Char-Broil The Big Easy Oil-less Turkey Fryer

Food Safety

Food safety is a very important part of enjoying the outdoor cooking experience. To keep food safe from harmful bacteria, follow these four basic steps:

- Clean: Wash hands, utensils, and surfaces with hot soapy water before and after handling raw meat and poultry.

- Separate: Separate raw meats and poultry from ready-to-eat foods to avoid cross-contamination. Use a clean platter and utensils when removing cooked foods.

- Cook: Cook meat and poultry thoroughly to kill bacteria. Use a thermometer to ensure proper internal food temperatures.

- Chill: Refrigerate prepared foods and leftovers promptly.

Grease Tray

- Never use drippings directly from the grease tray to make gravy. Use the included foil tray liner to catch drippings, then reheat the drippings to kill bacteria. Replacement foil tray liners and other accessories can be found at www.charbroil.com

How To Tell If Meat Is Cooked Thoroughly

- Meat and poultry cooked in the appliance often browns very fast on the outside. Use only thawed meat and a meat thermometer to be sure food has reached a safe internal temperature, and cut into food to check for visual signs of doneness.

- We recommend food to be at least 40°F before cooking in your appliance.

- Whole poultry should reach 165° F. Juices should run clear and flesh should not be pink.

- Beef, veal and lamb steaks, roasts and pork chops can be cooked to 145° F.

- NEVER partially cook meat or poultry and finish cooking later. Cook food completely to destroy harmful bacteria.

- Use a meat thermometer to ensure proper internal food temperatures.

USDA Recommended

Internal Cooking Temperatures

Ground Meat

- Beef, Pork, Veal, Lamb: 160°F

- Turkey, Chicken: 165°F

Fresh Beef, Veal, Lamb

- Medium Rare: 145°F (let stand 3 minutes before cutting)

- Medium: 160°F

- Well Done: 170°F

Poultry

- Chicken & Turkey, whole: 165°F

- Poultry Parts: 165°F

- Duck & Goose: 165°F

Fresh Pork

- Medium Rare: 145°F (let stand 3 minutes before cutting)

- Medium: 160°F

- Well Done: 170°F

Storing Your Appliance

- Clean cooking basket.

- Store in dry location.

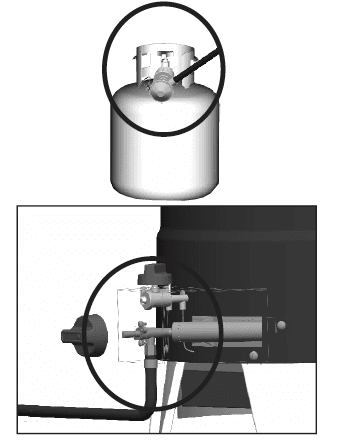

- When LP cylinder is connected to an appliance, store it outdoors in a well-ventilated space and out of reach of children.

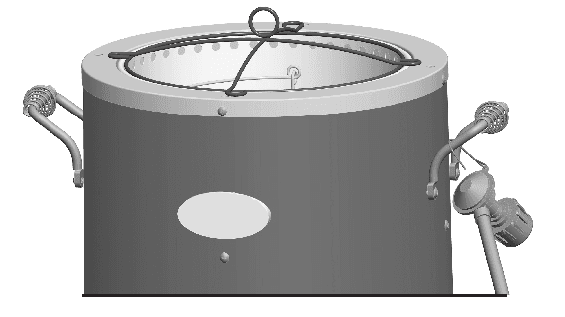

- If the regulator is disconnected from the LP cylinder, a hook is provided to hang the regulator from the handle as shown.

- Cover appliance if stored outdoors. Choose from a variety of covers offered by the manufacturer.

- Store indoors ONLY if LP cylinder is turned off and is disconnected, removed from appliance and stored outdoors.

- When removing appliance from storage, follow “Cleaning the Burner Assembly” instructions before starting.

USE AND CARE

DANGER

- NEVER store a spare LP cylinder under or near the appliance or in an enclosed area.

- Never fill a cylinder beyond 80% full.

- An over filled or improperly stored cylinder is a hazard due to possible gas release from the safety relief valve. This could cause an intense fire with risk of property damage, serious injury or death.

- If you see, smell or hear gas escaping, immediately get away from the LP cylinder/appliance and call your fire department.

- Keep LP tank at a minimum distance of 24” (inches) away from appliance at all times.

