dryer drum. Check that all parts are included.

Parts needed

Check local codes. Check existing electrical supply and venting, and read “Electrical Requirements” and “Venting Requirements” before purchasing parts. Mobile home installations require metal exhaust system hardware, available for purchase from the dealer from whom you purchased your dryer. For further information, please reference the “Assistance or Service” section of the “Use and Care Guide”.

If using a power supply cord

Use a UL-listed power supply cord kit marked for use with clothes dryers. The kit should contain:

- A UL-listed 30-amp power supply cord, rated 120/240 volt minimum. The cord should be type SRD or SRDT and be at least 4 ft. (1.22 m) long. The wires that connect to the dryer must end in ring terminals or spade terminals with upturned ends.

- A UL listed strain relief.

Installation clearances

The location must be large enough to allow the dryer door to open fully.

Dryer Dimensions

- Most installations require a minimum 5½” (140 mm) clearance behind the dryer for the exhaust vent with an elbow. See “Venting Requirements.”

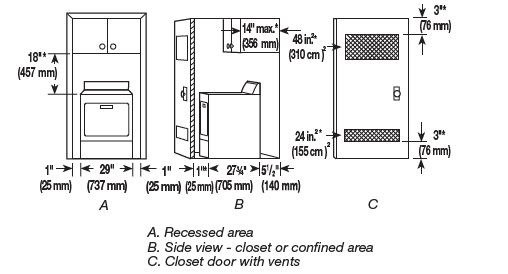

Minimum spacing for a recessed area or closet installation

The dimensions shown following are for the minimum spacing allowed.

- Additional spacing should be considered for ease of installation and servicing.

- Additional clearances might be required for wall, door, and floor moldings.

- Additional spacing of 1″ (25 mm) on all sides of the dryer is recommended to reduce noise transfer.

- For closet installation, with a door, minimum ventilation openings at the top and bottom of the door are required. Louvered doors with equivalent ventilation openings are acceptable.

- Companion appliance spacing should also be considered.

Minimum Required Spacing

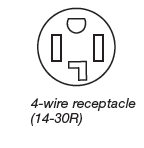

If your outlet looks like this

Then choose a 4-wire power supply cord with ring or spade terminals and UL listed strain relief. The 4-wire power supply cord, at least 4 ft. (1.22 m) long, must have 4 10-gauge solid copper wires and match a 4-wire receptacle of NEMA Type 14-30 R. The ground wire (ground conductor) may be either green or bare. The neutral conductor must be identified by a white cover.

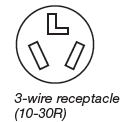

If your outlet looks like this

Then choose a 3-wire power supply cord with ring or spade terminals and UL listed strain relief. The 3-wire power supply cord, at least 4 ft. (1.22 m) long, must have 3 10-gauge solid copper wires and match a 3-wire receptacle of NEMA Type 10-30R.

If connecting by direct wire

The power supply cable must match the power supply (4-wire or 3-wire) and be:

- Flexible armored cable or nonmetallic sheathed copper cable (with ground wire), covered with flexible metallic conduit. All current-carrying wires must be insulated.

- 10-gauge solid copper wire (do not use aluminum).

- At least 5 ft. (1.52 m) long.

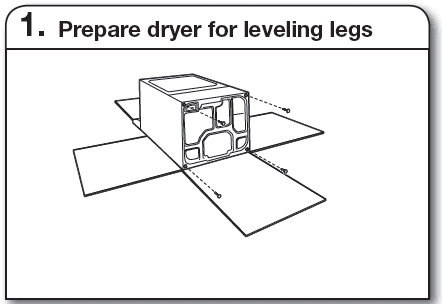

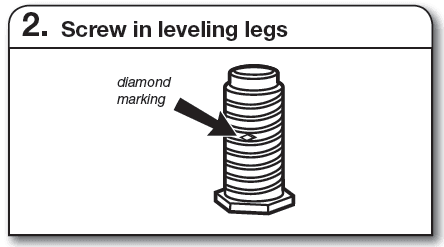

Install Leveling Legs

To avoid damaging the floor, use a large flat piece of cardboard from a dryer carton; place it under the entire back edge of the dryer. Firmly grasp the dryer body (not the console panel) and gently lay the dryer down on cardboard.

