Husqvarna Z 254 Zero Turn Mower

INTRODUCTION

INTRODUCTION

Driving and Transport on Public Roads

- Check applicable road traffic regulations before transporting on public roads. If the machine is transported, you must always use approved fastening equipment and ensure that the machine is well anchored. DO NOT operate this machine onpublic roadways.

Towing

- If machine is equipped with a tow hitch, use extreme caution when towing. Never allow children or others in or on the towed equipment. Make wide turns to avoid jack-knifing. Travel slowly and allow extra distance to stop.

- Do not tow on sloped ground. The weight of the towed equipment may cause loss of traction and loss of control. Follow the manufacturer’s recommendation for weight limits for towed equipment. Do not tow near ditches, canals, and other hazards.

Operating

- This machine is constructed only for mowing grass on lawns and even ground without obstacles such as stones, tree stumps, etc. The machine can also be used for other tasks when equipped with special accessories provided by the manufacturer. Operating instructions for the accessories are provided with delivery. All other types of uses are incorrect. The manufacturer’s directions concerning operation,

maintenance, and repairs must be carefully followed. Lawn mowers and all power equipment, can be potentially dangerous if used improperly. Safety requires good judgement, careful use by these instructions and common sense. - The machine must only be operated, maintained, and repaired by persons familiar with the machine’s special characteristics and who are also knowledgeable about the safety instructions. Use only approved repair parts to maintain this machine. Accident prevention regulations, other general safety regulations, occupational safety rules, and traffic regulations must be followed without fail. Unauthorized modifications to the design of the machine may absolve the manufacturer from liability for any resulting personal injury or property damage.

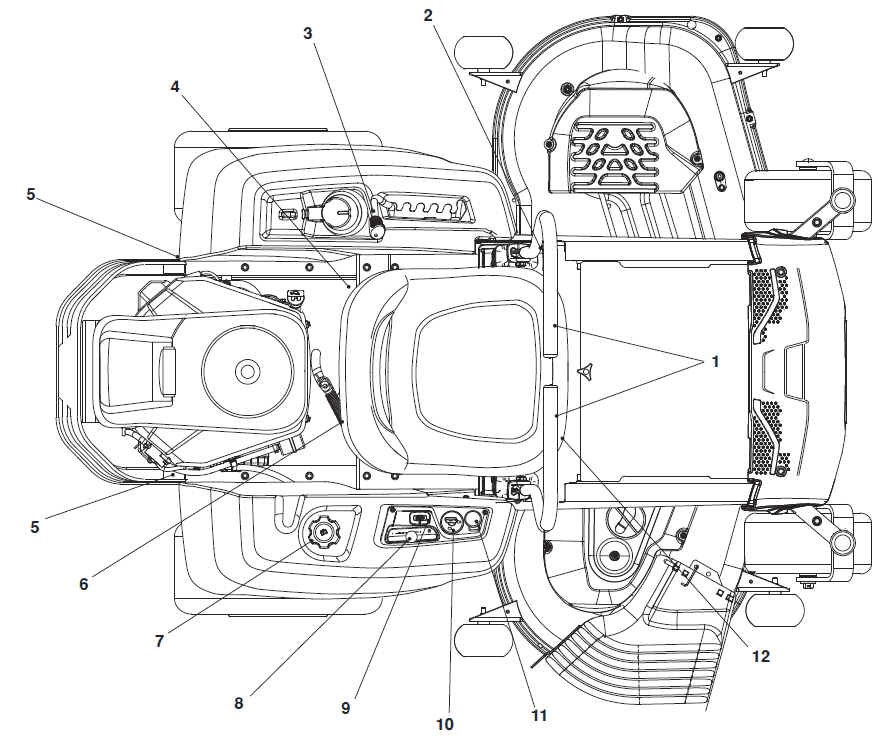

CONTROLS

- This operator manual describes the Husqvarna Zero Turn Rider. The rider is fitted with a Kohler four-stroke overhead valve engine.

- Transmission from the engine is made via a belt-driven hydraulic pumps. Using the left and right steering controls, the flow is regulates the direction and speed.

