QILIN BWT20C Handheld Laser Cleaning System

Security information

When using the system, please ensure that the operation is correct and safe. Some signs or words will be used to remind you of dangerous matters, and some important information.

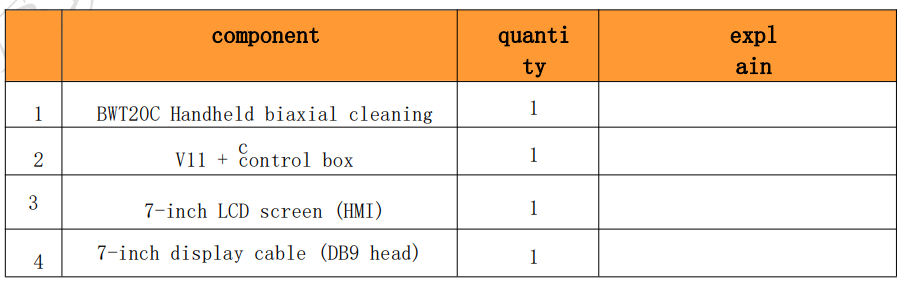

Receiving goods, unpacking, and inspection

The product uses shock-proof soft packaging. If the package has any external damage marks, please check the damage to the equipment and notify the carrier and the carrier of the damage in written documents.

Remove all the goods from the packaging, and keep the packaging materials and wiring spare parts. When dismantling the package and removing the goods, please be careful with the goods for safety. After removing the goods, please check if the parts are complete and intact. If missing parts or parts are damaged, please contact Qilin Laser immediately. If any obvious damage to the equipment, do not install or debug the equipment. BWT20C The shipping list of the user’s manual is shown in the following table: (As the product will be updated and upgraded, the shipping list may also be adjusted.)