LP Cylinder Removal, Transport and Storage

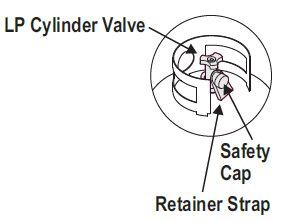

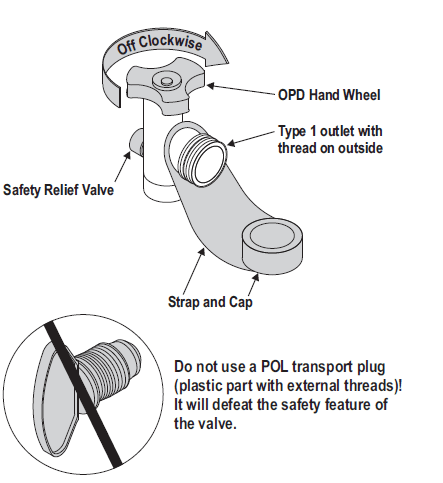

- Turn OFF the control knob and LP cylinder valve. Turn coupling nut counterclockwise by hand only – do not use tools to disconnect. Install safety cap onto LP cylinder valve. Always use cap and strap supplied with valve. Failure to use safety cap as directed may result in serious personal injury

and/or property damage.

LP (Liquefied Petroleum Gas)

- LP gas is nontoxic, odorless and colorless when produced. For Your Safety, LP gas has been given an odor (similar to rotten cabbage) so that it can be smelled.

- LP gas is highly flammable and may ignite unexpectedly when mixed with air.

- A disconnected LP cylinder in storage or being transported must have a safety cap installed (as shown). Do not store an LP cylinder in enclosed spaces such as a carport, garage, porch, covered patio or other building. Never leave an LP cylinder inside a vehicle which may become overheated by the sun.

- Do not store an LP cylinder in an area where children play.

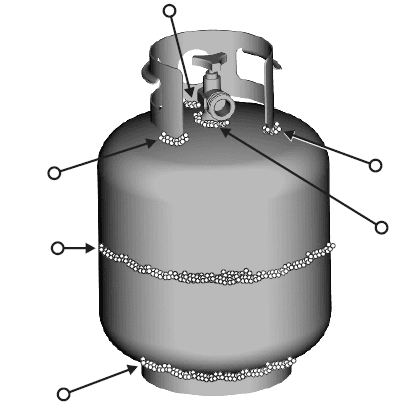

LP Cylinder

- The LP cylinder used with your appliance must meet the following requirements:

- Use LP cylinders only with these required measurements: 12″ (30.5cm) (diameter) x 18″ (45.7 cm) (tall) with 20 lb. (9 kg.) capacity maximum.

- LP cylinders must be constructed and marked in accordance with specifications for LP cylinders of the U.S. Department of Transportation (DOT) or the National Standard of Canada, CAN/CSA-339, Cylinders, Spheres and Tubes for Transportation of Dangerous Goods; and commission, as applicable. See LP cylinder collar for marking.

- LP cylinder valve must have:

- Type 1 outlet compatible with regulator or appliance.

- Safety relief valve.

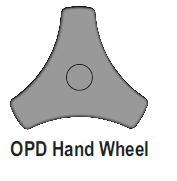

- UL listed Overfill Protection Device (OPD). This OPD safety feature is identified by a unique triangular hand wheel. Use only LP cylinders equipped with this type of valve.

- LP cylinder must be arranged for vapor withdrawal and include collar to protect LP cylinder valve. Always keep LP cylinders in upright position during use, transit or storage.

LP Cylinder Filling

- Use only licensed and experienced dealers.

- LP dealer must purge new cylinder before filling.

- Dealer should NEVER fill LP cylinder more than 80% of LP cylinder volume. Volume of propane in cylinder will vary by temperature.

- A frosty regulator indicates gas overfill. Immediately close LP cylinder valve and call local LP gas dealer for assistance.

- Do not release liquid propane (LP) gas into the atmosphere. This is a hazardous practice.

- To remove gas from LP cylinder, contact an LP dealer or call a local fire department for assistance. Check the telephone directory under “Gas Companies” for nearest certified LP dealers.

LP Cylinder Exchange

- Many retailers that sell this appliance offer you the option of replacing your empty LP cylinder through an exchange service Use only those reputable exchange companies that inspect, precision fill, test and certify their cylinders. Exchange your cylinder only for an OPD safety feature-equipped cylinder as described in the “LP Cylinder” section of this manual.