- Steering/Brake levers

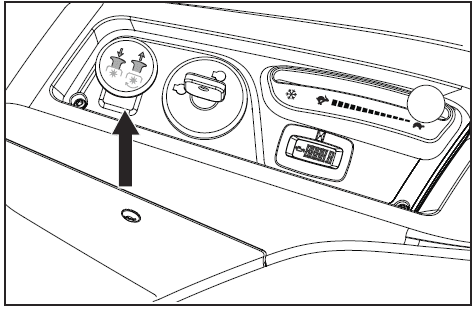

- Tracking adjustment, left side

- Deck lift

- Fuses

- Bypass linkages

- Fuel shut off valve

- Fuel tank

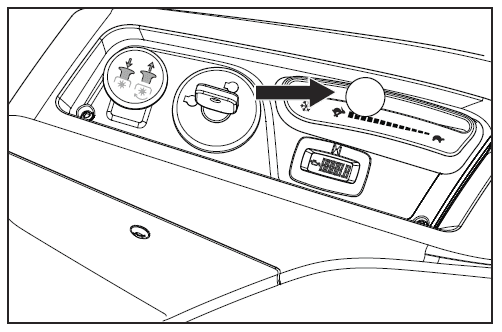

- Throttle control

- Service meter

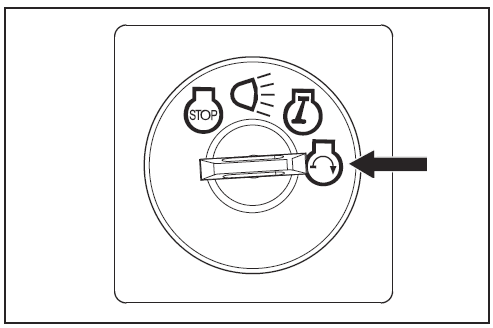

- Ignition switch

- Blade switch

- Seat adjustment lever

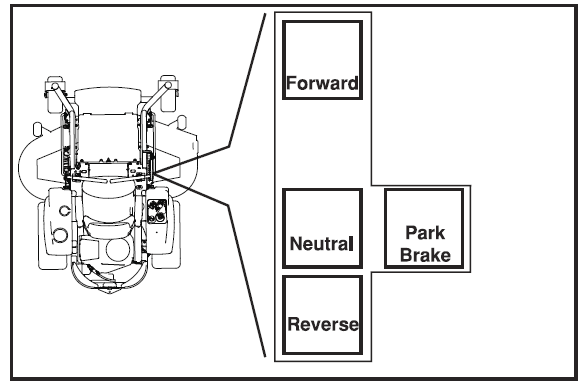

Steering Control Levers

- The machine’s speed and direction are continuously variable using the two steering controls. The steering controls can be moved forward or backward about a neutral position. Furthermore, there is a neutral position, which is locked if the steering controls are moved outward.

- When both controls are in the neutral position (N), the machine stands still. By moving both controls an equal amount forward or backward, the machine moves in a straight line forward or backward respectively. In order, for example, to turn right while moving forward, move the right control towards the neutral position. The rotation of the right wheel is reduced and the machine turns to the right.

- Zero turn can be achieved by moving one control backward (behind the neutral position) and carefully moving the other steering control forward from its neutral position. The rotation direction when zero turning is determined by which steering control is moved backward behind the neutral position. If the left steering control is pulled backward, the machine turns to the left. Use extra care when using this maneuver. If the steering controls are in uneven positions when standing still or do not fit in the slots for moving the controls outward, they can be adjusted.

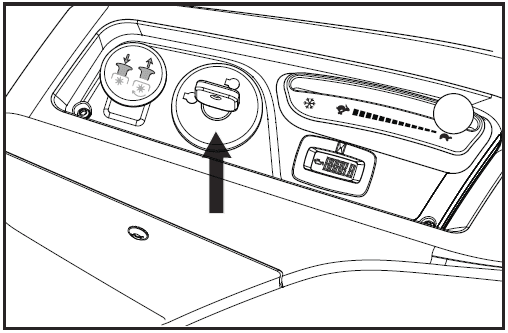

Ignition Switch

- The ignition switch is placed on the control panel and is used to start and stop the engine.

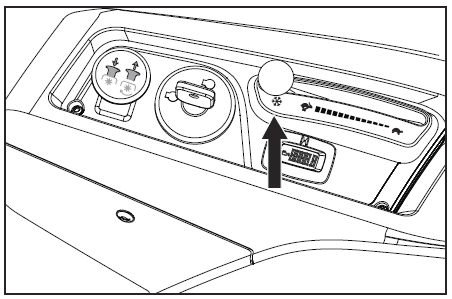

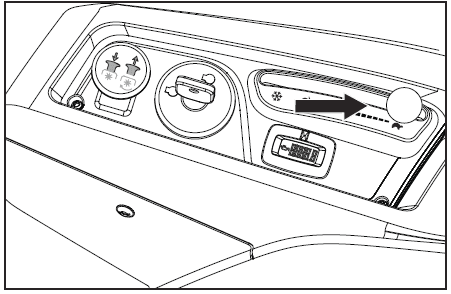

Throttle Control

- The throttle control regulates the engine speed and the rate of rotation of the blades, assuming the blade switch is pulled out. See Blade Switch.

- To increase or decrease the engine speed, the control is moved forward or back respectively. Avoid idling the engine for long periods, as there is a risk of fouling the spark plugs. USE FULL THROTTLE WHEN MOWING, for best mower performance and battery charging

Cold Weather Control

- In temperatures below 32OF, move the throttle control forward past the start detent to the snowflake symbol. Once the engine has started, slowly move the throttle control back to the full throttle position.

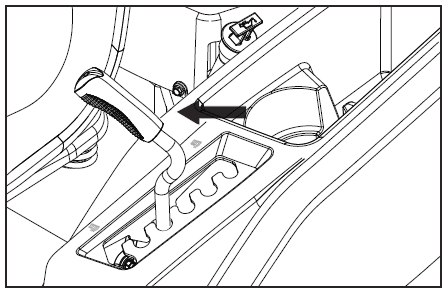

Cutting Height Lever

- To set the deck cutting height, pull the cutting height lever inwards and move it to the desired height notch.

