Garmin LiveScope Plus LVS34 Transducer

Important Safety Information

To obtain the best performance and to avoid damage to your boat, you must install the Garmin® device

according to these instructions. Read all installation instructions before proceeding with the installation. If you experience difficulty during the installation, go to support.garmin.com for more information.

Software Update

You must update the Garmin chartplotter software when you install this device. For instructions on updating the software, see your chartplotter owner’s manual at support.garmin.com.

Installation Support Videos

You can view videos online for assistance when installing this device. You can access the videos by going to garmin.com/videos/lvs34 in your web browser or by scanning this QR code with your smartphone.

Tools Needed

- Drill

- Drill bit suitable for the GLS™ 10 sonar module selected mounting hardware and surface

- Flat screwdriver or 8 mm wrench or socket to install the barrel mount clamp

- Electrical tape (preferred) or cable ties

Parts Bags

The installation hardware for the transducer is included in labeled bags. As you complete the installation process, each procedure begins with a reference to the label on the parts bag needed to complete the procedure. You can use this table to review or verify the parts bags needed for the installation procedures.

NOTE: You should leave all parts in the labeled bags until you are instructed to open a bag in the instructions. Not all hardware is used for all installation types.

| Contains parts needed when installing the perspective mount | |

| B | Contains parts needed when installing the perspective or shaft mount |

| C | Contains parts needed when installing the perspective, shaft, or barrel mount |

| D | Contains parts needed when installing the barrel mount |

| E | Contains parts needed when installing the shaft mount |

| F | Contains the optional low-profile mounting screws |

Mounting Considerations

NOTICE

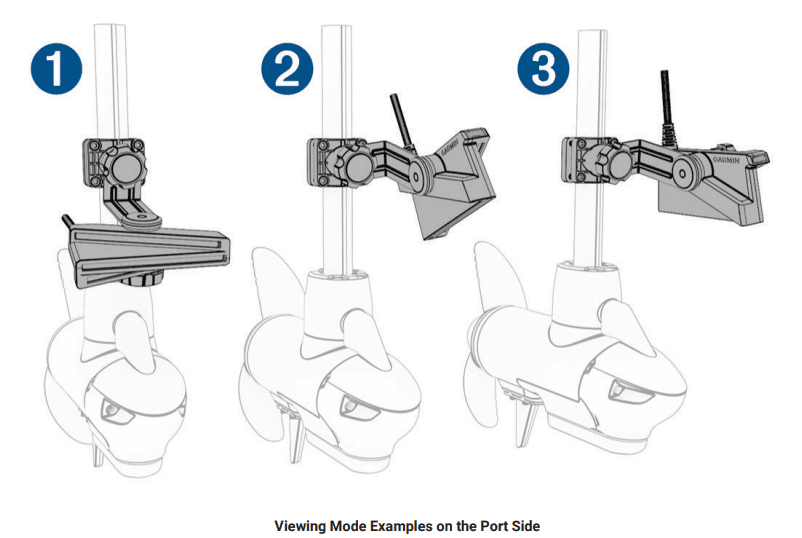

The use of third-party or self-fabricated mounts could lead to transducer damage or loss. Damage or loss sustained when using a third-party or self-fabricated mount is not covered under warranty. Using the hardware supplied, you can mount the transducer on your trolling motor in one of three ways

- Perspective Mount (Installing the Transducer on the Perspective Mode Mount, page 5)

- You can mount the transducer on the trolling motor shaft using the perspective view mount and bracket.

- When using the perspective view bracket, the transducer can be used for perspective, downward, and forward views.

- Barrel Mount (Installing the Transducer on a Trolling Motor Barrel, page 9)

- You can mount the transducer on either side of the trolling motor barrel.

- When mounted on the barrel, the transducer can be used for downward and forward views.

- When mounted on the barrel, the transducer cannot be used for perspective view.

- Shaft Mount (Installing the Transducer on the Trolling Motor Shaft, page 12)

- You can mount the transducer on either side of the trolling motor shaft.

- When mounted directly on the shaft, the transducer can be used for downward and forward views.

- When mounted directly on the shaft, the transducer cannot be used for a perspective view.

- Mounting the transducer directly on the shaft allows a lower-profile installation than using the perspective-mount bracket. When planning the installation, you should observe these considerations.

- You must angle the transducer correctly for the selected view to work properly.

