Expert Grill BG2824BP Outdoor 4 Burner Gas Grill

SAFETY INFORMATION

- This grill is intended for use outdoors and should not be used in a building, garage or any other enclosed or covered area.

- This outdoor grill is not intended for installation in or on recreation vehicles and/or boats.

- A minimum clearance of 36 inches from combustible constructions to the sides of the grill and 36 inches from the back of the grill to combustible constructions must be maintained. This outdoor cooking gas appliance must not be placed under overhead combustible construction.

- Inspect the hoses before each use for excessive abrasion or wear, or cuts that may affect safe operation of the grill. If there is evidence of excessive abrasion or wear, or the hose is cut, it must be replaced prior to the grill being put into operation. The replacement hose assembly must be those specified by the manufacturer.

- Keep your grill in an area clear and free from combustible materials, gasoline and other flammable vapors and liquids.

- Do not touch metal parts of grill until it has completely cooled (about 45 minutes) to avoid burns, unless you are wearing protective gear (pot holders, gloves, BBQ mittens, etc…).

- DO NOT obstruct the flow of combustion and ventilation air to this appliance.

- Keep the ventilation openings of the tank enclosure free and clear from debris.

- Check all gas connections for leaks with a soapy water solution and brush. Never use an open flame to check for leaks.

- Never use charcoal in the grill

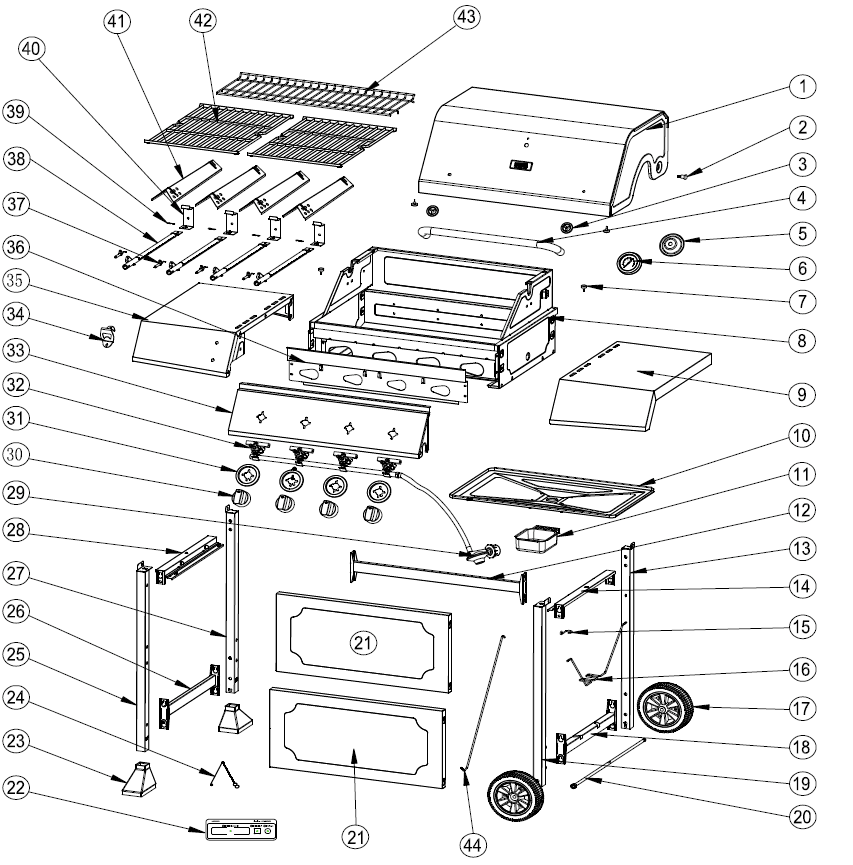

EXPLODED VIEW

PARTS LIST

| PART | DESCRIPTION | PART NO | QTY |

| 1 | ※Lid Assembly | 2824BP01 | 1 |

| 2 | ※Lid Axis | 2411017 | 2 |

| 3 | Lid Handle Bezel | 5201176 | 2 |

| 4 | Lid Handle | 5210044 | 1 |

| 5 | Temperature Gauge Bezel | 5208127 | 1 |

| 6 | Temperature Gauge | 2411016 | 1 |

| 7 | ※Lid Spacer | 2100158 | 4 |

| 8 | ※Firebox Assembly | 5210047 | 1 |

| 9 | Right Side Shelf | 5210046 | 1 |

| 10 | Drip Tray | 5210054 | 1 |

| 11 | Grease Cup | 5210023 | 1 |

| 12 | Rear Beam | 5210058 | 1 |