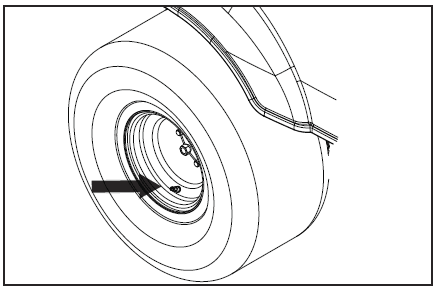

- IMPORTANT INFORMATION To obtain an even cutting height, it is important that the air pressure in all tires is 15 psi / 103 kPa / 1 bar

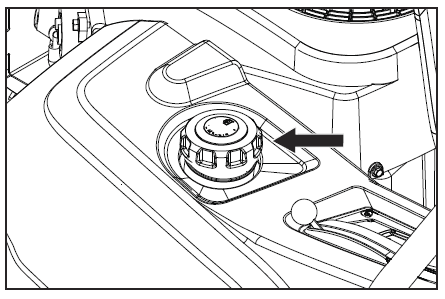

Fuel Tank

- Read the safety instructions before refueling. The machine has one fuel tank, just behind the console. The tank capacity is 3½ gallons (13.25 litres). Regularly check the gas cap gasket for damage and keep the cap properly tightened. The engine will run on a minimum of 85-octane unleaded gasoline (no oil mix).

- Environmentally adapted alkylate gasoline can be used. See also Technical Data concerning ethanol fuel. Methanol fuel is not allowed. Do not use E85 alcohol based fuel. Damage to engine and components may occur. When operating in temperatures below 32° F. (0° C.), use fresh, clean winter grade gasoline to insure good cold weather starting.

Tracking

If the mower is not tracking straight, check the air pressure in both rear tires. Recommended air pressure for the rear tires is 15 psi (1 bar).

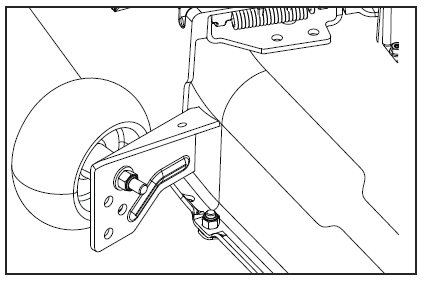

- Tracking adjustments are made using the tracking bolts. The tracking bolts act as limiting devices for the motion control levers when in the full-forward position.

- For preliminary tracking adjustment, move unit to an open, unobstructed area such as an empty parking lot or open field.

- Using a ½” wrench, back the tracking bolts out until flush with nut.

- Test operate unit by driving it at full throttle and the full forward position on both motion control levers. Gradually turn in the tracking bolt on the right hand side until the unit noticeably starts drifting right.

- Drive forward at full throttle with both motion control levers in the full forward position. Gradually turn in the left tracking bolt until unit tracks straight

OPERATION

Training

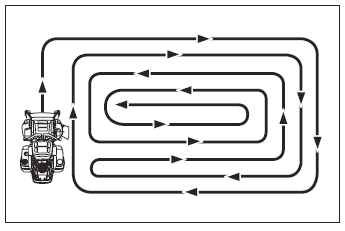

- Due to unique steering capabilities, zero turn mowers are far more maneuverable than typical riding mowers. This section should be reviewed in its entirety prior to attempting to move the mower under its own power. When first operating the mower or until becoming comfortable with controls, use a reduced throttle speed and reduced ground speed. DO NOT move control levers to the furthest forward or reverse positions during initial operation.

- First time users should become familiar with the mower’s movement on a hard surface, such as concrete or blacktop PRIOR to attempting to operate on turf. Until the operator becomes comfortable with the mower controls and zero turning capability, overly aggressive maneuvers may damage turf.

Steering

- To move forward and backward

- The direction and speed of the mower’s movements are effected by the movement of the control lever(s) on each side of mower. The left control lever controls the left wheel. The right control lever controls the right wheel.

- To turn to the right

- While moving in a forward direction, pull the right lever back towards the neutral position while maintaining the position of the left lever, this will slow the rotation of the right wheel and cause the machine to turn in that direction.

- To turn to the left

- While moving in a forward direction pull the left lever back towards the neutral position while maintaining the position of the right lever, this will slow the rotation of the left wheel and cause the machine to turn in that direction.

- To zero turn

- While moving in a forward direction, first pull both control levers back until the mower stops or slows dramatically. Then by alternating one lever slightly to the forward position and the other in the reverse position, complete the turn.

Starting the Engine

- Sit on the seat.

- Raise the mower deck to the highest position.

- Disengage the mower blades by pressing the blade switch downwards.

- Move the steering / park brake controls firmly out to the locked position.

- Move the throttle lever to the full throttle position.

- NOTE: There is a detent at the full throttle position to aid in setting the control.

- If the temperature is below 32OF, move the throttle lever up to the cold weather (snowflake) starting position. When the engine has started, move the throttle lever back to full throttle detent and allow the engine to warm up for a short period before operating the unit. Failure to move the throttle from the cold weather starting position will result in poor engine performance, smoke and spark plug fouling

- NOTE: There is a detent at the full throttle position to aid in setting the control.

- Press in and turn the ignition key to the start position.

- When the engine starts, immediately release the ignition key back to the run position

- Set the engine speed with the throttle. Allow the engine to run at a moderate speed, approximately mid throttle, for a short time before use.

