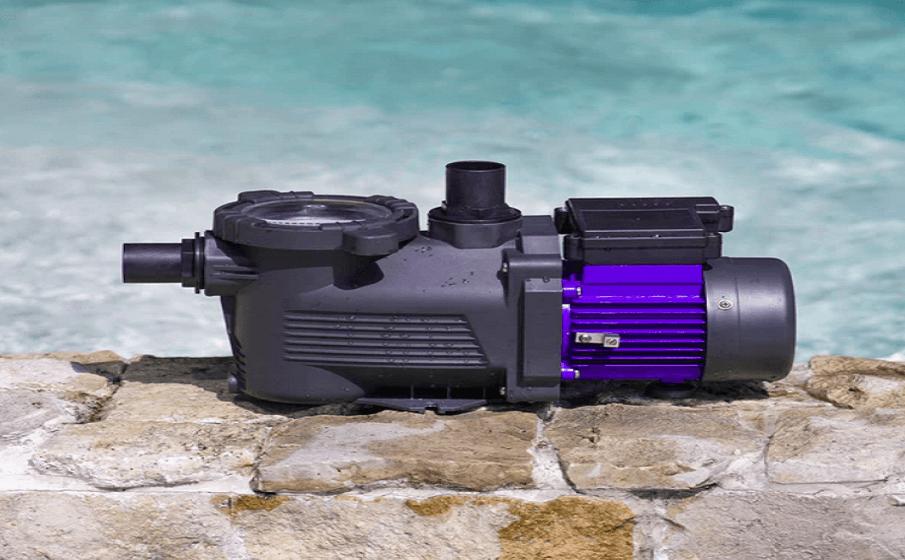

AQUASTRONG 220V Variable Speed Ground Pool Pump

Introduction

- This manual is an essential guide for the safe operation and maintenance of the Aquastrong Variable Speed Pool Pump. It includes vital safety information, so please read the instructions carefully before use. Adherence to safe practices and reasonable care is paramount. We are grateful for your choice of the Aquastrong Variable Speed Pool Pump and trust that it will serve you well, offering long-lasting performance and exceptional reliability. Your feedback is valuable to us; feel free to contact us with any suggestions. We will thoughtfully consider your input and respond, whether we implement your suggestions or not. Your support is greatly appreciated. Please note that all data, diagrams, and specifications in this manual are subject to the latest product information. In case of any discrepancy between the manual and the nameplate, the nameplate should be referred to as the authoritative source.

General

- This manual offers comprehensive guidance on the installation, operation, and maintenance of our pumps, essential for ensuring safe and effective usage. We advise thorough reading and retention for future reference.

- Our swimming pool pumps, designed for permanent installation in pools, are horizontal, self-priming centrifugal units. The incorporation of a non-return valve facilitates immediate priming. To ensure optimal performance, the water temperature should not surpass 95°F. Our pump materials have been rigorously tested for hydraulic efficiency and electrical safety. Prior to installation, it is critical to review this manual thoroughly. Installation must adhere to prevailing industry standards. We absolve ourselves of any liability resulting from non-compliance with these installation instructions. Adherence to the provided electrical wiring diagrams is recommended to prevent overloading the pump motor.

Wiring

Black – Hot Wire (110V); White – Hot Wire (110V); Green – Ground Wire

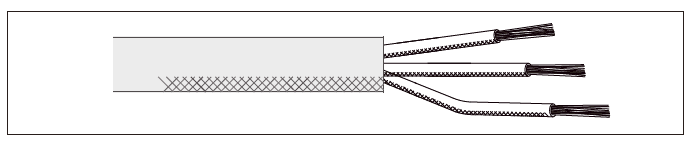

- Peel off the black cable skin to reveal the 3 wires inside, strip each cable by 2/3 inch with a wire stripper, then strip the insulation to reveal 1/5 inch copper wire.Prepare the pump wire extension, repeat the above steps

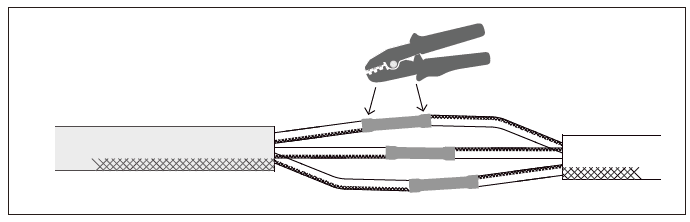

- Insert the stripped wires into the butt connectors in the wire pigtail from the pump. Firmly crimp each splice with crimping plier to tightly hold the wires In place. Attention: Please pay attention to correct matching when wiring an extension cable.