| 13 | Right Back Leg | 5206531 | 1 |

| 14 | Right Drip Tray Support | 5210056 | 1 |

| 15 | Hose Clip Hook | 2300961 | 1 |

| 16 | Gas Cylinder Hook | 2409212 | 1 |

| 17 | Wheel | 2100530 | 2 |

| 18 | Right Side Beam | 5206532 | 1 |

| 19 | Right Front Leg | 5206530 | 1 |

| 20 | Axle | 2409211 | 1 |

| 21 | Front Panel | 5210057 | 2 |

| 22 | Hardware Pack | 5210059 | 1 |

| 23 | Leg End Cap | 2411024 | 2 |

| 24 | ※Match Holder | 2411023 | 1 |

| 25 | Left Front Leg | 5210052 | 1 |

| 26 | Left Side Beam | 5206939 | 1 |

| 27 | Left Back Leg | 5210052 | 1 |

| 28 | Left Drip Tray Support | 5210055 | 1 |

| 29 | ※Regulator & Hose assembly | 5210038 | 1 |

| 30 | Control Knob | 2410625 | 4 |

| 31 | ※Knob Bezel | 5210049 | 4 |

| 32 | ※Manifold & Gas Valve Assembly | 5210027 | 1 |

| 33 | ※Control Panel | 5210051 | 1 |

| 34 | ※Bottle Opener | 5014838 | 1 |

| 35 | Left Side Shelf | 5210045 | 1 |

| 36 | ※Thermal Baffle | 5210048 | 1 |

| 37 | ※Tube Burner Ignition Pin | 2411019 | 4 |

| 38 | ※Tube Burner | 2411018 | 4 |

| 39 | ※R Pin | 2307001 | 4 |

| 40 | ※Tube Burner Support | 5204373 | 4 |

| 41 | Heat Tent | 5210050 | 4 |

| 42 | Cooking Grate | 2411021 | 2 |

| 43 | Warming Rack | 2411020 | 1 |

| 44 | Tank Blocking Wire | 2411662 | 1 |

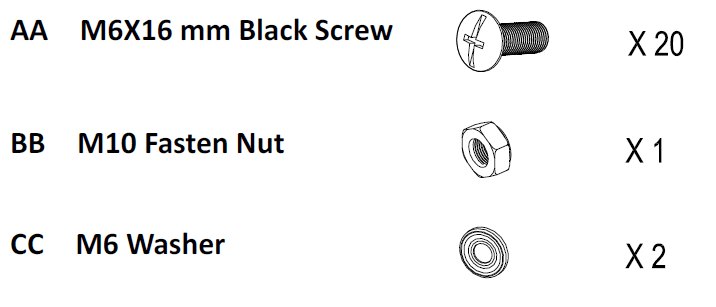

HARDWARE CONTENTS

ASSEMBLY INSTRUCTIONS

IMPORTANT: ASSEMBLE ON FLAT AND SOFT SURFACE TO AVOID SCRATCHING. 6 X16mm Black Screw X 2

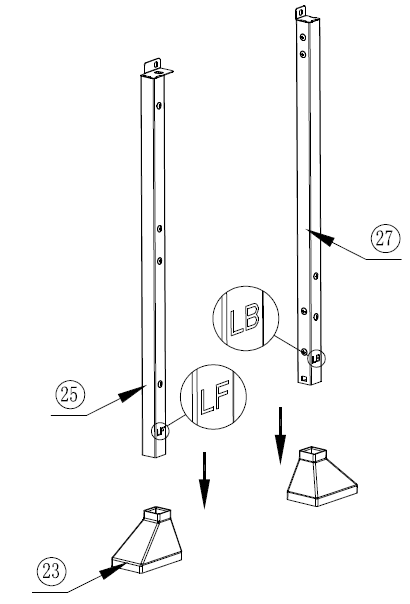

- Put the Left Back Leg (27) and Left Front Leg (25) into Leg End Caps (23) as shown

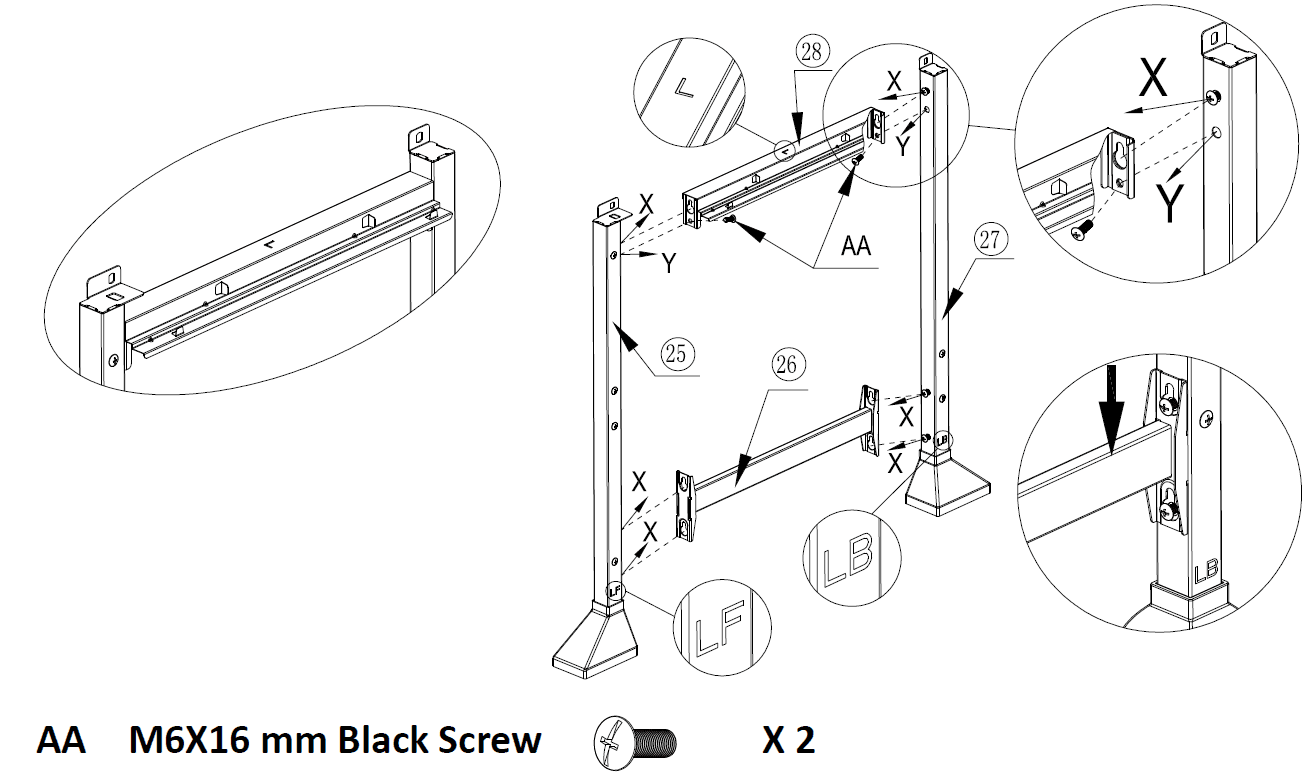

- Assemble the Left Side Cart Frame.

- 2.1. Loosen 6pcs pre‐assembled M6X16mm Screws from “X” position and leave the screw heads protruding approximately 5mm.

- 2.2. Hang Left Side Beam (26) and Left Drip Tray Support (28) with “L” marking to Left Front Leg (25) and Left Back Leg (27), then fasten the screws on the “X” position.

- 2.3. Take 2pcs AA Screws from the hardware pack, and fasten the screws on “Y” position.

- Note: Be sure part 28 and 26 are installed correctly as per the image shown.

