Lennox ML180UH

Parts Arrangement

ML180UH Gas Furnace

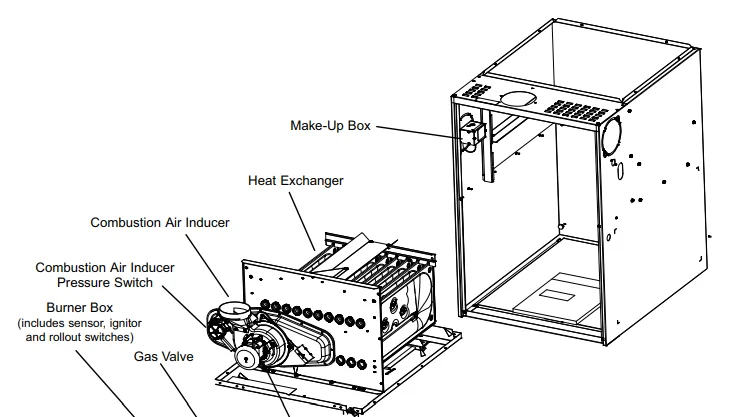

The ML180UH unit is shipped ready for installation in the upflow or horizontal right position (for the horizontal left position, the combustion air pressure switch must be moved). The furnace is shipped with the bottom panel in place. The bottom panel must be removed if the unit is to be installed in a horizontal application. The panel may also be removed in upflow applications.

Shipping and Packing List

Package 1 of 1 contains

- 1 − Assembled ML180UH unit

- 1 − Bag assembly containing the following:

- 2 − Screws

- 1 − Snap bushing

- 1 − Snap plug

- 1 − Wire tie

- 1 − Vent warning label

- 1 − Owner’s manual and warranty card

The following items may be ordered separately:

- 1 − Thermostat

- 1 − Suspension kit (for horizontal installations)

- 1 − Propane/LP changeover kit

- 1 − Return air base

- 1 − High altitude kit

- 1 − Side filter kit

Check equipment for shipping damage. If you find any damage, immediately contact the last carrier.

Use of Furnace as Construction Heater

Lennox does not recommend the use of ML180UH units as a construction heater during any phase of construction. Very low return air temperatures, harmful vapors, and operation of the unit with clogged or misplaced filters will damage the unit. ML180UH units may be used for heating of buildings or structures under construction if the following conditions are met:

- The vent system must be permanently installed per these installation instructions.

- A room thermostat must control the furnace. The use of fixed jumpers that will provide continuous heating is not allowed.

- The return air duct must be provided and sealed to the furnace.

- Return air temperature range between 60°F (16°C) and 80°F (27°C) must be maintained.

- Air filters must be installed in the system and must be maintained during construction.

- Air filters must be replaced upon construction completion.

- The input rate and temperature rise must be set per the furnace rating plate.

- One hundred percent (100%) outdoor air must be provided for combustion air requirements during construction. Temporary ducting may supply outdoor air to the furnace. Do not connect the duct directly to the furnace. Size the temporary duct following these instructions in the section for Combustion, Dilution, and Ventilation Air in a confined space with air from outside.

- The furnace heat exchanger, components, duct system, air filters, and evaporator coils must be thoroughly cleaned following final construction clean-up.

- All furnace operating conditions (including ignition, input rate, temperature rise, and venting) must be verified according to these installation instructions.

Combustion, Dilution & Ventilation Air

In the past, there was no problem in bringing in sufficient outdoor air for combustion. Infiltration provided all the air that was needed. In today’s homes, tight construction practices make it necessary to bring in air from outside for combustion. Take into account that exhaust fans, appliance vents, chimneys, and fireplaces force additional air that could be used for combustion out of the house. Unless outside air is brought into the house for combustion, negative pressure (outside pressure is greater than inside pressure) will build to the point that a downdraft can occur in the furnace vent pipe or chimney.

As a result, combustion gases enter the living space, creating a potentially dangerous situation. In the absence of local codes concerning air for combustion and ventilation, use the guidelines and procedures in this section to install ML180UH furnaces to ensure efficient and safe operation. You must consider combustion air needs and requirements for exhaust vents and gas piping.

