Ingersoll Rand UP6 Oil Flooded Air Compressor

ABBREVIATIONS & SYMBOLS

- #### Contact Ingersoll Rand for the serial number

- –>#### Up to Serial No.

- ####–> From Serial No.

- * Not illustrated

- ±Option

- NR Not required

- AR As required

- SM Sitemaster/Sitepack

- HA High ambient machine

- WC Watercooled machine

- AC Aircooled machine

- ERS Energy recovery system

- T.E.F.C. Totally enclosed fan-cooled motor (IP55)

- O.D.P. Open drip-proof (motor)

FOREWORD

The contents of this manual are considered to be proprietary and confidential to Ingersoll Rand and should not be reproduced without the prior written permission of Ingersoll Rand. Nothing contained in this document is intended to extend any promise, warranty, or representation, expressed or implied, regarding the Ingersoll Rand products described herein. Any such warranties or other terms and conditions of sale of products shall be in accordance with the standard terms and conditions of sale for such products, which are available upon request.

This manual contains instructions and technical data to cover routine operation and scheduled maintenance tasks by operation and maintenance staff. Major overhauls are outside the scope of this manual and should be referred to an authorized Ingersoll Rand service department. All components, accessories, pipes, and connectors added to the compressed air system should be:

- of good quality, procured from a reputable manufacturer and, wherever possible, be of a type approved by Ingersoll Rand.

- clearly rated for a pressure at least equal to the machine’s maximum allowable working pressure.

- compatible with the compressor lubricant/coolant.

- accompanied by instructions for safe installation, operation, and maintenance.

Details of approved equipment are available from Ingersoll Rand Service departments. The use of non-genuine spare repair parts other than those included within the Ingersoll Rand approved parts list may create hazardous conditions over which Ingersoll Rand has no control. Therefore, Ingersoll Rand does not accept any liability for losses caused by equipment in which non-approved repair parts are installed. Standard warranty conditions may be affected.

Ingersoll Rand reserves the right to make changes and improvements to products without notice and without incurring any obligation to make such changes or add such improvements to products sold previously. The intended uses of this machine are outlined below, and examples of unapproved usage are also given; however, Ingersoll Rand cannot anticipate every application or work situation that may arise.

IF IN DOUBT, CONSULT SUPERVISION.

This machine has been designed and supplied for use only in the following specified conditions and applications:

- Compression of normal ambient air containing no known or detectable additional gases, vapors, or particles.

- Operation within the ambient temperature range specified in the GENERAL INFORMATION section of this manual.

The use of the machine in any of the situation types listed in Table 1:

- Is not approved by Ingersoll Rand,

- May impair the safety of users and other persons, and

- May prejudice any claims made against Ingersoll Rand.

TABLE 1

Use of the machine to produce compressed air for:

- direct human consumption

- indirect human consumption, without suitable filtration and purity checks.

Use of the machine outside the ambient temperature range specified in the GENERAL INFORMATION SECTION of this manual. Use of the machine where there is any actual or foreseeable risk of hazardous levels of flammable gases or vapors. THIS MACHINE IS NOT INTENDED AND MUST NOT BE USED IN POTENTIALLY EXPLOSIVE ATMOSPHERES, INCLUDING SITUATIONS WHERE FLAMMABLE GASES OR VAPORS MAY BE PRESENT. Use of the machine fitted with non-Ingersoll Rand-approved components. Use of the machine with safety or control components missing or disabled.

