Craftsman 88957-179-CC 2-Stage Snow Thrower

SAFETY INSTRUCTIONS

- Use only an approved gasoline container.

- Extinguish all cigarettes, cigars, pipes, and other sources of ignition.

Never fuel a machine indoors. - Never remove the gas cap or add fuel while the engine is hot or running.

- Allow the engine to cool for at least two minutes before refueling.

- Neveroverfill fueltank. Fill the tank to no more than 1/2 inch below the bottom of the filler neck to provide space for fuel expansion.

- Replace the gasoline cap and tighten securely.

- If gasoline is spilled, wipe it off the engine and equipment.

Move the machine to another area. Wait 5 minutes before starting the engine. - The machine or fuel container inside where there is an open flame, spark pilot light (e.g., furnace, waterheater,spaceheater,clothesdryer, etc.).

- Allow the machine to cool for at least 5 minutes before storing.

- Never fill containers inside a vehicle on a truck trailer bed with a plastic liner. Always place containers on the ground away from your vehicle before filling.

- If possible, remove gas-powered equipment from the truck trailer and refuel on the ground. If this is not possible, then refuel such equipment on a trailer with a portable container, rather than from a gasoline dispenser nozzle.

- Keep the nozzle in contact with the rim of the fuel tank or

container opening at all times until fueling is complete. Do

not use a nozzlelock-open device.

OPERATION

- Do not put hands or feet near rotating parts, in the auger/impeller housing, or chute assembly. Contact with the rotating part can Amputate hands and feet.

- The auger/impeller control lever is a safety device. Never bypass its operation. Doing so makes the machine unsafe and may cause personal injury.

- The control levers must operate easily in both directions and automatically return to the disengaged position when released.

- Never operate with a missing or damaged chute assembly. Keep

All safety devices are in place and working. - Never run an engine indoors or in a poorly ventilated area. Engine Exhaust contains carbon monoxide, an odorless and deadly gas.

- Does the influence of alcohol or drugs? The muffler and engine become hot and can cause a burn. Do not touch. Keep children away.

ASSEMBLY

REMOVING FROM THE CARTON

- Cut the corners of the carton and lay the sides flat on the ground. Remove and discard all packing inserts.

- Move the snowthrower out of the carton.

- The carton has been completely emptied before discarding it.

LOOSE PARTS

Two replacement auger shearpins are included included the handle panel. Refer to the Operation section for more information regarding shear pin replacement.

ASSEMBLY

- Place the shift lever in the Forward-6position.

- Observe the lower rear area of the snowthrower to be sure both

cables are aligned with roller guides before pivoting the handle

upward. See Figure 1.

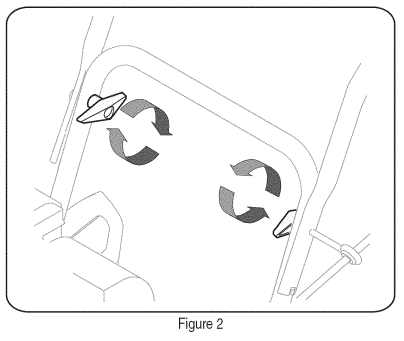

- Secure the handle by tightening the plastic wing knob located on both the left and right sides of the handle.SeeFigure2. Remove and discard rubber bands, if present. They are for packaging purposes only.

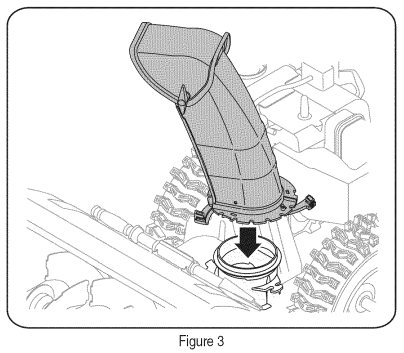

- Position the chute assembly over the base. See Figure 3.

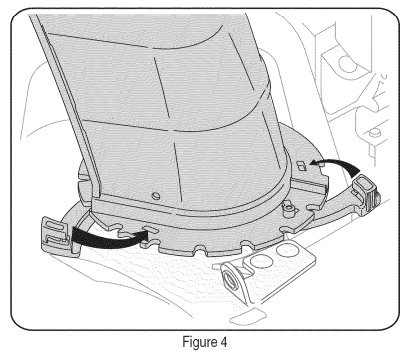

- Close the flange keepers to secure the chute assembly to the chute base.SeeFigure4. The flangekeepers will click into place when properly secured.