A portion of this information has been reprinted with permission from the National Fuel Gas Code (ANSI-Z223.1). This reprinted material is not the complete and official position of the ANSI on the referenced subject, which is represented only by the standard in its entirety. All gas-fired appliances require air for the combustion process. If sufficient combustion air is not available, the furnace or other appliances will operate inefficiently and unsafely. Enough air must be provided to meet the needs of all fuel-burning appliances and appliances such as exhaust fans that force air out of the house.

When fireplaces, exhaust fans, or clothes dryers are used at the same time as the furnace, much more air is necessary to ensure proper combustion and to prevent a downdraft. Insufficient air causes incomplete combustion, which can result in carbon monoxide. In addition to providing combustion air, fresh outdoor air dilutes contaminants in the indoor air. These contaminants may include bleaches, adhesives, detergents, solvents, and other contaminants that can corrode furnace components. The requirements for providing air for combustion and ventilation depend largely on whether the furnace is installed in an unconfined or a confined space.

Unconfined Space

An unconfined space is an area such as a basement or large equipment room with a volume greater than 50 cubic feet (1.42 m3) per 1,000 Btu (.29 kW) per hour of the combined input rating of all appliances installed in that space. This space also includes adjacent rooms, which are not separated by a door. Though an area may appear to be unconfined, it might be necessary to bring in outdoor air for combustion if the structure does not provide enough air by infiltration. If the furnace is located in a building of tight construction with weather stripping and caulking around the windows and doors, follow the procedures in the air from outside section.

Confined Space

A confined space is an area with a volume less than 50 cubic feet (1.42 m3) per 1,000 Btu (.29 kW) per hour of the combined input rating of all appliances installed in that space. This definition includes furnace closets or small equipment rooms. When the furnace is installed so that supply ducts carry air circulated by the furnace to areas outside the space containing the furnace, the return air must be handled by ducts that are sealed to the furnace casing and that terminate outside the space containing the furnace.

This is especially important when the furnace is mounted on a platform in a confined space such as a closet or small equipment room. Even a small leak around the base of the unit at the platform or at the return air duct connection can cause a potentially dangerous negative pressure condition. Air for combustion and ventilation can be brought into the confined space either from inside the building or from outside.

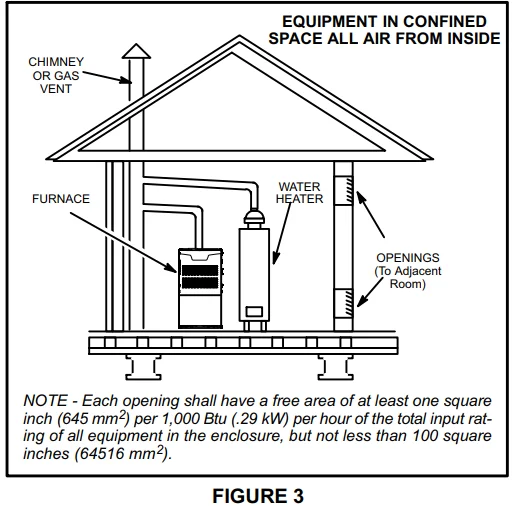

Air from Inside

If the confined space that houses the furnace adjoins a space categorized as unconfined, air can be brought in by providing two permanent openings between the two spaces. Each opening must have a minimum free area of 1 square inch (645 mm2) per 1,000 Btu (.29 kW) per hour of total input rating of all gas-fired equipment in the confined space. Each opening must be at least 100 square inches (64,516 mm2). One opening shall be within 12 inches (305 mm) of the top of the enclosure and one opening within 12 inches (305 mm) of the bottom. See figure 3.