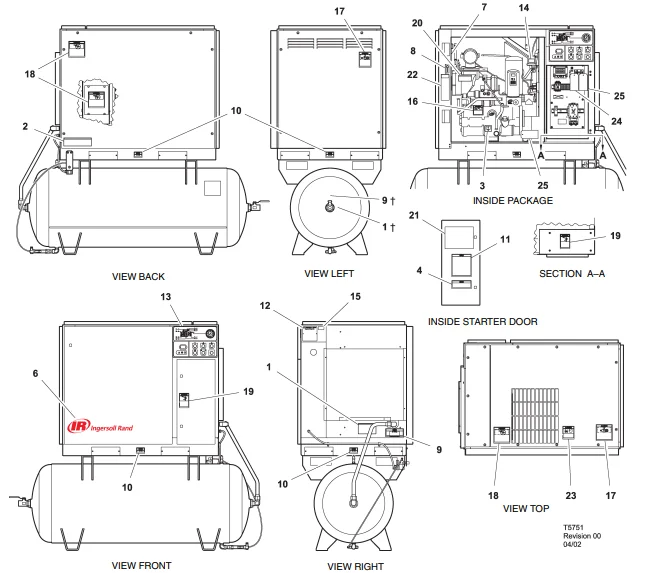

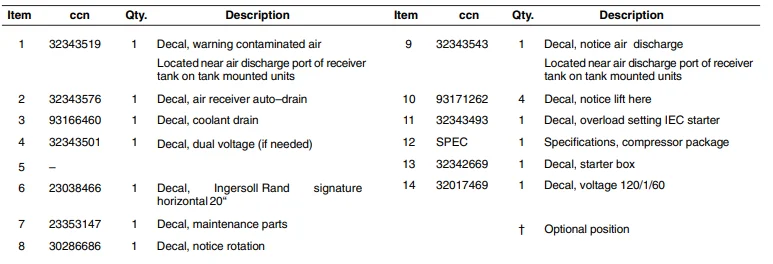

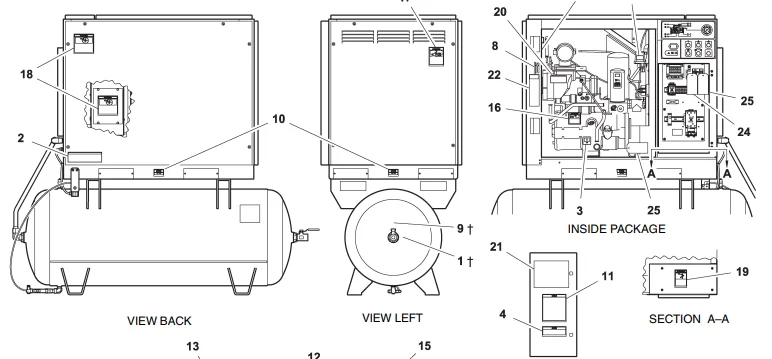

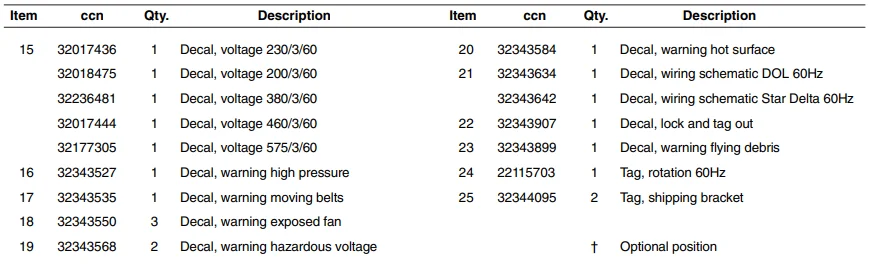

DECALS

SAFETY

General Information

- Ensure that the operator reads and understands the decals and consults the manuals before maintenance or operation.

- Ensure that the Operation and Maintenance manual is not removed permanently from the machine.

- Ensure that maintenance personnel are adequately trained, competent, and have read the Maintenance Manuals.

- Do not point air nozzles or sprayers toward anyone.

- Compressed air and electricity can be dangerous. Before undertaking any work on the compressor, ensure that the electrical supply has been isolated and the compressor has been relieved of all pressure.

- Wear eye protection when operating or servicing the compressor.

- All persons positioned near operating machinery should be equipped with hearing protection and given instructions on its use in accordance with workplace safety legislation.

- Make sure that all protective covers are in place and that the canopy/doors are closed during operation.

- The specification of this machine is such that it is not suitable for use in flammable gas risk areas.

- Installation of this compressor must be in accordance with recognized electrical codes and any local Health and Safety Codes.

- The use of plastic bowls on-line filters can be hazardous. Their safety can be affected by either synthetic lubricants or the additives used in mineral oils. Ingersoll Rand recommends that only filters with metal bowls should be used on a pressurized system.

Compressed Air

Compressed air can be dangerous if incorrectly handled. Before doing any work on the unit, ensure that all pressure is vented from the system and that the machine cannot be started accidentally.

WARNING: Imposing a normal or emergency stop on the compressor will only relieve pressure upstream of the minimum pressure valve on top of the separator tank.

- If maintenance work is required downstream of this valve, ensure that all pressure is relieved at the process vent point external to the compressor.

- Ensure that the machine is operating at the rated pressure and that the rated pressure is known to all relevant personnel.

- All air pressure equipment installed in or connected to the machine must have safe working pressure ratings of at least the machine’s rated pressure.

- If more than one compressor is connected to one common downstream plant, effective isolation valves must be fitted and controlled by work procedures so that one machine cannot accidentally be pressurized/over-pressurized by another.

- Compressed air must not be used for a direct feed to any form of breathing apparatus or mask.

- The discharged air contains a very small percentage of compressor lubricant, and care should be taken to ensure that downstream equipment is compatible.

- If the discharged air is to be ultimately released into a confined space, adequate ventilation must be provided.

- When using compressed air, always use appropriate personal protective equipment.

- All pressure-containing parts, especially flexible hoses and their couplings, must be regularly inspected, be free from defects, and be replaced according to the Manual instructions.