To avoid damaging the floor, use a large flat piece of cardboard from a dryer carton; place it under the entire back edge of the dryer. Firmly grasp the dryer body (not the console panel) and gently lay the dryer down on cardboard.

Electrical Connection Options

Choose the electrical connection type

![]() Power supply cord 4-wire receptacle (NEMA Type 14-30R): Go to steps 1-2 on page 9 for power supply cord strain relief: then steps 3-6 for the 4-wire Power Supply Cord Connection section. Then, go to Venting Requirements.

Power supply cord 4-wire receptacle (NEMA Type 14-30R): Go to steps 1-2 on page 9 for power supply cord strain relief: then steps 3-6 for the 4-wire Power Supply Cord Connection section. Then, go to Venting Requirements.![]() Power supply cord 3-wire receptacle (NEMA Type 10-30R): Go to steps 1-2 on page 9 for power supply cord strain relief: then steps 3-5 for the 3-wire Power Supply Cord Connection section. Then go to Venting Requirements.

Power supply cord 3-wire receptacle (NEMA Type 10-30R): Go to steps 1-2 on page 9 for power supply cord strain relief: then steps 3-5 for the 3-wire Power Supply Cord Connection section. Then go to Venting Requirements.![]() 4-wire direct connection: Go to steps 1-2 on page 10 for direct wire strain relief: then steps 3-8 for the 4-wire Direct Wire Connection section. Then go to Venting Requirements.

4-wire direct connection: Go to steps 1-2 on page 10 for direct wire strain relief: then steps 3-8 for the 4-wire Direct Wire Connection section. Then go to Venting Requirements.![]() 3-wire direct connection: Go to steps 1-2 on page 11 for direct wire strain relief: then steps 3-7 for 3-wire Direct Wire Connection section. Then go to Venting Requirements.

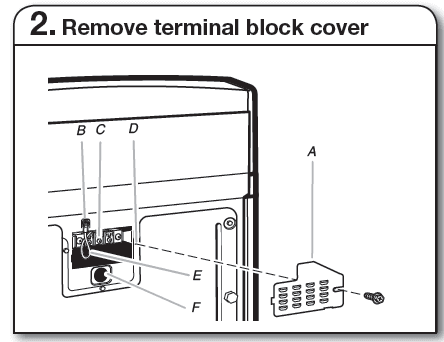

3-wire direct connection: Go to steps 1-2 on page 11 for direct wire strain relief: then steps 3-7 for 3-wire Direct Wire Connection section. Then go to Venting Requirements. Before you start, disconnect the power. Remove the hold-down screw (D) and terminal block cover (A).

Before you start, disconnect the power. Remove the hold-down screw (D) and terminal block cover (A).

- A. Terminal block cover

- B. External ground conductor screw

- C. Center terminal block screw

- D. Hold-down screw

- E. Neutral ground wire

- F. Hole below terminal block cover

Power Supply Cord Connection

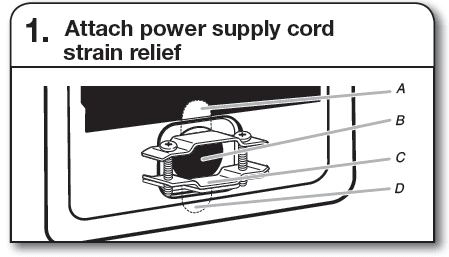

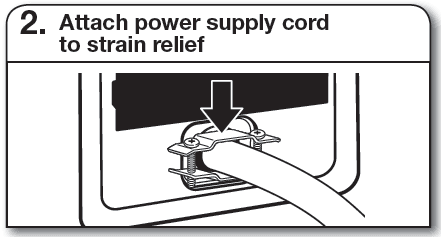

Power supply cord strain relief Remove the screws from a 3/4″ (19 mm) UL-listed strain relief (UL marking on strain relief). Put the tabs of the two clamp sections (C) into the hole (B) below the terminal block opening so that one tab is pointing up (A) and the other is pointing down (D), and hold them in place. Tighten strain relief screws just enough to hold the two clamp sections (C) together.

Remove the screws from a 3/4″ (19 mm) UL-listed strain relief (UL marking on strain relief). Put the tabs of the two clamp sections (C) into the hole (B) below the terminal block opening so that one tab is pointing up (A) and the other is pointing down (D), and hold them in place. Tighten strain relief screws just enough to hold the two clamp sections (C) together. Put the power supply cord through the strain relief. Be sure that the wire insulation on the power supply cord is inside the strain relief. The strain relief should have a tight fit with the dryer cabinet and be in a horizontal position.