- Installing the transducer with the included knobs allows for tool-free transitions between sonar views.

- You can use the included low-profile hardware instead of the knobs for a more permanent transducer view position.

- You should mount the transducer in a location where it will not be jarred when launching, hauling, or storing.

- You must install the sonar module in a location with adequate ventilation where it will not be exposed to extreme temperatures.

- You should mount the sonar module in a location where the LEDs are visible, where the cables can be connected, and where the device will not be submerged.

Cable Considerations

NOTICE: Zip ties and cable clamps can over-tighten and damage or break the cable, or cause cable fatigue due to repeated rotation of the motor.

You should use black electrical tape to secure the cable above and below the rotating joint. If you secure the cable with zip ties, do not over-tighten the zip ties. You should secure the cable above and below the pivot joint of your trolling motor.

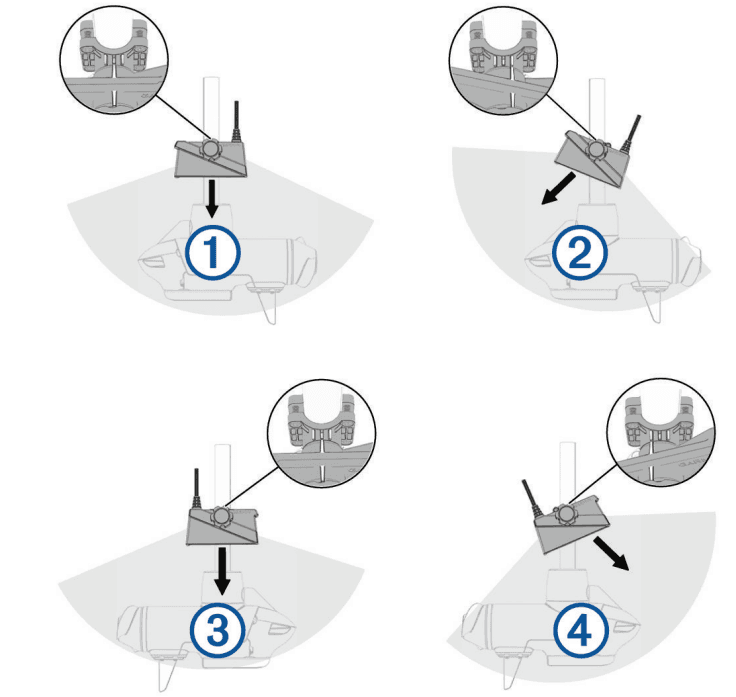

Routing the Transducer Cable

You should test-fit the transducer and cable before installation.

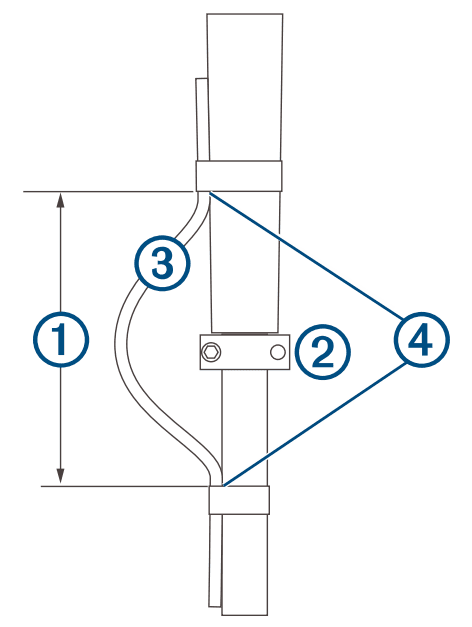

- Allow a loose gap of at least 10 cm ( 4 in.) above and 10 cm (4 in.) 1 below the rotating joint to 2 create a loop 3 in the cable. The loop must be large enough to allow full rotation of the transducer in both directions. Allow a minimum of 25 cm (10 in.)of cable to cover the 20 cm (8 in.) section between mounting points.

- Use black electrical tape 4 to secure the transducer cable to the shaft.

- Test the full rotation of the trolling motor to ensure the cable clears the rotating joint and is not pulled tight due to tension during rotation.

Installing the Ferrite Bead on the Transducer Cable

NOTICE: To comply with FCC regulations, and with similar regulations of other countries if applicable, and to reduce electromagnetic interference (EMI) or “noise,” you should install a ferrite bead on each transducer cable.

