Craftsman 1395399 Garage Door Opener

INTRODUCTION

This garage door opener has been designed and tested to offer safe service provided it is installed, operated, maintained and tested in strict accordance with the instructions and warnings contained in this manual.

CAUTION

- When you see these Safety Symbols and Signal Words on the following pages, they will alert you to the possibility of serious injury or death if you do

not comply with the warnings that accompany them. The hazard may come from something “cratca or from electric shock. Read the warnings carefully.

Preparing your Garage Door

Before you begin:

- Disable locks.

- Remove any ropes connected to garage door.

- Complete the following test to make sure your garage door is balanced and is not sticking or binding:

- Lift the door about halfway as shown. Release the door. If balanced, it should stay in place supported entirely by its springs

- Raise and lower the door to see if there is any binding or sticking If your door binds, sticks, or is out of balance, call a trained door systems technician.

WARNING

To prevent possible SERIOUS INJURY OR DEATH:

- ALWAYS call a trained door systems technician if garage door binds, ctute, o. is cut of balance. An unbalanced garage door may not reverse when required.

- NEVER try to loosen, move or adjust garage door, door springs, cables, pulleys, brackets or their hardware, all of which are under EXTREME tension.

- Disable ALL locks and remove ALL ropes connected to garage door BEFORE installing and operating garage door opener to crit emangeror.

- CAUTION

- To prevent damage to garage door and opener:

- ALWAYS disable locks BEFORE installing and operating the opener.

- ONLY operate garage door opener at 120V, 60 Hz to avoid malfunction and damage.

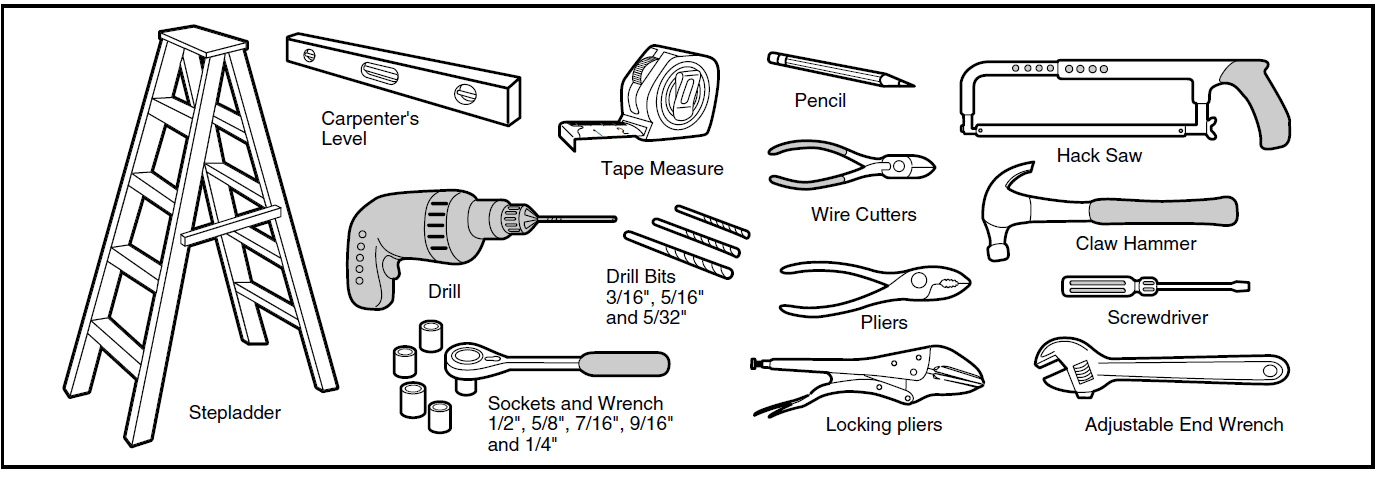

Tools Needed

- During assembly, installation and adjustment of the opener, instructions will call for hand tools as illustrated below

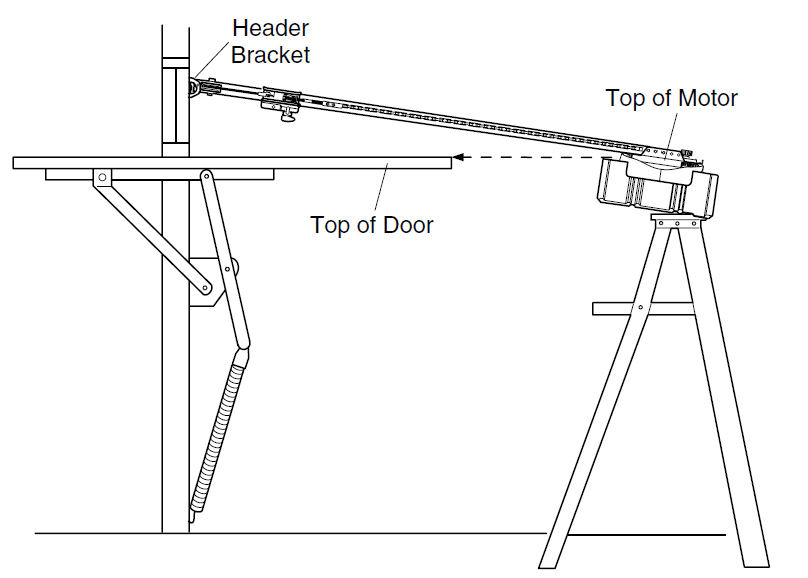

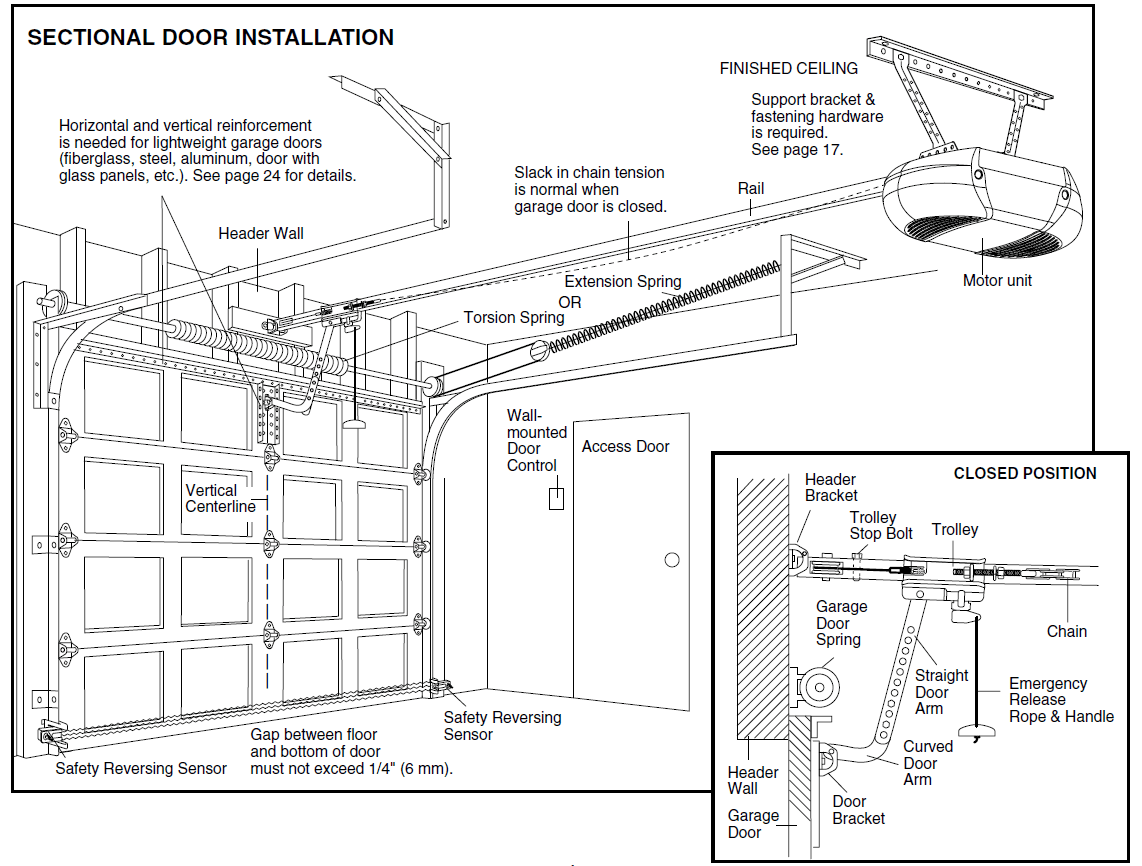

Planning

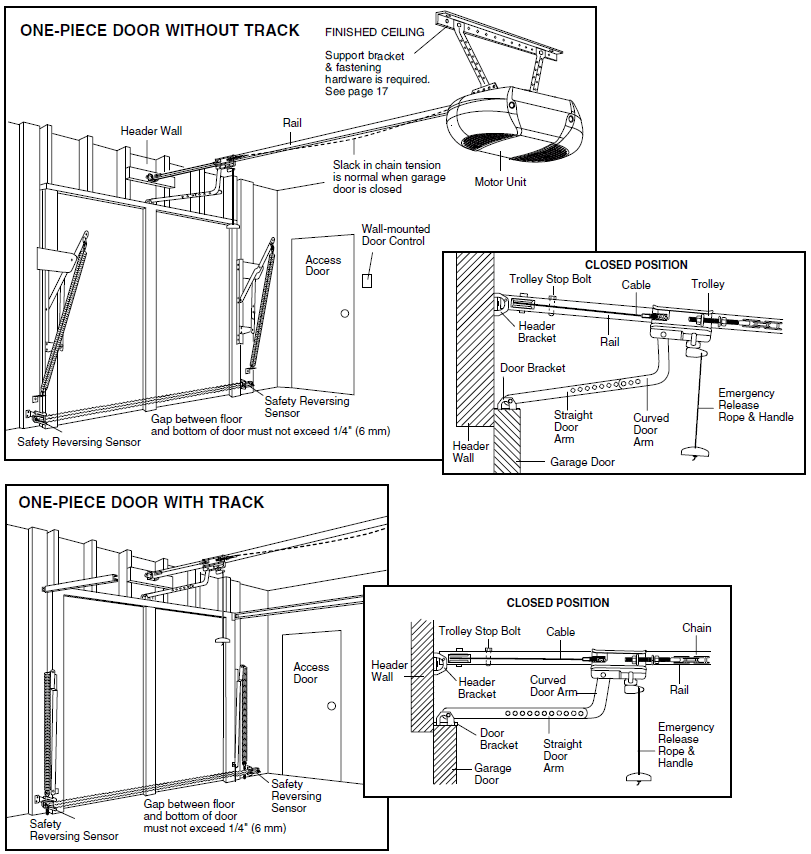

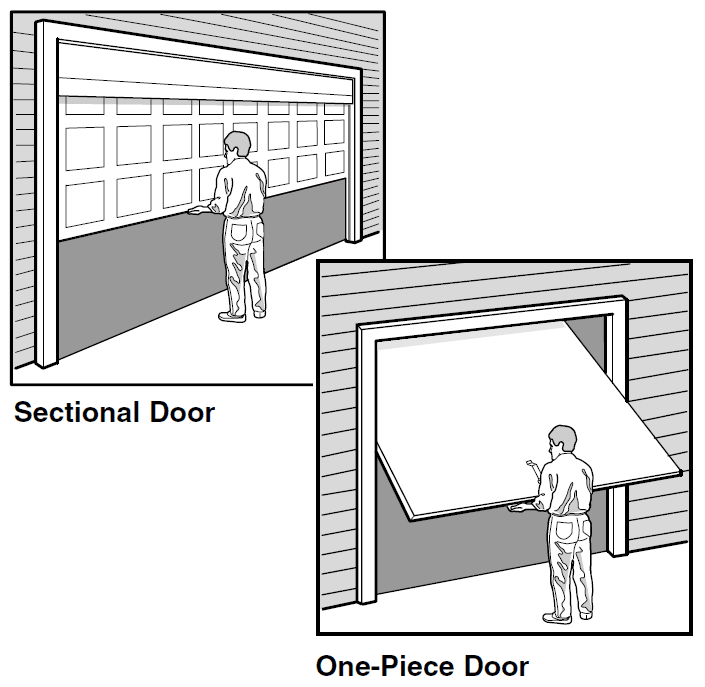

Identify the type and height of your garage door. Survey your garage area to see if any of the conditions below apply to your installation. Additional materials may be required. You may find it helpful to refer back to this page and the accompanying illustrations as you proceed with the installation of your opener. Depending on your requirements, there are several installation steps which may call for materials or hardware not included in the carton.