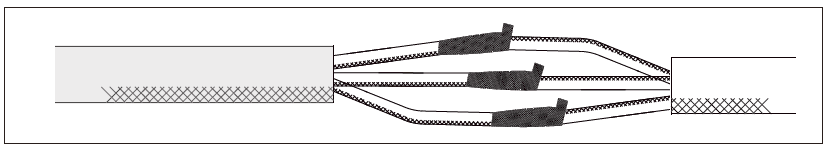

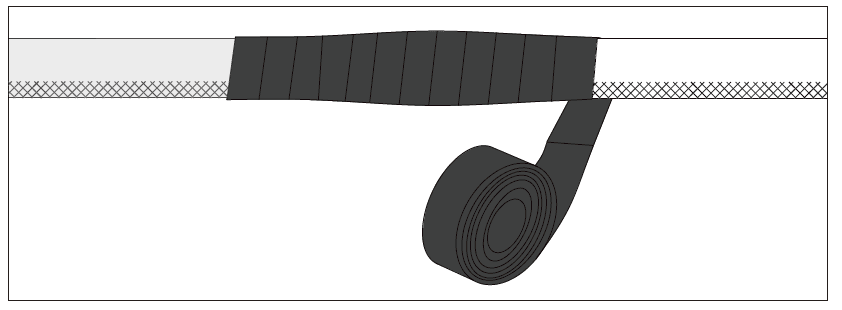

- Winding the waterproof electrical tape on the butt splice connections of three strands of wire.

- Winding the waterproof electrical tape over wire.

Guarantee

- Our pumps are warranted against material and manufacturing defects for a period of 24 months from the date of delivery. This warranty does not cover wear parts, gaskets, covers, and the filtering basket. Compliance with the assembly and/or maintenance manual is required for the warranty to be valid. In the

event of a warranty claim, presentation of the purchase invoice is mandatory. Under this warranty, the vendor’s sole obligation is to repair or replace, free of charge, any product or component recognized as defective by the vendor’s technical services. All other expenses related to the warranty claim, including but not limited to transportation costs, shall be borne by the purchaser. To qualify for warranty service, the product must be approved by the vendor’s after-sales service prior to any repair or replacement. - This warranty does not cover any visible defects, damages due to normal wear, incorrect assembly, misuse, or unauthorized modifications to the product. For any inquiries or clarification regarding this warranty, please contact our after-sales service at [email protected].

Technical data of pumps

| Technical date | PSP150PM | PSP200PM | PSP300PM |

| Votagles | 220-240V | ||

| Frequency | 50Hz/60Hz | ||

| Rate current | 5 A | 7.2 A | 9.5 A |

| HP | 1.5 HP | 2 HP | 3 HP |

| Protection/insulation | IPX5/ Class F | ||

| Max. Flow rate | 8189 GPH | 10566 GPH | 11359 GPH |

| Max. Head | 65 ft | 75 ft | 80 ft |

| Maximum Ambient Temperatuer | 104°F (40°C) | ||

| Maximum Liquid Ambient Temperature | 122°F (50°C) | ||

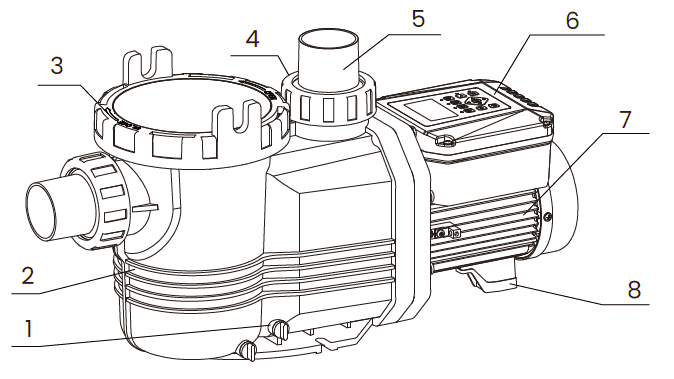

For example:

- Plug screw

- Pump body

- Filter Cover

- Nut

- Connection

- Terminal box

- Motor

- Support foot

- This appliance is not intended for use by persons (including children) with reduced physical, sensory or mental capabilities, or lack of experience and knowledge, unless they have been given supervision or instruction concerning use of the appliance by a person responsible for their safety. Children should be supervised to ensure that they do not play with the appliance. The pump must not be used when people are in the water.

Pump Fixing

- Caution for Pump Installation: Ensure the pump is protected from moisture and potential flooding. It’s recommended not to install the pump more than 3 meters above the water level to ensure optimal performance.