- Always keep new and exchanged LP cylinders in upright position during use, transit or storage.

- Leak test new and exchanged LP cylinders BEFORE connecting to the appliance.

LP Cylinder Leak Test

For your safety

- Leak test must be repeated each time LP cylinder is exchanged or refilled.

- Do not smoke during leak test.

- Do not use an open flame to check for gas leaks.

- This appliance must be leak tested outdoors in a well-ventilated area, away from ignition sources such as gas fired or electrical appliances. During leak test, keep appliance away from open flames or sparks.

- Use a clean paintbrush and a 50/50 mild soap and water solution. Brush soapy solution onto areas indicated by arrows in figure below.

- Do not use household cleaning agents. Damage to gas train components can result.

Connecting Regulator to the LP Cylinder

- LP cylinder must be properly secured onto appliance. (Refer to assembly section.)

- Turn all control knobs to the OFF position.

- Turn LP cylinder OFF by turning hand-wheel clockwise to a full stop.

- Remove the protective cap from LP cylinder valve. Always use cap and strap supplied with valve.

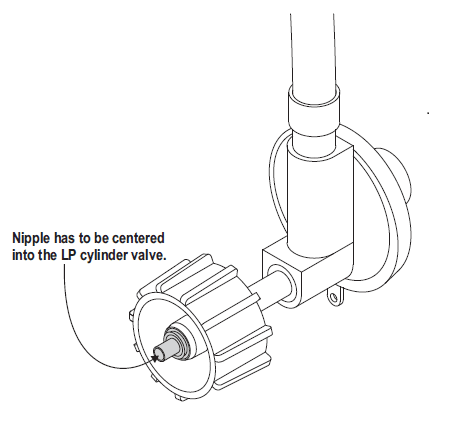

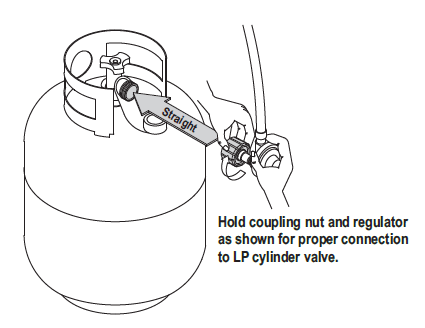

- Hold regulator and insert nipple into LP cylinder valve. Hand-tighten the coupling nut, holding regulator in a straight line with LP cylinder valve so as not to cross-thread the connection.

- Turn the coupling nut clockwise and tighten to a full stop. The regulator will seal on the back-check feature in the LP cylinder valve, resulting in some resistance. An additional one-half to three-quarters turn is required to complete the connection. Tighten by hand only – do not use tools.

Leak Testing Valves, Hose and Regulator

- Turn control knob to OFF.

- Be sure regulator is tightly connected to LP cylinder.

- Completely open LP cylinder valve by turning hand wheel counterclockwise. If you hear a rushing sound, turn gas off immediately. There is a major leak at the connection. Correct before proceeding.

- Brush soapy solution onto areas circled below.

- If “growing” bubbles appear, there is a leak. Close LP cylinder valve immediately and retighten connections. If leaks cannot be stopped do not try to repair. Call for replacement parts. Order new parts by giving the serial, model number and name and part number of items needed (see parts list) to the Grill Service Center at the number listed on front cover.

- Always close LP cylinder valve after performing leak test by turning hand wheel clockwise.

Ignitor Lighting

Do not lean over appliance while lighting.

- Turn ON LP gas cylinder.

- Press and turn the control knob to ON.

- Turn ROTARY IGNITOR knob rapidly.

- If ignition does not occur in 5 seconds, turn the burner control knob OFF, wait 5 minutes, and repeat lighting procedure.

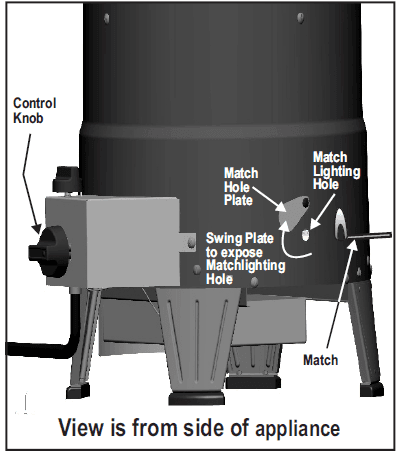

Match-Lighting

Do not lean over appliance while lighting.