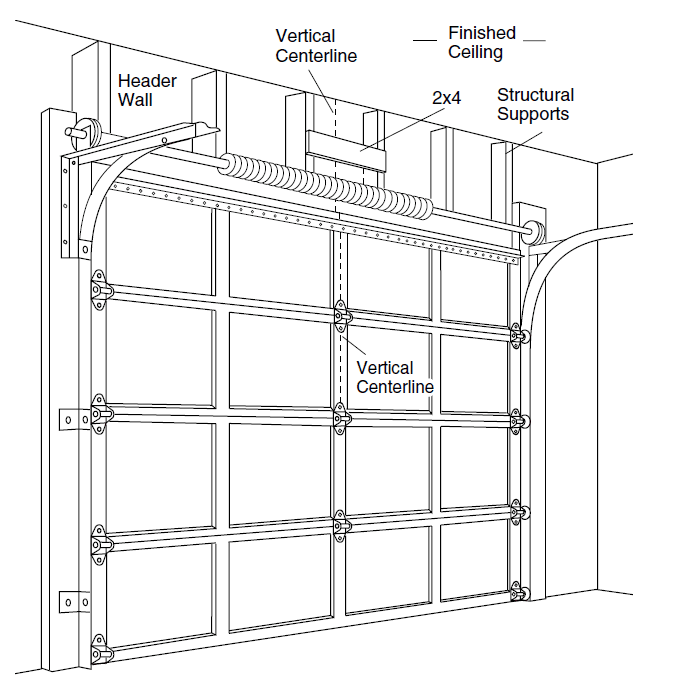

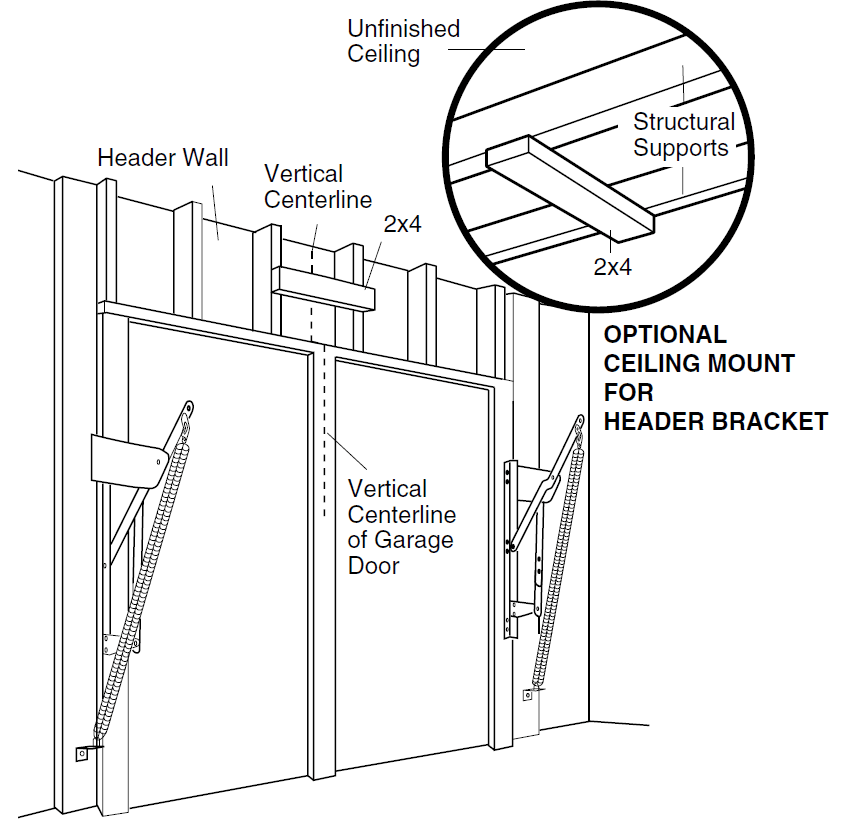

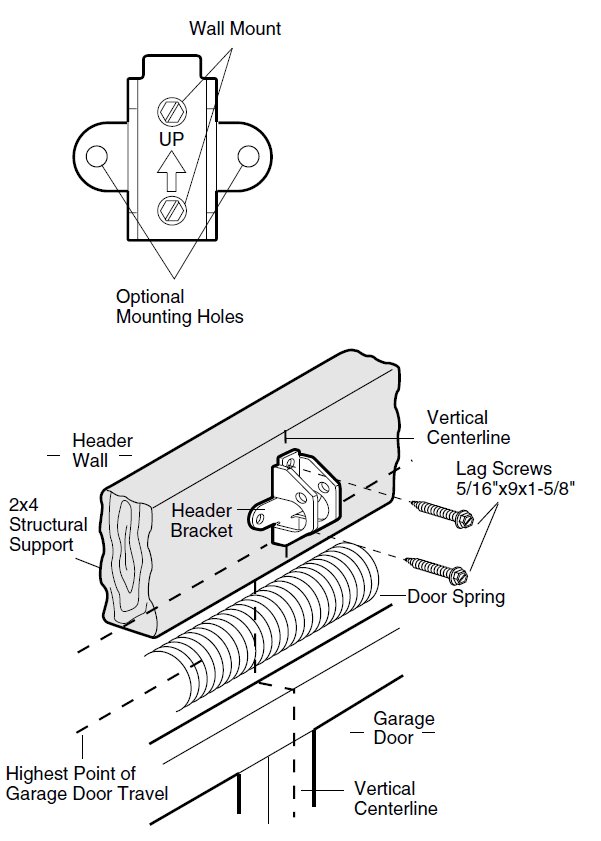

- Installation Step 1 – Look at the wall or ceiling above the garage door. The header bracket must be securely fastened to structural supports.

- Installation Step 5 – Do you have a finished ceiling in your garage? If so, a support bracket and additional fastening hardware may be required.

- Installation Step 10 – Depending upon garage construction, extension brackets or wood blocks may be needed to install sensors.

- Installation Step 10 – Alternate floor mounting of the safety reversing sensor will require hardware not provided.

- Do you have an access door in addition to the garage door? If not, Model 53702 Emergency Key Release is required. See the Accessories page.

- Look at the garage door where it meets the floor. Any gap between the floor and the bottom of the door must not exceed 1/4″ (6 mm). Otherwise, the safety reversal system may not work properly. See Adjustment Step 3. Floor or door should be repaired.

- SECTIONAL DOOR INSTALLATIONS

- Do you have a steel, aluminum, fiberglass or glass panel door? If so, horizontal and vertical reinforce- ment is required (Installation Step 11).

- The opener should be installed above the center of the door. If there is a torsion spring or center bearing plate in the way of the header bracket, it may be installed within 4 feet (1.22 m) to the left or right of the door center. See Installation Steps 1 and 11.

- If your door is more than 7 feet high (2.13 m), see rail extension kits listed on Accessories page

ONE-PIECE DOOR INSTALLATIONS

ONE-PIECE DOOR INSTALLATIONS

- Generally, a one-piece door does not require reinforcement. If your door is lightweight, refer to the information relating to sectional doors in Installation Step 11.

- Depending on your door’s construction, you may need additional mounting hardware for the door bracket (Step 11).