- Regardless of the pump’s height above the water and the capacity of the chosen model, be aware that priming can take several minutes. Install the pump and its components in a dry, well-ventilated area to prevent environmental damage and ensure the longevity and safe operation of the pump. Adequate measures should be taken to safeguard the pump against environmental factors

- Aquastrong Variable Speed Pool Pumps are easily assembled. For inquiries or technical support, contact Aquastrong at [email protected]

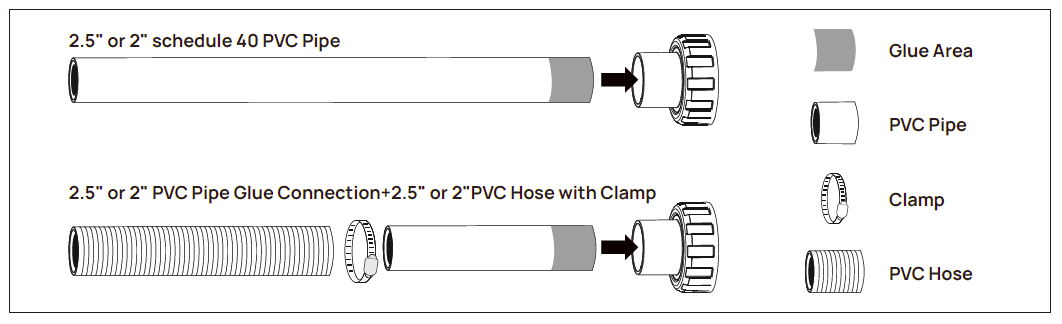

Installation of the pipes

- The pipes can be connected using either 2.5-inch or 2-inch PVC rigid pipes for a direct connection. Alternatively, a combination of PVC rigid pipes and PVC flexible hoses can be used, secured with hose clamps for a reliable connection. This flexible approach allows for a more adaptable installation, accommodating

different setup requirements while ensuring a secure and efficient connection for the pump system.

Electrical Installation

- The user shall inspect and make sure about the effectiveness of protective earthing of the building installation. In such case, an authorized qualified person shall inspect the building installation.It is obligatory for the pump electrical power supply to have residual current device (RCD) having a rated residual operating current not exceeding 30mA.

- Up to 100FT: Mandatory use of 12AWG power line.

- 100 to 200FT: Strongly recommended to use 10AWG power line.

- Beyond 200FT: Essential to consult a local professional electrical engineer.

- Never work on a pump without first checking that the electrical power is switched off

Servicing

- The Aquastrong Variable Speed Pool Pumps are designed for low maintenance; however, we recommend periodic cleaning of the pre-filter to ensure optimal performance. To perform this task, first shut off the suction and delivery valves. Then, carefully loosen the black nuts and remove the pre-filter cover. Withdraw the filtering basket and clean it thoroughly. Inspect the pre-filter cover gasket and replace it if you notice any damage. If the pump is not in use during winter, it is crucial to drain it (by removing the drain plug) to prevent damage from freezing. Additionally, clean the pump and store it in a dry, well-ventilated area. In case of malfunction, avoid attempting any repairs yourself and instead contact our technical support team for assistance. For your safety, always disconnect the pump from the electrical supply before undertaking any servicing activities.

Problems and Solutions

POSSIBLE FAULTS

- Pump does not prime

- Low flow rate

- Pump makes noise

- Pump does not start

- Motor makes noise but does not start

| BLE FAULTS | CAUSES | SOLUTIONS | ||||

| 1 | 2 | 3 | 4 | 5 | ||

| Air entry | Verity watertightness of connectors and seals | |||||

| Bad watertightness of cover | Clean the cover and verify the seals | |||||

| Excessive suction height | Set pump at a suitable level | |||||

| Incorrect voltage | Verify the voltage specified on the nameplate and that of the mains | |||||

| No water in prefilter | Fill prefilter with water | |||||

| Filter clogged | Clean filter | |||||

| Diameter of section line smaller than required | Correctly dimension section line | |||||