Air from Outside

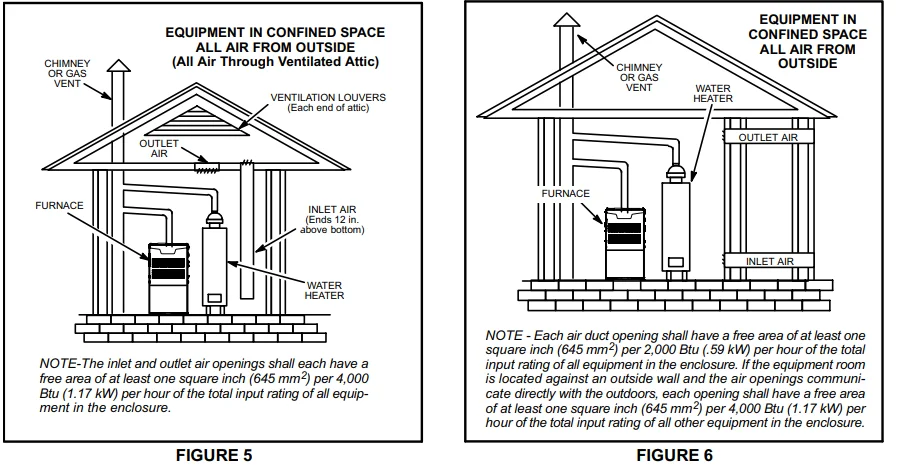

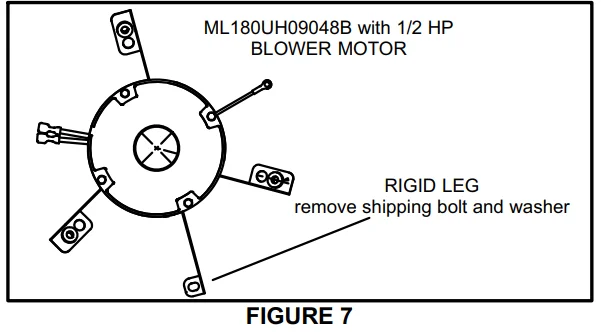

If air from outside is brought in for combustion and ventilation, the confined space must have two permanent openings. One opening shall be within 12 inches (305 mm) of the top of the enclosure and one opening within 12 inches (305 mm) of the bottom. These openings must communicate directly or by ducts with the outdoors or spaces (crawl or attic) that freely communicate with the outdoors, or indirectly through vertical ducts.

Each opening shall have a minimum free area of 1 square inch (645 mm2) per 4,000 Btu (1.17 kW) per hour of total input rating of all equipment in the enclosure. See figures 4 and 5. When communicating with the outdoors through horizontal ducts, each opening shall have a minimum free area of 1 square inch (645 mm2) per 2,000 Btu (.56 kW) per total input rating of all equipment in the enclosure. See figure 6.

When ducts are used, they shall be of the same cross-sectional area as the free area of the openings to which they connect. The minimum dimension of rectangular air ducts shall be no less than 3 inches (75 mm). In calculating free area, the blocking effect of louvers, grilles, or screens must be considered.

If the design and free area of protective covering are not known for calculating the size opening required, it may be assumed that wood louvers will have 20 to 25 percent free area, and metal louvers and grilles will have 60 to 75 percent free area. Louvers and grilles must be fixed in the open position or interlocked with the equipment so that they are opened automatically during equipment operation.

Setting Equipment

The ML180UH gas furnace can be installed as shipped in either the upflow position or the horizontal position. Select a location that allows for the required clearances that are listed on the unit nameplate. Also consider gas supply connections, electrical supply, vent connection, and installation and service clearances [24 inches (610 mm) at unit front]. The unit must be level.

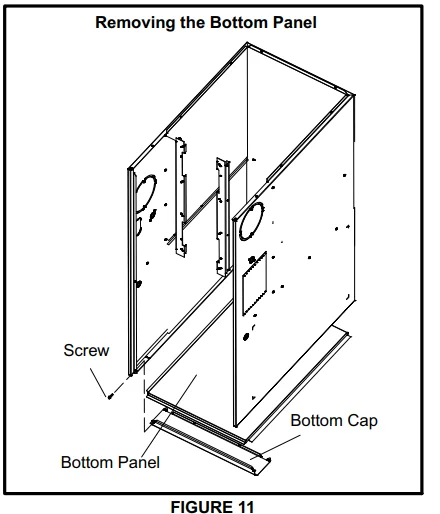

NOTE − Units with 1/2 hp blower motors are equipped with three flexible legs and one rigid leg. See figure 7. The rigid leg is equipped with a shipping bolt and a flat white plastic washer (rather than the rubber mounting grommet used with a flexible mounting leg). The bolt and washer must be removed before the furnace is placed into operation. After the bolt and washer have been removed, the rigid leg will not touch the blower housing.

Upflow Applications

Allow for clearances to combustible materials as indicated on the unit nameplate. Minimum clearances for closet or alcove installations are shown in Figure 8.