ASSEMBLY STEP 1

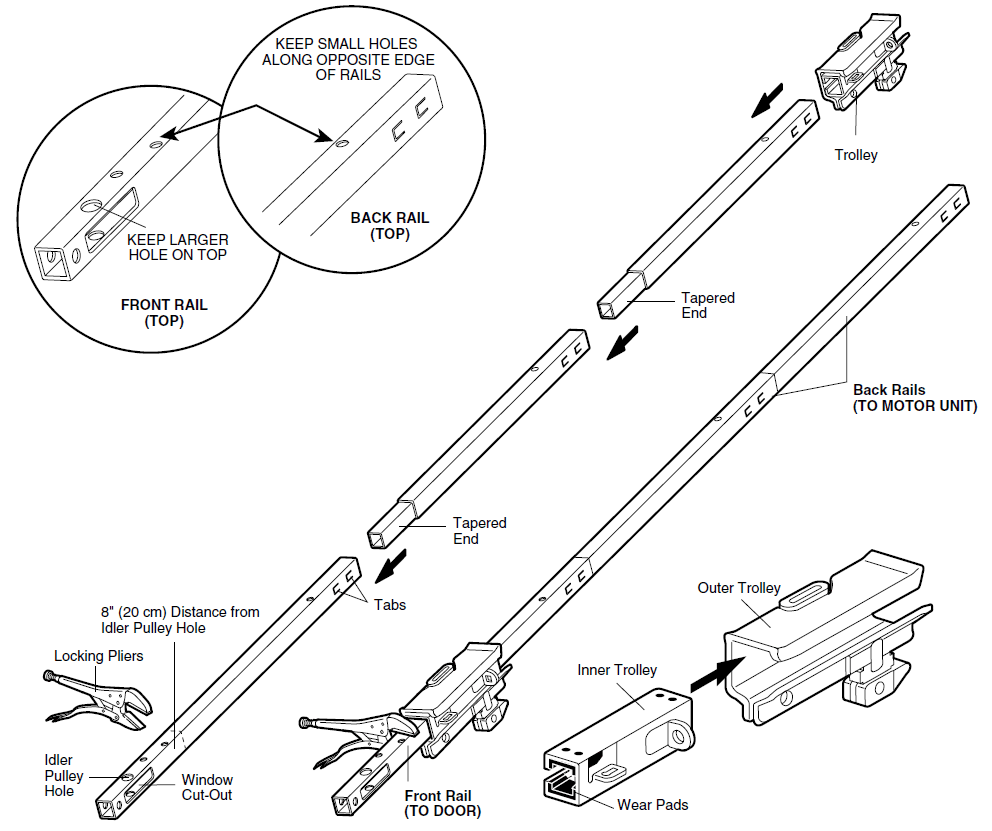

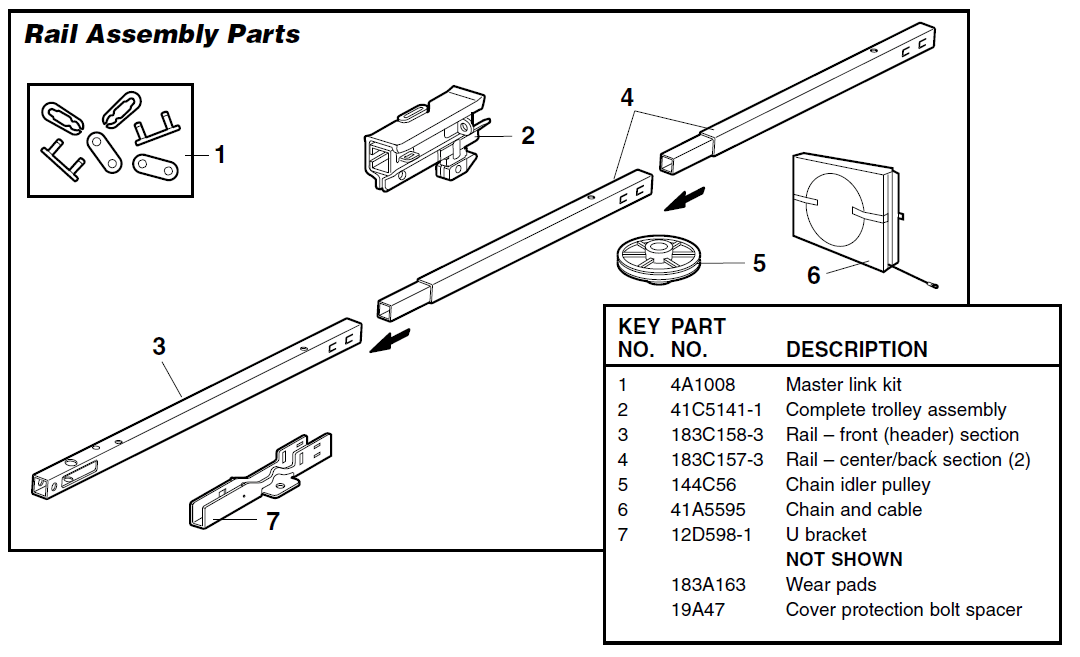

Assemble the Rail & Install the Trolley

To avoid installation difficulties, do not run the garage door opener until instructed to do so. The front rail has a cut out “window” at the door end (see illustration). The hole above this window is larger on the top of the rail than on the bottom. A smaller hole 3-1/2″ (8.9 cm) away is close to the rail edge. Rotate the back rail so it has a similar hole close to the opposite edge, about 4-3/4″ (12 cm) from the far end. A 3-piece rail uses two back rails.

- Remove the straight door arm, hanging brackets and clevis pin packaged inside the front rail and set aside for Installation Step 5 and 12.

- Align the rail sections on a flat surface exactly as shown and slide the tapered ends into the larger ones. labs along the side will lock into place.

- Place the motor unit on packing material to protect the cover, and rest the back end of the rail on top. For convenience, put a support under the front end of the rail.

- As a temporary trolley stop, clamp a locking pliers onto the rail, 8″ (20 cm) from the center of the idler pulley hole, as shown.

- Check to be sure there are 4 plastic wear pads inside the inner trolley. If they became loose during shipping, check all packing material. Snap them back into position as shown.

- Connect the inner and outer trolleys as shown.

- Slide the trolley assembly along the rail from the back end to the locked pliers

ASSEMBLY STEP 2

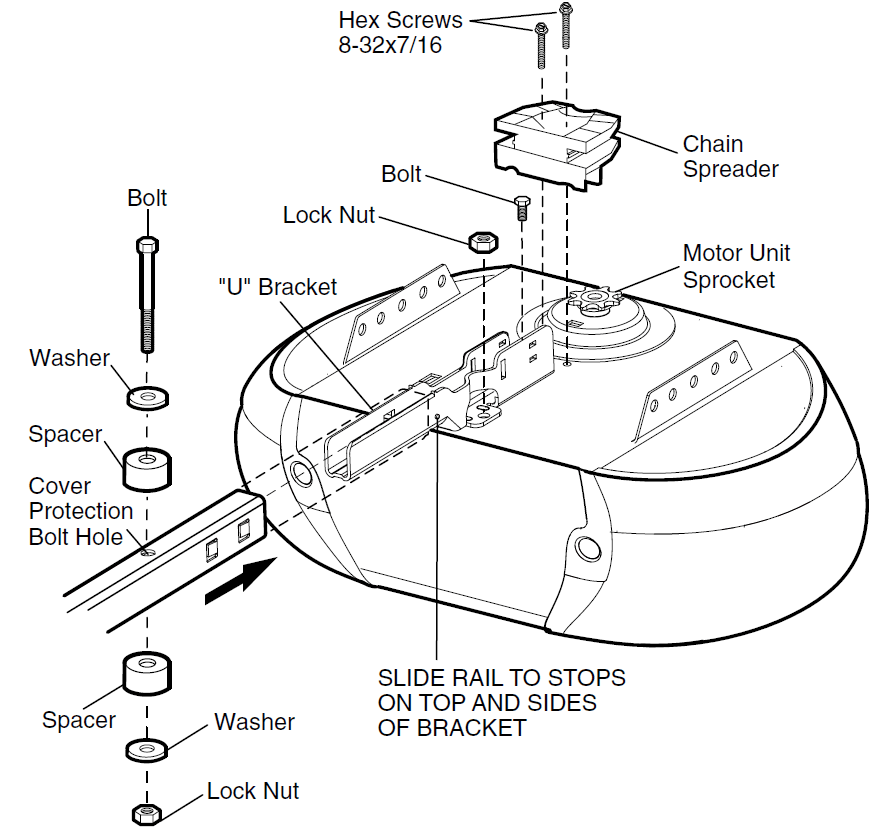

Fasten the Rail to the Motor Unit

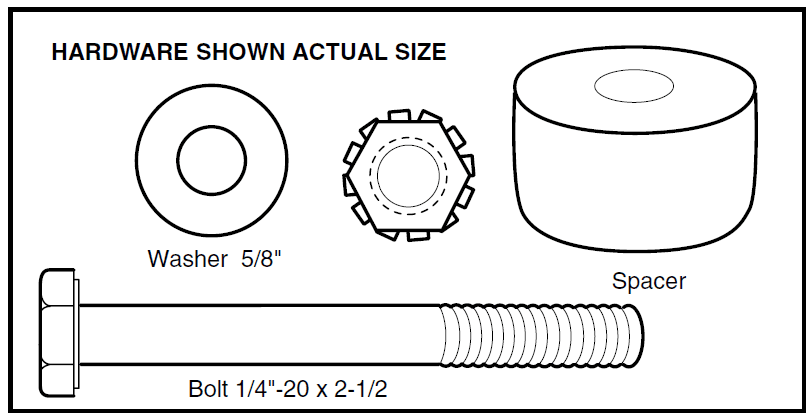

- Insert a 1/4-20×2-1/2 bolt, washer and spacer into the cover protection bolt hole on the back end of the rail as shown. Install lower spacer and washer

then tighten securely with a 1/4″-20 lock nut. Do NOT overtighten. - Remove the bolt and lock nut from the top of the motor unit.

- Attach spreader to the motor unit with two screws.

- Place the U bracket, flat side down onto the bolt, mounted on the motor unit and align the bracket hole with the screw hole. Fasten with the previously removed screw and lock nut.

- Align the rail assembly with the top of the motor unit. Slide the rail end onto the U-bracket, all the way to the stops that protrude on the top and sides of the bracket.

ASSEMBLY STEP 3

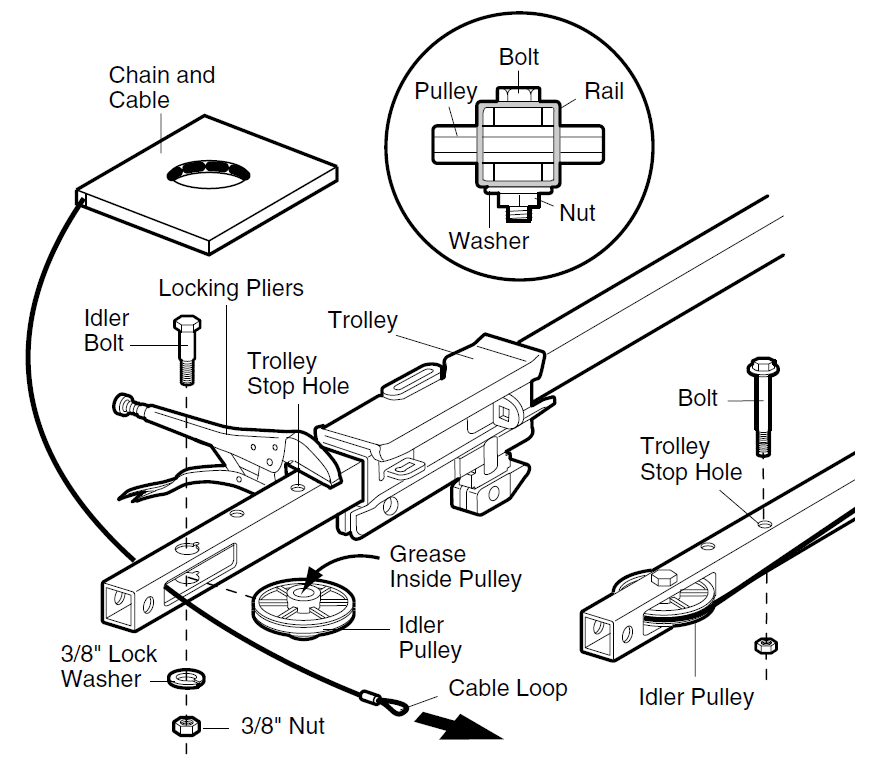

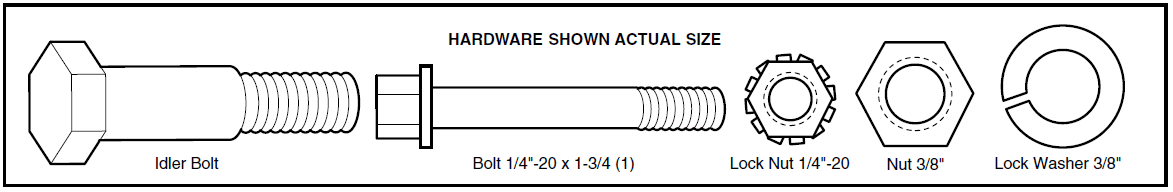

Install the Idler Pulley

- Lay the chain/cable beside the rail, as shown. Grasp the end with the cable loop and pass approximately 12″ (30 cm) of cable through the window. Allow it to hang until Assembly Step 5.

- Remove the tape from the idler pulley. The inside center should be pre-greased. If dry, regrease to ensure proper operation.

- Place the idler pulley into the window as shown.

- Insert the idler bolt from the top through the rail and pulley. Tighten with a 3/8″ lock washer and nut underneath the rail until the lock washer is compressed.

- Rotate the pulley to be sure it spins freely.

- Insert a 1/4 -20×1-3/4 bolt into the trolley stop hole in the front of the rail as shown. Tighten securely with a 1/4″-20 lock nut.