| Discharge clogged | Inspect filter and discharge line | |||||

| Incorrect pump attachment | Attach pump correctly | |||||

| Refuses in the pump | Clean pump and inspect the filter | |||||

| No tension | Reset the fuses | |||||

| Motor blocked | Call the technical service | |||||

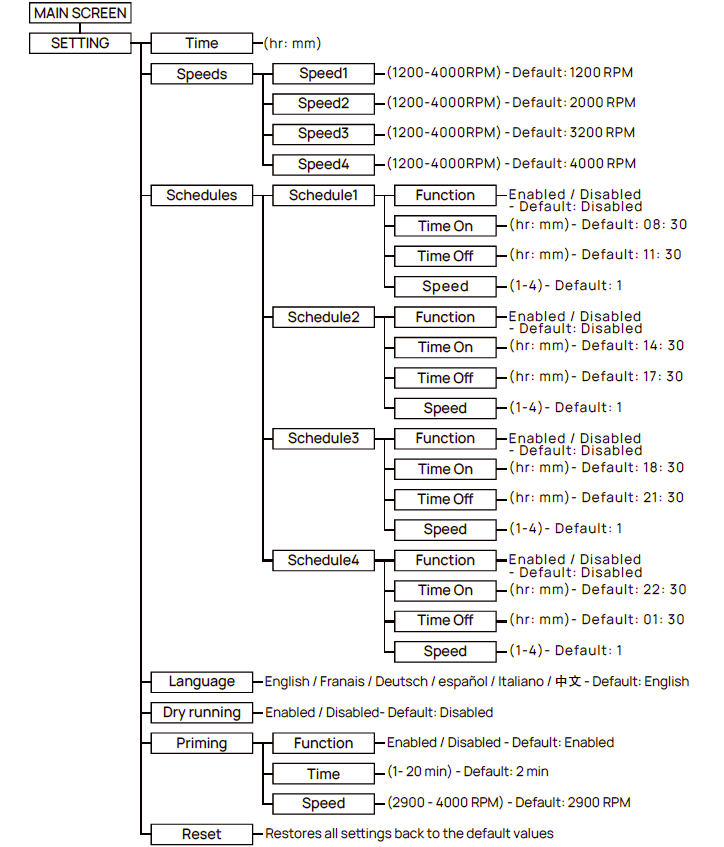

Programming Flow Chart

- Caution:

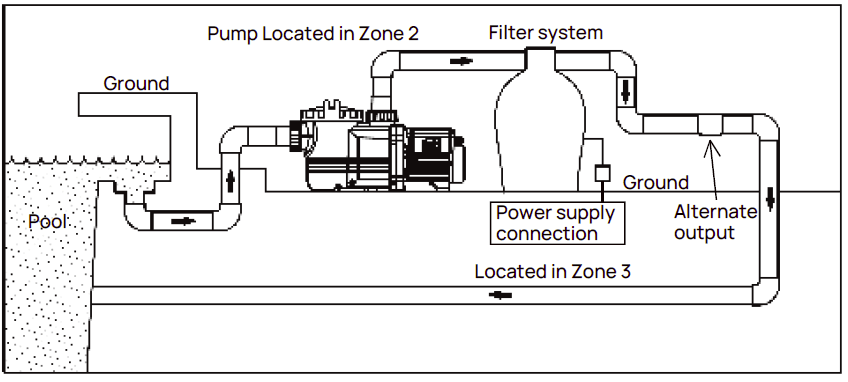

- The pump should be installed in Zone 2, typically at least 7 feet from the pool. Its power supply connection must be in Zone 3, generally a minimum1o2ffeet from the pool, as per the International Standard: Electrical Installations of Buildings Part 7 – Requirements for Special Installations or Locations – Swimming Pools and other Basins (IEC60364-7-702).

- Despite having an earthing terminal, the pump must be connected to the equipotential bonding terminal in the electrical wiring before use. The equipotential bonding terminal is indicated by the following symbol. For any uncertainties, consult an electrical specialist.

- The pump must be powered either via an isolating transformer or through a Residual Current Device (RCD) with a rated residual operating current not exceeding 30 mA. Electrical installations should align with national wiring regulations.

- In case of supply cord damage, replacement must be done by the manufacturer, an authorized service agent, or a qualified professional to prevent hazards. The pump is designed for continuous operation. An all-pole disconnection switch, directly linked to the supply terminals, is required. This switch should ensure contact separation in all poles for safety. For any inquiries or installation needs, please consult a professional or an electrical specialist.

Pre-Start Pump Check

- Verify that the main power supply’s voltage and frequency match the specifications on the pump’s identification plate.

- Ensure that the pump shaft rotates smoothly and freely.

- Remove the pre-filter cover and fill the pump with water to just below the suction pipe’s lower level.

- Securely reattach the pre-filter cover.

- If the motor fails to start or no water is being pumped, consult the troubleshooting guide provided later in this manual.

- WARNING: NEVER operate the pump dry or with the water inlet blocked.

- Starting the Pump

- Once the pump is filled with water, open all suction and delivery valves, then initiate the motor. Allow time for self-priming. Proper priming is achieved when the water level reaches just below the transparent cover.