- Position the included ferrite bead on the transducer cable, near the connector.

- Snap the ferrite bead securely around the transducer cable.

Using the Optional Split Collar

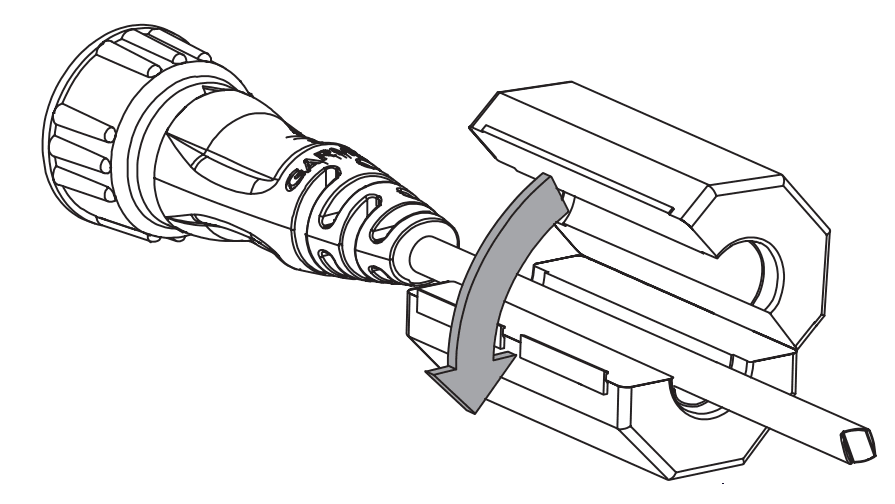

If you plan to drill a hole or need to route the cable through a tight space during installation, you can remove the existing solid locking collar on the cable before routing it. After routing the cable to the final location, you can install the included split locking collar before making the connection.

- Use side-cutting pliers to cut through the existing solid collar.

NOTE: Take care when cutting the existing collar to avoid damaging the cable or the connector. - Remove the solid collar from the cable connector and save the existing o-ring if it is not damaged.

- Route the cable to the connection location.

- If needed, separate the two pieces of the optional split collar.

- Snap the pieces together around the cable connector.

- Insert either the original o-ring or the included replacement o-ring around the connector and into the collar.

Installing the Transducer on the Perspective Mode Mount

Labels identifying the parts bags required for this procedure: A,B,C

NOTE: To avoid obstructions in the sonar image, you should mount the transducer on the shaft as far from the motor as possible.