ASSEMBLY STEP 4

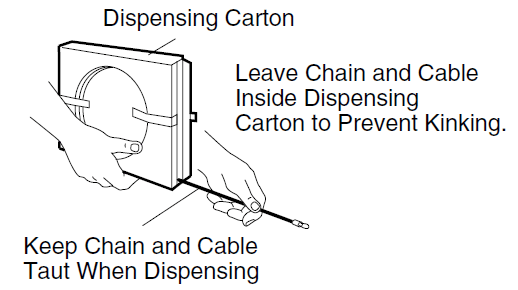

Install the Chain/Cable

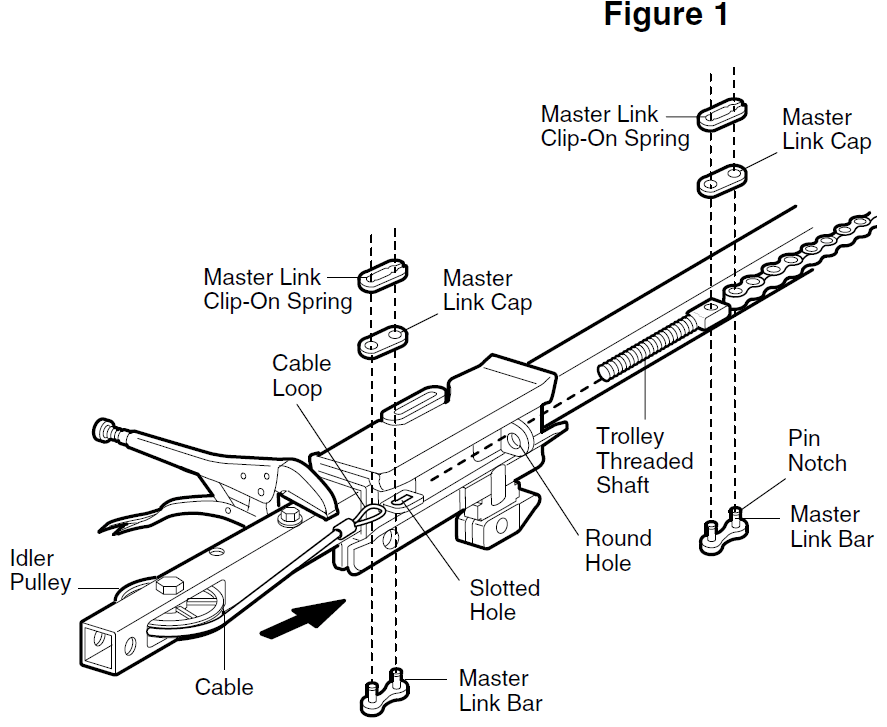

- Pull the cable around the idler pulley and toward the trolley.

- Connect the cable loop to the retaining slot on the trolley, as shown (Figure 1):

- From below, push pins of the master link bar up through cable loop and trolley slot

- Push master link cap over pins and past pin notches

- Slide clip-on spring over cap and onto pin notches until both pins are securely locked in place.

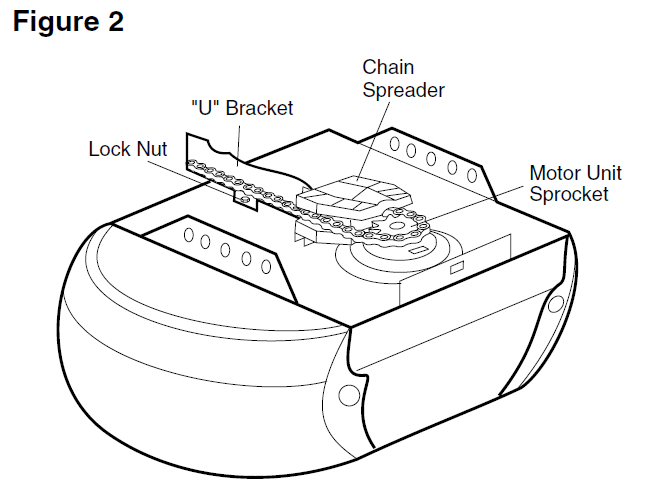

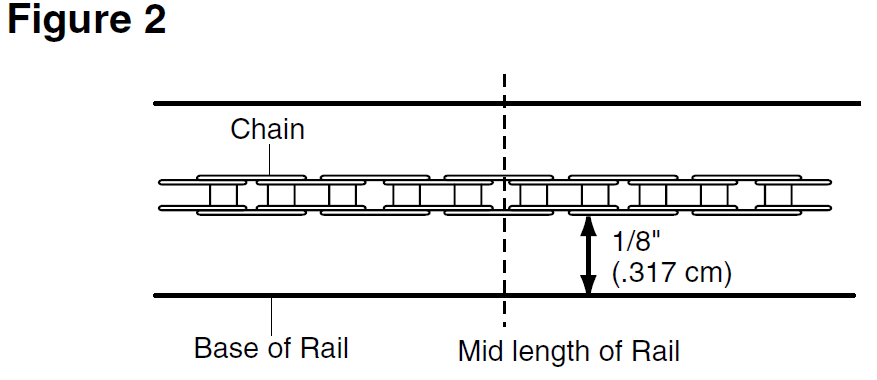

- With the trolley against the pliers, dispense the remainder of the cable/chain along the rail toward the motor unit into the slot on the chain spreader, around the sprocket onto the chain spreader and continuing to the trolley assembly. The sprocket teeth must engage the chain (Figure 2).

- Check to make sure the chain is not twisted, then connect it to the threaded shaft with the remaining master link.

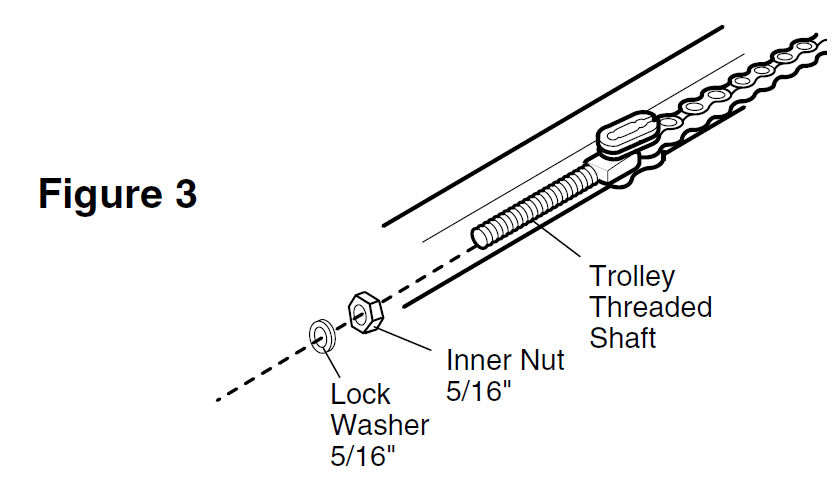

- Thread the inner nut and lock washer onto the trolley threaded shaft (Figure 3).

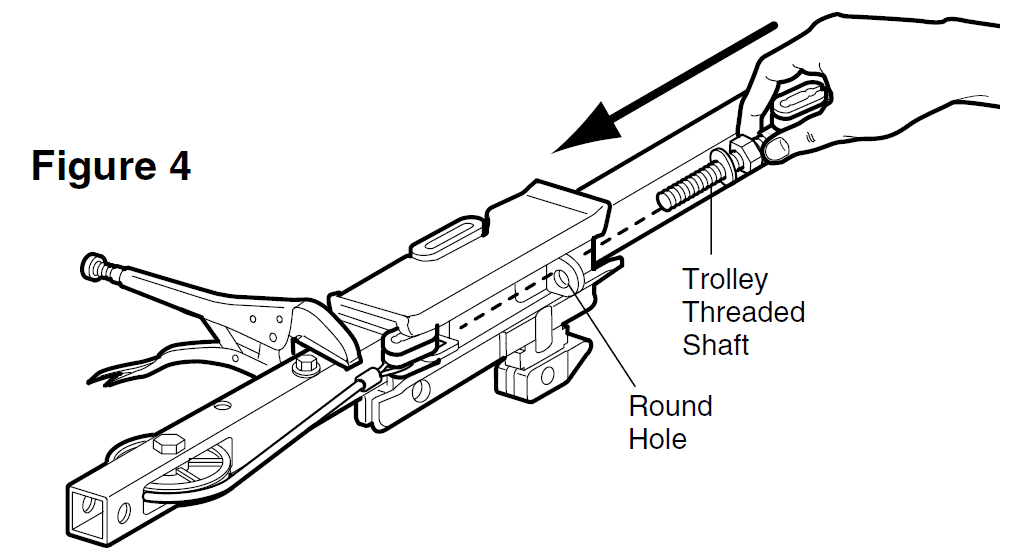

- Insert the trolley threaded shaft through the hole in the trolley. Be sure the chain is not twisted (Figure 4).

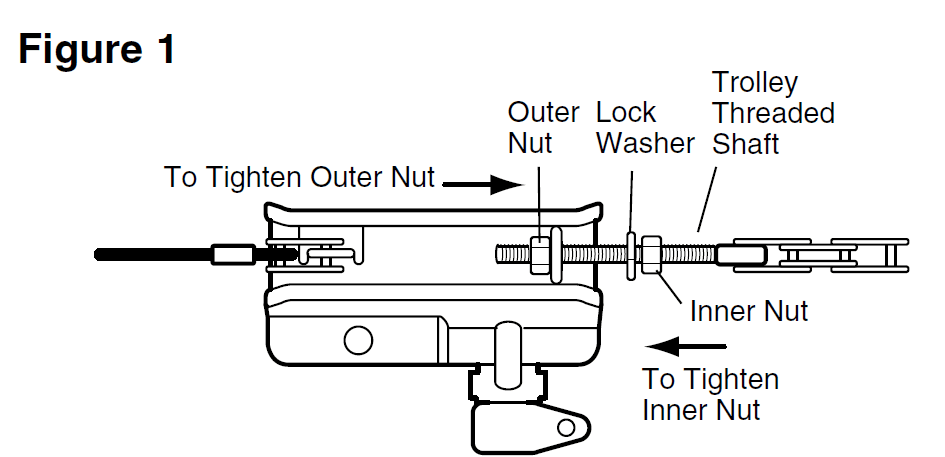

- Loosely thread the outer nut onto the trolley threaded shaft.

- Remove the locking pliers

ASSEMBLY STEP 5

Tighten the Chain

- Spin the inner nut and lock washer down the trolley threaded shaft, away from the trolley.

- To tighten the chain, turn outer nut in the direction shown (Figure 1).

- When the chain is approximately 1/8 (.317 cm ) above the base of the rail at its midpoint, re-tighten the inner nut to secure the adjustment. Sprocket noise can result if chain is too loose.

- When installation is complete, you may notice some chain droop with the door closed. This is normal. If the chain returns to the position shown in Figure 2

when the door is open, do not re-adjust the chain.

- NOTE: During future maintenance, ALWAYS pull the emergency release handle to disconnect trolley before adjusting chain.

- NOTE: You may notice loosening of chain after Adjustment Step 3 (Test the Safety Reversal System). Check for proper tension and readjust chain if necessary. Then repeat Adjustment Step 3. You have now finished assembling your garage door opener. Please read the following warnings before proceeding to the installation section

INSTALLATION

INSTALLATION STEP 1

Determine the Header Bracket Location

WARNING

To prevent possible SERIOUS INJURY or DEATH:

- Header bracket MUST be RIGIDLY fastened to structural support on feeder val (a ceiling, otherwise garage door might not reverse when required. DO NO

install header bracket over drywall. - Concrete anchors MUST be used if mounting header bracket or 2×4 into masonry.

- NEVER try to loosen, move or adjust garage door, springs, cables, pulleys, brackets, or their hardware, of which are under EXTREME tension.

- ALWAYS call a trained door systems technician if garage door binds, sticks, or is out of balance. An unbalanced garage door might not reverse when required.