- Compressed air can be dangerous if incorrectly handled. Before doing any work on the unit, ensure that all pressure is vented from the system and that the machine cannot be started accidentally.

- Avoid bodily contact with compressed air.

- All safety valves located in the separator tank must be checked periodically for correct operation.

- Do not over-pressurize the receiver tank or similar vessels beyond design limits.

- Do not use a receiver tank or similar vessels that fail to meet the design requirements of the compressor. Contact your distributor for assistance.

- Do not drill into, weld, or otherwise alter the receiver tank or similar vessels.

Materials

The following substances are used in the manufacture of this machine and may be hazardous to health if used incorrectly:

- preservative grease

- rust preventative

- compressor coolant

- AVOID INGESTION, SKIN CONTACT, AND INHALATION OF FUMES.

Transport

- When loading or transporting machines, ensure that the specified lifting and tie-down points are used.

- Lifting equipment must be properly rated for the weight of the compressor.

- Do not work on or walk under the compressor while it is suspended.

Electrical

Keep all parts of the body and any hand-held tools or other conductive objects away from exposed live parts of the compressor’s electrical system. Maintain dry footing, stand on insulating surfaces, and do not contact any other portion of the compressor when making adjustments or repairs to exposed live parts of the compressor’s electrical system.

WARNING: Any electrical connections or adjustments should only be made by a suitably qualified electrician.

- Close and lock all access doors when the compressor is left unattended.

- Do not use extinguishers intended for Class A or Class B fires on electrical fires. Use only extinguishers suitable for Class BC or Class ABC fires.

- Attempt repairs only in clean, dry, well-lighted, and ventilated areas.

- Connect the compressor only to electrical systems that are compatible with its electrical characteristics and that are within its rated capacity.

Condensate Disposal

As wastewater regulations vary by country and region, it is the responsibility of the user to establish the limitations and regulations in their particular area. Ingersoll Rand and its associated distributors are happy to advise and assist in these matters. For further information, consult the Material Safety Data Sheets.

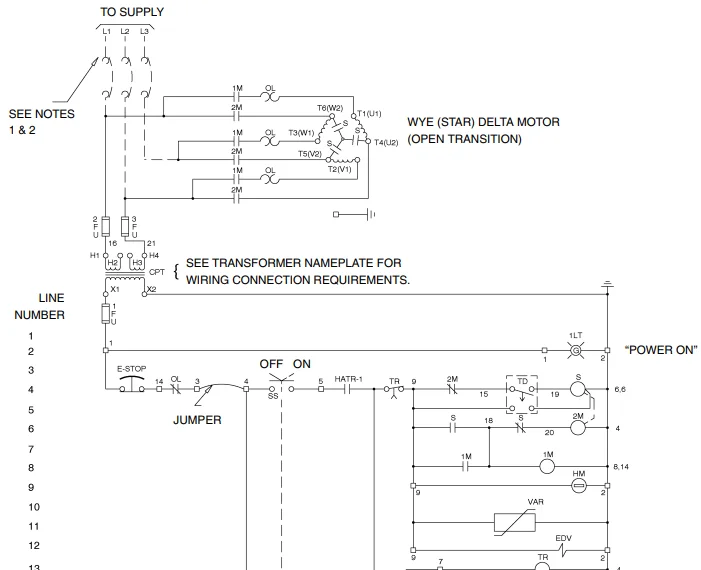

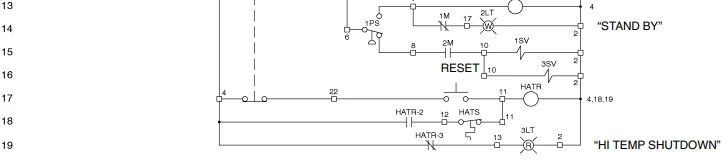

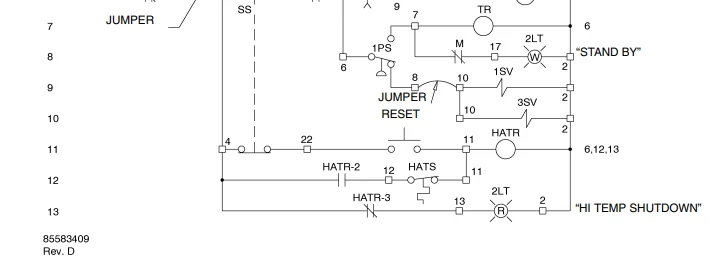

GENERAL INFORMATION

LEGEND

- CPT Transformer, control

- EDV Valve, electric drain

- E-STOP Button, emergency stop

- FU Fuse

- HM Hourmeter

- HATR Relay, high air temperature

- HATS Switch, high air temperature

- 1M Contactor (main)

- 2M Contactor (delta)

- OL Overload, motor starter

- PS Switch, pressure

- SS Switch, selector

- S Contactor (wye/star)

- 1SV Valve, solenoid (Load) N.C.