Return Air −− Upflow Applications

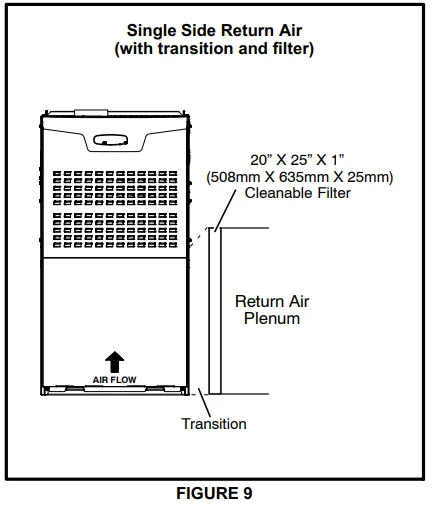

Return air can be brought in through the bottom or either side of the furnace installed in an upflow application. If the furnace is installed on a platform with a bottom return, make an airtight seal between the bottom of the furnace and the platform to ensure that the furnace operates properly and safely. The furnace is equipped with a removable bottom panel to facilitate installation. Markings are provided on both sides of the furnace cabinet for installations that require side return air. Cut the furnace cabinet to the maximum dimensions shown on page 2. NOTE − 60C and 60D units that require air volumes over 1800 cfm (850 L/s) must have one of the following:

- Single side return air with transition to accommodate 20 x 25 x 1 in. (508 x 635 x 25 mm) cleanable air filter. (Required to maintain proper air velocity.) See figure 9.

- Single-sided return air with an optional return air base. See figure 10.

- Bottom return air.

- Return air from both sides.

- Bottom and one side return air.

Refer to the Engineering Handbook for additional information.

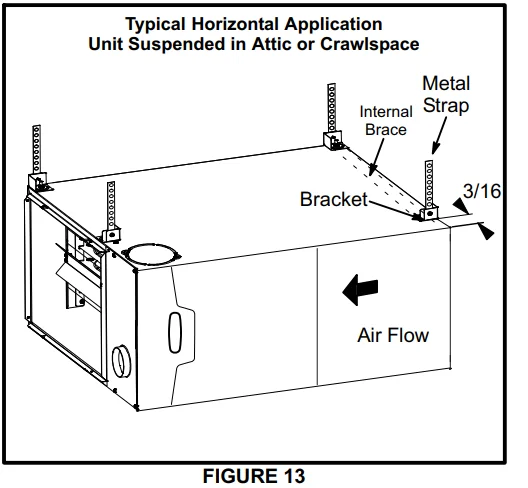

Removing the Bottom Panel

Remove the two screws that secure the bottom cap to the furnace. Pivot the bottom cap down to release the bottom panel. Once the bottom panel has been removed, reinstall the bottom cap. See figure 11.

Horizontal Applications

The ML180UH furnace can be installed in horizontal applications. Order a horizontal suspension kit (51W10) from Lennox, or use an equivalent suspension method. Allow for clearances to combustible materials as indicated on the unit nameplate. Minimum clearances for closet or alcove installations are shown in Figure 12.

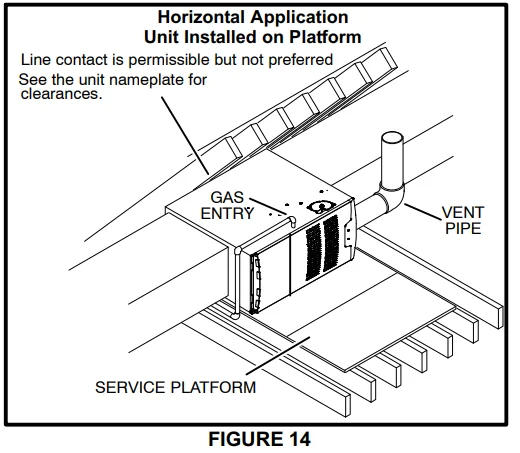

This furnace may be installed in either an attic or a crawl space. Either suspend the furnace from roof rafters or floor joists, as shown in Figure 13, or install the furnace on a platform, as shown in Figure 14.

NOTE − Heavy-gauge perforated sheet metal straps may be used to suspend the unit from roof rafters or ceiling joists. When straps are used to suspend the unit in this way, support must be provided for both ends. The straps must not interfere with the plenum or exhaust piping installation. Cooling coils and supply and return air plenums must be supported separately.