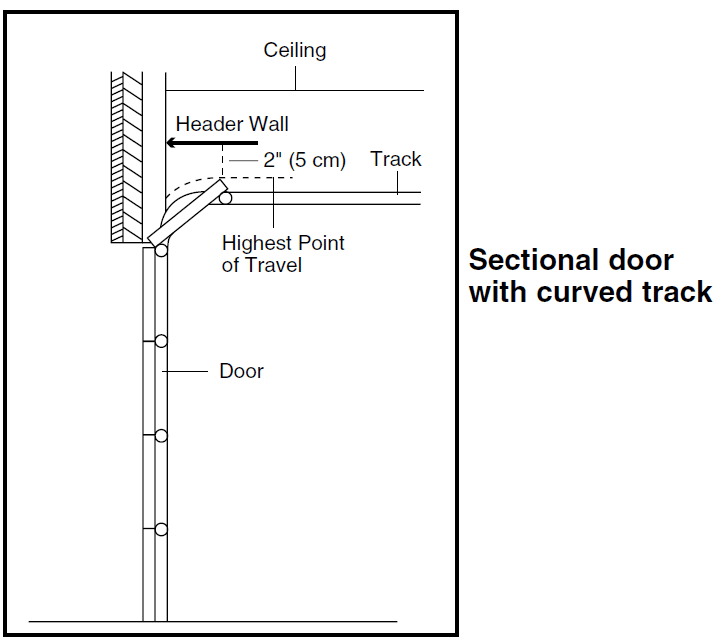

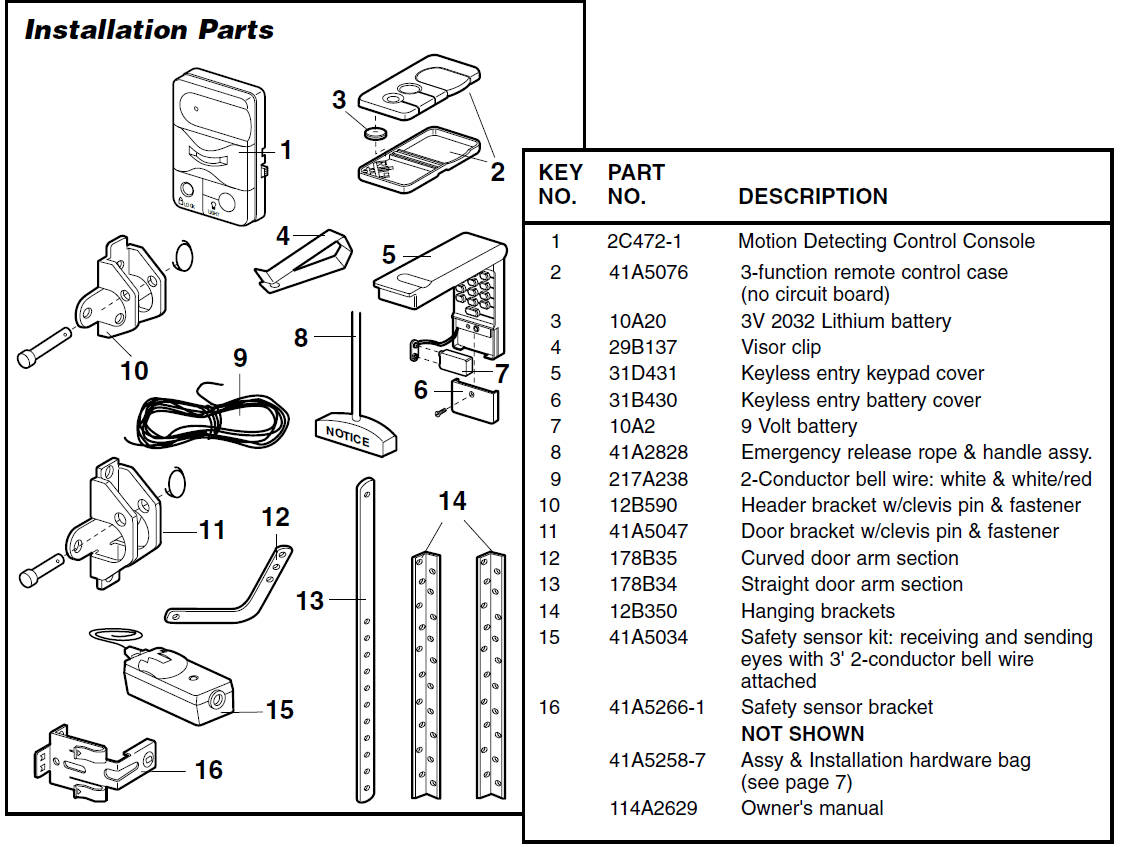

- Installation procedures vary according to garage door types. Follow the instructions which apply to your door.

SECTIONAL DOOR AND ONE-PIECE DOOR WITH TRACK

- Close the door and mark the inside vertical centerline of the garage door.

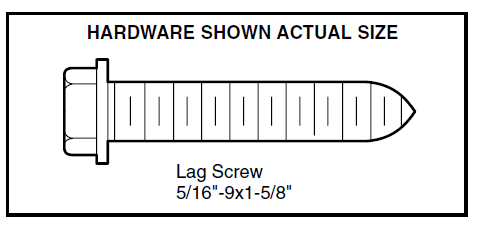

- Extend the line onto the header wall above the door. You can fasten the header bracket within 4 feet (1.22 m) of the left or right of the door centeronly if a torsion spring or center bearing plateis in the way; or you can attach it to the ceiling (see page 14) when clearance is minimal. (It may be mounted on the wall upside down if necessary, to gain approximately 1/2″ (1 cm). If you need to install the header bracket on a 2×4 (on wall or ceiling), use lag screws (not provided)

to securely fasten the 2×4 to structural supports as shown here and on page 13.

- Open your door to the highest point of travel as shown. Draw an intersecting horizontal line on the header wall 2″ (5 cm) above the high point. This height will provide travel clearance for the top edge of the door.

- NOTE: Door clearance brackets are available for sectional doors when headroom clearance is less than 2″ (5cm). See accessory page 39.

- NOTE: Door clearance brackets are available for sectional doors when headroom clearance is less than 2″ (5cm). See accessory page 39.

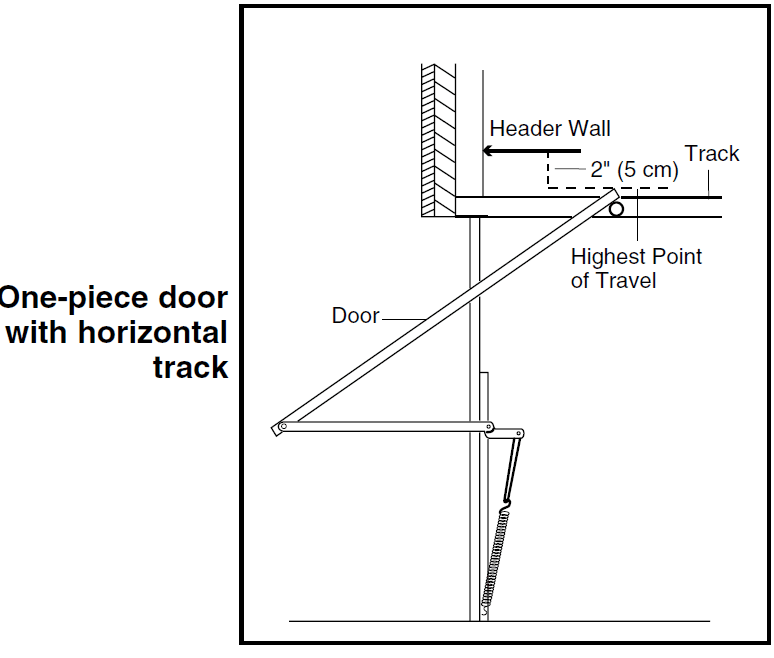

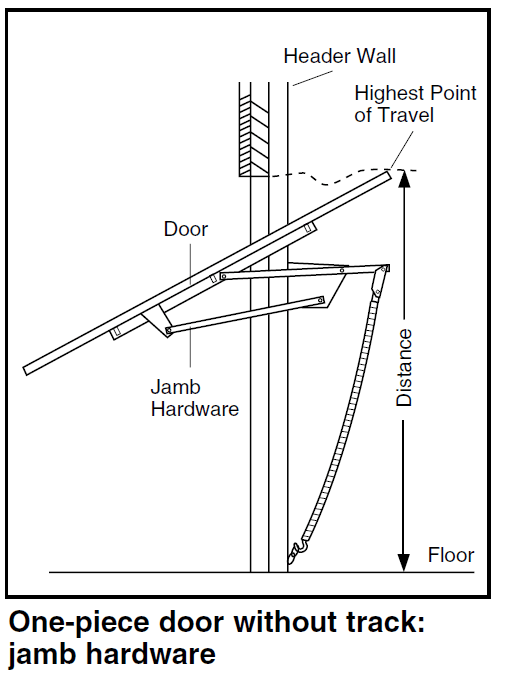

ONE-PIECE DOOR WITHOUT TRACK

- Close the door and mark the inside vertical centerline of your garage door. Extend the line onto the header wall above door as shown. If headroom clearance is minimal, you can install the header bracket on the ceiling, See page 14. If you need to install the header bracket on a 2×4 (on wall or ceiling), use lag screws( not provided) to securely fasten the 2×4 to structural support as shown.

INSTALLATION STEP 2

Install the Header Bracket

You can attach the header bracket either to the wall above the garage door, or to the ceiling. Follow the instructions which will work best for your particular

requirements. Do not install the header bracket over drywall. If installing into masonry, use concrete anchors (not provided).

WALL HEADER BRACKET INSTALLATION

- Center the bracket on the vertical centerline with the bottom edge of the bracket on the horizontal line as shown (with the arrow pointing toward the ceiling)

- Mark the vertical set of bracket holes. Drill 3/16″| pilot holes and fasten the bracket securely to a structural support with the hardware provided.

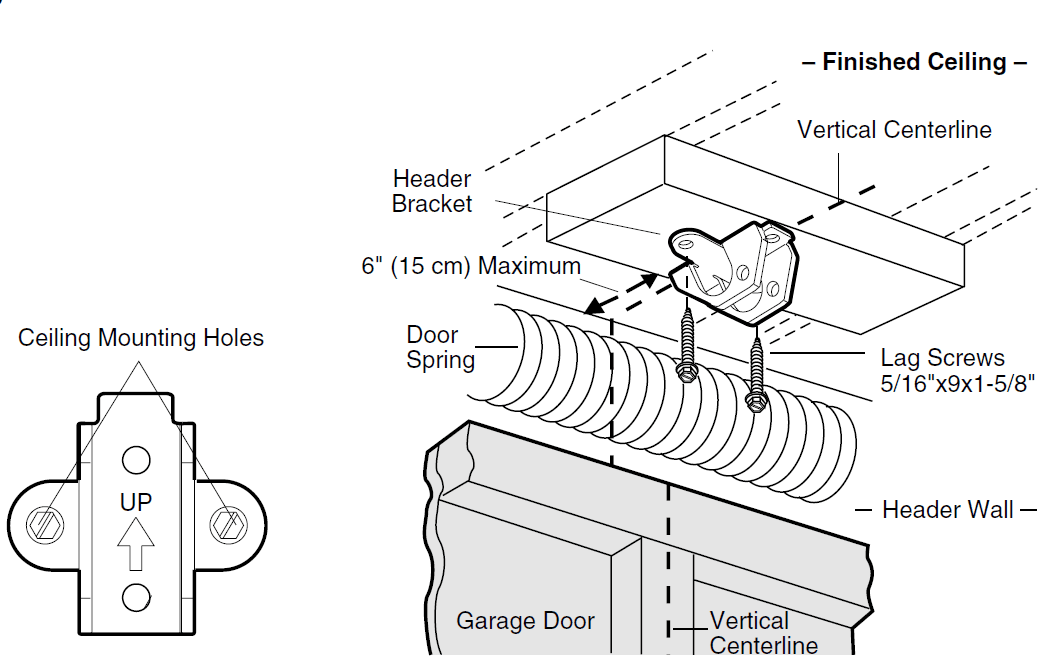

CEILING HEADER BRACKET INSTALLATION

- Extend the vertical centerline onto the ceiling as shown.