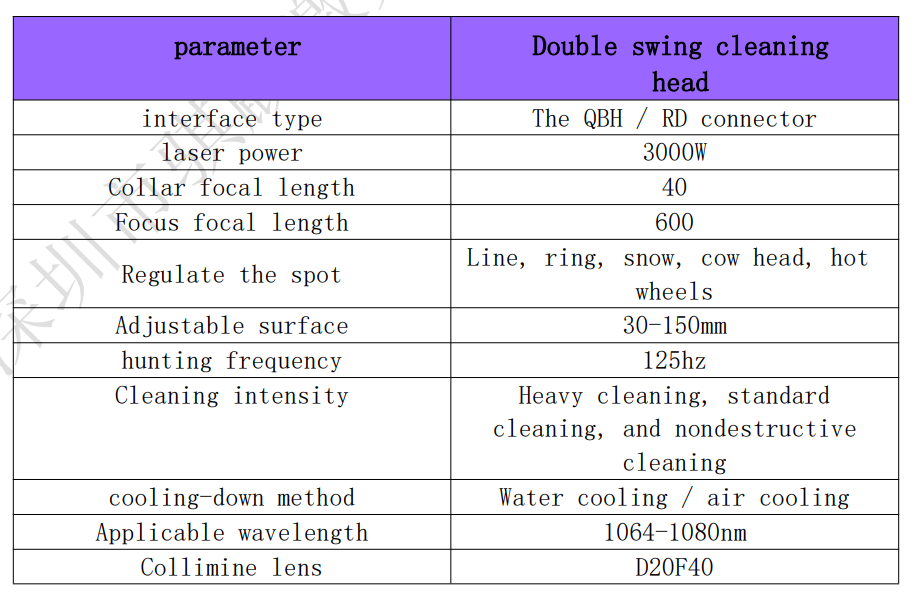

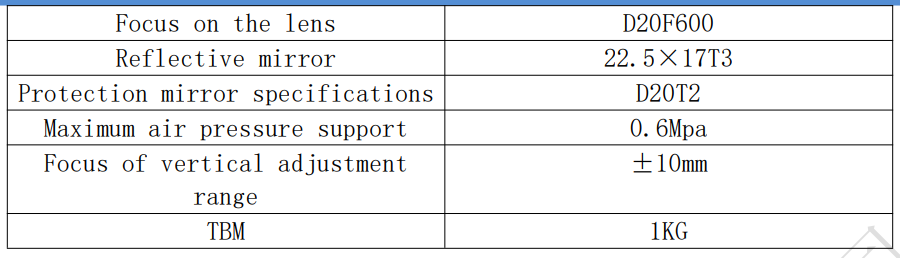

Qilin double swing handheld laser welding /cleaning system introduction

Qilin double swing handheld laser control system is a control system for fiber laser cleaning. There are five cleaning modes: line, ring, snowflake, cowhead, and hot wheel. The overall weight is light, fast cooling of the optical cavity, ergonomic design, high-end chip, a variety of safety protection measures, greatly improving the work efficiency.

Product installation size drawing

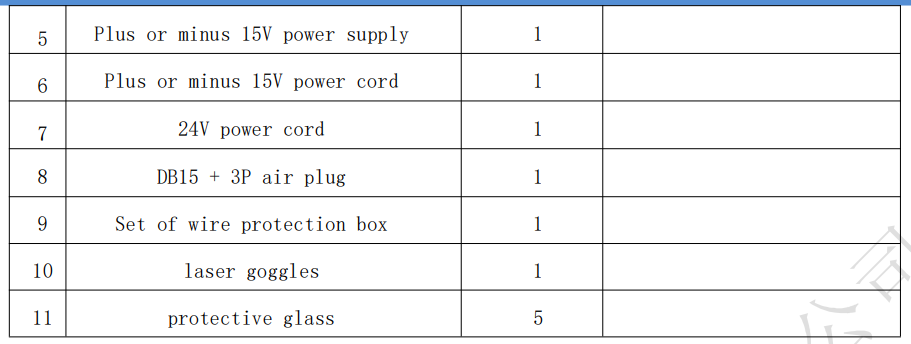

Touch-screen installation dimensions

The installation dimensions of the touch screen are shown below:

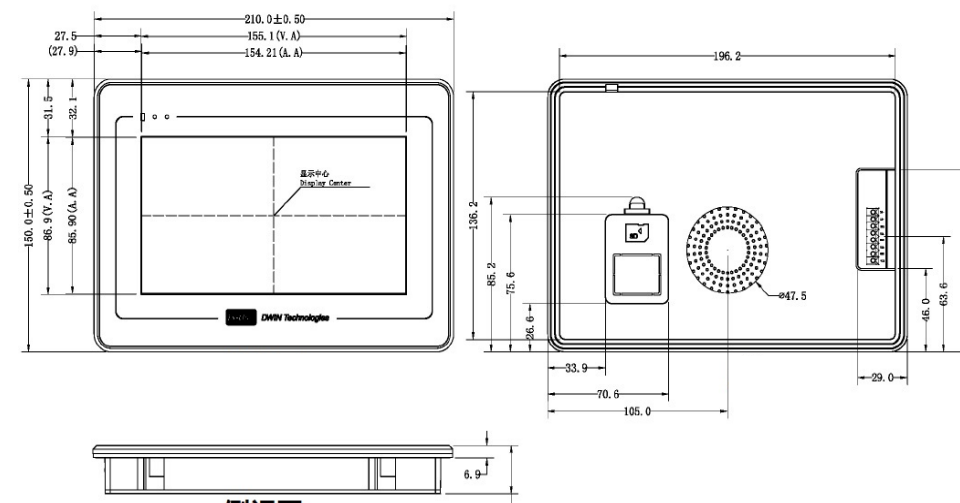

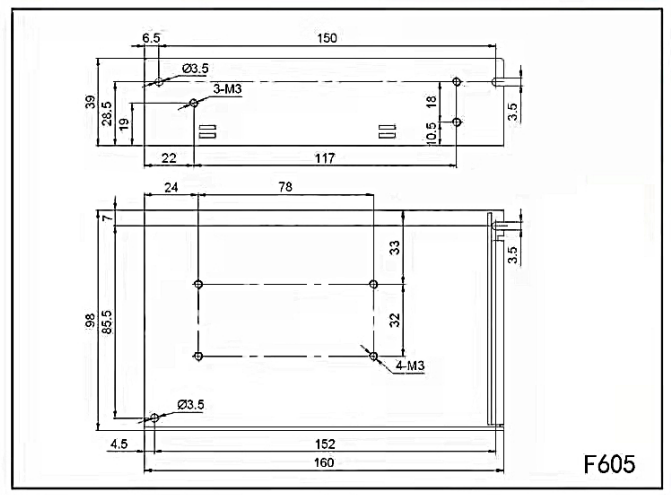

Control box mounting dimensions

The installation size of the control box is shown in the following figure

Installation dimensions of a 15V switching power supply

The installation size of the 15V switching power supply is shown in the following figure

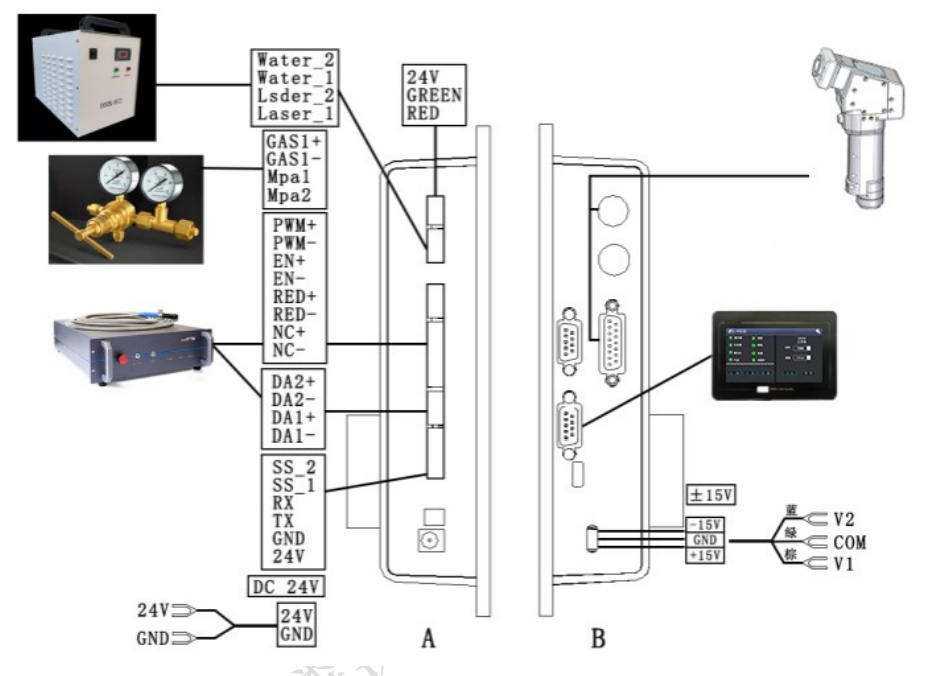

Wiring of the control box

The following figure shows the wiring diagram of the whole system. The system wiring

can refer to the schematic diagram and refer to the relevant chapter for detailed information interface definition.

Structural diagram of the gun and pipe, and the water pipe interface

Figure 2.21 Schematic diagram of water pipe connection, DB15, and Samsung Aviation plug socket.

- Water pipe: a water pipe in and out, forming a closed water cycle.

- Tracheal: single connector, gas output.

- DB15 interface: connect the control system and the gun head communication

function. - Samsung Air Plug: Connect the conduction and trigger signal connector.