- Turn ON LP cylinder.

- Swing match hole plate to expose match lighting hole. Place lit match into match lighting hole of appliance as pictured below. Make sure lit match is placed inside hole and near burner.

- Push in and turn control knob to ON. Be sure burner lights and stays lit.

- Once lit, swing match hole plate back to cover up match lighting hole. Caution: Plate maybe hot.

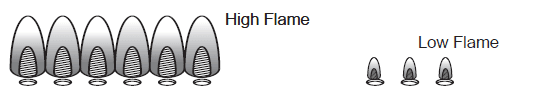

Burner Flame Check

- Light burner. Looking through viewing hole on top of appliance, you should see the flame height as shown below. Turn control knob from ON to OFF. The Flame height should decrease and then go out. Always check flame prior to each use. If only low flame is seen refer to “Sudden drop or low flame” in the Troubleshooting Section.

Turning Appliance Off

- Turn control knob to position. Turn LP cylinder off by turning hand-wheel clockwise to a full stop.

Ignitor Check

- Turn gas off at LP cylinder. Turn ignitor knob. “Click” should be heard each time at electrode. See “Troubleshooting” if no click or spark.

Valve Check

- Important: Make sure gas is off at LP cylinder before checking valve. Knob locks in position. To check valve, first push in knob and release, knob should spring back. If knob does not spring back, replace valve assembly before using this appliance. Turn knob to ON position then turn back to position. Valve should turn smoothly.

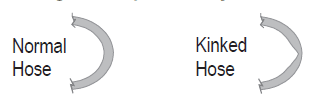

Hose Check

- Before each use, check to see if hose is cut, worn or kinked. Replace damaged hose before using appliance. Use only valve/hose/regulator specified by manufacturer.

General Appliance Cleaning

- Meat Thermometer: Do not immerse or soak in water. Wash with warm soapy water and wipe dry.

- Do not mistake brown or black accumulation of grease and smoke for paint. Interiors are not painted at the factory (and should never be painted).Apply a strong solution of detergent and water or use a grill cleaner with scrub brush on insides of appliance lid and bottom. Rinse and allow to completely air dry. Do not apply a caustic grill/oven cleaner to painted surfaces. A black surface improves the appliances performance.

- Plastic parts: Wash with warm soapy water and wipe dry. Do not use cortisol, abrasive cleaners, degreasers or a concentrated grill cleaner on plastic parts. Damage to and failure of parts can result.

- Painted surfaces: Wash with mild detergent or non-abrasive cleaner and warm soapy water. Wipe dry with a soft nonabrasive cloth.

- Stainless steel surfaces: To maintain the high quality appearance, wash with mild detergent and warm soapy water and wipe dry with a soft cloth after each use. Baked-on grease deposits may require the use of an abrasive plastic cleaning pad. Use only in direction of brushed finish to avoid damage. Do not use abrasive pad on areas with graphics.

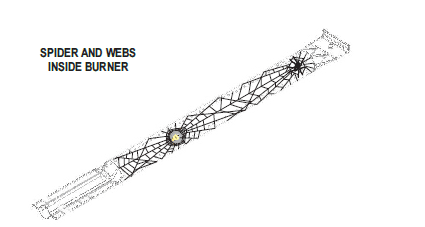

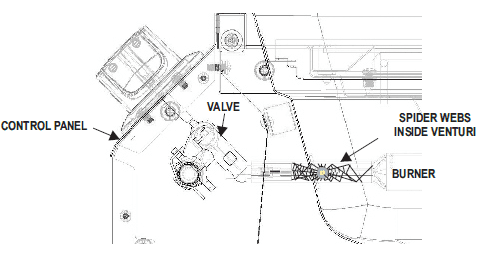

SPIDER ALERT!

If you notice that your the appliance is getting hard to light or that the flame isn’t as strong as it should be, take the time to check and clean the venture’s.

If you notice that your the appliance is getting hard to light or that the flame isn’t as strong as it should be, take the time to check and clean the venture’s.

In some areas of the country, spiders or small insects have been known to create “flashback” problems. The spiders spin webs, build nests and lay eggs in the the appliance’s venture tube(s) obstructing the flow of gas to the burner. The backed-up gas can ignite in the venture behind the control panel. This is known as a flashback and it can damage your the appliance and even cause injury.