- Center the bracket on the vertical mark, no more than 6″ (15 cm) from the wall. Make sure the arrow is pointing away from the wall. The bracket can be mounted flush against the ceiling when clearance is minimal.

- Mark the side holes. Drill 3/16″ pilot holes and fasten bracket securely to a structural support with the hardware provided.

INSTALLATION STEP 3

Attach the Rail to the Header Bracket

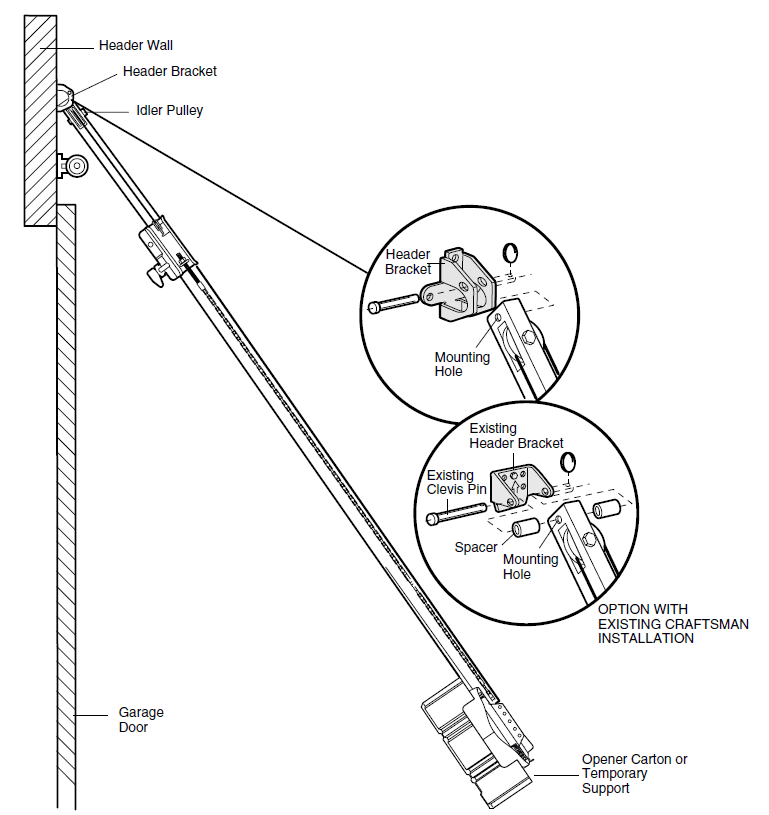

NOTE: (Optional) With an existing Craftsman installation, you may re-use the old header bracket with the two plastic spacers included in the hardware bag. Place the spacers inside the bracket on each side of the rail, as illustrated.

- Position the opener on the garage floor below the header bracket. Use packing material as a protective base.

- NOTE: If the door spring is in the way you’ll need help. Have someone hold the opener securely on a temporary support to allow the rail to clear the spring.

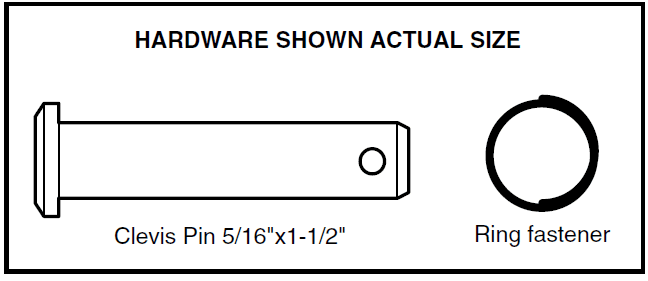

- Position the front rail end within the header bracket and join with a 5/16″x1-1/2″ clevis pin as shown.

- Insert a ring fastener to secure.

INSTALLATION STEP 4

Position the Opener

Follow instructions which apply to your door type as illustrated.

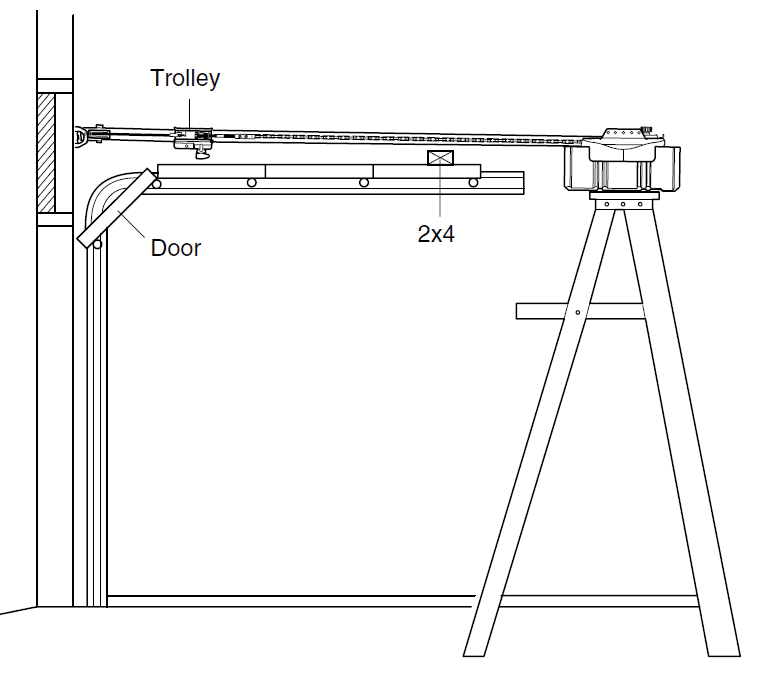

SECTIONAL DOOR OR ONE-PIECE DOOR WITH TRACK

A 2×4 laid flat is convenient for setting an ideal door- to-rail distance.

- Raise the opener onto a stepladder. You will need help at this point if the ladder is not tall enough.

- Open the door all the way and place a 2×4 laid flat on the top section beneath the rail.

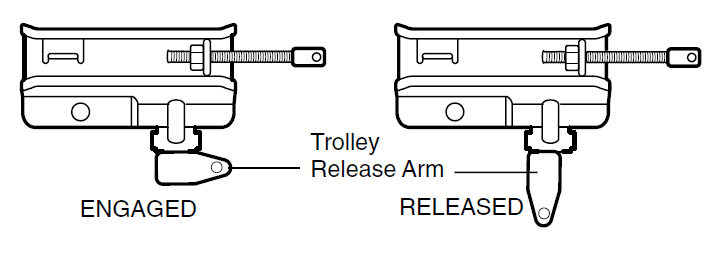

- If the top section or panel hits the trolley when you raise the door, pull down on the trolley release arm to disconnect inner and outer sections. Slide the outer trolley toward the motor unit. The trolley can remain disconnected until Installation Step 12 is completed.

ONE-PIECE DOOR WITHOUT TRACK

- With the door fully open and parallel to the floor, measure the distance from the floor to the top of the door.

- Using a stepladder as a support, raise the top of the opener to this height.

- The top of the door should be level with the top of the motor unit. Do not position the opener more than 2″ (5 cm) above this point.

INSTALLATION STEP 5

Hang the Opener

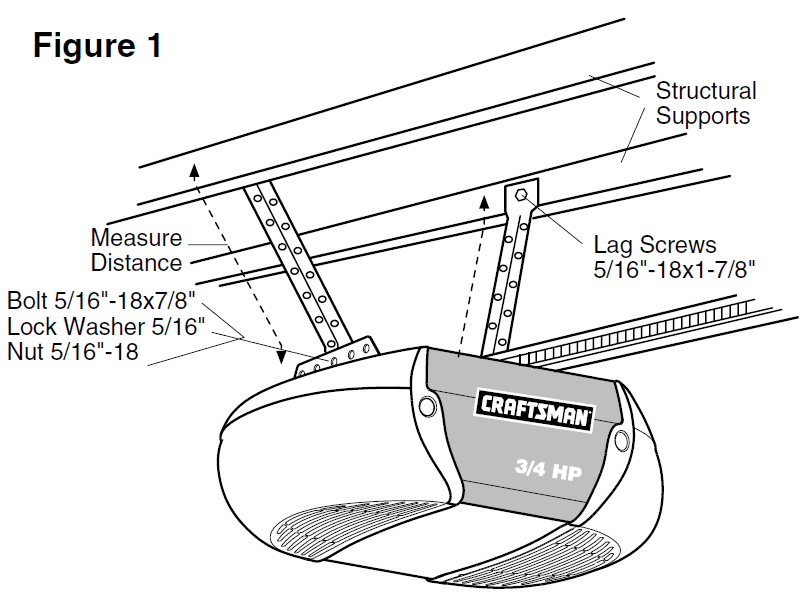

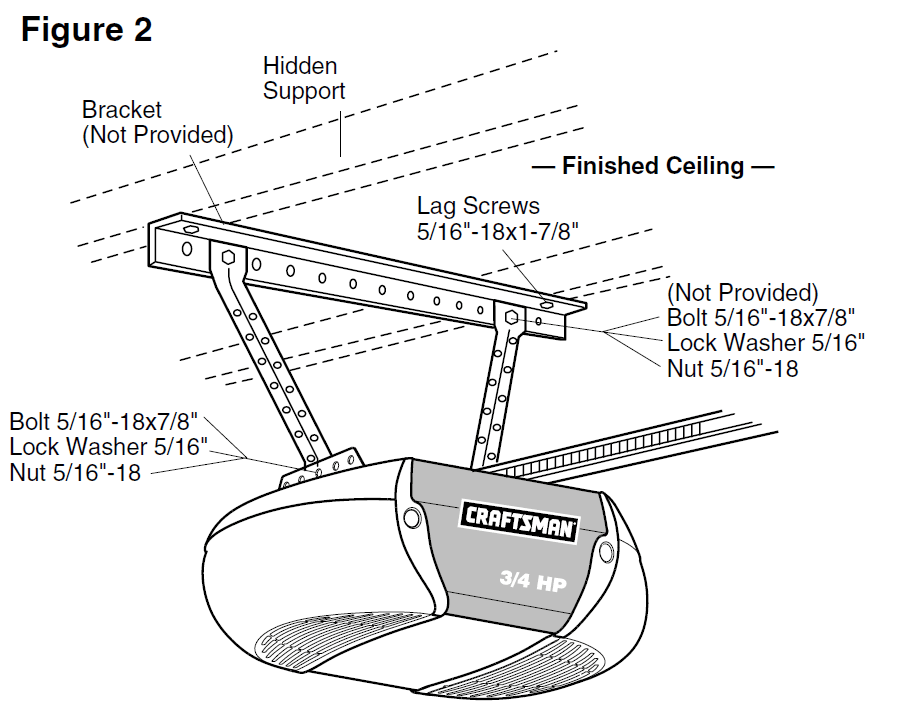

Two representative installations are shown. Yours may be different. Hanging brackets should be angled (Figure 1) to provide rigid support. On finished ceilings (Figure 2), attach a sturdy metal bracket to structural supports before installing the opener. This bracket and fastening hardware are not provided. (See Accessories).