Power interface

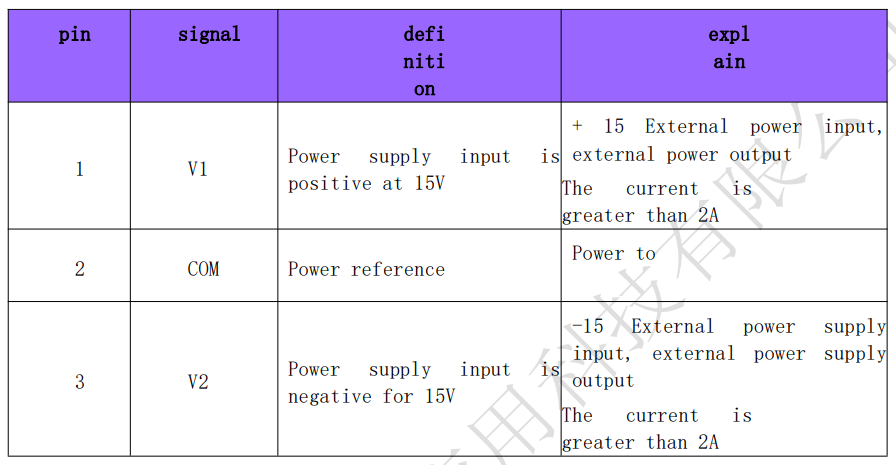

+ 15V interface is the interface to provides power for the motor drive inside the control box, the voltage is positive or minus 15V (+ 15V), Table 2.3.1 shows the definition of the + 15V interface power line.

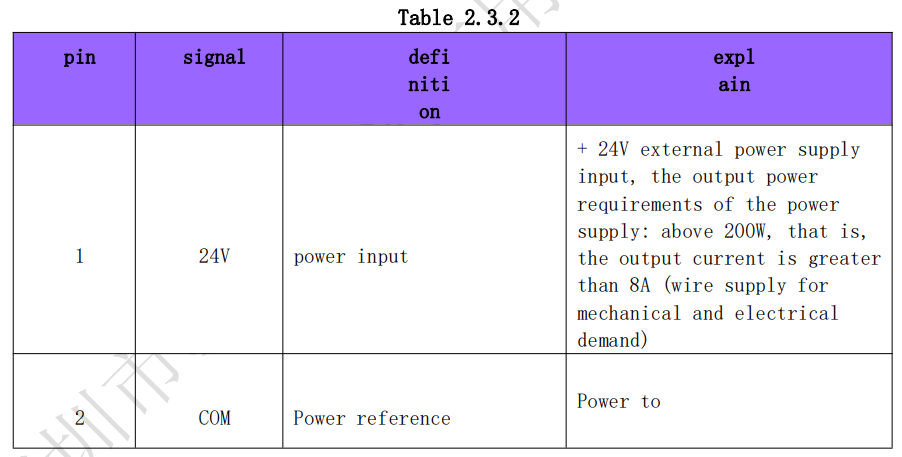

The DC24V interface is the interface for providing the power supply for the internal

control system of the control box. The DC voltage is 24V (DC24V). Table 2.3.2 defines the wiring of the POWER 2 power cord.

Figure 2.3.2 shows the schematic diagram of the POWER 2 power supply line

Table 2.3.2 shows the definition of the + 24V interface power line.

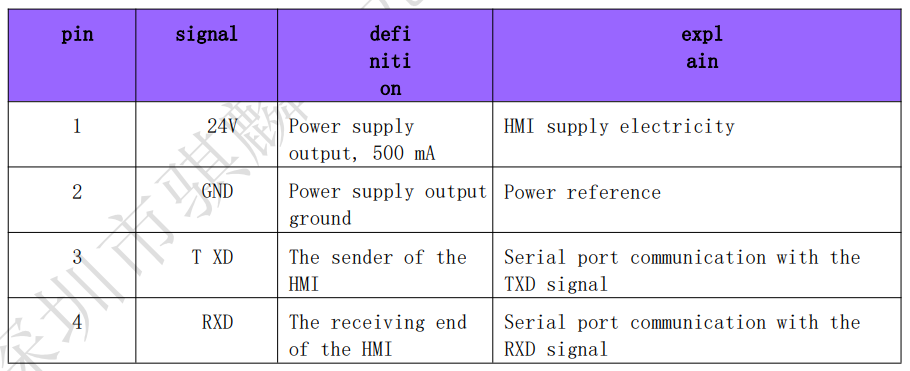

human-computer interface HMI

The HMI interface is a DB9 black plug through which the motherboard supplies and

communicates to the HMI,

Table 2.4 defines the HMI interface.