- USE FULL THROTTLE WHEN MOWING

Mowing Tips

- Observe and flag rocks and other fixed objects to avoid collisions.

- Begin with a high cutting height and reduce it until the desired mowing result is attained. The average lawn should be cut to 2½” during the cool season and over 3″ during the hot months. For healthier and better looking lawns, mow often after moderate growth. For best cutting performance, grass over 6″ in height should be mowed twice. Make the first cut relatively high, the second to the desired height.

- The mowing result will be best with a high engine speed (blades rotate rapidly) and low speed (rider moves slowly). If the grass is not too long and dense, the driving speed can be increased without negatively affecting the mowing result.

- When mowing large areas, start by turning to the right so that clippings will discharge away from shrubs, fences, driveways, etc. After one or two rounds, mow in the opposite direction making left hand turns until finished.

- Use compressed air to clean top surface of the deck. Avoid flooding water on top surface, engine and electrical components.

- When the mulching kit is used, it is important that the mowing interval is frequent

Operating On Hills

- Read the Safety Instructions Driving on Slopes in the Safety section.

- The slowest speed possible should be used before starting up or down hills.

- Avoid stopping or changing speed on hills.

- If stopping is absolutely necessary, pull steering controls into the neutral position and the push to the outside of the unit to engage the park brake.

- To restart movement, move the steering controls back to the neutral position.

- Press forward to regain forward motion.

- Make all turns slowly.

Weak Battery

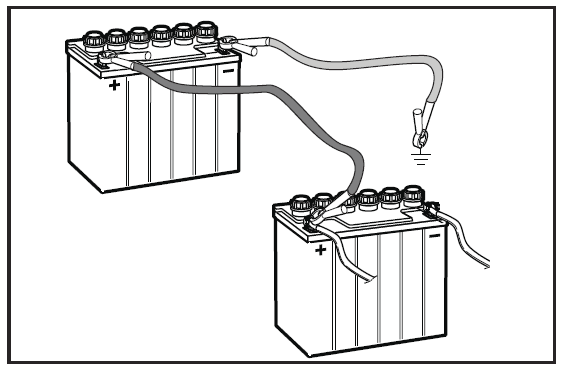

If the battery is too weak to start the engine, it should be recharged. (See Battery in the Maintenance section.) If jumper cables are used for emergency starting, follow this procedure:

Jumper Cable Use

- Connect each end of the RED cable to the POSITIVE (+) terminal on each battery, taking care not to short against chassis.

- Connect one end of the BLACK cable to the NEGATIVE (-) terminal of the fully charged battery.

- Connect the other end of the BLACK cable to a good CHASSIS GROUND on the mower with the discharged battery, away from the fuel tank and battery.

To remove cables, reverse order

- Remove BLACK cable first from chassis and then from the fully charged battery.

- Remove RED cable last from both batteries.