- Measure the distance from each side of the motor unit to the structural support.

- Cut both pieces of the hanging bracket to the required lengths.

- Drill 3/16™ pilot holes in the structural supports.

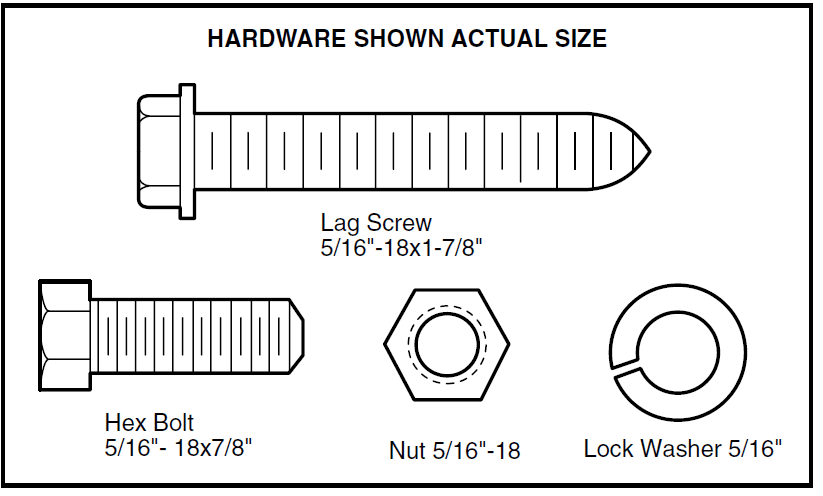

- Attach one end of each bracket to a support with 5/16″-18×1-7/8″ lag screws.

- Fasten the opener to the hanging brackets with 5/16″- 18×7/8* hex bolts, lock washers and nuts.

- Check to make sure the rail is centered over the door (or in line with the header bracket if the bracket is not centered above the door).

- Remove the 2×4. Operate the door manually. If the door hits the rail, raise the header bracket.

- NOTE: DO NOT connect power to the opener at this time.

- NOTE: DO NOT connect power to the opener at this time.

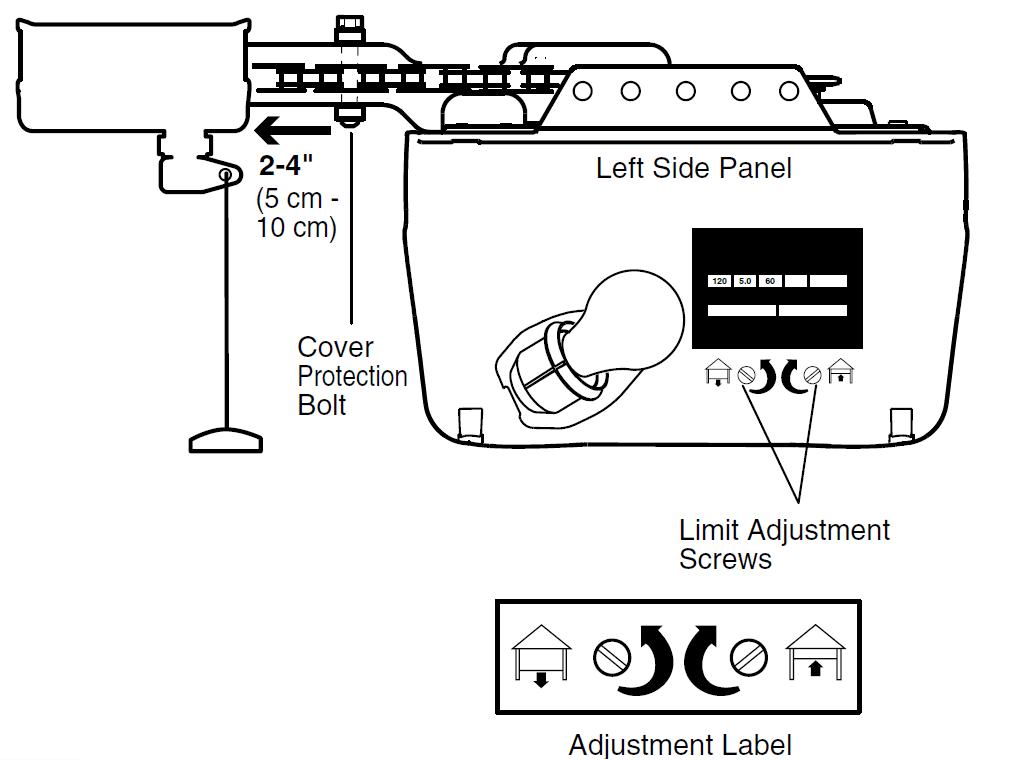

ADJUSTMENT STEP 1

Adjust the UP and DOWN Travel Limits

- Limit adjustment settings regulate the points at which the door will stop when moving up or down. To operate the opener, press the Door Control push button. Run the opener through a complete travel cycle.

- Does the door open and close completely?

- Does the door stay closed and not reverse unintentionally when fully closed?

- If your door passes both of these tests, no limit adjustments are necessary unless the reversing test fails (see Adjustment Step 3, page 30).

- Adjustment procedures are outlined below. Read the procedures carefully before proceeding to Adjustment Step 2. Use a screwdriver to make limit adjustments. Run the opener through a complete travel cycle after each adjustment.

- NOTE: Repeated operation of the opener during adjustment procedures may cause the motor to overheat and shut off. Simply wait 15 minutes and try again.

- NOTE: If anything interferes with the door’s upward travel, it will stop. If anything interferes with the door’s downward travel (including binding or unbalanced doors), it will reverse

HOW AND WHEN TO ADJUST THE LIMITS

- If the door does not open completely but opens at least five feet (1.5 m):

- Increase up travel. Tum the UP limit adjustment screw clockwise. One turn equals 3* (7.5 cm) of trolley travel.

- NOTE: To prevent the trolley from hitting the cover protection bolt, keep a minimum distance of 2-4″ (5 cm – 10 cm) between the trolley and the bolt.

- Increase up travel. Tum the UP limit adjustment screw clockwise. One turn equals 3* (7.5 cm) of trolley travel.

- If door does not open at least 5 feet (1.5 m):

- Adjust the UP (open) force as explained in Adjustment Step 2.

- If the door does not close completely:

- Increase down travel. Turn the down limit adjustment screw counterclockwise. One turn equals 3* (7.5 cm) of trolley travel. If door still won’t close completely, try lengthening the door arm (page 26) and decreasing the down limit.

- If the opener reverses in fully closed position:

- Decrease down travel. Turn the down limit adjustment screw clockwise. One turn equals 3″ (7.5 cm) of trolley travel.

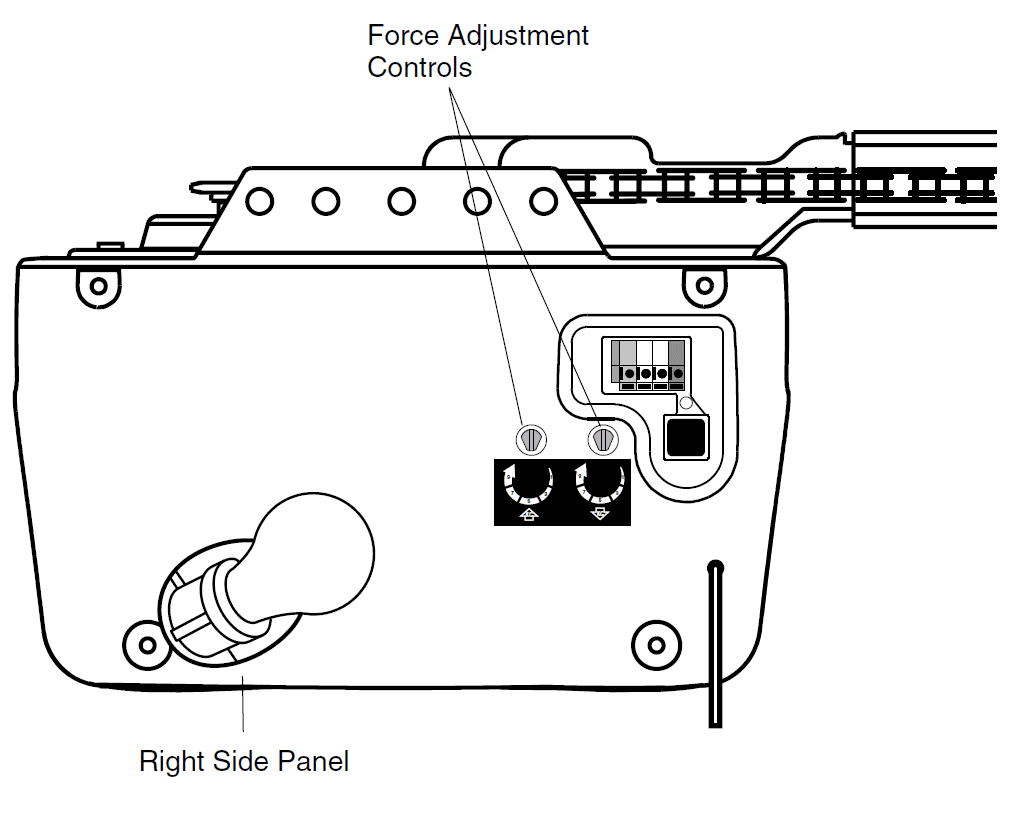

ADJUSTMENT STEP 2

Adjust the Force

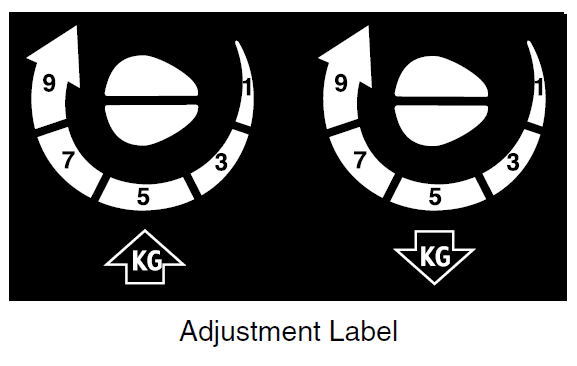

- Force adjustment controls are located on the right side panel of the motor unit. Force adjustment settings regulate the amount of power required to open and close the door.

- If the doors are set too light, door travel may be interrupted by nuisance reversals in the down direction and stops in the up direction. Weather occasional adjustment may be needed.

- The maximum force adjustment range is about 3/4 of a complete turn. Do not force controls beyond that point. Turn force adjustment controls with a screwdriver.

- NOTE: If anything interferes with the door’s upward travel, it will stop. If anything interferes with the door’s downward travel (including binding or

unbalanced doors), it will reverse.

HOW AND WHEN TO ADJUST THE FORCES

- Test the DOWN (close) force

- Grasp the door bottom when the door is about should reverse. Reversal halfway through down travel does not guarantee reversal on a one-inch (2.5 cm) obstruction. See Adjustment Step 3, page 30. If the door is hard to hold or doesn’t reverse, DECREASE the DOWN (close) force by turning the control counterclockwise. Make small adjustments until the door reverses normally. After each adjustment, run the opener through a complete cycle.