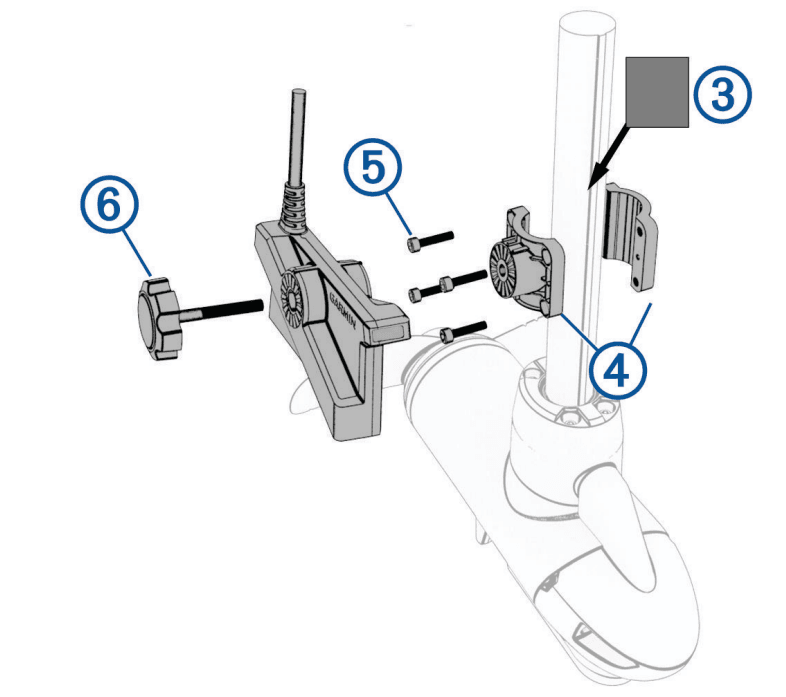

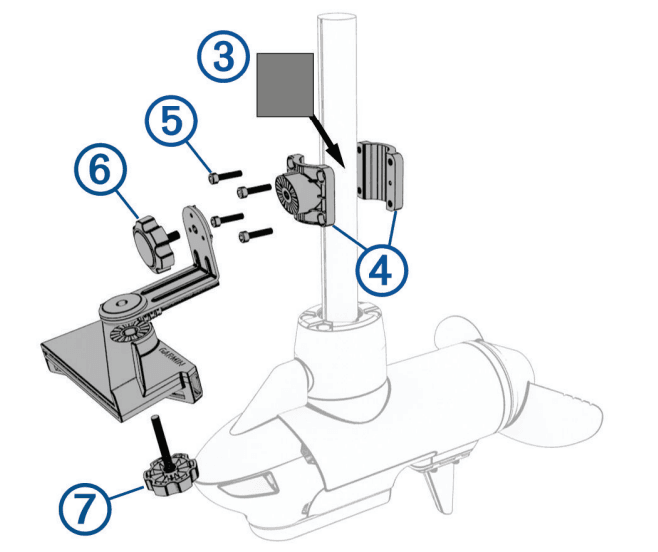

- Remove the perspective mode extension arm, the front half of the mounting bracket, and the short knob from the parts bag A.

- Remove the back half of the mounting bracket and four screws from parts bag B .

- Remove the long knob from parts bag C.

- If the trolling motor shaft is equal to or less than 25 mm (1 in.) in diameter, remove the rubber liner from parts bag C.

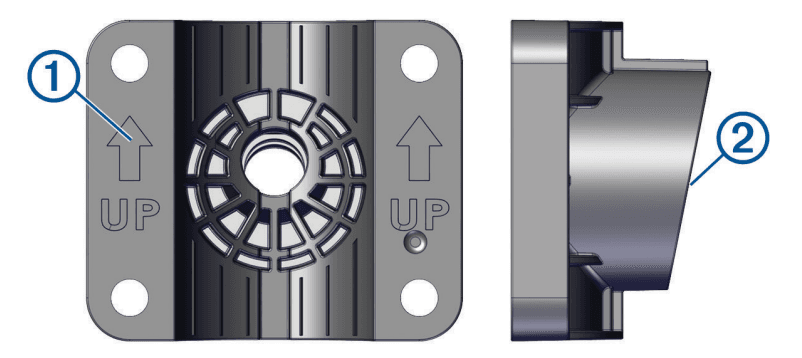

- Identify arrow 1 on the front half of the mounting bracket to ensure that you orient the bracket with the wide end of slant 2 at the top when you attach the bracket to the trolling motor shaft.

NOTE: The perspective mode bracket has an 11-degree angle to allow the extension arm to transition between all three sonar views.

NOTE: The perspective mode bracket has an 11-degree angle to allow the extension arm to transition between all three sonar views. - If you are installing the transducer on a trolling motor shaft equal to or less than 25 mm (1 in.) in diameter,wrap the rubber liner 3 around the shaft in the location you want to install the mount.

NOTE: The rubber liner is not needed when installing the transducer on a trolling motor with a shaft diameter larger than 25 mm (1 in.).

NOTE: The rubber liner is not needed when installing the transducer on a trolling motor with a shaft diameter larger than 25 mm (1 in.). - Orient the mounting bracket 4 on the shaft so the arrows on the inside of the front half of the bracket point up. The bracket should be aligned so the center screw hole faces the front of the trolling motor.

- Place the bracket around the rubber liner on the trolling motor shaft, insert the screws 5 into the mount bracket, and secure them using the M5 hex wrench in parts bag C.

- (Optional) Transition the trolling motor from the deployed to the stowed position and back again to test the location of the mounting bracket and make any adjustments as needed.

- With the 90-degree angle pointing downward, attach the shorter length of the extension arm to the mounting bracket using the shorter knob 6.

- Place the transducer below the longer length of the extension arm and attach it using the longer knob 7.

NOTE: You can secure the extension arm to the mounting bracket and the transducer to the extension arm using the included low-profile hardware instead of the knobs if you do not plan to switch transducer modes frequently during use (Installing the Transducer Using Low Profile Mounting Hardware, page 16). - Secure the transducer cable to the motor shaft or other secure location.