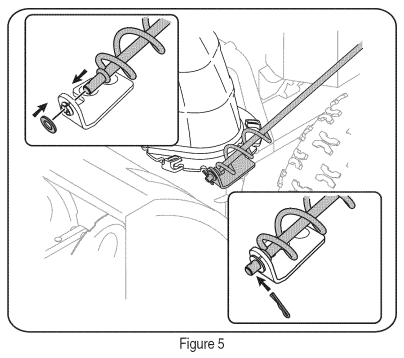

- a.Remove the flat washer and hairpin clip from the end of the

chute directional control.- b.Insert the end of the chutedirectional control into the lower bracket and secure with the flat washer and hairpin clip just removed. See Figure 5. If necessary, the lower bracket can be adjusted. Refer to Chute Bracket Adjustment in the Service& Maintenance Section.

SET-UP

Chute Clean-Out Tool

A chute clean-out tool is fastened to the top of the auger housing with a mounting clip.SeeFigure6. The tool is designed to clear the chute assembly of ice and snow. This item is fastened with a cable tie at the factory. Cut the cable and tie the snowthrower.

Tire Pressure

The tires are over-inflated for shipping purposes. Check the tire

Pressure before operating the snowthrower. Refer to the tire sidewall

fortiremanufacturer’srecommendedpsianddeflate(or inflate)the

tires as necessary

ADJUSTMENTS

Skid Shoes

The snow thrower skids are adjusted upward at the factory for

shipping purposes. Adjust them downward, if desired, before operating the snowthrower.

- For close snow removal on a smooth surface, raise kids’ shoes

higher on the auger housing. - Use a middle or lower position when the area to be cleared is uneven, such as a gravel driveway

To adjust the skid shoes:

- Loosen the four hex nuts (two on each side) and carriage bolts.

Moveskidshoesto the desired position. SeeFigure7. - Make certain the entire bottom surface of the skid shoe is against the ground to avoid uneven wear on the skid shoes.

- Refit nuts and bolts securely.

Chute Assembly

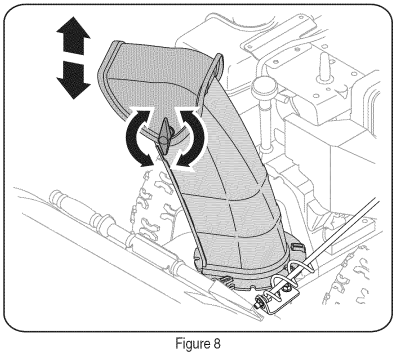

The distances now can be adjusted by changing the angle of the chute assembly. Todo so:

- Stop the engine by removing the ignition key, and loosen the

plastic wing knob found on the left side of the chute assembly. - Pivot the chute upward or downward before tightening the wing knob. See Figure 8

Check the adjustment of the auger control as follows:

- When the auger control is released and in the disengaged”up” position, the cable should have very little slack.ItshouldNOTbe

tight. - In a well-ventilated area, start the snowthrower engine. Refer to Starting the Engine in the Operation section.

- The position (behind the snow thrower). Engage the auger.

- Allow the audience to remain engaged for approximately ten (10) seconds before releasing the auger control. Repeat this several times.

- With the auger control in the disengaged ngaged d”up” position, walk to the front of the machine.

- Confirm that the auger has completely stopped rotating and

shows no signs of motion. If the auger shows ANY signs of

rotating, immediately return to the operator’s position and shut off. The engine. Wait for ALL moving parts to stop before adjusting the auger control. - To adjust the control cable, loosen the upper hex bolt on the

auger cable bracket. SeeFigure9. - Position bracket upward to provide more slack (or downward

to increase cable tension. - Retighten the upper hex bolt.

- Repeat steps 2-6 above to verify proper adjustment has been

achieved.