In some areas of the country, spiders or small insects have been known to create “flashback” problems. The spiders spin webs, build nests and lay eggs in the the appliance’s venture tube(s) obstructing the flow of gas to the burner. The backed-up gas can ignite in the venture behind the control panel. This is known as a flashback and it can damage your the appliance and even cause injury.

To prevent flashbacks and ensure good performance the burner and venture assembly should be removed from the the appliance and cleaned before use whenever the the appliance has been idle for an extended period.

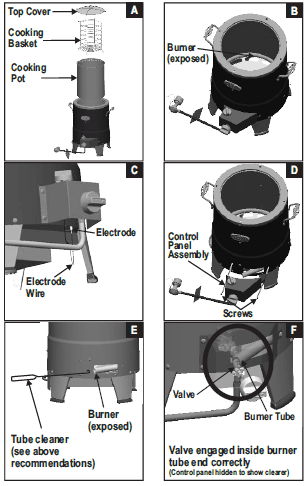

Cleaning the Burner Assembly

Follow these instructions to clean and/or replace parts of burner assembly or if you have trouble igniting appliance.

- Turn gas OFF at control knob and LP cylinder and disengage regulator from cylinder.

- Remove top cover, cooking basket and cooking pot, shown

- A. This will expose the burner from inside, shown B.

- Wire brush entire outer surface of burner to remove food residue and dirt.

- Clean any blocked ports with a stiff wire such as an open paper clip.

- Disconnect electrode wire underneath appliance, shown C.

- Remove screws and disengage control panel assembly from unit, shown D.

- Clean inner burner as recommended below, shown E. We suggest three ways to clean the burner tube. Use the one easiest for you.

- (A) Bend a stiff wire (a light weight coat hanger works well into a small hook. Run hook through burner tube several times.

- (B) Use a narrow bottle brush with a flexible handle (do not use a brass wire brush), run the brush through burner tube several times.

- (C) Wear eye protection: Use an air hose to force air into the burner tube and out the burner ports. Check each port to make sure air comes out each hole.

- (A) Bend a stiff wire (a light weight coat hanger works well into a small hook. Run hook through burner tube several times.

- Check burner for damage, due to normal wear and corrosion some holes may become enlarged. If any large cracks or holes are found replace burner.

- Attach electrode to burner.

- Carefully replace control panel assembly .

- Reposition inner liner, cooking basket and top cover.

For more manuals by Char-Broil visit, ManualsLibraryy

Char-Broil The Big Easy Oil-less Turkey Fryer-FAQs

How long does it take to cook in The Big Easy Oil-less Fryer?

Cooking time is approximately 10 minutes per pound, which is slightly longer than traditional oil fryers (about 4 minutes per pound).

How do I light the Char-Broil Big Easy?

Press and turn the burner control knob to the flame icon, then turn the rotary ignitor knob rapidly. If it doesn’t light within 5 seconds, turn it off, wait 5 minutes, and try again.

What size turkey can the Big Easy cook?

The Big Easy can accommodate turkeys up to 16 pounds. For best results, avoid exceeding 18 pounds.

How does the Char-Broil oil-less fryer work?

It uses a propane burner to heat air between a double-wall cooking chamber, radiating TRU-Infrared™ heat to cook meat evenly, resulting in juicy and flavorful dishes.

Can I cook a frozen turkey in The Big Easy?

No, turkeys must be completely thawed before cooking. Remove giblets, the neck, and anything inside the cavity beforehand.

How do I air fry a turkey?

Coat the turkey with olive oil, salt, and pepper. Place it on the stand legs down, optionally adding apple wood chips. Air fry for 10 minutes per pound or until the internal temperature reaches 165°F.

How long should I brine a turkey?

Brine for about 12 hours, though 24 hours is preferred for better flavor. After brining, let the turkey air dry for at least 12–24 hours to achieve crispy skin.

Can I leave deep fryer oil to cool down on its own?

Yes, let the oil cool to 250°F (121°C) before draining, which typically takes 1½ to 2 hours, to avoid damage to the fryer.

How do I control the heat on the Char-Broil Big Easy?

Adjust the dampers to regulate temperature. Ensure the damper creates a proper seal; replace it if it’s bent or warped.

What does “charbroil” mean in cooking?

Charbroiling involves cooking food over direct heat, such as charcoal or gas grills, to achieve a smoky, grilled flavor.

Does The Big Easy reduce oil use compared to traditional fryers?

Yes, it eliminates the need for oil, making it a healthier alternative to traditional deep frying.