- Route the transducer cable to the installation location of the sonar module while taking these precautions.

- You must route the cable so that it does not come in contact with the propeller when the trolling motor is operating.

- You should not route the cable close to electrical wires or other sources of electrical interference.

- You must route the cable so it is not pinched when the trolling motor is deployed or stowed.

NOTE: If necessary, for extra cable length you can connect an optional extension cable, available at buy.garmin.com or from your Garmin dealer.

- Position the transducer to your desired angle (Viewing Modes, page 7).

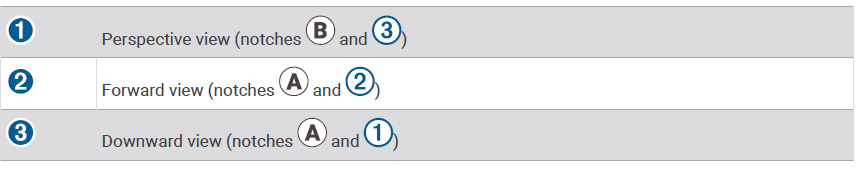

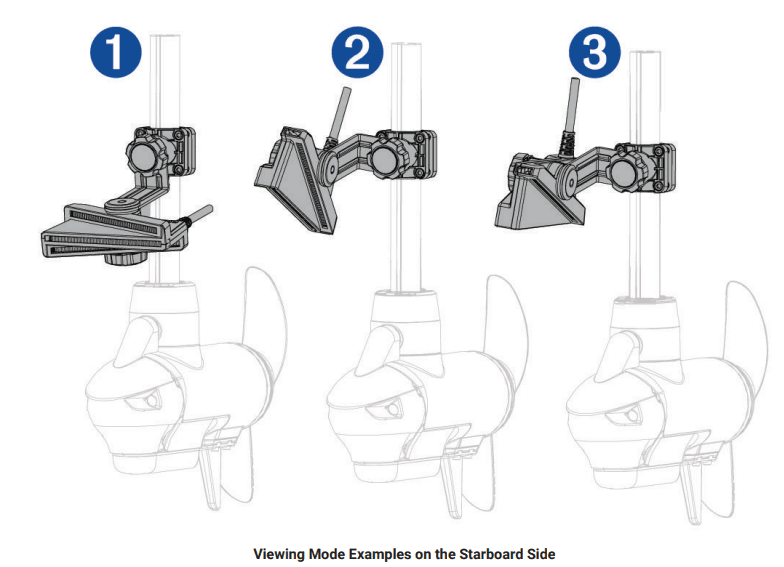

Viewing Modes

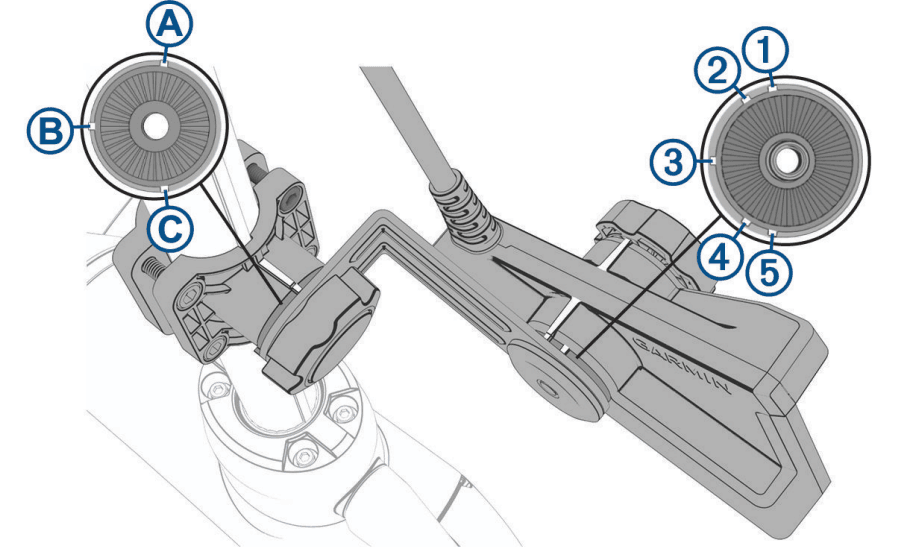

Using the perspective mode mount and extension arm, you can change the orientation angle of the transducer between three sonar views. When installing the transducer using the recommended adjustment knobs, no tools are necessary to change the orientation between these three fields of view. You must loosen the knobs to change the orientation of the arm and transducer, and tighten them to set the orientation. You can verify the sonar view using the notches on the perspective mount bracket, the shaft mount, and the transducer.