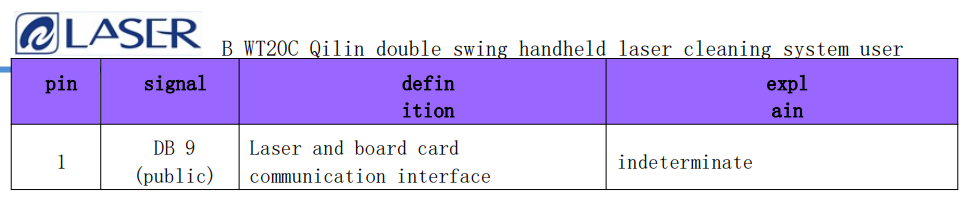

the laser decoding interface

LASER RS232 The interface is the board card and the laser communication

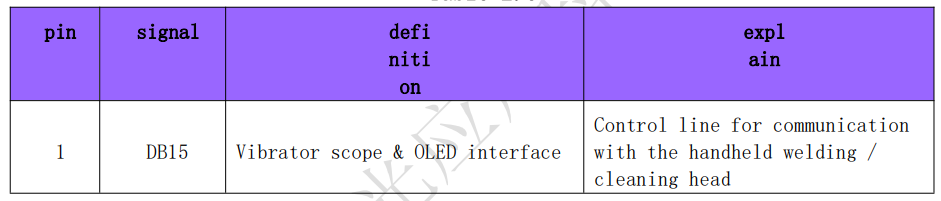

Double swing handheld laser welding head interface

The motherboard provides a vibrating scope interface, compatible with the common digital lens interface on the market. Table 2.6 shows the definition of the vibration scope interface.

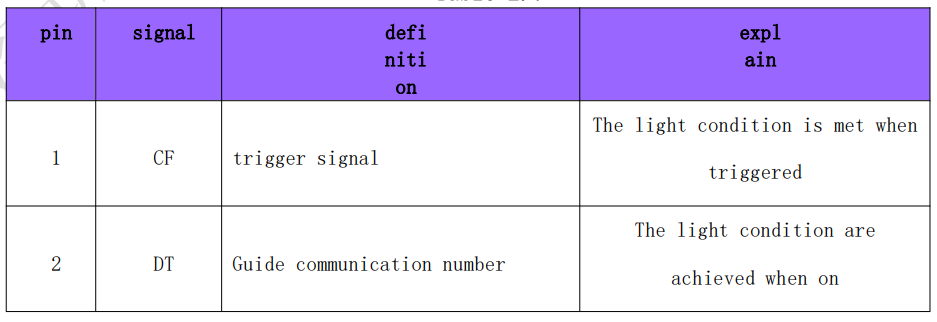

Lead trigger line (Note: special for lead wire welding)

The control box provides a special security trigger signal line interface, which can provide a security guarantee for the operation.

Introduction of the fan interface

The control box provides a dedicated 24V fan port interface position, an independent socket, not easy to insert wrong.