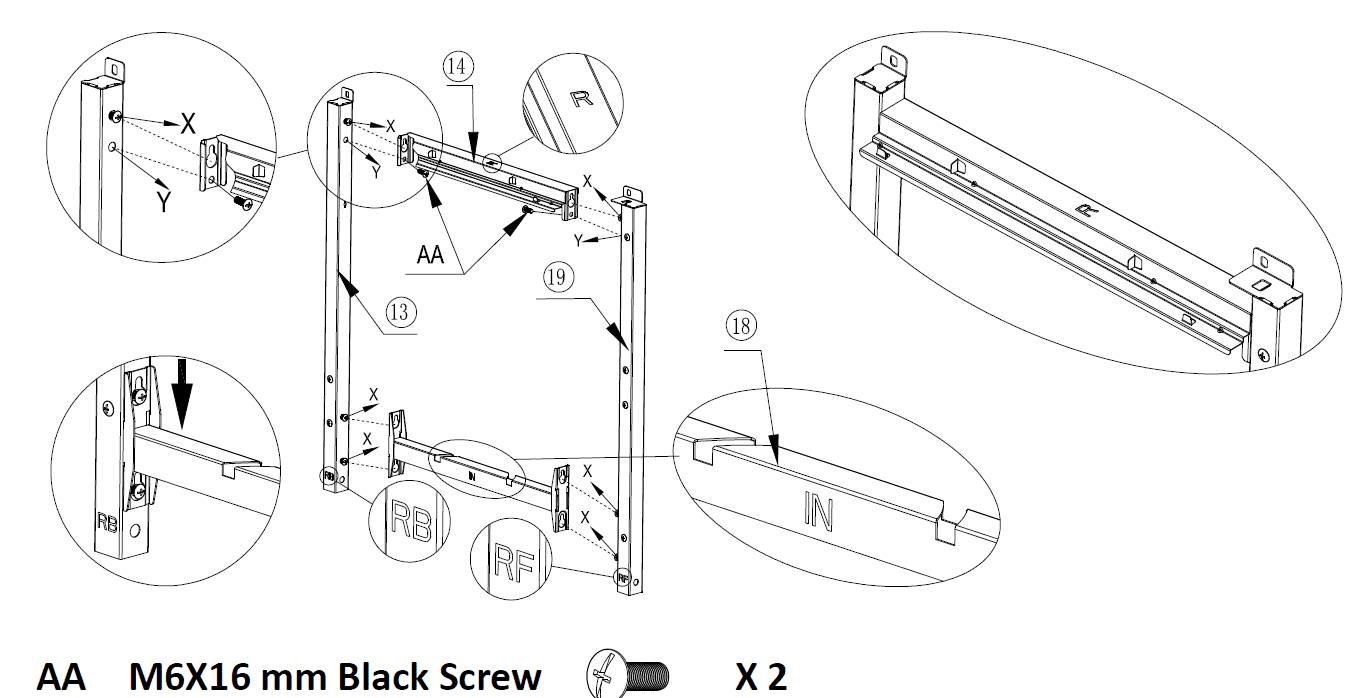

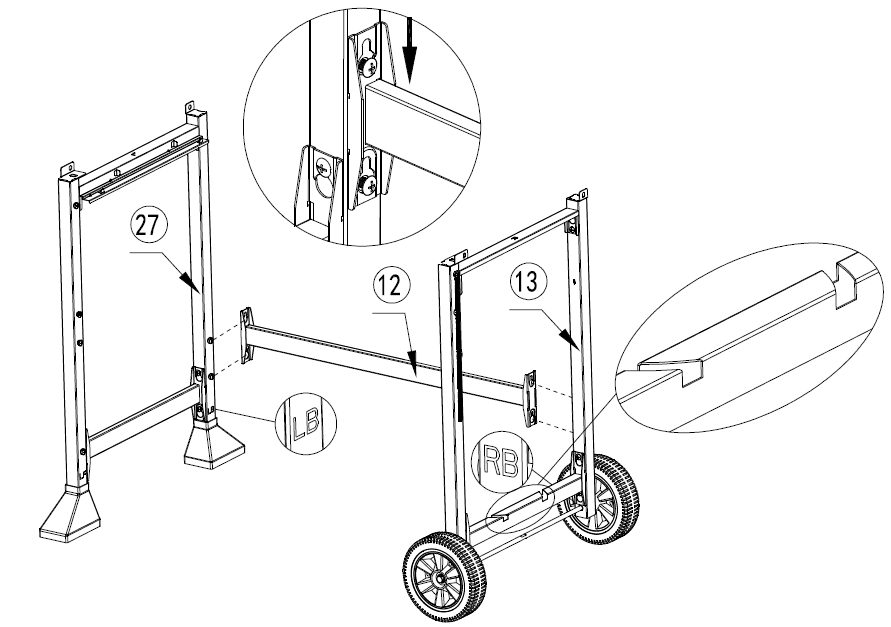

- Assemble Right Side Cart Frame.

- 3.1. Loosen 6pcs pre‐assembled M6X16mm Screws from “X” position, and leave the screw heads protruding approximately 5mm.

- 3.2. Hang Right Side Beam (18) and Right Drip Tray Support (14) with “R” marking to Right Front Leg (19) and Right Back Leg (13) ,then fasten the screws on “X” position

- 3.3. Take 2pcs AA Screws from hardware pack, and fasten the screws on “Y” position.

- Note: Be sure part 14 and 18 are installed correctly as per the image shown

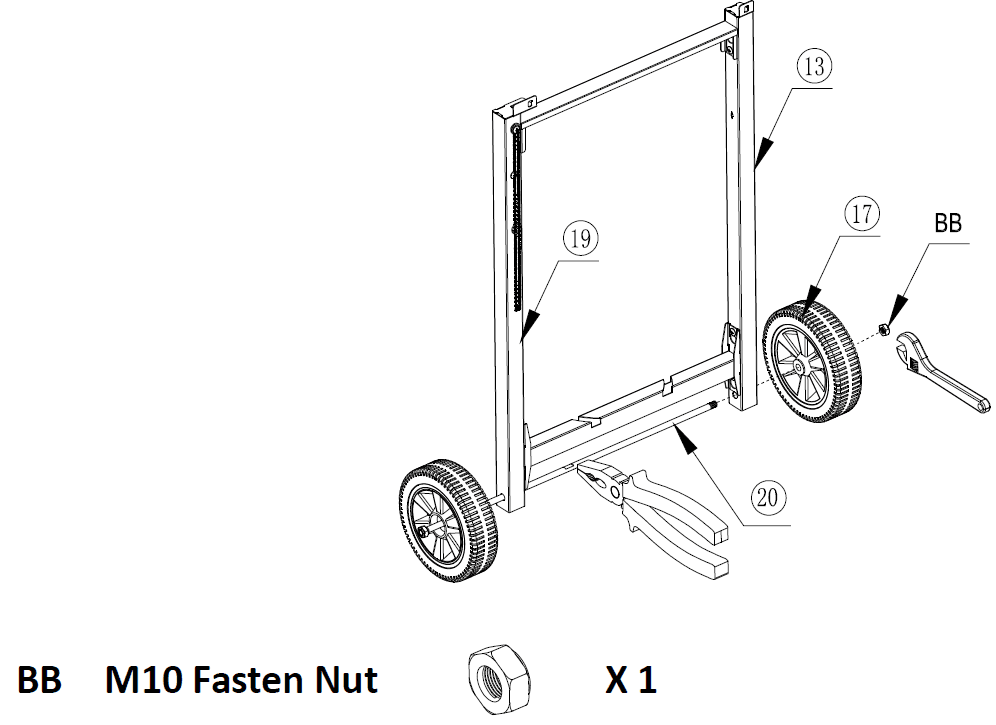

- Thread Axle (20) through the Wheel (17), Right Front Leg (19), Right Back Leg (13), then fasten BB nut as shown

- Attach Rear Beam

- 5.1. Loosen 4pcs pre‐assembled M6X16mm Screws from Left Back Leg (27) and Right Back Leg (13), leave the screw heads protruding approximately 5mm

- 5.2. Hang Rear Beam (12) onto Left & Right Back Leg on the screws and hand tighten only the screws on this point