- 3SV Valve, solenoid (Blowdown) N.O.

- TD Relay, Delta starting (10 seconds)

- TR Relay, auto restart time delay (6 min)

- VAR Varistor

Terminal points

Terminal points L1, L2, L3 Light, transformer type

L1, L2, L3 Light, transformer type

NOTES

- An approved fused disconnect or circuit breaker per code requirements must be provided by the customer.

- Dashed lines represent wiring by the customer.

- Sizing of electrical components not supplied by Ingersoll Rand is the responsibility of the customer and should be done in accordance with the information on the compressor data plate and local electrical codes.

- The unit will not restart automatically after a power outage.

- Circuit shown in normal position, de-energized.

- All wiring to be in accordance with local codes.

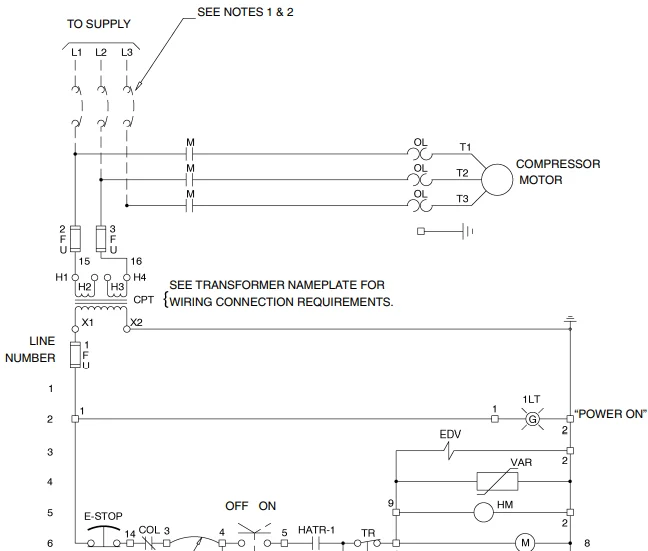

LEGEND

- CPT Transformer, control

- EDV Valve, electric drain

- E-STOP Button, emergency stop

- FU Fuse

- HM Hourmeter

- HATR Relay, high air temperature

- HATS Switch, high air temperature

- M Contactor (main)

- OL Overload, motor starter

- PS Switch, pressure

- SS Switch, selector

- 1SV Valve, solenoid (Load) N.C.

- 3SV Valve, solenoid (Blowdown) N.O.

- TR Relay, time delay (6 min)

- VAR Varistor

Terminal points

Terminal points L1, L2, L3 Light, transformer type

L1, L2, L3 Light, transformer type

NOTES

- An approved fused disconnect or circuit breaker per code requirements must be provided by the customer.

- Dashed lines represent wiring by the customer.

- Sizing of electrical components not supplied by Ingersoll Rand is the responsibility of the customer and should be done in accordance with the information on the compressor data plate and national and local electrical codes.

- The unit will not restart automatically after a power outage.

- Circuit shown in normal position, de-energized.

- All wiring to be in accordance with local codes.

INSTALLATION / HANDLING

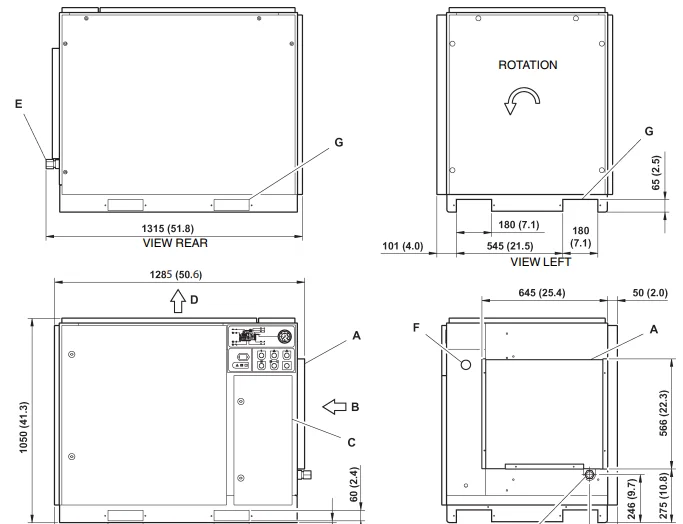

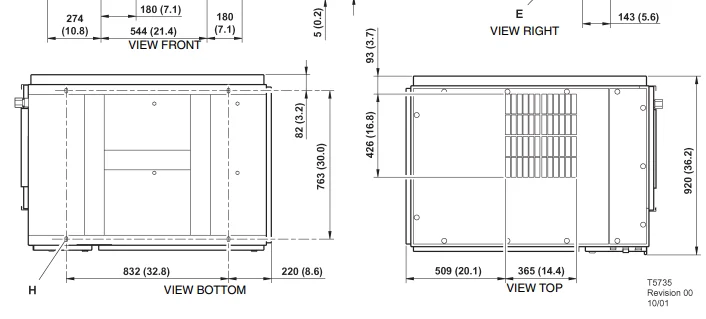

BASE MOUNTED UNITS

KEY

- A pre-filter

- B Compressor and cooling air intake

- C Starter box

- D Cooling air exhaust

- E 1.00” NPT air discharge

- F Customer power inlet

- G Fork lift openings (Fork lift hole covers must be installed after the unit is in place to reduce noise and ensure proper cooling of the package.)