Put the power supply cord through the strain relief. Be sure that the wire insulation on the power supply cord is inside the strain relief. The strain relief should have a tight fit with the dryer cabinet and be in a horizontal position.

4-wire Power Supply Cord Connection

IMPORTANT: A 4-wire connection is required for mobile homes and where local codes do not permit the use of 3-wire connections.

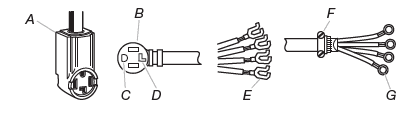

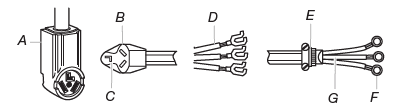

- A. 4-wire receptacle (NEMA type 14-30R)

- B. 4-prong plug

- C. Ground prong

- D. Neutral prong

- E. Spade terminals with upturned ends

- F. 3/4″ (19 mm) UL listed strain relief

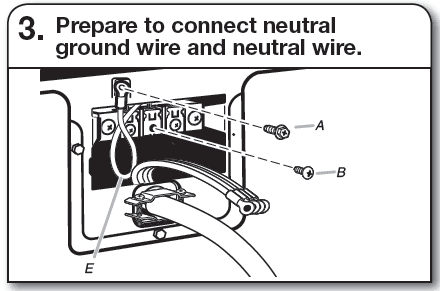

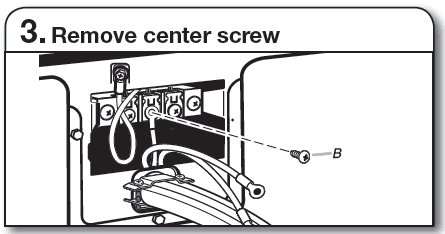

G. Ring terminals Remove center terminal block screw (B). Remove neutral ground wire (E) from the external ground conductor screw (A).

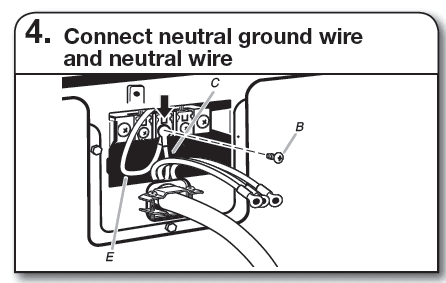

Remove center terminal block screw (B). Remove neutral ground wire (E) from the external ground conductor screw (A). Connect the neutral ground wire (E) and the neutral wire (white or center) (C) of the power supply cord under the center terminal block screw (B). Tighten screw.

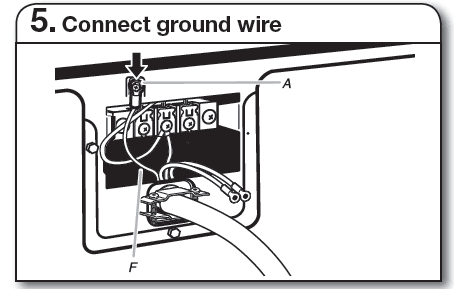

Connect the neutral ground wire (E) and the neutral wire (white or center) (C) of the power supply cord under the center terminal block screw (B). Tighten screw. Connect the ground wire (F) (green or bare) of the power supply cord to the external ground conductor screw (A). Tighten screw.

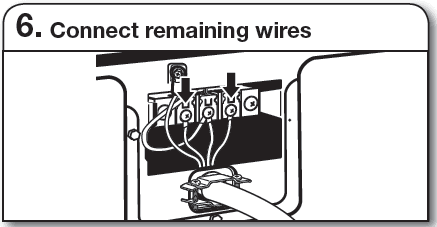

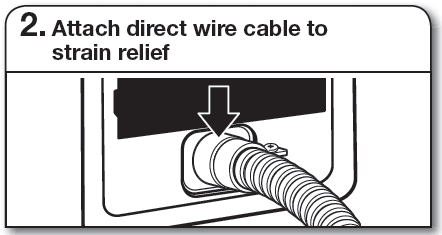

Connect the ground wire (F) (green or bare) of the power supply cord to the external ground conductor screw (A). Tighten screw. Connect the remaining wires to the outer terminal block screws. Tighten screws. Finally, reinsert the tab of the terminal block cover into the slot of the dryer rear panel. Secure the cover with a hold-down screw. Now, go to Venting Requirements.