NOTE − When the furnace is installed on a platform in a crawlspace, it must be elevated enough to avoid water damage and to allow the evaporator coil to drain.

Return Air −− Horizontal Applications

Return air must be brought in through the end of a furnace installed in a horizontal application. The furnace is equipped with a removable bottom panel to facilitate installation. See figure 11.

Filters

This unit is not equipped with a filter or rack. A field-provided high-velocity filter is required for the unit to operate properly. Table 1 lists recommended filter sizes. A filter must be in place at any time the unit is operating.

Duct System

Use industry-approved standards (such as those published by Air Conditioning Contractors of America or American Society of Heating, Refrigerating and Air Conditioning Engineers) to size and install the supply and return air duct system. This will result in a quiet and low-static system that has uniform air distribution.

NOTE − Do not operate the furnace in the heating mode with an external static pressure that exceeds 0.5 inches w.c. Higher external static pressures may cause erratic limit operation.

Supply Air Plenum

If the furnace is installed without a cooling coil, a removable access panel must be installed in the supply air duct. The access panel should be large enough to permit inspection (either by smoke or reflected light) of the heat exchanger for leaks after the furnace is installed. The furnace access panel must always be in place when the furnace is operating, and it must not allow leaks into the supply air duct system.

Return Air Plenum

NOTE − Return air must not be drawn from a room where this furnace, or any other gas-fueled appliance (i.e., water heater), or carbon monoxide-producing device (i.e., wood fireplace) is installed.

When return air is drawn from a room, a negative pressure is created in the room. If a gas appliance is operating in a room with negative pressure, the flue products can be pulled back down the vent pipe and into the room. This reverse flow of the flue gas may result in incomplete combustion and the formation of carbon monoxide gas. This toxic gas might then be distributed throughout the house by the furnace duct system.

In upflow applications, the return air can be brought in through the bottom or either side of the furnace. If a furnace with the bottom return air is installed on a platform, make an airtight seal between the bottom of the furnace and the platform to ensure that the unit operates properly and safely. Use fiberglass sealing strips, caulking, or an equivalent sealing method between the plenum and the furnace cabinet to ensure a tight seal. If a filter is installed, size the return air duct to fit the filter frame.

Venting

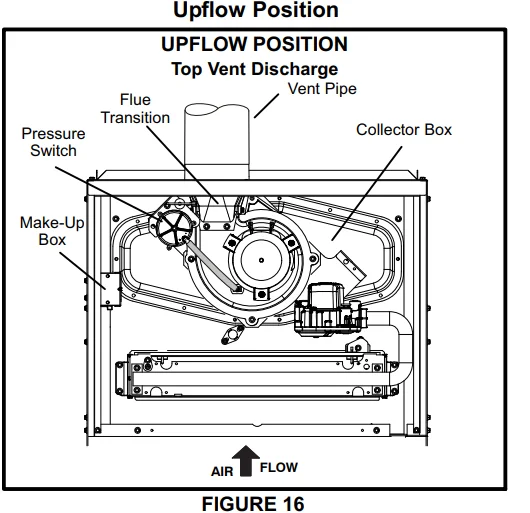

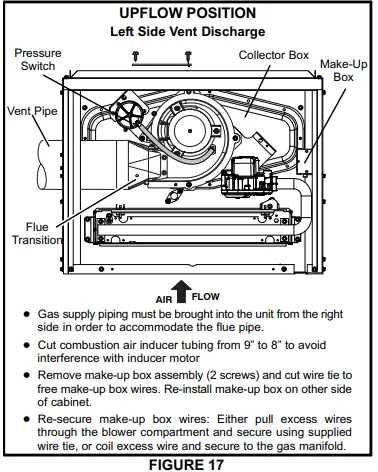

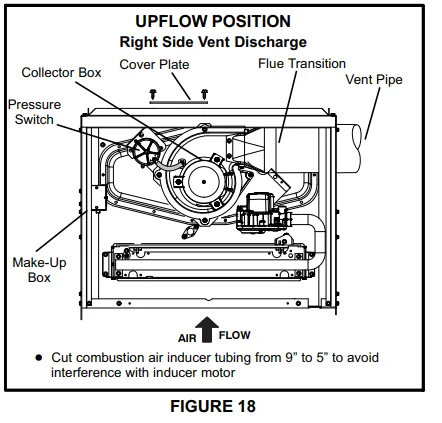

A 4-inch diameter flue transition is factory-installed on the combustion air inducer outlet of all models. Figure 16 shows the combustion air inducer as shipped from the factory.