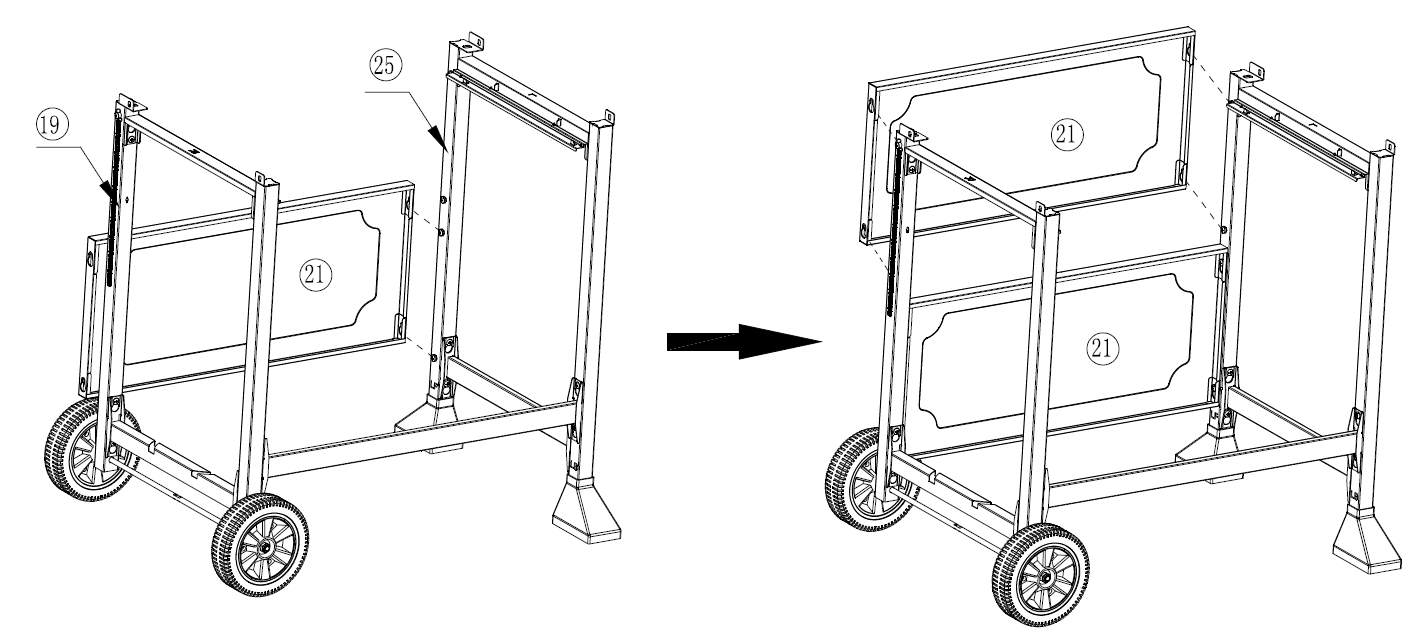

- Assemble the front panel

- 6.1. Loosen 8pcs pre‐assembled M6X16mm Screws from Left Front Leg (25) and Right Front Leg (19), leave the screw heads protruding approximately 5mm.

- 6.2. Attach Front Panels (21) to the cart and fasten the screws as shown. Then fully tighten all the screws of rear beam this time

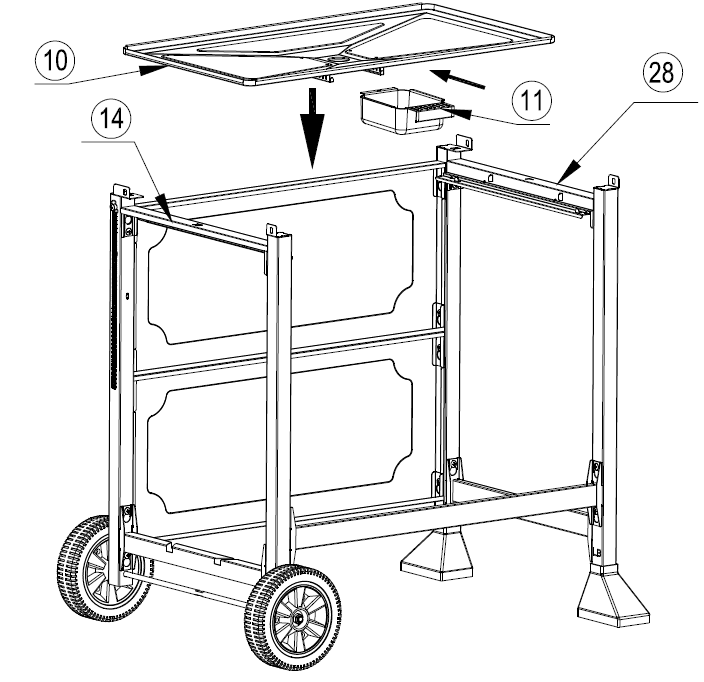

- Attach Drip Tray (10) and Grease Cup (11) onto the cart as shown.

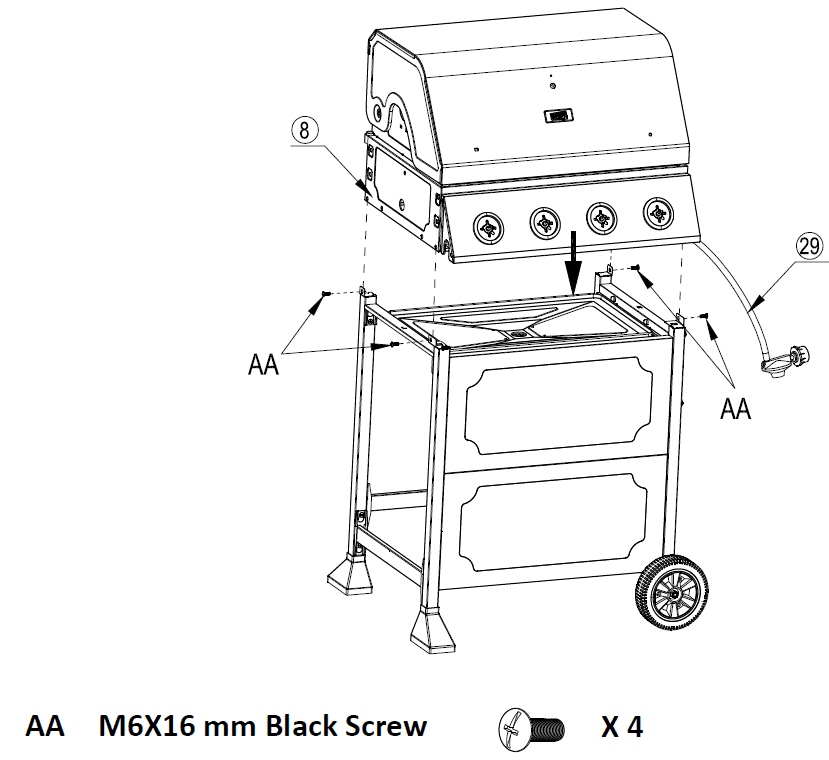

- Use two people to lift and place the Firebox Assembly onto the cart and fasten 4pcs AA Screws as shown.

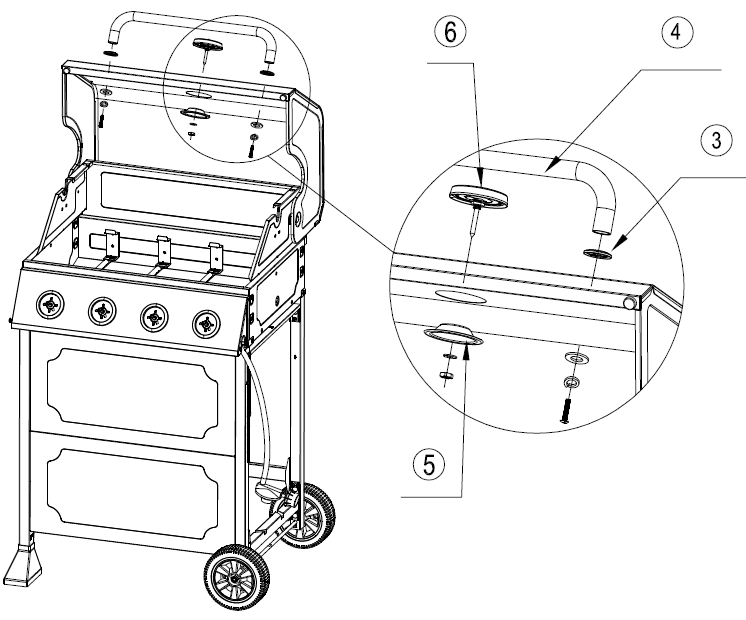

- Assemble Lid Handle and Temperature Gauge

- 9.1. Attach Lid Handle (4) together with Lid Handle Bezels (3) onto Lid Assembly and fasten the screws.