Connect the remaining wires to the outer terminal block screws. Tighten screws. Finally, reinsert the tab of the terminal block cover into the slot of the dryer rear panel. Secure the cover with a hold-down screw. Now, go to Venting Requirements.

3-wire Power Supply Cord Connection

Use where local codes permit connecting the cabinet-ground conductor to neutral wire.

- A. 3-wire receptacle (NEMA type 10-30R)

- B. 3-wire plug

- C. Neutral prong

- D. Spade terminals with upturned ends

- E. 3/4″ (19 mm) UL listed strain relief

- F. Ring terminals

- G. Neutral (white or center wire)

Remove the center terminal block screw (B).

Remove the center terminal block screw (B). Connect the neutral wire (white or center) (C) of the power supply cord to the center terminal block screw (B). Tighten screw.

Connect the neutral wire (white or center) (C) of the power supply cord to the center terminal block screw (B). Tighten screw. Connect the remaining wires to the outer terminal block screws. Tighten screws. Finally, reinsert the tab of the terminal block cover into the slot of the dryer rear panel. Secure the cover with a hold-down screw. Now, go to Venting Requirements.

Connect the remaining wires to the outer terminal block screws. Tighten screws. Finally, reinsert the tab of the terminal block cover into the slot of the dryer rear panel. Secure the cover with a hold-down screw. Now, go to Venting Requirements.

Direct Wire Connection

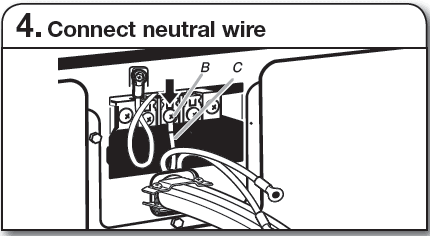

Direct wire strain relief

Unscrew the removable conduit connector (A) and any screws from a 3/4″ (19 mm) UL-listed strain relief (UL marking on strain relief). Put the threaded section of the strain relief through the hole (B) below the terminal block opening. Reaching inside the terminal block opening, screw the removable conduit connector onto the strain relief threads (C).

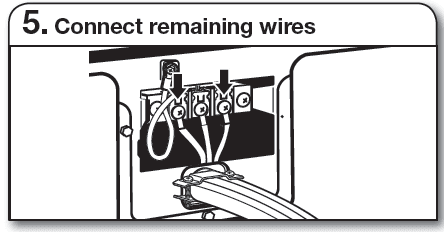

Unscrew the removable conduit connector (A) and any screws from a 3/4″ (19 mm) UL-listed strain relief (UL marking on strain relief). Put the threaded section of the strain relief through the hole (B) below the terminal block opening. Reaching inside the terminal block opening, screw the removable conduit connector onto the strain relief threads (C). Put direct wire cable through the strain relief. The strain relief should have a tight fit with the dryer cabinet and be in a horizontal position. Tighten strain relief screws.

Put direct wire cable through the strain relief. The strain relief should have a tight fit with the dryer cabinet and be in a horizontal position. Tighten strain relief screws.

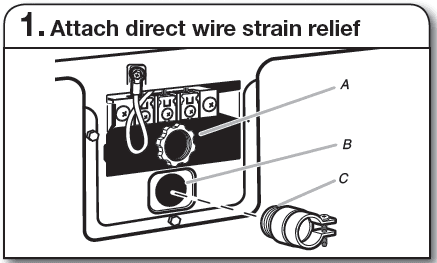

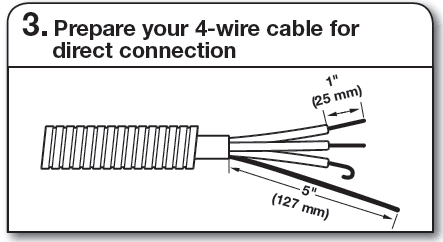

4-wire Direct Wire Connection

IMPORTANT: A 4-wire connection is required for mobile homes and where local codes do not permit 3-wire connections. Direct wire cable must have 5 ft. (1.52 m) of extra length so the dryer may be moved if needed. Strip 5″ (127 mm) of outer covering from the end of the cable, leaving bare ground wire at 5″ (127 mm). Cut 11/2″ (38 mm) from the remaining 3 wires. Strip insulation back 1″ (25 mm). Shape ends of wires into hooks.