- If the door reverses during the down (close) cycle and the opener lights aren’t flashing. INCREASE DOWN (close) force by turning the control clockwise. Make small adjustments until the door completes a close cycle. After each adjustment, run the opener through a complete travel cycle. Do not increase the force beyond the minimum amount required to close the door.

- Test the UP (open) force

- Grasp the door bottom when the door is about halfway through UP (open) travel. The door should stop. If the door is hard to hold or doesn’t stop, DECREASE UP (open) force by turning the control counterclockwise. Make small adjustments until the door stops easily and opens fully. After each adjustment, run the opener through a complete travel cycle.

- If the door doesn’t open at least 5 feet (1.5 m), INCREASE UP (open) force by turning the control clockwise. Make small adjustments until the door opens completely. Readjust the UP limit if necessary. After each adjustment, run the opener through a complete travel cycle

ADJUSTMENT STEP 3

Test the Safety Reversa/ System

- TEST

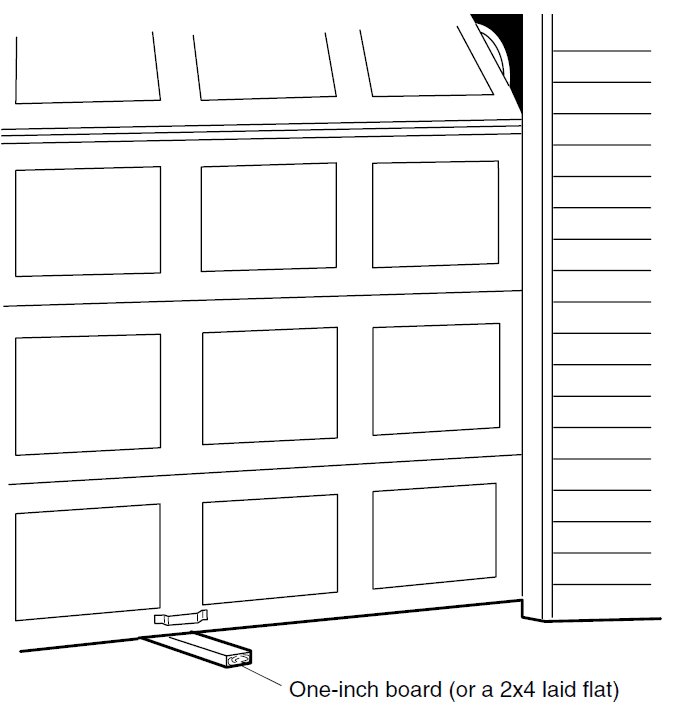

- With the door fully open, place a one-inch board (or a 2×4 laid flat) on the floor, centered under the garage door.

- Operate the door in the down direction. The door must reverse on striking the obstruction.

- ADJUST

- If the door stops on the construction, it is not traveling far enough in the down direction. Increase the DOWN limit by turning the DOWN limit adjustment screw counterclockwise 1/4 turn.

- NOTE: On a sectional door, make sure limit adjustments do not cause the trolley to move within 2-1/2″ (6.3 cm) of the trolley stop bolt. If necessary lengthen straight door arm to maintain this minimum distance.

- Repeat the test.

- When the door reverses on the one-inch (2.5 cm) board, remove the obstruction and run the opener through 3 or 4 complete travel cycles to test adjustment.

IMPORTANT SAFETY CHECK

Repeat Adjustment Steps 1, 2, and 3 after:

- Each adjustment of door arm length, limits, or force controls.

- Any repair to or adjustment of the garage door (including springs and hardware).

- Any repair to or buckling of the garage floor.

- Any repair to or adjustment of the opener.

ADJUSTMENT STEP 4

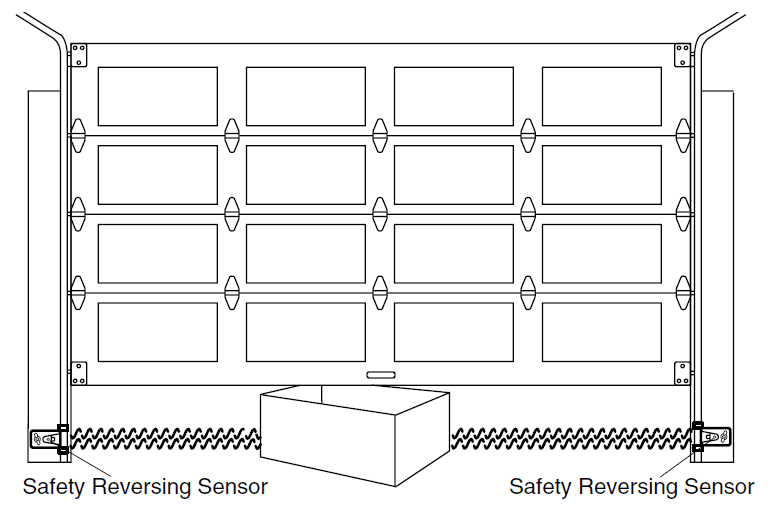

Test the Protector System

- Press the remote control push button to open the door.

- Place the opener carton in the path of the door.

- Press the remote control push button to close the door. The door will not move more than an inch (2.5 cm), and the opener ights will flash.

- The garage door opener will not close from a remote if the indicator light in either sensor is off (alerting) you to the fact that the sensor is misaligned or obstructed)

- If the opener closes the door when the safety reversing sensor is obstructed (and the sensors are no more than 6 (15 cm) above the floor), call for a trained door systems technician

OPERATION

Using Your Garage Door Opener

- Your Security+ opener and hand-held remote control have been factory-set to a matching code which changes with each use, randomly accessing over 100 billion new codes. Your opener will operate with up to eight Security+ remote controls and one Security+ Keyless Entry System

- If you purchase a new remote, or if you wish to deactivate any remote, follow the instructions in the Programming section. Activate your opener with any of the following:

- The hand-held Remote Control: Hold the large push button down until the door starts to move.

- The wall-mounted Door Control: Hold the push button down until the door starts to move.

- The Keyless Entry (See Accessories): If provided with your garage door opener, it must be programmed before use. See Programming

When the opener is activated (with the safety reversing sensor correctly installed and aligned)

- If open, the door Will close. If closed; It will open.

- If closing, the door will reverse.

- If opening, the door will stop.

- If the door has been stopped in a partially open position; it will close.

- If obstructed while closing; the door will reverse. If the obstruction interrupts the sensor beam, the opener lights will blink for five seconds.

- If obstructed while opening, the door will stop.

- If fully open, the door will not close when the beam is broken. The sensor has no effect in the opening cycle. If the sensor is not installed, or is misaligned, the door won’t close from a hand-held remote. However, you can close the door with the Door Control, the Outdoor Key Switch, or Keyless Entry, if you activate them until down travel is complete. If you release them too soon, the door will reverse.

- The opener lights will turn on under the following conditions: when the opener is initially plugged in; when power is restored after interruption; when the opener is activated. They will turn off automatically after 4-1/2 minutes or provide constant light when the Light feature on the Motion Detecting Control Console is activated. Bulb size is 100 watts maximum.

- Security+ Light Feature: Lights will also turn on when someone walks through the open garage door. With a Motion Detecting Control Console, this feature may be turned off as follows: With the opener lights off, press and hold the light button for 10 seconds, until the light goes on and off again. To restore this feature, start with the opener lights on, then press and hold the light button for 10 seconds until the light goes off, then on again.

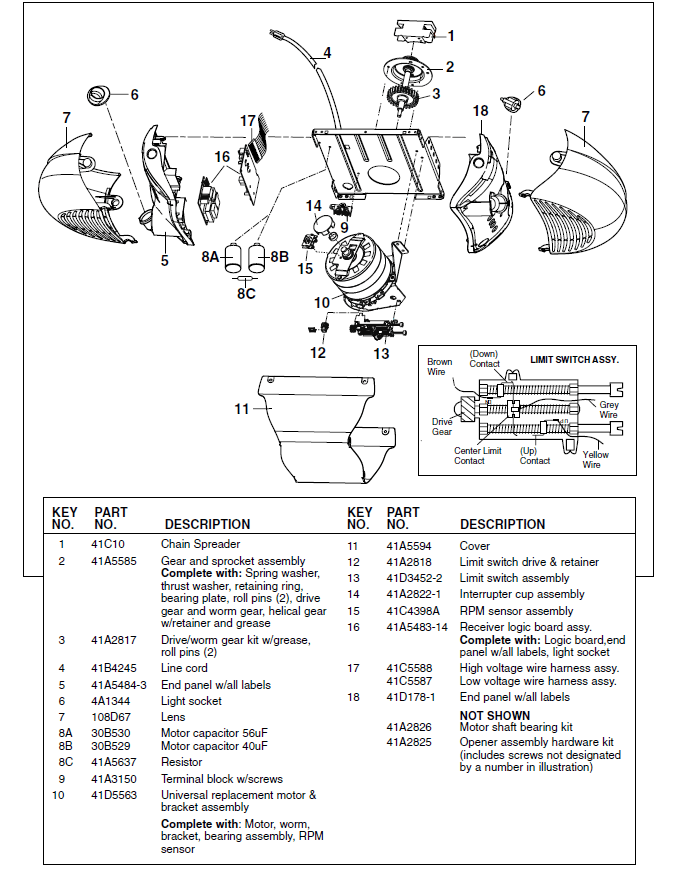

REPAIR PARTS

Motor Unit Assembly Parts

For more manuals by Craftsman, visit ManualsLibraryy

Craftsman 1395399 Garage Door Opener-FAQs

Why does my Craftsman garage door opener keep tripping?

1. Check the circuit breaker or fuse for a reset.

2. Inspect and replace remote batteries if needed.

3. Reprogram the remote or wall switch to fix the issue.

Why is my Craftsman garage door opener clicking?

1. Clicking sounds often indicate the opener is in lock mode.

2. Check the wall control station for a lock button or switch that might have been accidentally activated.

Why does my Craftsman garage door opener light stay on?

1. The light button on the Multi-Function door control may have been pressed accidentally.

2. Alternatively, the logic board or door control circuit could be faulty.

How do I adjust my garage door limiter?

1. Locate the “Up” limit switch adjuster on the opener.

2. Use a screwdriver to turn the adjuster clockwise for every three inches the door needs to travel.

3. Test and readjust as necessary.

How can I program a garage door opener without a remote?

1. Locate the garage door opener control panel in your car.

2. Press and hold the “Program” button on the panel until a light flashes, following your car manual instructions.

How do I deactivate a garage door opener?

Press and hold the colored Smart Button (green, red, orange, yellow, or purple) on the motor housing for several seconds. This will disconnect all remotes currently paired.

Why does my Craftsman garage door keep opening?

1. Check for dirty, blocked, or misaligned sensor eyes.

2. Ensure the wheels are not binding in the tracks.

3. Inspect for stuck buttons or frayed low-voltage wires leading to the sensors or wall controls.

How do I stop my garage door opener from making noise?

1. Apply white lithium grease to the gears.

2. If noise persists, consider installing a Vibration Reduction Kit (041A8420) or Vibration Isolator (G89LM).

Why does my garage door opener click but not move?

1. The motor could be worn out or have a broken part.

2. A common issue is a broken main gear drive that requires replacement.

How do I keep my garage door opener light on?

1. Use the Smart Control Panel to adjust light settings.

2. Set the light duration to stay on for 1-1/2 to 4-1/2 minutes.

3. Toggle the motion detection and entry light features as needed.

ONE-PIECE DOOR INSTALLATIONS

ONE-PIECE DOOR INSTALLATIONS