- H 4 slots 15 (0.6) x 25 (1.0)

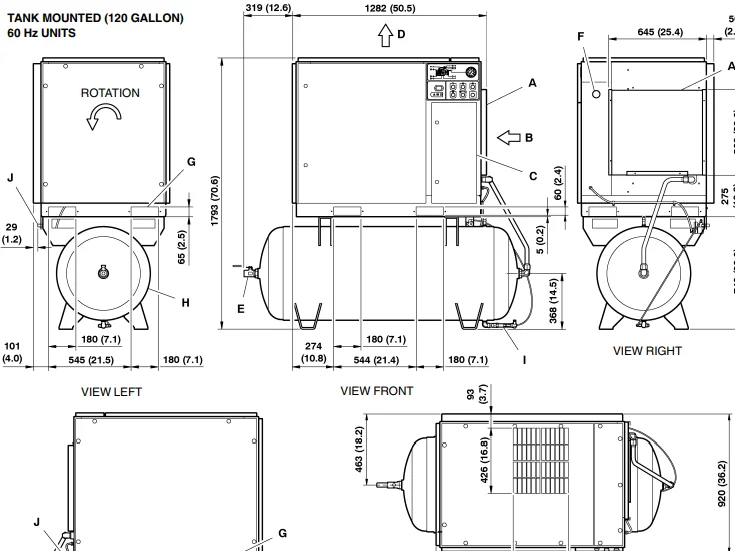

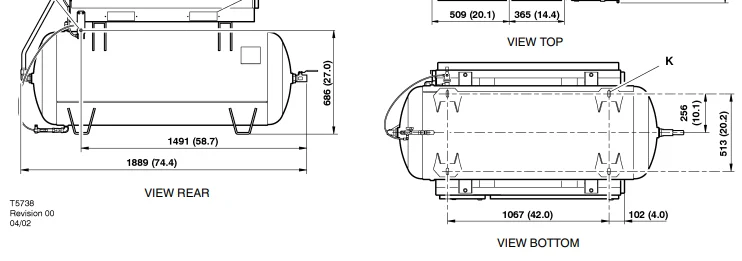

TANK MOUNTED (120 GALLON) 60 Hz UNITS

KEY

- A pre-filter

- B Compressor and cooling air intake

- C Starter box

- D Cooling air exhaust

- E 1.00” NPT air discharge

- F Customer power inlet

- G Fork lift openings

- H Air receiver (120 gallons)

- I Automatic drain valve

- J 0.25-inch condensate drain

- K 4 slots 17 (0.7) x 44 (1.8)

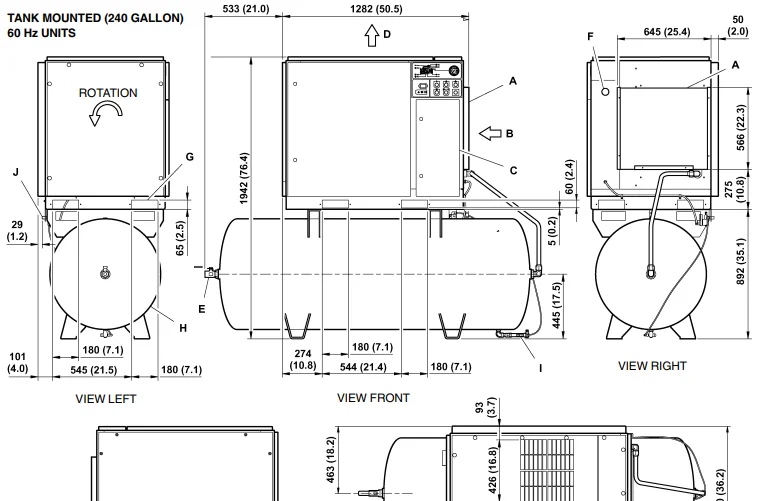

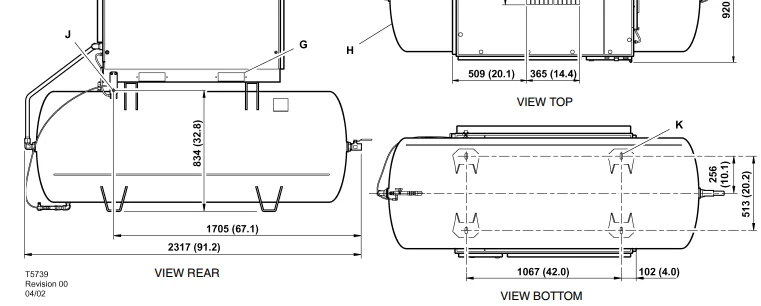

TANK MOUNTED (240 GALLON) 60 Hz UNITS

KEY

- A pre-filter

- B Compressor and cooling air intake

- C Starter box

- D Cooling air exhaust

- E 1.00” NPT air discharge

- F Customer power inlet

- G Fork lift openings

- H Air receiver (240 gallons)