OPERATION

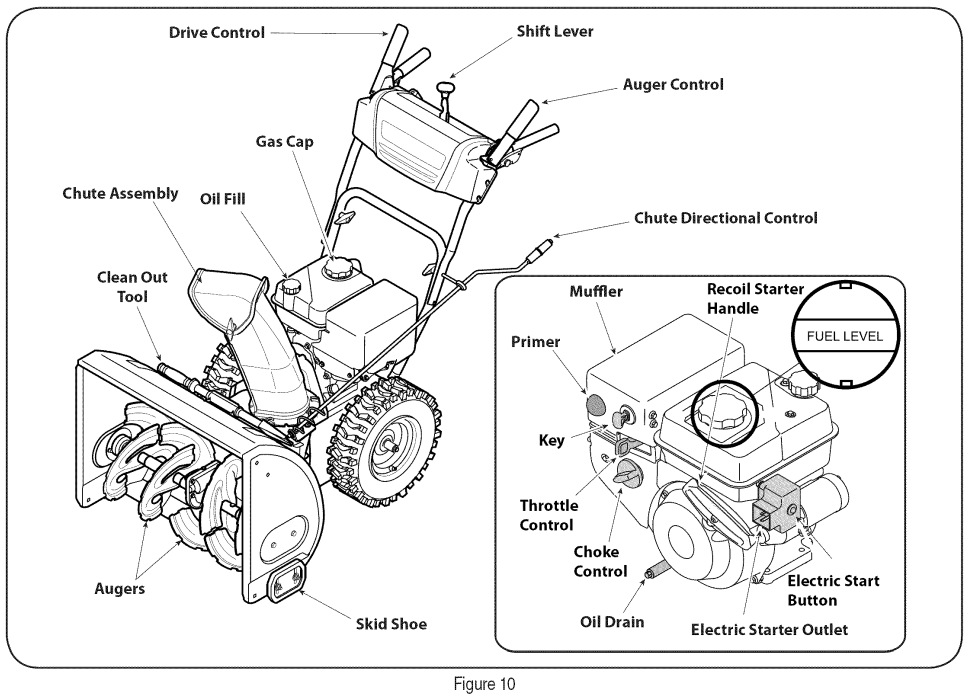

Now that you have set up your snow thrower, it’s important to become acquainted with its controls and features. Refer to Figure 10.

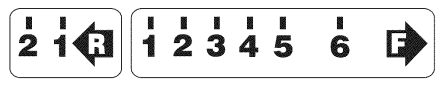

SHIFT LEVER

The shift lever is located on the dashboard. Place the shift lever into

any of the eight positions to control the direction of travel and ground

speed

Forward

Your snow thrower has six forward (F) speeds. Position one (1) is the

slow estand position six(6) is the fastest.

Reverse

Your snow thrower has two reverse(R) speeds.One(1)is the slower

and two(2) is the faster

KEY

The key is a safety device. It must be fully inserted for the engine to start. Remove the key when the snow thrower is not in use.

CHOKE CONTROL

The choke control is found on the rear of the engine and is activated by turning the rotary choke knob to the CHOKE position.Activating the choke control closes the choke plate on The carburetor aids in starting the engine.

THROTTLE CONTROL

The throttle control is located on the rear of the engine. It regulates the speed of the engine and shuts it off when the engine when moved into the OFF position.

Primer

Depressing the primer forces fuel directly into the carburetor to aid in cold-weather starting

RECOIL STARTER HANDLE. HANDLE This handle is used to manually start the engine.

ELECTRIC STARTER BUTTON: Pressing the electric 120V power source

ELECTRIC STARTER OUTLET: Requires the use of a three-prong outdoor extension cord (included) and a 120V power source/wall outlet.

OIL FILL: Engine oil level can be checked and oil added through the oil fill.

GAS CAP: Unthread the gas cap to add gasoline to the fuel tank.

CLEAN-OUT TOOL

The chute clean-out tool is conveniently fastened to the rear of the auger housing with a mounting clip. Should snow and ice become

lodged in operation, proceed as follows to safely clean the chute assembly and chute opening

- Release both the Auger Control and the Drive Control.

- Stop the engine by removing the ignition key.

- Remove the clean-out tool from the clip that secures it to the

rear of the auger housing. - Use the shovel-shaped clean-out tool to dislodge and scoop any snow and ice that has formed in and near the chute assembly.

- Refasten the clean-out tool to the mounting clip on the rear of the auger housing, reinsert the ignition key, and start the snow thrower’s engine.

- While standing in the position n(behind the snow thrower), engage the auger control for a few seconds to clear any

remaining snow and ice from the chute assembly.