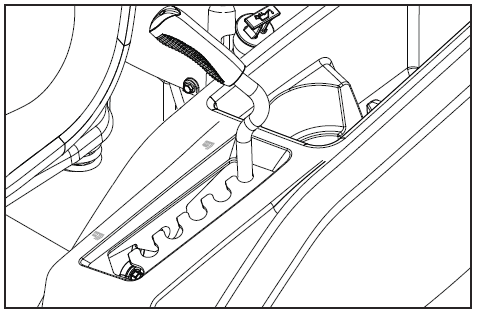

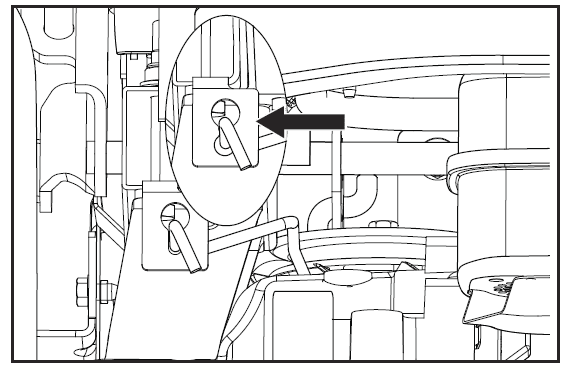

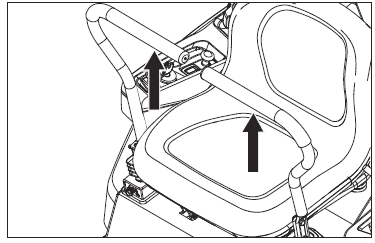

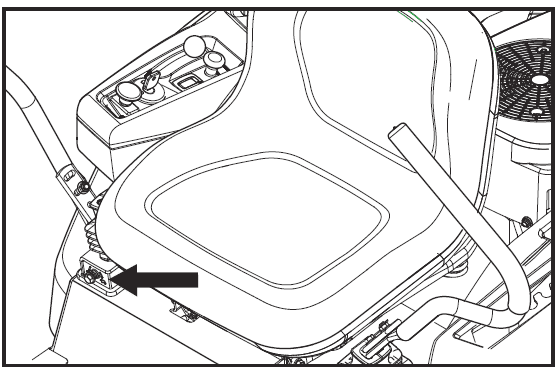

Moving Machine By Hand

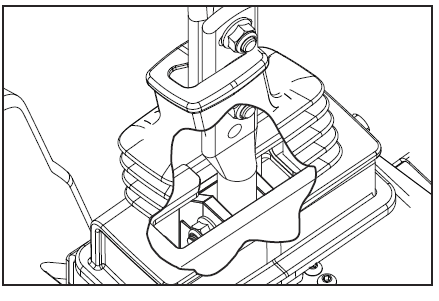

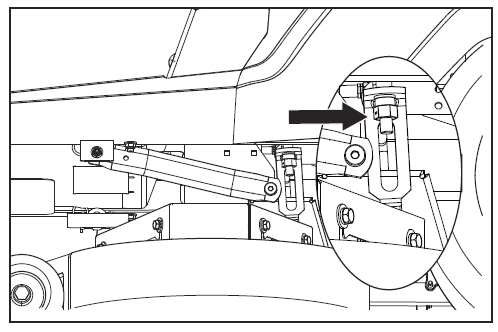

When pushing or pulling the mower, engage the EZT bypass linkages. The EZT bypass linkages are located on the rear of the frame, below the rear engine guard.

- Raise the deck into the highest cutting position.

- Move the steering / park brake controls inwards to the neutral position.

- Pull the EZT bypass linkages up and out of the keyhole slots. Release the levers with the head outside the frame and held in the bypass position.

- To reengage the EZT’s to drive, reverse the above procedure.

- Load the machine into truck or trailer by driving slowly up the ramps. DO NOT LIFT! The machine is not intended to be lifted by hand.

MAINTENANCE

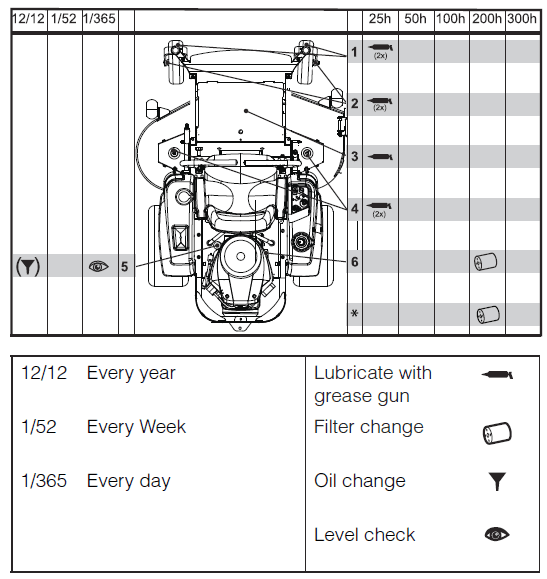

Maintenance Schedule

The following is a list of maintenance procedures that must be performed on the machine. For those points not described in this manual, visit an authorized service workshop. An annual service carried out by an authorized service workshop is recommended to maintain your machine in the best possible condition and to ensure safe operation. Read General Maintenance in the Safety section

|

MAINTENANCE | Daily | At least once each year | Maintenance interval in hours | ||||

| Before | After | 25 | 50 | 100 | 300 | ||

| Check the park brake | ● | ||||||

| Check the engine’s oil level (every refueling) | ■ | ||||||

| Check the safety system | ● | ||||||

| Check for fuel and oil leakages | ♦ | ||||||

| Check/clean the engine’s cooling air intake | ■ | ||||||

| Check the mower deck | ● | ||||||

| Check for loose hardware (screws, nuts) | ● | ||||||

| Clean under the mower deck | ● | ||||||

| Start the engine and blades, listen for unusual sounds | ♦ | ||||||

| Check for damage | ♦ | ||||||

| Thoroughly clean around the engine | ♦ | ||||||

| Clean around belts, belt pulleys | ♦ | ||||||

| Check the tire pressures | ● | ||||||

| Check battery connections | ● | ||||||

| Sharpen3)/ Replace mower blades | ● | ||||||

| Clean the engine’s cooling air intake 2) | ■ | ■ | |||||

| Clean the foam air cleaner prefilter 2) | ■ | ■ | |||||

| Clean the paper air cleaner filter cartridge 2) | ■ | ||||||

| Check/adjust the park brake | ♦ | ♦ | |||||

| Inspect muffler/spark arrestor | ♦ | ♦ | |||||

- 1) First change after 8-10 hours. When operating with a heavy load or at high ambient temperatures, replace every 50 hours.

- 2) In dusty conditions, cleaning and replacement are required more often.

- 3) Performed by authorized service workshop.

- ● = Described in this manual

- ♦ = Not described in this manual

- ■ = Refer to the engine manufacturer’s manual

|

MAINTENANCE | Daily | At least once each year | Maintenance interval in hours | ||||

| Before | After | 25 | 50 | 100 | 300 | ||

| Check/adjust throttle cable | ■ | ||||||

| Check the condition of belts, belt pulleys | ● | ● | |||||

| Change the engine oil 1) | ■ | ■ | |||||

| Replace the engine oil filter | ■ | ■ | |||||

| Clean/replace the spark plugs | ■ | ■ | |||||

| Replace the fuel filter | ■ | ■ | |||||

| Replace paper air filter 2) | ■ | ■ | |||||

| Check the caster wheels (every 200 hours) | ● | ● | |||||

| Replace the air cleaner’s foam pre-filter 2) | ■ | ||||||

| Check/adjust the mower deck | ● | ● | |||||

| Check the engine valve clearance 3) | ♦ | ♦ | |||||

| Perform the 300-hour service 3) | ♦ | ♦ | |||||

- 1) First change after 8-10 hours. When operating with a heavy load or at high ambient temperatures, replace every 50 hours.