- I Automatic drain valve

- J 0.25-inch condensate drain

- K 4 slots 17 (0.7) x 44 (1.8)

NOTES

- Coolant (lubricant) fill quantity (approximate): 3.4 US gallons (13 liters).

- Recommended clearance in front of the control panel door 42 inches (1067 mm) or minimum as required by the latest National Electrical Codes (NEC) or applicable local codes.

- Recommended clearances on left and right sides 36 inches (914 mm).

- Minimum recommended clearance for the rear of the compressor is to be 6 inches (152 mm).

- External piping shall not exert any unresolved moments or forces on the unit. Use a pipe size of large or larger at the discharge connection.

- There should be no plastic or PVC piping attached to this unit or used for any lines downstream.

- Any field-installed ducting to and from the compressor cannot add more than 1/2” (12.5 mm) water gauge total air resistance.

- Do not pipe into a common header with a reciprocating compressor unless the reciprocating compressor utilizes a discharge pulsation damper.

- Sizing of electrical components not supplied by Ingersoll Rand is the responsibility of the customer and should be done in accordance with the information on the compressor data plate and national and local electrical codes.

OPERATING INSTRUCTIONS

GENERAL OPERATION

- The compressor is an electric motor-driven, single-stage screw compressor, complete with accessories piped, wired, and baseplate-mounted. It is a totally self-contained air compressor package.

- The standard compressor is designed to operate in an ambient range of 35.6F–104F (2C to 40C) with a special option package available to operate in ambient temperature ranges from 35.6F up to 124F (2C up to 50C). The maximum temperature is applicable to either version up to a maximum elevation of 3280 ft (1000 m) above sea level. Above this altitude, a significant reduction in maximum allowable ambient temperature is required.

- Compression in the screw-type air compressor is created by the meshing of two (male & female) helical rotors.

- The air/coolant mixture discharges from the compressor into the separation system. This system removes all but a few PPM of the coolant from the discharge air. The coolant is returned to the cooling system, and the air passes through the aftercooler and out of the compressor.

- Cooling air is moved through the coolers by the cooling fan and discharged from the machine.

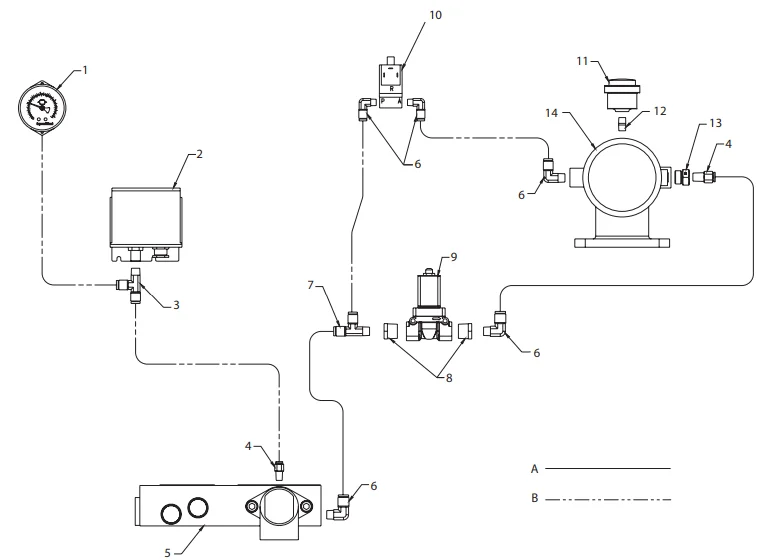

ELECTRO-PNEUMATIC CONTROL AND INSTRUMENTATION

KEY

- Pressure gauge

- Pressure switch

- Tee

- Connector

- Combination block

- Elbow

- Tee, male run

- Reducer bushing

- Valve, solenoid (Blowdown)

- Valve, solenoid (Load)

- Indicator air filter

- Nipple

- Adaptor

- Intake valve assembly

NOTES:

- A. Tubing 3/8 inch

- B. Tubing 1/4 inch

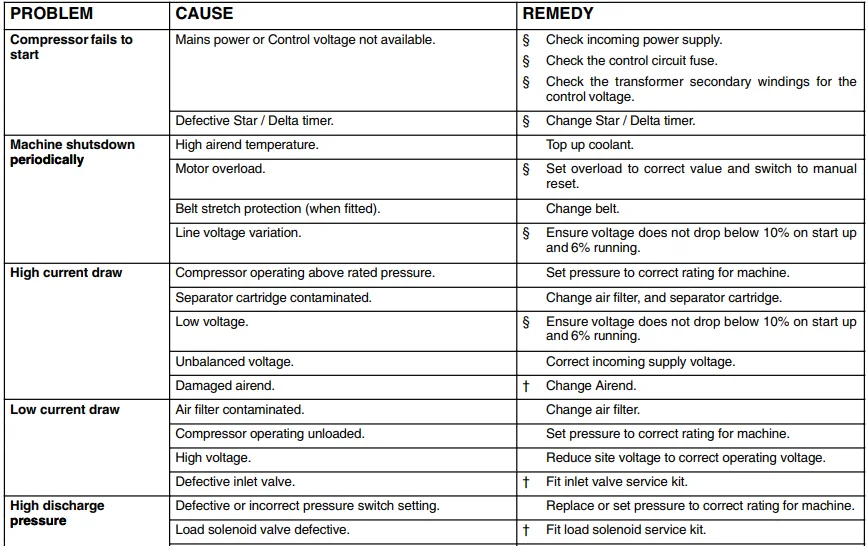

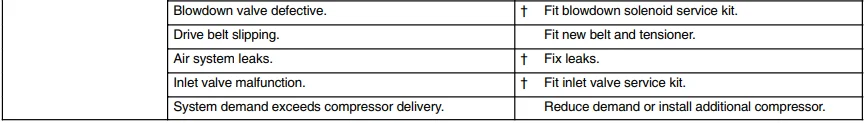

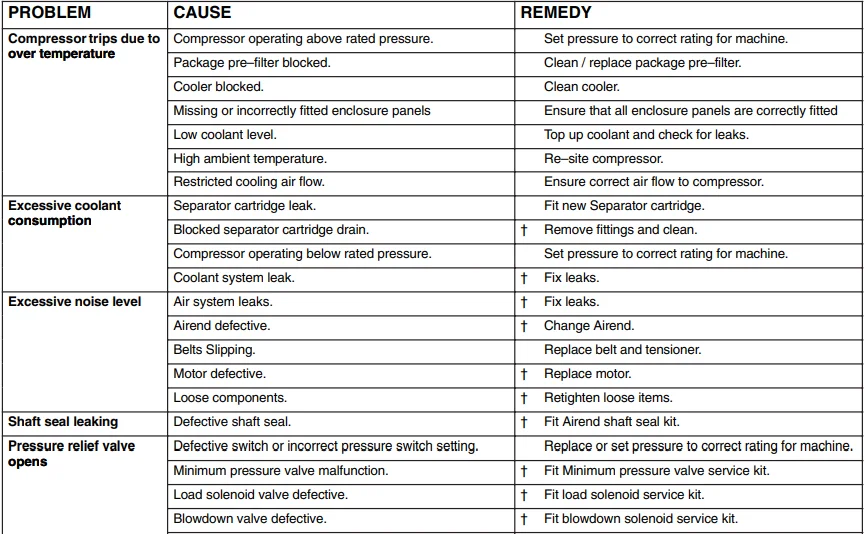

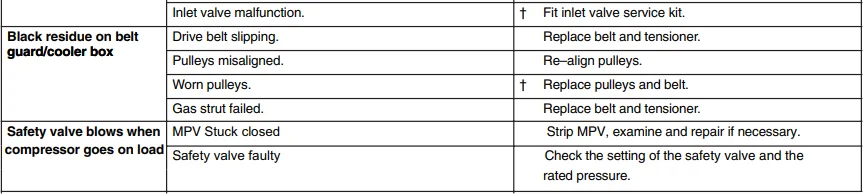

TROUBLE SHOOTING

BONDED WARRANTY & REGISTERED START-UP

Warranty

The Company warrants that the equipment manufactured by it and delivered hereunder will be free of defects in material and workmanship for a period of twelve months from the date of placing the Equipment in operation or eighteen months from the date of shipment from the factory, whichever shall first occur.

The Purchaser shall be obligated to promptly report any failure to conform to this warranty, in writing to the Company in said period, whereupon the Company shall, at its option, correct such nonconformity by suitable repair to such equipment or furnish a replacement part F.O.B. point of shipment, provided the Purchaser has stored, installed, maintained, and operated such Equipment in accordance with good industry practices and has complied with specific recommendations of the Company.

Accessories or equipment furnished by the Company, but manufactured by others, shall carry whatever warranty the manufacturers have conveyed to the Company and which can be passed on to the Purchaser. The Company shall not be liable for any repairs, replacements, or adjustments to the Equipment or any costs of labor performed by the Purchaser or others without the Company’s prior written approval.