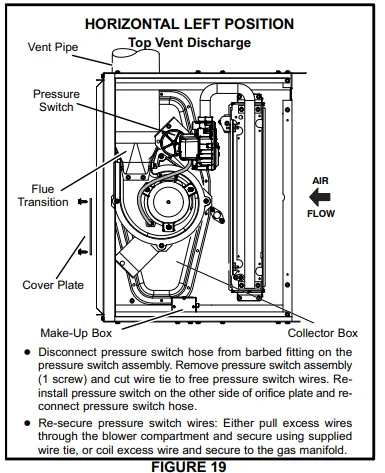

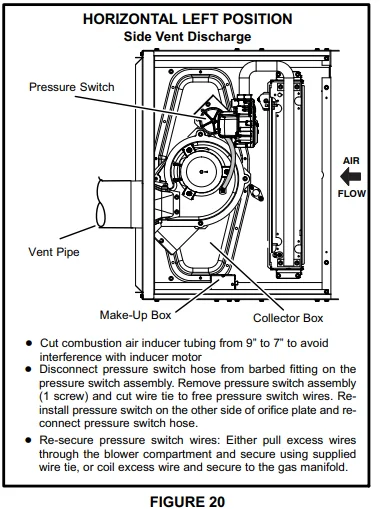

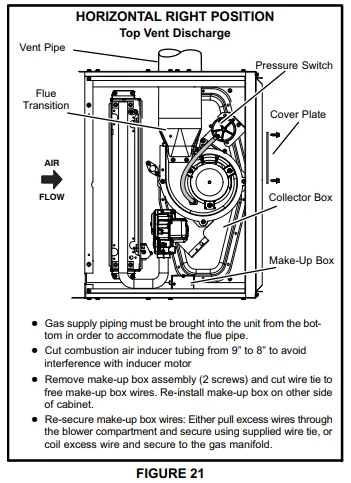

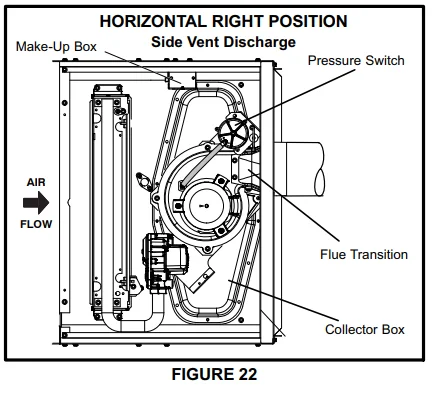

If necessary, reposition the combustion air inducer, pressure switch, and/or make-up box as needed per the following steps. See figures 16 through 22.

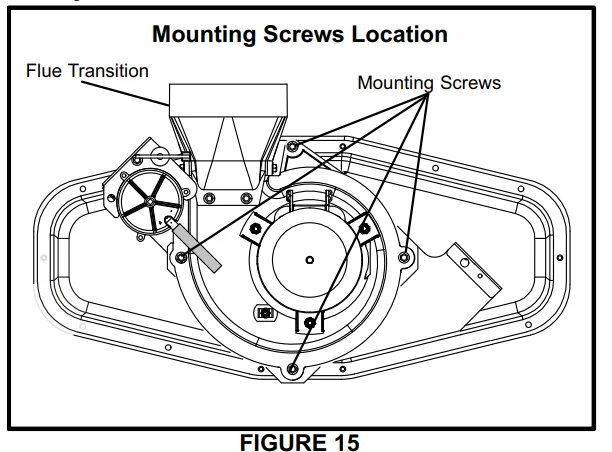

- Remove the four mounting screws (figure 15) that secure the combustion air inducer/pressure switch assembly to the orifice plate. Lift the assembly and rotate it 90 degrees clockwise or counterclockwise to either the 3 o’clock position or the 9 o’clock position. Re-secure with four screws. The gasket should be left in place.

- Use tin snips to cut the preferred opening on the cabinet for repositioning the flue outlet. Use the cut-out piece as a cover plate to patch the unused opening on the cabinet.