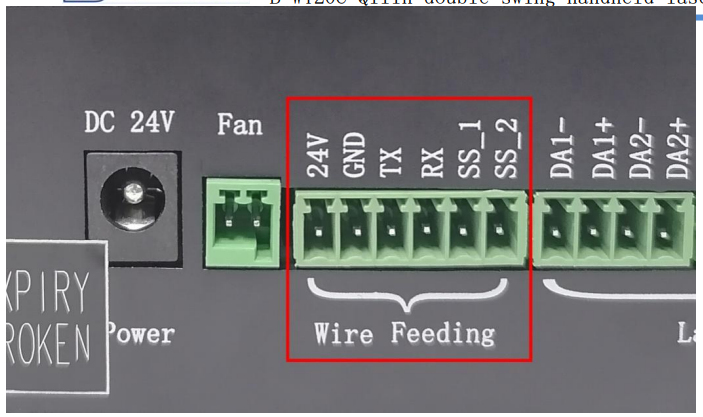

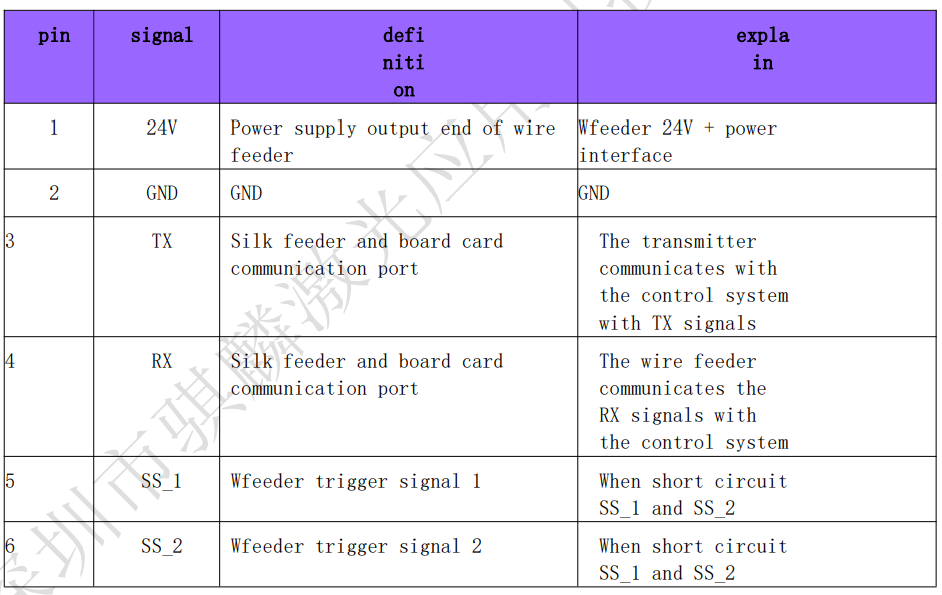

Control interface of the wire feeding machine (note: special wire feeder for welding)

The control box provides a special communication interface for the control wire feeder, and the 24V power supply is directly connected to the power input end of the control box, and can be provided.