- 2) In dusty conditions, cleaning and replacement are required more often.

- 3) Performed by authorized service workshop.

- ● = Described in this manual

- ♦ = Not described in this manual

- ■ = Refer to the engine manufacturer’s manual

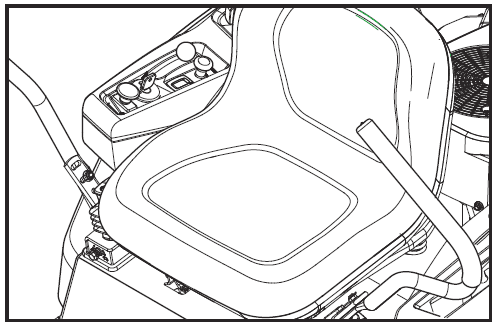

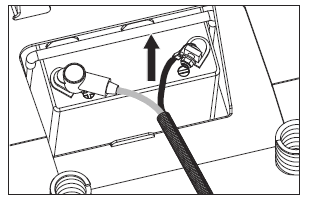

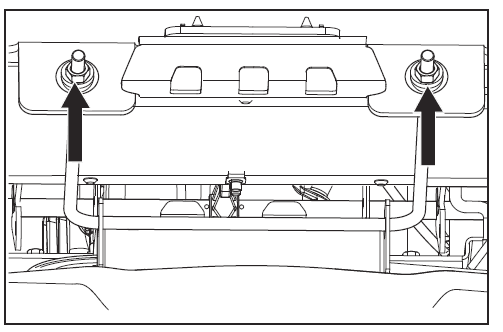

Replacing battery

- Lift seat and rotate forward.

- Using two ½” wrenches disconnect BLACK battery cable then RED battery cable.

- Position deck to lowest setting.

- Front underside of frame, remove the nuts that secure the battery hold-down.

- Carefully remove the battery from the mower.

- Install new battery with cable terminals routed toward the center of the battery.

- Reinstall battery hold-down and secure with nuts removed in Step 4.

- Reconnect RED battery cable to positive (+) battery terminal with bolt and hex nut.

- Connect BLACK grounding cable to negative (-) battery terminal with remaining hex bolt and hex nut

- Replace terminal boot cover.

- Lower seat

STANDARD BATTERY STATE OF CHARGE

APPROXIMATE BATTERY CHARGING TIME* TO FULL CHARGE AT 80OF / 27OC Maximum Rate at: 50 Amps 30 Amps 20 Amps 10 Amps 12.6V 100% – FULL CHARGE – 12.4V 75% 20 min. 35 min. 48 min. 90 min. 12.2V 50% 45 min. 75 min. 95 min. 180 min. 12.0V 25% 65 min. 115 min. 145 min. 280 min. 11.8V 0% 85 min. 150 min. 195 min. 370 min.

Park Brake

- Visually check that no damage is found on the steering control levers, links or switches belonging to the park brake. Perform a standstill test and check that there is sufficient braking action.

- To adjust the park brake, contact the Husqvarna service workshop. To adjust the park brake tension, move the boot covering the steering control base. Tighten the ½” pivot nut until the braking action is correct. Replace the steering boot, making sure the boot top sits between the two adjustment bolts on the steering control. For any further adjust to the park brake, contact the Husqvarna service workshop.

Tire Pressures

- All tires should be at 15 psi / 103 kPa / 1 bar.

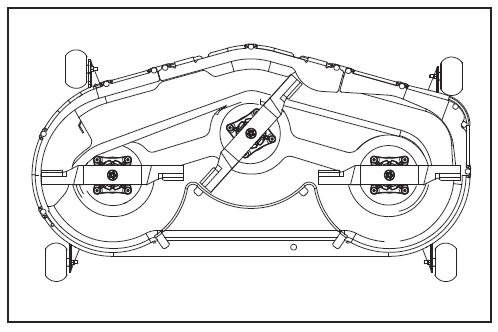

Anti-scalp Rollers

Anti-scalp rollers are properly adjusted when they are just slightly off of the ground when the deck is at the desired cutting height in the operating position. Anti-scalp rollers then keep the deck in the proper position to help prevent scalping in most terrain conditions. The anti-scalp rollers can be set in three positions:

- Upper position 1½” to 2½” (38 to 64 mm) grass

- Middle position 2½” to 4″ (64 to 102 mm) grass

- Lower position 4″ to 6″ (102 to 128) mm grass. The rollers should be approximately ¼” (6.5 mm) from the ground.

V-belts

- Check every 100 hours of operation. Check for severe cracking and large nicks.

- NOTE: The belt will show some small cracks in normal operation. The belts are not adjustable. Replace belts if they begin to slip from wear.