The ML180UH series units are classified as fan-assisted Category I furnaces when vertically vented according to the latest edition of the National Fuel Gas Code (NFPA 54 / ANSI Z223.1) in the USA. A fan-assisted Category I furnace is an appliance equipped with an integral mechanical means to either draw or force combustion products through the combustion chamber and/or heat exchanger. The ML180UH is not approved for use with horizontal venting.

NOTE − Use these instructions as a guide. They do not supersede local codes. This furnace must be vented according to all local codes, these installation instructions, and the provided venting tables in these instructions.

The venting tables in this manual were extracted from the National Fuel Gas Code (NFPA 54 / ANSI Z223.1) and are provided as a guide for proper vent installation. Proper application, termination, construction, and location of vents must conform to local codes having jurisdiction. In the absence of local codes, the NFGC serves as the defining document. Refer to the tables and the venting information contained in these instructions to properly size and install the venting system.

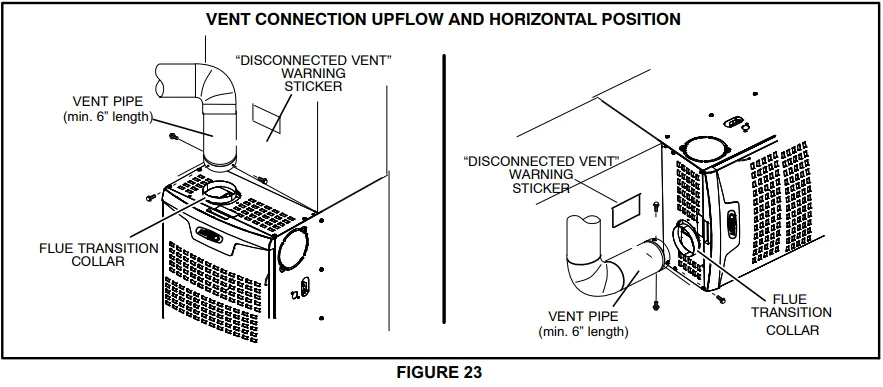

Use self-drilling sheet metal screws or a mechanical fastener to firmly secure the vent pipe to the round collar of the flue transition. If self-drilling screws are used to attach the vent pipe, it is recommended that three be used. Drive one self-drilling screw through the front and one through each side of the vent pipe and collar. See figure 23. Install the first vent connector elbow at a minimum of six inches (152 mm) from the furnace vent outlet. See figure 23.

For More Manuals By Lennox, Visit ManualsLibraryy

Lennox ML180UH-FAQS

What is the efficiency rating of the Lennox ML180UH?

The ML180UH has an AFUE efficiency of 80%, making it an energy-efficient option for homes.

Where is the air filter located?

For horizontal units, the washable air filter is located behind the return air grille or inside the blower compartment. Turn off power, remove the panel or grille, and slide out the filter.

How often should I change the air filter?

Standard one-inch disposable filters should be replaced every three months. Washable filters should be cleaned regularly as recommended by the manufacturer.

What happens if the furnace filter is installed backward?

Installing the filter backward reduces efficiency, overworks the blower, and increases energy costs. Always follow the airflow arrows when inserting the filter.

How do I install the air filter correctly?

Turn off the furnace, remove the panel or grille, align the filter with the airflow direction marked on it, slide it in, and replace the panel.

Can I use a thicker or different-sized filter?

It’s recommended to use the size specified for your unit. Using a thicker filter (e.g., 16x25x4 instead of 16x25x1) may require adjustments or affect airflow.

How do I set my thermostat for the Lennox furnace?

Set a comfortable temperature: 68–72°F in winter and 78°F in summer. Adjust at night or when away to save energy.

What is the difference between Lennox EL and ML series?

The EL Series is high-efficiency and quiet, offering advanced features, while the ML Series is reliable, energy-efficient, and rugged, designed for long-term, trouble-free operation.

What are common problems with Lennox units?

Common issues include dirty filters, obstructed vents, power issues, refrigerant leaks, dirty coils, broken fan motors, or faulty capacitors. Regular maintenance can prevent most problems.

How long will a Lennox AC or furnace last?

With proper maintenance, Lennox HVAC systems typically last 15–20 years.