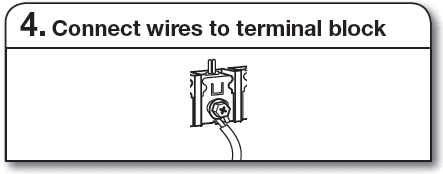

Direct wire cable must have 5 ft. (1.52 m) of extra length so the dryer may be moved if needed. Strip 5″ (127 mm) of outer covering from the end of the cable, leaving bare ground wire at 5″ (127 mm). Cut 11/2″ (38 mm) from the remaining 3 wires. Strip insulation back 1″ (25 mm). Shape ends of wires into hooks. To connect wires to a terminal block, place the hooked end of the wire under the terminal block screw, facing to the right, squeeze the hooked end together, and tighten the screw.

To connect wires to a terminal block, place the hooked end of the wire under the terminal block screw, facing to the right, squeeze the hooked end together, and tighten the screw.

Vent System Chart (Long Vent Models Only)

| Number of 90° turns or elbows | Type of vent | Box/louvered, or Angled hoods |

| 0 | Rigid metal | 120 ft. (36.6 m) |

| 1 | Rigid metal | 110 ft. (33.5 m) |

| 2 | Rigid metal | 100 ft. (30.5 m) |

| 3 | Rigid metal | 90 ft. (27.4 m) |

| 4 | Rigid metal | 80 ft. (24.4 m) |

| 5 | Rigid metal | 70 ft. (21.3 m) |

Vent System Chart

| Number of 90° turns or elbows | Type of vent | Box/louvered hoods | Angled hoods |

| 0 | Rigid metal | 64 ft. (20 m) | 58 ft. (17.7 m) |

| 1 | Rigid metal | 54 ft. (16.5 m) | 48 ft. (14.6 m) |

| 2 | Rigid metal | 44 ft. (13.4 m) | 38 ft. (11.6 m) |

| 3 | Rigid metal | 35 ft. (10.7 m) | 29 ft. (8.8 m) |

| 4 | Rigid metal | 27 ft. (8.2 m) | 21 ft. (6.4 m) |

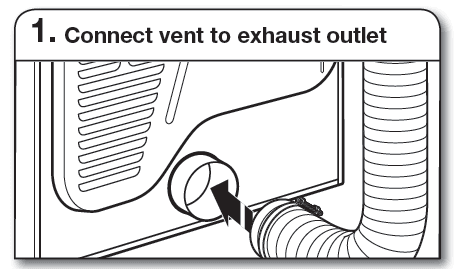

Connect Vent

Using a 4″ (102 mm) clamp, connect the vent to the exhaust outlet in a dryer. If connecting to the existing vent, make sure the vent is clean. The dryer vent must fit over the dryer exhaust outlet and inside the exhaust hood. Check that the end is secured to exhaust hood with a 4″ (102 mm) clamp.

Using a 4″ (102 mm) clamp, connect the vent to the exhaust outlet in a dryer. If connecting to the existing vent, make sure the vent is clean. The dryer vent must fit over the dryer exhaust outlet and inside the exhaust hood. Check that the end is secured to exhaust hood with a 4″ (102 mm) clamp. Move dryer to a final location. Avoid crushing or kinking the vent. After the dryer is in place, remove corner posts and cardboard from under the dryer.

Move dryer to a final location. Avoid crushing or kinking the vent. After the dryer is in place, remove corner posts and cardboard from under the dryer. Check the level of the dryer from side to side. Repeat from front to back.

Check the level of the dryer from side to side. Repeat from front to back.

Reverse Door Swing (Optional)

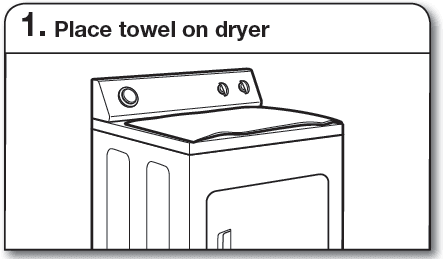

Place a towel on top of the dryer to avoid damaging the surface.