- 9.2. Attach Temperature Gauge (6) together with Temperature Gauge Bezel (5) onto Lid Assembly and fasten the screws

OPERATING INSTRUCTIONS

LIQUID PROPANE GAS TANK INSTALLATION

- Gas grills that are set to operate with Liquid Propane Gas come with a high capacity hose and regulator assembly. (Note: Only use the pressure regulator and hose assembly supplied with the grill or a replacement pressure regulator and hose assembly specified by the manufacturer). This assembly is designed to connect directly to a standard 20 lb. L.P. Tank. L.P. tanks are not included with the grill. L.P. tanks can be purchased separately at an independent dealer.

Connecting a Liquid Propane Gas Tank to the Grill

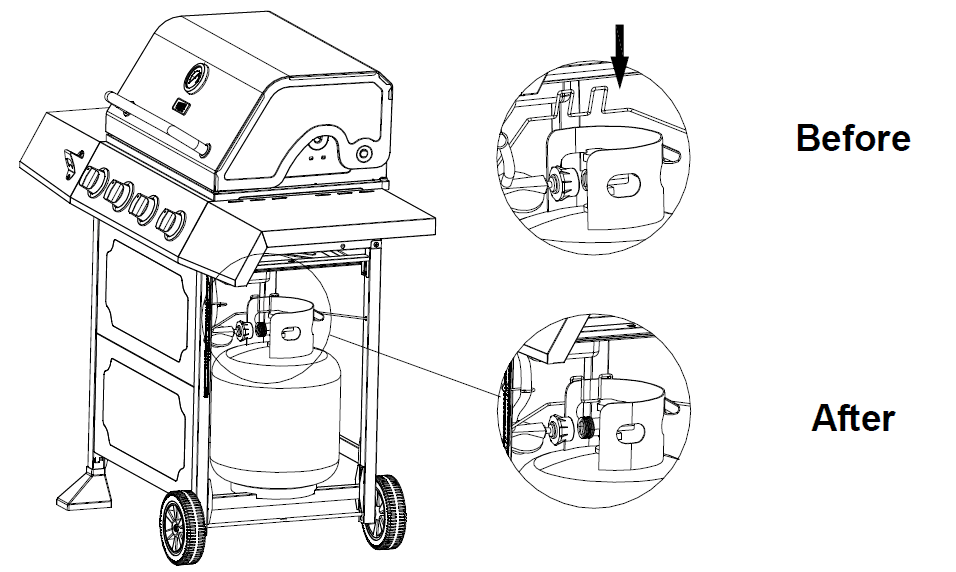

- Place a 20 Ib. tank into the slot on right side beam, then put down gas cylinder hook onto the tank. See Fig. 1. Make sure the tank valve is in the OFF position.

- Check the tank valve to ensure it has proper external mating threads to fit the hose and regulator assembly provided (Type 1 connection per ANSI Z21.58b‐2002).

- Inspect the valve connection port of the regulator assembly. Look for damage or debris. Remove any debris. Inspect hose for damage. Never use damaged or plugged equipment.

- Make sure all burner knobs are in the OFF position.

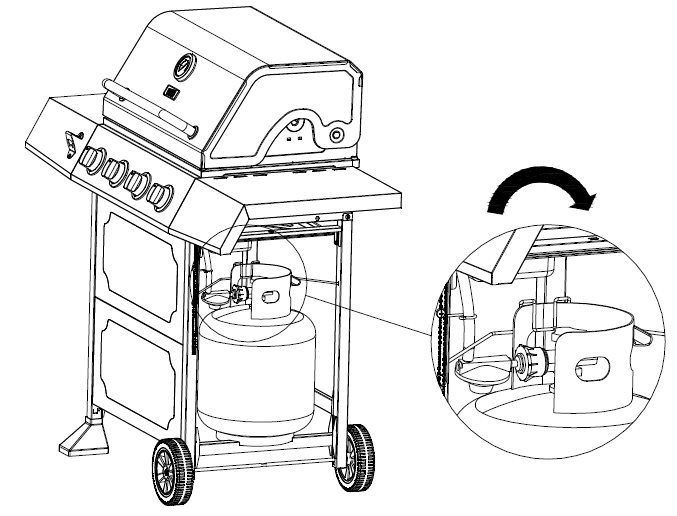

- Connect the hose and regulator assembly to the tank valve(See Fig. 2)Hand tighten the quick coupling nut clockwise to a full stop. DO NOT use a wrench to tighten because it could damage the quick coupling nut and result in a hazardous condition.

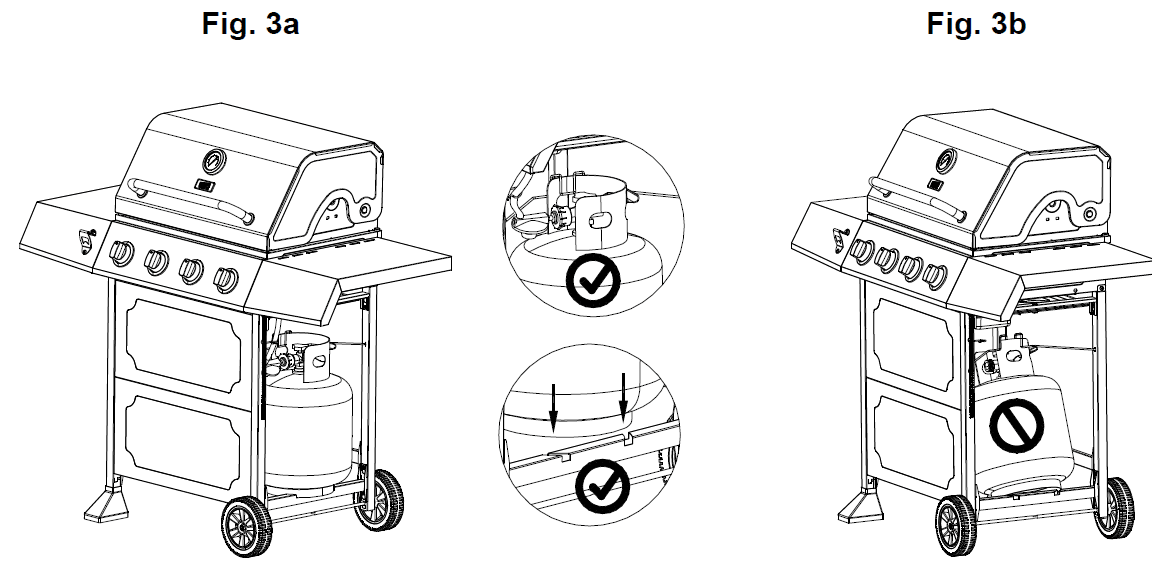

- Open the tank valve fully (counterclockwise). Use a soapy water solution to check all connections for leaks before attempting to light your grill. See “Leakage Testing” on page 18. If a leak is found, turn the Tank Valve off and do not use your grill until the leak is repaired. Gas tank must be placed onto the slot on right side beam vertically and be sure the cylinder hook is placed correctly on the left side collar of the tank (see Fig.3a). Do not operate the grill if the gas tank is tilted or the hook is placed incorrectly (see Fig. 3b)