NOTE: The notches are not labeled on the transducer hardware, so you can use these tables and diagrams to understand the positioning of the transducer and perspective view bracket when changing between sonar views.

| A and 1 Port downward view | |

| A and 2 | Port forward view |

| B and 3 | Perspective view |

| C and 4 | Starboard forward view |

| D and 5 | Starboard downward view |

You should align the marks on the transducer and extension arm to verify the appropriate orientation before tightening the knob.

You should align the marks on the transducer and extension arm to verify the appropriate orientation before tightening the knob.

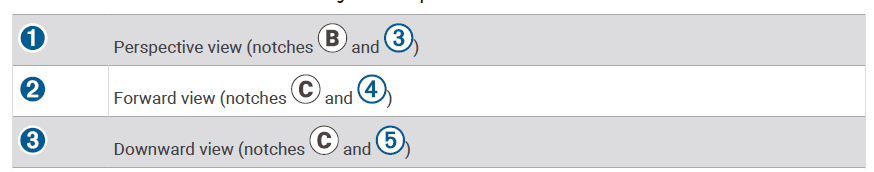

Trolling Motor Barrel Mount Orientation

The orientation angle depends on which side of the trolling motor you have mounted the transducer on, and your desired field of view. When installing the transducer using the recommended adjustment knob, no tools are necessary to change the orientation from forward to downward, or vice versa. You must loosen the knob to change the orientation and tighten it to set the orientation.

NOTE: You should align the marks as shown on the transducer and mount to verify the appropriate orientation before tightening the knob.

| 1 Port side, downward view | |

| 2 | Port side, forward view |

| 3 | Starboard side, downward view |

| 4 | Starboard side, forward view |

Installing the Transducer on the Trolling Motor Shaft

Labels identifying the parts bags required for this procedure:

NOTE: To avoid obstructions in the sonar image, you should mount the transducer on the shaft as far from the motor as possible.

- Remove the back of the shaft-mount bracket and four screws from the parts bag B.

- Remove the front half of the shaft mount bracket from the parts bag E.

- If the trolling motor shaft is equal to or less than 25 mm (1 in.) in diameter, remove the rubber liner from the parts bag C.

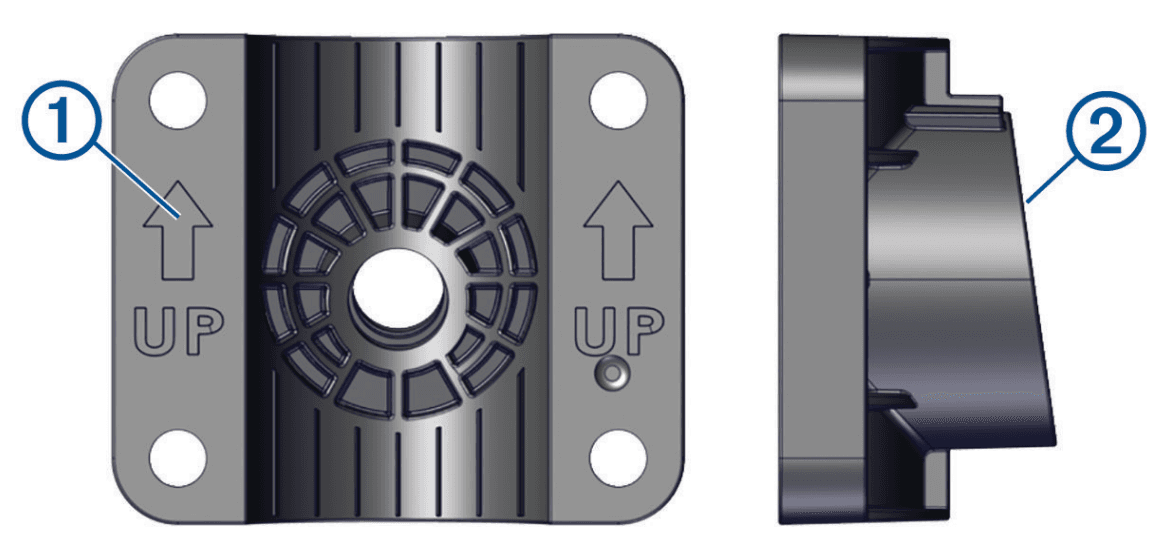

- Identify arrow 1 on the front half of the shaft mount bracket to ensure that you orient the bracket with the narrow end of angle 2 at the top when you attach the bracket to the trolling motor shaft.