The effects of corrosion, erosion, and normal wear and tear are specifically excluded. Performance warranties are limited to those specifically stated within the Company’s proposal. Unless responsibility for meeting such performance warranties is limited to specified tests, the Company’s obligation shall be to correct in the manner and for the period of time provided above. THE COMPANY MAKES NO OTHER WARRANTY OR REPRESENTATION OF ANY KIND WHATSOEVER, EXPRESSED OR IMPLIED, EXCEPT THAT OF TITLE, AND ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE ARE HEREBY DISCLAIMED.

Correction by the Company of nonconformities, whether patent or latent, in the manner and for the period of time provided above, shall constitute fulfillment of all liabilities of the Company for such nonconformities, whether based on contract, warranty, negligence, indemnity, strict liability, or otherwise with respect to or arising out of such Equipment. The Purchaser shall not operate Equipment which is considered to be defective without first notifying the Company in writing of its intention to do so. Any such use of Equipment will be at the Purchaser’s sole risk and liability. Register online at air.ingersollrand.com.

For More Manuals By Ingersoll-Rand, Visit ManualsLibraryy.

Ingersoll Rand UP6 Oil Flooded Air Compressor-FAQs

What is an oil-flooded air compressor?

An oil-flooded air compressor uses oil for lubrication, cooling, and sealing inside the compression chamber. In the Ingersoll Rand UP6, oil helps reduce wear, control operating temperature, and improve efficiency. The oil is separated from the compressed air before discharge using an air/oil separator system. This design is common in rotary screw compressors because it provides durability and reliable continuous operation.

How do I remove excess oil from an Ingersoll Rand UP6 without fully draining it?

If the compressor is overfilled, first shut it down and allow pressure to release safely. Check the sight glass to confirm the oil level. Excess oil can sometimes be removed through the oil drain valve slowly, capturing small amounts into a clean container rather than performing a full drain. Never open pressurized components. Always follow manufacturer safety procedures to avoid injury or contamination.

What causes too much oil in a compressor system?

Common causes of oil carry-over include overfilling the oil reservoir, low operating temperatures, clogged separator filters, damaged scavenge lines, and degraded oil. When oil cannot separate properly from compressed air, it may enter downstream equipment. Regularly monitoring temperature, replacing separator elements, and changing oil annually can help prevent oil carry-over issues.

Why is oil coming out of my air compressor?

Oil discharge usually indicates a failing air/oil separator, overfilled oil sump, blocked return (scavenge) line, or excessive internal pressure. It may also occur if the compressor runs below the recommended temperature. Inspect separator elements and ensure oil levels are correct. Continued oil discharge can contaminate air tools and production lines, so prompt maintenance is recommended.

How much oil does an Ingersoll Rand UP6 hold?

The oil capacity varies depending on the specific UP6 model and tank size. Smaller units may hold several gallons, while larger industrial models require significantly more. The exact capacity should always be confirmed in the model’s service manual or on the specification plate. Maintaining oil within the recommended sight-glass range is critical for safe operation.

Is it worse to overfill or underfill compressor oil?

Both conditions are harmful. Overfilling can increase crankcase pressure, damage seals, and cause oil carry-over into the air system. Underfilling reduces lubrication, leading to overheating and premature wear. For rotary screw compressors like the UP6, maintaining the correct oil level ensures proper sealing, cooling, and long service life.

How do I properly bleed pressure from the compressor?

To release pressure safely, shut the unit off and allow it to unload. Follow manufacturer procedures and use the system’s pressure relief valve if necessary. Always wear safety glasses and never open fittings under pressure. Ensure the air tank and separator tank are fully depressurized before performing maintenance or checking internal components.

What are the signs of a faulty drain valve?

A faulty drain valve may leak continuously, fail to release condensate, or cause pressure loss. You might notice excessive moisture in the air lines or pooling water beneath the unit. In automatic drain systems, failure can also cause separator inefficiency. Regular inspection prevents corrosion, contamination, and costly downstream damage.

What are the signs of oil carry-over in compressed air systems?

Signs include oily residue in air lines, contaminated filters, reduced air quality, and excessive oil consumption. You may also observe smoke-like discharge from air tools. Oil carry-over can affect pneumatic equipment performance and damage sensitive machinery. Checking separator elements and monitoring operating temperature helps diagnose the issue early.

How can I prevent oil problems in my UP6 compressor?

Preventive maintenance is key. Keep oil at the proper level, replace air/oil separators as scheduled, inspect scavenge lines for blockage, and change oil annually or per service intervals. Ensure the compressor operates within its designed temperature range. Routine inspections reduce downtime and extend the lifespan of your Ingersoll Rand UP6 system.