L.P. TANK INFORMATION

- Never use a dented or rusted L.P. tank or cylinder with a damaged valve. L.P. cylinders are equipped with an O.P.D. (Overfilling Prevention Device). The device shuts off the flow of gas to a cylinder after 80% capacity is reached. This limits the potential for release of gas when the cylinder is heated, averting a fire or possible injury.

- The L.P. cylinder must have a shut‐off valve terminating in an L.P. gas supply cylinder outlet specified, as applicable, for connection No. 510 in the standard for compressed gas cylinder valve outlet and inlet connection ANSI/CGA‐V‐1. Cylinders must not be stored in a building, garage, or any other enclosed area. (The L.P. cylinder must have an overfill protection device and a collar to protect the cylinder valve.)

- The L.P. gas supply cylinder must be constructed and marked in accordance with the specifications for L.P. gas cylinders of the U.S. Department of Transportation (DOT) or the National Standard of Canada, CAN/CAS‐B339, “Cylinders, Spheres and Tubes for the Transportation of Dangerous Goods and

Commission.”

L.P. TANK USE

- When turning the L.P. tank on, make sure to open the valve SLOWLY two (2) complete turns to ensure proper gas flow. Most gas tanks now come equipped with a leak detector mechanism internal to the tank. When gas is allowed to escape rapidly it shuts off the gas supply. Opening the valve rapidly may simulate a gas leak, causing the safety device to activate, and restricting gas flow causing low flames. Opening the valve slowly will ensure this safety feature is not falsely triggered.

- When not in use, gas supply cylinder valve is to be in the OFF position.

- The tank supply system must be stored upright to allow for vapor withdrawal.

- The regulator and hose assembly must be inspected before each use of the grill. If there is excessive abrasion or wear or if the hose is cut, it must be replaced prior to the grill being used again

LEAKAGE CHECK

Although all gas connections on the grill are leak tested prior to shipment, a complete gas tightness check must be performed at the installation site due to possible shifting during shipment, installation or excessive pressure unknowingly being applied to the unit. Periodically check the whole system for leaks and immediately check the system if the smell of gas is detected.

- Do not smoke while leak testing.

- Extinguish all open flames.

- Never leak test with an open flame.

- Mix a solution of equal parts mild detergent or liquid soap and water.

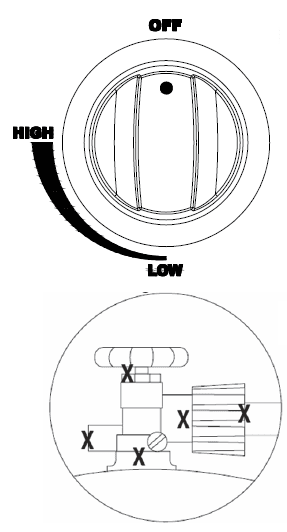

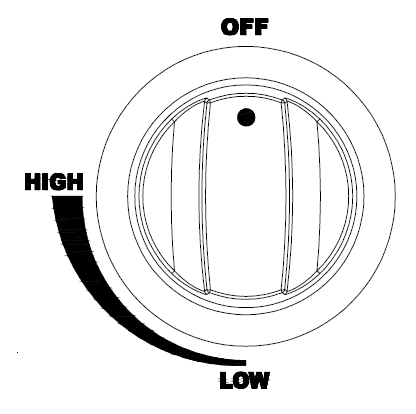

- Turn off the burner control knobs. (see Fig. 6)

- Turn the top knob of the fuel supply cylinder counterclockwise two (2) rotations to open.

- Apply the soap solution to the connections of the fuel supply assembly. Spoon leak check solution at all: ”X” locations (see Fig. 7). If no soap bubbles appear, there is no gas leak. If bubbles form at the connections, a leak is detected. If a leak is detected, immediately turn off the gas supply, tighten any leaking fittings, turn gas on, and repeat steps 5‐6.

- Turn off the knob on the fuel supply cylinder.

- Turn on the burner control knobs for a moment to release the pressure in the hose, then turn the control knobs back off.

- Wash off soapy solution with cold water and towel dry. Check all gas supply fittings before each use and each time, make sure the gas supply cylinder is connected to the regulator. Have a qualified service technician to replace the grill leak parts if any time need. Also it is recommended to perform a leak test at least once a year whether or not the L.P. gas supply cylinder has been disconnected.

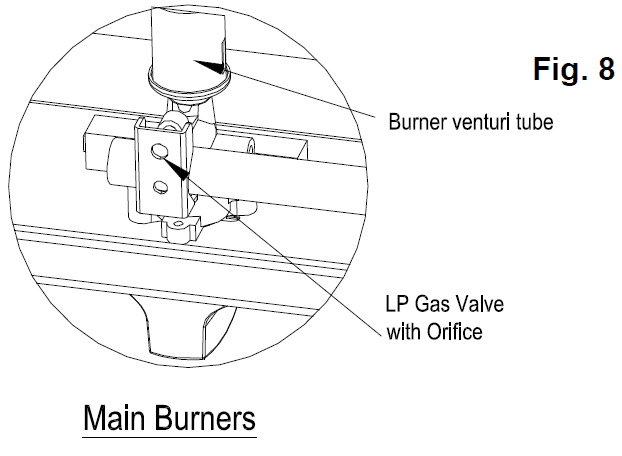

- Please refer to diagram for proper installation (see Fig. 8). Visually check the connection between the burner venturi tube and gas valve orifice. Make sure the burner venturi tube fits over the gas valve orifice.

- Storage of an outdoor gas cooking appliance indoor is permissible only if the cylinder is disconnected and removed from the appliance

- Please refer to diagram for proper installation (see Fig. 8). Visually check the connection between the burner venturi tube and gas valve orifice. Make sure the burner venturi tube fits over the gas valve orifice.