BEFORE STARTING THE ENGINE

Oil

The unit was shipped with oil in the engine. Check the oil level before

Each operation is to ensure adequate oil in the engine. Forfurther

Instructions: refer to the stepson page 16

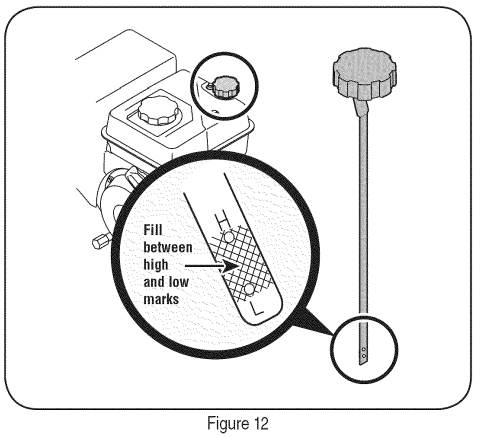

- Remove the oil filler dipstick, and wipe the dipstick clean.

- Insert the cap/dipstick into the oil filler neck, but do NOT screwit in.

- Remove the oil filler cap/dipstick if the level is low, slowly add

oil (5%30, with a minimum classification of SF/SG) until the oil level register between high (H) and low (L). - Replace and tighten the cap/dipstick firmly before starting the engine.

Gasoline

Use automotive gasoline (unleaded or low-leaded) with a minimum of 87 octane. Gasoline with up to 10% ethanol or 15% MTBE (Methyl Tertiary Butyl Ether) can be used. Never use an oil/gasoline mixture or dirty gasoline. Avoid getting dirt, dust, or water in the fuel tank. DO NOT use E85 gasoline.

STARTING THE ENGINE

- Make certain both the auger control and drive control are in the

disengaged (released) position. - Insert the key into the slot. Make sure it snaps into place. Do not attempt to turn the key.

Electric Starter

Determine that your home’s wiring is a three-wire grounded system.

Ask a licensed electrician if you are not certain. If you have a grounded three-prong receptacle, proceed as follows. If you do not have the proper house wiring, DO NOT use an electric starter under any conditions.

- Plug the extension cord into the outlet located on the engine’s

surface. Plug the other end of the extension cord into a three-prong outlet

120-volt, grounded, AC outlet in a well-ventilated area - Move to FAST(rabbit)_T position.

- Move the CHOKEIJL position(cold engine start). If the engine is a warplace choke in the RUN position.

- Push the primer three (3)times, making sure to cover the vent hole in the primer bulb when pushing. The engine is warm, push the primer only once. Always cover the vent hole when pushing. Cool weather may require priming to be repeated.

- Push the starter button to start the engine. Once the engine starts, immediately release the starter button. The electric starter is equipped with real overload protection; the system will temporarily shut down to allow the starter to cool if the electric starter becomes overloaded.

- As the engine warms, slowly rotate the choke control to the RUN position. If the engine fails, restart the engine and run with a choke in a half-choke position for a short period, and then slowly rotate the choke into the RUN position.

- After the engine is running,disconnectpowercordfromelectric

starter. When disconnecting the end at the wall outlet, disconnect the opposite end from the engine.

Recoil Starter

- Move throttle control to FAST (rabbit)_J_ position.

- Move the CHOKEI,’_¢1position(cold engine start). If the engine is warm, place the choke in the RUN position.

- Push the primer three (3)times, making sure to cover the vent hole when pushing. If the engine is warm, push the primer only once. Always cover the vent hole when pushing. Cool weather may require priming to be repeated.

- Pull gently on the starter handle until it begins to resist. He pulls quickly and forcefully to overcome the compression. The handle to snap back. Return the rope SLOWLY to the original position. If required, repeat this step.

- As the engine warms, slowly rotate the choke control to the RUN position. If the engine fails, restart the engine and run with the choke at half-choke position for a short period, and then slowly rotate the choke into the RUN position.

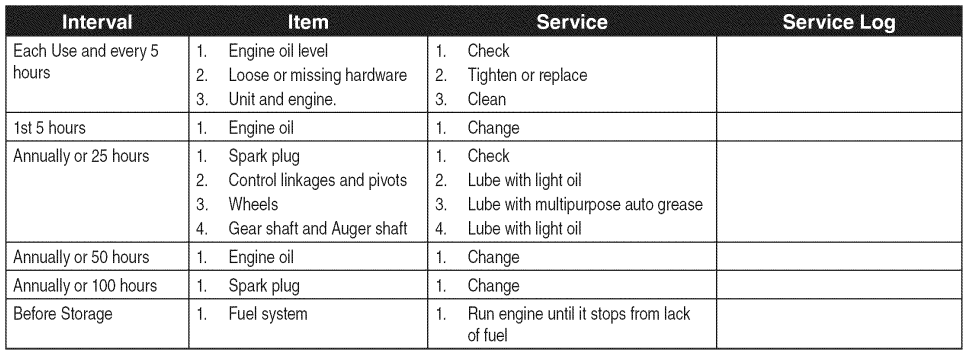

Service and maintenance

ENGINE MAINTENANCE

Checking Engine Oil

When adding oil to the engine, refer to the viscosity chart below. Engine oil capacity is 600ml (approx.20 oz.). Do not overfill. Use a 4-stroke, an equivalent high detergent, premium quality motor oil certified to meet or exceed U.S. automobile manufacturers’ requirements for service classification SG, SR Motor oils classified SG, SF will show this designation on the container.