Function

- The Aquastrong Variable Speed Pool Pump is an advanced version of the standard pool pump, featuring an added controller for enhanced system management.

- Attention: Users should not remove or alter the display face sticker. If the sticker is damaged or improperly affixed, the pump must be sent to an authorized service agent or the manufacturer for repair.

- The controller is equipped with a power limit function, which is a top priority. If the pump’s power exceeds the set threshold, the controller will adjust by reducing the pump’s speed. This may result in the speed displayed being occasionally lower than the set speed, ensuring efficient and safe operation.

User’s guide

Overview

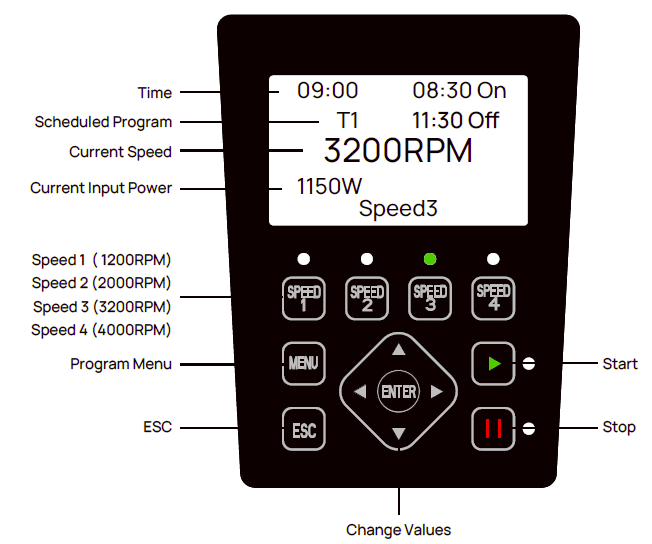

The functions of the controller is shown below:

- Time: Built in the time clock.

- Speed Display: Expressed in RPM. Shows the operating speed.

- Preset pump speed: Four optional preset running speeds available.

- Display: Time, four preset running speeds, power, schedule settings and fault codes.

- Display interface

Description of Controls

| Speed 1 | Press the button to choose a motor speed; the LED next to it lights up to show selection. | |

| Speed 2 | Press the button to choose a motor speed; the LED next to it lights up to show selection. | |

| Speed 3 | Press the button to choose a motor speed; the LED next to it lights up to show selection. | |

| Speed 4 | Press the button to choose a motor speed; the LED next to it lights up to show selection. | |

| Menu | Press the button to access the parameter adjustment menu when the motor is off. | |

| ESC | Back/Cancel | |

| Enter | Enter sub-menu, adjust speed settings or save them. | |

| Increase | Press this button to adjust (increase) the setting | |

| Decrease | Press this button to adjust (decrease) the setting | |

| Left | Move the cursor keys (select unit, Loop display) | |

| Right | Move the cursor keys (select unit, Loop display) | |

| Start | Press this button to start the motor, LED next to the button switches on | |

| Stop | Press this button to stop the motor, LED next to the button turn red. Drive fault reset key |

For more manuals by AQUASTRONG visit ManualsLibraryy

AQUASTRONG 220V Variable Speed Ground Pool Pump-FAQs

How long should I run my variable speed pool pump each day?

Most pool owners run their variable speed pump for 12 hours daily—around 3–4 hours on high speed for cleaning and 8–9 hours on low speed for filtration.

How does a variable speed pool pump work?

It uses a permanent magnet motor, similar to those in electric cars. This motor allows you to adjust the flow rate, improving energy efficiency and optimizing water circulation.

How much power does a variable speed pool pump use?

A variable speed pump typically consumes around 300 watts. Running it for 8 hours daily results in approximately 72 kWh per month.

Is it better to run my pool pump during the day or at night?

Running the pump during the day is recommended because evaporation increases at night, which can lead to water cooling. The sun helps maintain water temperature.

What is the most efficient way to operate a variable speed pool pump?

1. Run the pump at lower RPMs (1,500–2,000 RPM) for 18–22 hours to save energy.

2. Increase to a higher RPM for 2–4 hours daily for proper cleaning and circulation

Can I run my pool pump 24/7?

Yes, running the pump continuously improves water circulation and filtration, keeping the pool cleaner. However, it may increase electricity costs.

How long does a variable speed pool pump last?

On average, 8 to 12 years before requiring a replacement. Regular maintenance can help extend its lifespan.

What voltage does a variable speed pool pump require?

Most models operate at 220-240V, as higher voltage improves efficiency and performance.