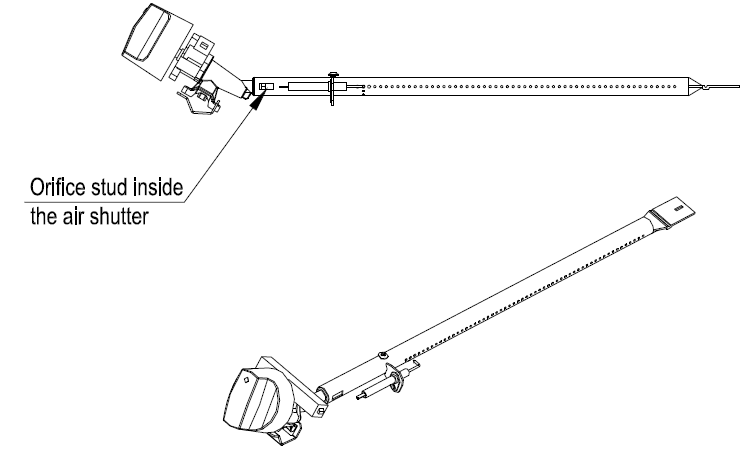

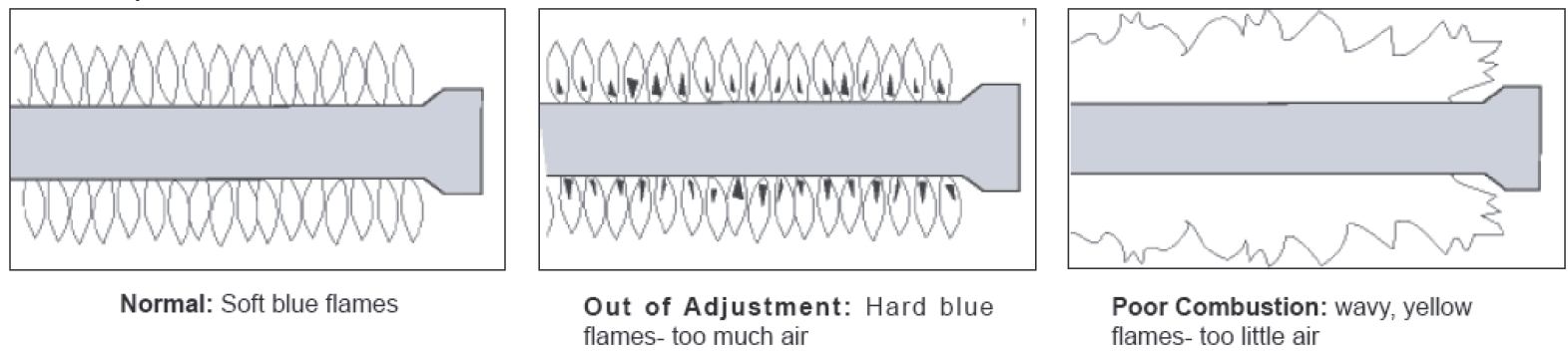

CHECKING ORIFICES ALIGNMENT WITH BURNERS

- Orifices may shift during assembly and movement. Check the orifices alignment with the burners according to the following illustrations before lighting.

- Main Burner and Orifice Relationship

LIGHTING INSTRUCTIONS

WARNING: DO NOT lean over grill when lighting. Turn off Gas supply when appliance is not in use. DO NOT stand with head, body, or arms over the grill when lighting

- Check the control knobs are all in the OFF position.

- Open LP cylinder valve.

- Open lid before lighting.

- Push and turn the knob slowly to HIGH. The burner should ignite within three attempts.

- If burner does not ignite, turn the knob to OFF, wait 5 minutes and then repeat step 4.

- Once burner is lit, rotate knob to desired heating level from High to Low

- If the ignitor does not work, follow Match Lighting instructions.

- To turn off, turn the knob to HIGH first, then push in and turn to OFF position. Turn off the gas tank valve before disconnecting the LP gas tank.

MATCH LIGHTING

- Open lid before lighting

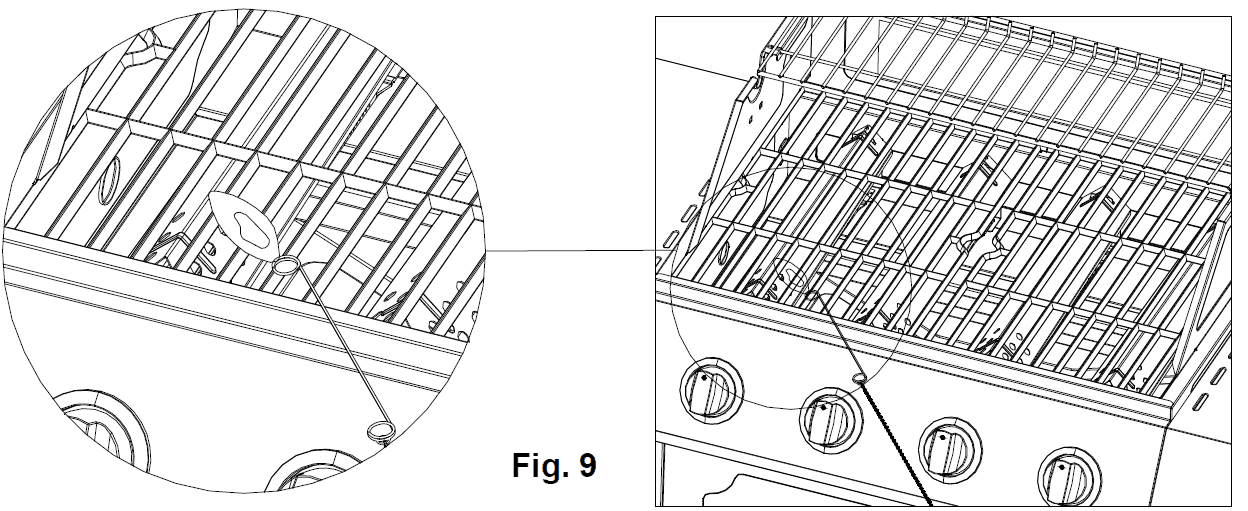

- Place a match in the end of Match Holder (hanging on the Right Front Leg). Strike the match and place it near side of the burner (see Fig.9)

- Push and turn the control knob to HIGH. The burner should ignite.

- NOTE: If the burner does not ignite within the first few attempts of match lighting, there is a problem with the gas supply. Turn off the gas at the burner and tank. DO NOT attempt to operate the grill until the problem is found and corrected

- NOTE: If the burner does not ignite within the first few attempts of match lighting, there is a problem with the gas supply. Turn off the gas at the burner and tank. DO NOT attempt to operate the grill until the problem is found and corrected

CARE AND MAINTENANCE

- IMPACT WITH HARD OBJECTS ‐ Never allow hard objects to strike the ceramic ignitor. You should take particular care when inserting or removing cooking grids and accessories into or from the grill. If objects such as these fall onto ceramic ignitor, it is likely to crack the ceramic.

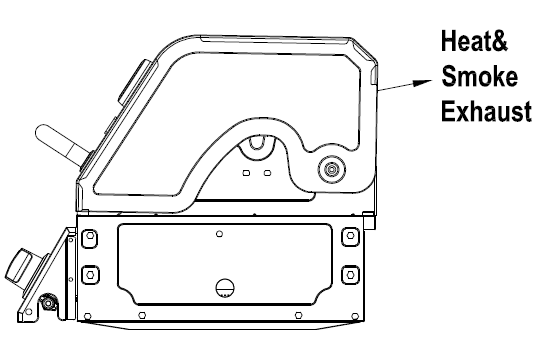

- IMPAIRED VENTILATION OF HOT AIR FROM GRILL ‐ In order for the burners to function properly, hot air created by the burners must have a way to escape. The burners may become deprived of oxygen causing them to backfire, especially if the burner output is set at HIGH. If this occurs repeatedly, the

burners may crack. This is the reason your grill was designed with ventilation louvers. These design features give the hot air an escape route. Accordingly, never operate your grill with very little or no open space at the cooking surface (the cooking grids provide sufficient space). Also, never cover the ventilation louvers with foil or other materials that prevent air flow. Specifically, do not cover the entire surface with foil, a large pan, etc.