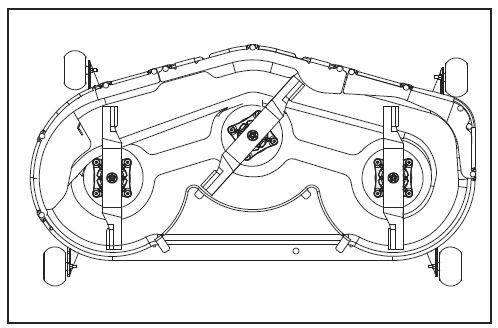

Deck Belt Removal

- Park on a level surface. Apply parking brake.

- Lower the deck into the lowest cutting position.

- Remove bolts from belt shields and remove shields.

- Remove any dirt or grass that may have accumulated around the cutter housings and entire deck surface.

- Remove tension on the belt by moving the idler arm.

- Carefully slip belt up over the top of the cutter housing pulleys and remove belt. Rolling belt over the pulleys may damage the belt.

Adjusting the Mower Deck

Leveling deck

- Adjust the deck while the mower is on a level surface. Make sure the tires are inflated to the correct pressure. See Technical Data / Transmission. If tires are under or over inflated, the deck cannot be properly adjusted. Raise the deck to the highest (transport) position. The deck should be adjusted slightly higher in the rear.

- NOTE: To insure accuracy of leveling procedure, mower deck drive belt must be installed prior to leveling deck.

- Wear heavy gloves. Turn each outer blade tip to align front to rear with the deck side-to-side.

- Measure from the floor surface up to the bottom of the blade tip on the discharge side of the mower deck. Record the measurement.

- Move to the opposite side, check that measurement is the same. If adjustment is required—with a ¾” or adjustable wrench, turn the lift link adjustment nuts on either side counter clockwise to lower or clockwise to raise. Adjust until both measurements are equal.

- Turn any blade to align with the deck front-to-rear. If the front blade tip does not measure 1/8″ to ½” higher in the rear—with a 5/8 or adjustable wrench, turn the nuts on the front suspension linkage. Clockwise raises the front of the mower, counter clockwise will lower the front. Adjust nuts until rear of mower deck is positioned level to 1/8″ higher in the rear than the side-to-side measurement.Turn any blade to align with the deck front-to-rear. If the front blade tip does not measure 1/8″ to ½” higher in the rear—with a 5/8 or adjustable wrench, turn the nuts on the front suspension linkage. Clockwise raises the front of the mower, counter clockwise will lower the front. Adjust nuts until rear of mower deck is positioned level to 1/8″ higher in the rear than the side-to-side measurement.

- NOTE: For illustration, the front foot rest has been removed. The adjustment can be made without removal

- NOTE: This will place the mower deck in a standard measurement position. Depending on the type of grass being mowed or environmental conditions, additional adjustments may be required to achieve the desired cut

- NOTE: For illustration, the front foot rest has been removed. The adjustment can be made without removal

Cleaning

- Regular cleaning, especially under the mower deck, will increase the machine’s life-span. Make it a habit to clean the machine directly after use (after it is cooled), before the debris sticks.

- Do not spray water on the top of the mower deck. Use compressed air to clean the top side of mower deck. Regularly clean the underside of the deck with normal water pressure. Do not use a high pressure washer or steam cleaner. Avoid spraying engine and electrical components with water.

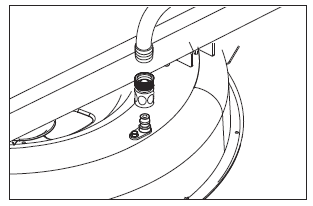

- For models fitted with a cleanout port, attach the quick connect (from the accessory packet) to any garden hose. After mowing, snap the hose to the cleanout port and turn on water supply

- Restart the mower and engage the blades to use the spinning action to wash away debris. Make sure the hose is away from the mower blades. Do not rinse hot surfaces with cold water. Let unit cool before washing.

Hardware

- Check daily. Inspect the entire machine for loose or missing hardware.

General

- Remove the ignition key to prevent unintentional movements during lubrication. When lubricating with an oil can, it must be filled with engine oil. When lubricating with grease, unless otherwise stated, use a high grade molybdenum disulphide grease. For daily use, the machine should be lubricated twice weekly.

- Wipe away excess grease after lubrication. It is important to avoid getting lubricant on the belts or the drive surfaces of the belt pulleys. Should this happen, attempt to clean them with spirits. If the belt continues to slip after cleaning, the belt must be replaced. Gasoline or other petroleum products must not be used to clean belts.