NOTE: The trolling motor shaft bracket has an 8-degree angle to reduce the effects of the trolling motor barrel interference with the transducer beam.

NOTE: The trolling motor shaft bracket has an 8-degree angle to reduce the effects of the trolling motor barrel interference with the transducer beam. - If you are installing the transducer on a trolling motor shaft equal to or less than 25 mm (1 in.) in diameter, wrap the rubber liner 3 around the shaft in the location you want to install the mount.

NOTE: The rubber liner is not needed when installing the transducer on a trolling motor with a shaft diameter larger than 25 mm (1 in.). - Place the shaft-mount bracket 4 around the rubber liner on the trolling motor shaft.

- Insert the screws 5 into the shaft mount bracket and secure them using the M5 hex wrench in parts bag C.

- (Optional) Transition the trolling motor from the deployed to the stowed position and back again to test the location of the mounting bracket and make any adjustments as needed.

- Remove the knob from parts bag C.

- Attach the transducer to the mount using the knob 6, and tighten the knob by hand.

NOTE: You can secure the transducer to the mount using the included low-profile hardware instead of the knob if you do not plan to switch transducer modes frequently during use (Installing the Transducer Using Low Profile Mounting Hardware, page 16). - Secure the transducer cable to the motor shaft or other secure location.

- Route the transducer cable to the installation location of the sonar module while taking these precautions.

- You must route the cable so that it does not come in contact with the propeller when the trolling motor is operating.

- You should not route the cable close to electrical wires or other sources of electrical interference.

- You must route the cable so it is not pinched when the trolling motor is deployed or stowed.

NOTE: If necessary, for extra cable length you can connect an optional extension cable, available at buy.garmin.com or from your Garmin dealer.

- Position the transducer to your desired angle, and tighten the knob (Installing the Transducer on the Trolling Motor Shaft, page 12).

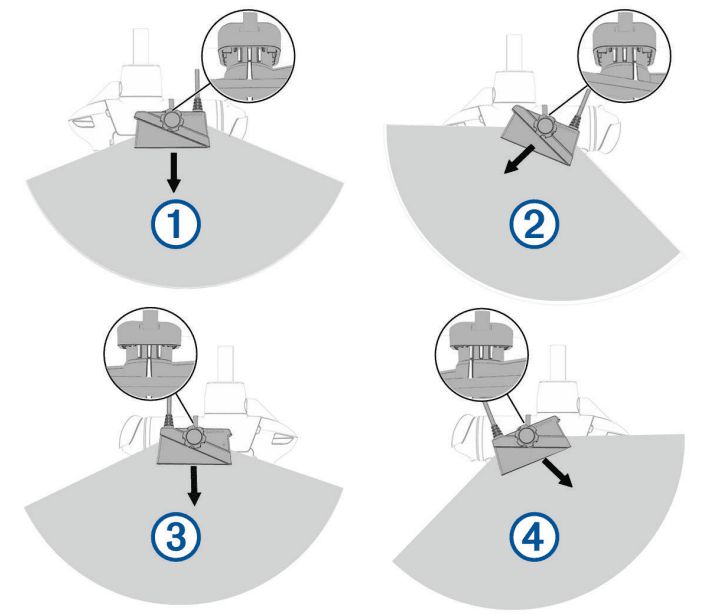

Trolling Motor Shaft Mount Orientation

The orientation angle depends on which side of the trolling motor shaft you mount the bracket on, and your desired field of view. When installing the transducer using the recommended adjustment knob, no tools are necessary to change the orientation from forward to downward, or vice versa. You must loosen the knob to change the orientation and tighten it to set the orientation.