- Remove the oil-filled dipstick, and wipe the dipstick clean.

- Insert the cap dipstick into the oil filler neck, but do NOT screwit in.

- Remove the oil filler cap/dipstick level is low, slowly add oil until the oil level registers between high (H) and low (L).SeeFigure12.

- Replace and tighten the cap/dipstick firmly before starting the engine

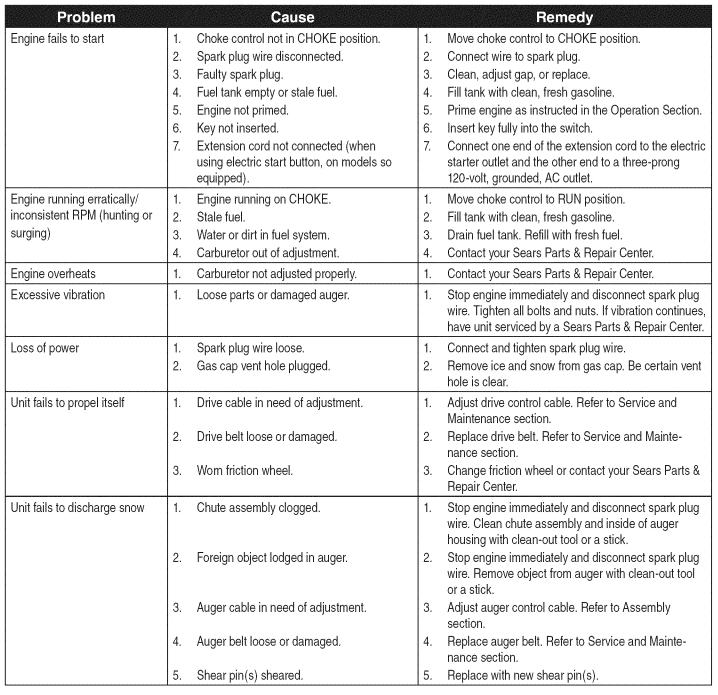

TROUBLESHOOTING

FOR MORE MANUALS BY CRAFTSMAN, VISIT MANUALSLIBRARYY

Craftsman 88957-179-CC 2-Stage Snow Thrower-FAQs

What type of fuel should I use?

Unleaded gasoline (87+ octane, ≤30 days old).

Avoid ethanol blends >10% (E15/E85 can damage the engine).

Use fuel stabilizer for storage.

What oil does my Craftsman snow blower need?

5W-30 conventional oil (check manual for exact specs).

Change oil annually or every 25-50 hours of use.

How do I operate the snow blower safely?

Wear safety glasses & gloves.

Start on cleared ground.

Engage auger first, then drive control.

Discharge chute away from people/objects.

How much snow can it handle?

12–21 inches of dry snow.

8–12 inches of wet/heavy snow (may require slower passes).

How do I maintain my snow blower?

Check shear bolts (replace if broken).

Lubricate auger bearings & cables.

Inspect skid shoes & scraper bar (adjust/replace if worn).

Store with empty fuel tank (or use stabilizer).

Why won’t my snow blower start?

Common fixes:

Old fuel → Drain & refill.

Clogged carburetor → Clean with carb spray.

Faulty spark plug → Replace annually.

Dead battery (if electric start) → Recharge or replace.

Should the choke be open or closed when starting?

Closed (full choke) for cold starts.

Open (no choke) once warmed up.

Leaving choke on too long floods the engine.

Can I use it on gravel or uneven surfaces?

Yes, but adjust skid shoes to prevent gravel from being thrown.

Keep auger slightly elevated to avoid picking up debris.

What’s the difference between a snow blower and snow thrower?

Snow thrower (single-stage): Light snow, auger-only.

Snow blower (2-stage): Heavy snow, auger + impeller for greater power.