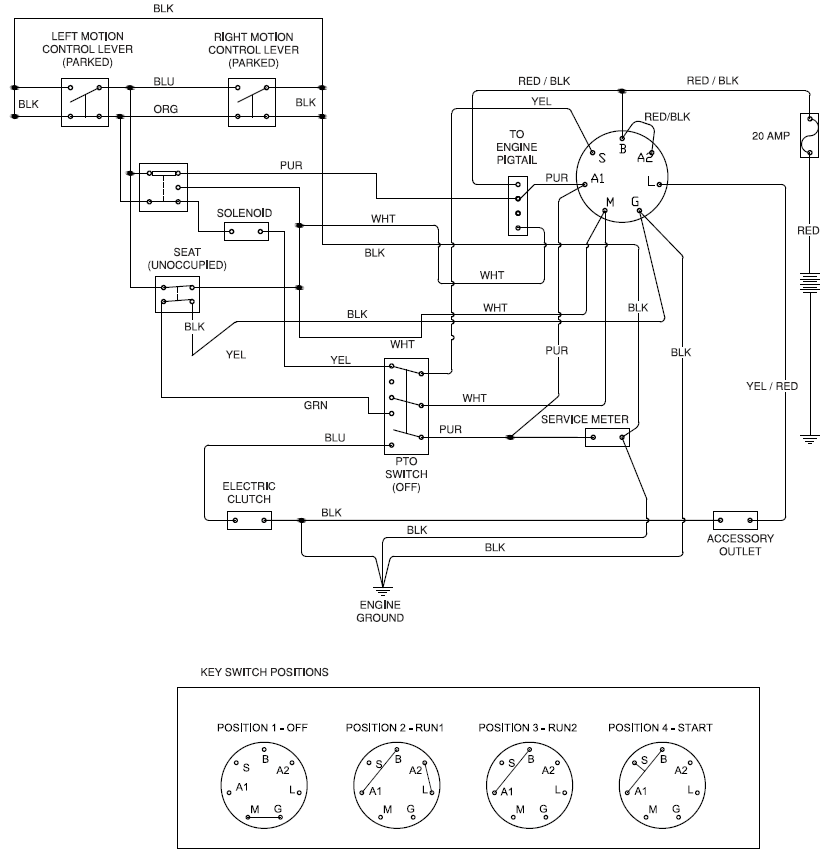

SCHEMATIC

TECHNICAL DATA

| Engine | Frame | ||

| Manufacturer | Kohler | Cutting Width | 54″ / 137 cm |

| Type | KT745 | Cutting Height | 1½” – 4″ / 3.8 – 10.2 cm |

| Power | 26 1) | Uncut Circle | 0 |

| Lubrication | Pressure with oil filter | Number of Blades | 3 |

| Fuel | Min 87 octane unleaded (Max ethanol 10%, Max MTBE 15%) | Blade Length | 18¼” / 46 cm |

| Fuel tank capacity | 3½ gallons / 13.25 litres | Anti-scalp Rollers | 4 Adjustable |

| Cooling | Air cooled | Sprung Seat | Standard |

| Air filter | Standard | Hinged Arm Rests | Optional |

| Alternator | 12V | Service Meter | Digital |

| Starter | Electric | Blade Engagement | Electromagnetic Clutch |

| Transmission | Deck Construction | Stamped | |

| Transmission | Hydrostatic transaxles | Productivity | 2.8 acres/h / 11311 m2/h |

| Steering control | Dual levers, foam gripped | Dimensions | |

| Speed forward | 0-6.5 mph / 0-10.5 km/h | Weight | 640 lbs / 290 kg |

| Speed reverse | 0-3.5 mph / 0-5.6 km/h | Base Machine Length | 75″ / 191 cm |

| Brakes | Mechanical park brake | Base Machine Height | 40″ / 102 cm |

| Front caster tires | 11 x 6-5 | Base Machine Width | 43¾ / 112 cm |

| Rear tires, turf pneumatic | 18 x 9.5-8 | Overall Width, Chute Up | 57″ / 145 cm |

| Tire pressure | 15 PSI / 103 kPa / 1 bar | Overall Width, Chute Down | 67½ / 171 cm |

For more manuals by Husqvarna, visit ManualsLibraryy

Husqvarna Z 254 Zero Turn Mower-FAQs

How often should I change the oil in my Husqvarna zero-turn mower?

Husqvarna recommends changing the oil after every 50 hours of use. It’s also essential to check the mower blades, fluid levels, and clean the mower at regular intervals.

How many fuses are there in a Husqvarna zero-turn mower?

There are two fuses located on the left-hand side of the mower, accessible by tilting the seat forward. The fuses are of the same type as automotive fuses, with ratings of 20 Amp (primary) and 7.5 Amp (mower deck coupling).

How long will my Husqvarna zero-turn mower last?

With proper care and regular maintenance, a Husqvarna zero-turn mower can last between 600-800 hours or more.

How often should I change the hydraulic fluid in my zero-turn mower?

It is recommended to check the hydraulic fluid every 100 hours of operation. If the fluid is still in good condition, you can wait up to 1000 hours before changing it.

How long do Husqvarna mower blades last?

Husqvarna Long Life Safety Blades should be replaced every 6-8 weeks, while Husqvarna Endurance Safety Blades last about 3-4 months.

What is the average lifespan of a zero-turn mower?

Zero-turn mowers generally last between 5 to 15 years, depending on usage, maintenance, and the mower’s quality.

How many volts should my zero-turn mower have?

A zero-turn mower operates on a 12-volt electrical system, with a fully charged battery having 12.6 volts.

Why does my Husqvarna lawn mower start and then shut off?

This issue could be caused by stale fuel, a dirty or damaged spark plug, or a clogged air filter.

How often should I sharpen the blades on my zero-turn mower?

It is recommended to sharpen the blades after every 20-25 hours of use, though this may vary based on your mowing frequency and lawn conditions.

INTRODUCTION

INTRODUCTION