NOTE: You should align the marks as shown on the transducer and mount to verify the appropriate orientation before tightening the knob.

| 1 Port side, downward view | |

| 2 | Port side, forward view |

| 3 | Starboard side, downward view |

| 4 | Starboard side, forward view |

Installing the Transducer on a Pole

You can use the included hardware to install the transducer on a pole (not included). Installing the transducer on a pole is similar to installing the transducer on a trolling motor shaft. If needed, you can refer to the diagram provided for installing the transducer on a trolling motor shaft when installing the transducer on a pole (Installing the Transducer on the Trolling Motor Shaft, page 12).

NOTE: The included shaft bracket features an 8-degree angle to reduce the effects of the trolling motor barrel interference with the transducer beam. When installing the transducer on a pole, you can purchase a flat bracket with no angle if you prefer. See your Garmin dealer or go to buy.garmin.com for details. Labels identifying the parts bags required for this procedure: B, C, E

- Remove the back of the shaft-mount bracket and four screws from parts bag B.

- Remove the front half of the shaft mount bracket from parts bag E.

- If the pole is equal to or less than 25 mm (1 in.) in diameter, remove the rubber liner from parts bag C.

- If the pole is equal to or less than 25 mm (1 in.) in diameter, wrap a rubber liner around the location you want to install the mount.

- Place the shaft-mount bracket around the rubber liner on the pole.

- Insert the screws into the shaft mount bracket, and secure them using the M5 hex wrench in the parts bag C.

- Remove the knob from the parts bag C.

- Place the transducer against the shaft-mount bracket, and secure it using the knob.

NOTE: You can secure the transducer to the mount using the included low-profile hardware instead of the knob if you do not plan to switch transducer modes frequently during use (Installing the Transducer Using Low Profile Mounting Hardware, page 16). - Secure the transducer cable to the pole or other secure location, and route the cable to the location of the sonar module.

LiveScope Plus LVS34 Specifications

| Dimensions (L x H x W) 161.7 x 77.5 x 47.8 mm (6.37 x 3.05 x 1.88 in.) | |

| Weight (transducer only) | 1018 g (2.25 lb.) |

| Frequencies | From 530 to 1,100 kHz |

| Operating temperature | From -10° to 40°C (from 14° to 104°F) |

| Storage temperature | From -40° to 85°C (from -40° to 185°F) |

| Maximum depth/distance | 61 m (200 ft.) |

| Field of view | Front to back: 135 degrees Side-to-side: 20 degrees |

For more manuals by Garmin, visit ManualsLibraryy

Garmin LiveScope Plus LVS34 Transducer-FAQs

Where should I mount my LiveScope transducer?

For best performance, mount the transducer as close to the boat’s centerline as possible. Avoid placing it in the path of the propeller, as this can interfere with sonar readings.

What is the maximum depth of the LVS34 transducer?

The LVS34 can reach a maximum depth of 61 meters (200 feet).

How far should the LiveScope transducer be from a trolling motor?

A good placement is 6 inches above the motor barrel, ensuring the transducer stays submerged even in rough waters.

What is the best placement for a transducer?

For thru-hull transducers, the best location is near the keel and transom where the water flow is smoothest. On outboard and sterndrive boats, install it close to the engine but ahead of it.

How many amps does the LiveScope LVS34 draw?

The LVS34 draws approximately 4.83A at 12V, with a typical power consumption of 58W.

Can I test my Garmin transducer out of water?

No, the transducer cannot read depth when the boat is out of the water.

Do I need to calibrate my Garmin LiveScope?

Yes, calibration is recommended for optimal performance. If not calibrated, the display may rock or bounce. In cases of interference, calibration may fail.

What is the range of the LVS34 transducer?

The LVS34 provides a clear view of up to 150 feet ahead, making it popular among anglers targeting crappie and bass.

NOTE: The perspective mode bracket has an 11-degree angle to allow the extension arm to transition between all three sonar views.

NOTE: The perspective mode bracket has an 11-degree angle to allow the extension arm to transition between all three sonar views. NOTE: The rubber liner is not needed when installing the transducer on a trolling motor with a shaft diameter larger than 25 mm (1 in.).

NOTE: The rubber liner is not needed when installing the transducer on a trolling motor with a shaft diameter larger than 25 mm (1 in.). NOTE: The trolling motor shaft bracket has an 8-degree angle to reduce the effects of the trolling motor barrel interference with the transducer beam.

NOTE: The trolling motor shaft bracket has an 8-degree angle to reduce the effects of the trolling motor barrel interference with the transducer beam.