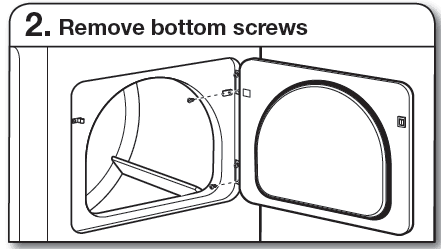

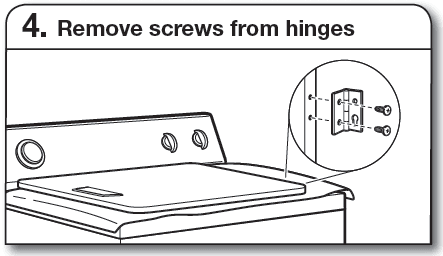

Place a towel on top of the dryer to avoid damaging the surface. Open the dryer door. Remove the bottom screws from the dryer cabinet side of the hinges. Loosen (do not remove) the top screws from the dryer cabinet side of the hinges.

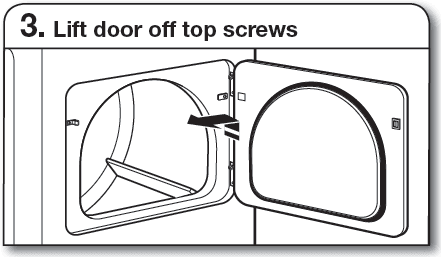

Open the dryer door. Remove the bottom screws from the dryer cabinet side of the hinges. Loosen (do not remove) the top screws from the dryer cabinet side of the hinges. Lift the door until the top screws in the dryer cabinet are in a large part of the hinge slot. Pull the door forward off the screws. Set the door (handle side up) on top of the dryer. Remove the top screws from the dryer cabinet.

Lift the door until the top screws in the dryer cabinet are in a large part of the hinge slot. Pull the door forward off the screws. Set the door (handle side up) on top of the dryer. Remove the top screws from the dryer cabinet. Remove screws attaching hinges to the door.

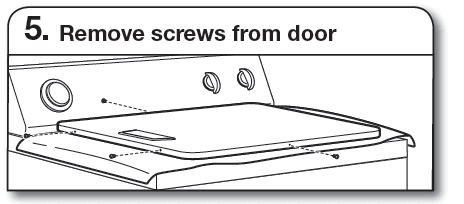

Remove screws attaching hinges to the door. Remove screws at the top, bottom, and side of the door (4 screws) that hold the inner and outer doors together. Holding the door over a towel on the dryer, grasp the sides of the outer door and lift to separate it from the inner door. Set the outer door aside.

Remove screws at the top, bottom, and side of the door (4 screws) that hold the inner and outer doors together. Holding the door over a towel on the dryer, grasp the sides of the outer door and lift to separate it from the inner door. Set the outer door aside.

For more manuals by Amana visit, ManualsLibraryy

Amana NED4655EW Front Load Electric Dryer-FAQs

Why won’t my Amana dryer start?

The most common reason is a power supply issue. Check if the power socket is working by unplugging the dryer and testing it in a different socket.

How many watts does the Amana dryer use?

The Amana NED4655EW dryer operates at 240 volts and uses approximately 5,600 watts of power.

Why isn’t my Amana dryer drying clothes?

This could be due to a clogged lint trap, blocked vent, or a malfunctioning heating element. Cleaning the lint trap and vent may resolve the issue. If not, consult a technician.

How long does an Amana dryer typically last?

Amana dryers usually last between 11 and 16 years. If your dryer is over 13 years old, consider replacing it. For newer models, repairs might be sufficient to fix issues.

Why won’t my dryer start even when I press the start button?

Possible causes include a blown thermal fuse, faulty motor, clogged vent, tripped circuit breaker, defective door latch, or a broken start switch.

How many watts and volts does a dryer use on average?

Most dryers use between 1,500 and 5,000 watts and connect to a 240-volt outlet.

Do dryers have internal fuses?

Yes, dryers typically have three internal fuses: a high-temperature fuse, a cycle timer fuse, and a low-temperature fuse. The high-temperature fuse is the most likely to blow.

Why does my dryer stop after running for only 5 minutes?

This could indicate overheating caused by lint buildup in the vents or a blocked exhaust hose. Clean the vents and exhaust to prevent this issue.

Which type of dryer dries clothes the fastest?

Vented dryers are the quickest, drying a small to regular load in 30 minutes to an hour. However, they are less energy-efficient compared to other models.