GENERAL MAINTENANCE

- Keep outdoor cooking gas appliance area clear and free from combustible materials, gasoline and other flammable vapors and liquids.

- Do not obstruct the flow of combustion and ventilation air.

- Keep the ventilation openings of the cylinder enclosure free and clear from debris.

- Visually check the burners.

GENERAL CLEANING

IMPORTANT: Before cleaning, make sure all controls are off and the grill is cool. Always follow label instructions on cleaning products.

- For routine cleaning, wash with soap and water using a soft cloth or sponge. Rinse with clean water and dry at once with a soft, lint‐free cloth to avoid spots and streaks.

- To avoid scratching the surface, do not use steel wool to clean the grill. Use a vinyl grill cover to protect finish from weather.

- DRIP TRAY

- The drip tray should be cleaned periodically to prevent heavy buildup of debris.

- NOTE: Allow the drip tray to cool before attempting to clean.

- Important: Do not leave the grill outside during inclement weather unless it is covered. Rain water can collect inside of the grill, the grill cart or the drip tray if left uncovered. If the drip tray is not cleaned after use and the grill is left uncovered, the drip tray will fill with water causing grease and water to spill into the grill cart. We recommend cleaning and storing the drip tray after every use.

- COOKING GRATES

- The cooking grates can be cleaned immediately after cooking is completed and after turning off the grill. Wear a barbecue mitt and scrub the cooking grates with a damp cloth. If the grill is allowed to cool down, cleaning the grates will be easier if removed from the grill and cleaned with a mild detergent.

- STAINLESS STEEL

- After initial usage, areas of the grill may discolor from the intense heat given off by the burners. This is normal. Purchase a mild stainless steel cleaner and rub in the direction of the grain of the metal. Specks of grease can gather on the surface of the stainless steel and bake on to the surface and give a worn appearance. For removal, use a non‐abrasive oven cleaner in conjunction with a stainless cleaner.

- NOTE: Always scrub in the direction of the grain.

- PORCELAIN PARTS

- Certain parts of your grill have a porcelain coating. Porcelain is a glass‐based product and is highly durable to standard wear and tear. However, porcelain is sensitive to concussive blows, which can create interlaced micro‐fractures or “spider webs.” Please take care not to strike any porcelain-covered parts with solid objects, drop them, or create any other concussive blows. These interlaced micro‐fractures are common and may lead to minor chipping. Neither the chipping nor the interlaced micro‐fractures will adversely affect the performance of your grill and are not covered under the warranty for porcelain parts.

TROUBLE SHOOTING

- Many solutions given here can make your grilling experience safer and more enjoyable. You can also call customer service department at 1‐855‐CHANT‐US (1‐855‐242‐6887) from 8:00am to 5:00pm Eastern time, Monday through Friday for assistance

| PROBLEM | POSSIBLE CAUSE | CORRECTIVE ACTION |

|

Grill will not light. | 1. The ignition wire came off the igniter/valve. 2. The distance between the ignition pin and the burner is greater than 5/32 in. ‐ 3/16 in. 3. The ignition wire is broken. 4. No gas supplied. | 1. Reconnect the ignition wire to the electrical igniter/valve. 2. Loosen the ignition pin and adjust the distance, then fasten it again. 3. Call customer service for a replacement ignition wire. 4. Turn on the regulator valve. |

| Burner flame is yellow and gas odor can be smelled. | 1. The air shutter opening is not properly set. 2. Spiders or insects block the air shutter. 3. Possible gas leaks. | 1. Loosen the air shutter and adjust the opening to have blue flames. 1/4 in. opening for LPG. 2. Clean blockages. 3. Check for the source of gas leaks. |

|

Excessive flare‐up. | 1. Grilling fatty meats.

2. Knobs on “HIGH”.

3. Spray water on gas flames.

4. Hood closed when grilling. | 1. Move the meats to the warming rack if flare up continues until flame settles down. 2. Grill fatty meats when the grids are cold while the knobs are on the “LP LOW” (when using LP Gas) 3. Never spray water on gas flames. 4. Hood up when grilling. |

|

Burner blows out. | 1. LP tank is empty. 2. Burner is not aligned with the control valve. 3. Gas supply is not sufficient. | 1. Refill the LP Tank. 2. Install the burner correctly. 3. Check the gas supply hose and make sure there are no leaks and no knots. |

| PROBLEM | POSSIBLE CAUSE | CORRECTIVE ACTION |

|

Low heat with the knob in “HIGH” position. |

1. Ports are blocked. 2. LP tank has run out. |

1. Clear ports of any obstructions. 2. Refill the LP tank. |

|

Low heat, LP gas. |

The propane regulator assembly incorporates an excess flow device designed to supply the grill with sufficient gas flow. Rapid changes in pressure can trigger the excess flow device, providing a low flame and low temperature. |

Please follow these instructions: 1. Make sure all burners are “OFF”. 2. Open the tank valve and wait 5 minutes. 3. Light the burner one at a time following the lighting instructions listed on the door liner |

For more manuals by Expert Grill, visit ManualsLibraryy

Expert Grill BG2824BP Outdoor 4 Burner Gas Grill-FAQs

How does a grill burner work?

A grill burner uses the venturi effect. Gas flows through a small orifice at the end of the burner, pulling in air and mixing it inside the burner tube. The propane-air mix exits through holes or slots and ignites to produce a flame.

How does a flame grill work?

Venturi tubes mix gas and air, delivering the mixture to the burners. The system regulates fuel flow, controlling the flame and heat during grilling.

How long should I preheat the Expert Grill?

Preheat your grill for 10–15 minutes before cooking. This prevents food from sticking to the grate and ensures proper searing and caramelization.

Are gas grills easy to use?

Yes, gas grills are very easy to use. Simply turn the knob, ignite the flame, and preheat. You’re ready to cook in under 10 minutes.

What are the two main types of gas grills?

The main types are propane and natural gas grills. Additional types include charcoal-gas hybrids and infrared grills, each offering different features.

How do I reduce the heat on my grill?

Adjust the air dampers. More airflow increases heat, while less airflow reduces it. Most grills have a top lid damper and bottom bowl dampers for control.

What is the temperature of a gas grill?

Temperatures vary, but typical settings are:

1. Low: 250°F

2. Medium: 350°F

3. High: 450°F

What are the heat zones on a gas grill?

Heat zones include:

1. Direct heat: Food is placed over lit burners for searing or crisping.

2. Indirect heat: Food is cooked on the unlit side at lower temperatures.

How do I season a grill?

Coat the grates with a thin layer of high-temperature oil (like canola or flaxseed oil). Heat the grill to 350–400°F and let it run for 30–60 minutes to season properly.