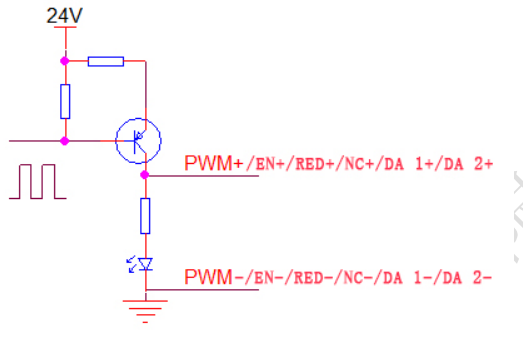

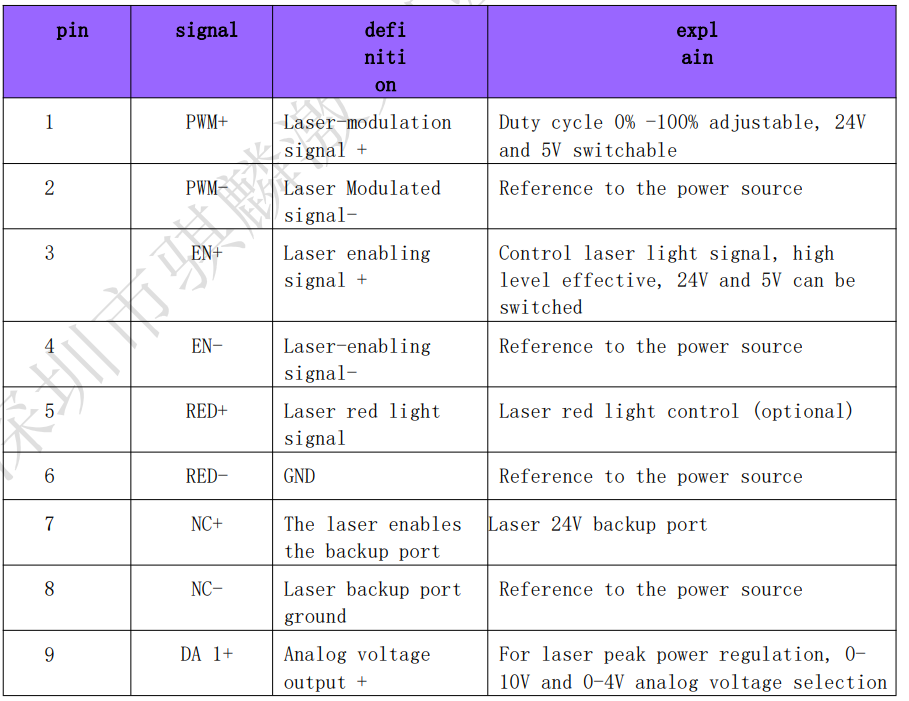

Laser control interface

The laser interface is an 8-PIN, green terminal + 4-PIN green terminal

Table 2.10 shows the laser interface definition.

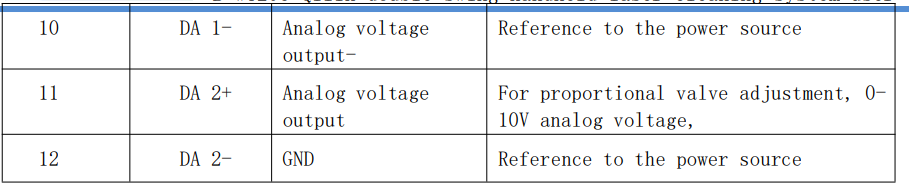

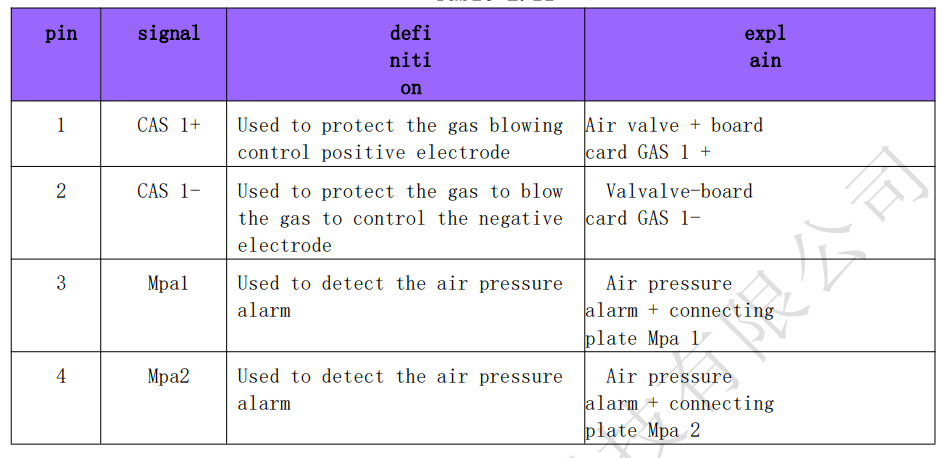

Gas control and air pressure detection interface (note: special welding interface)

The control box provides a dedicated IO interface; all output IO can use the OC output to

directly drive the relay, and the maximum current can reach 500 mA.. The wiring diagram is shown below.

Figure 2.11.1, schematic diagram of the gas control interface

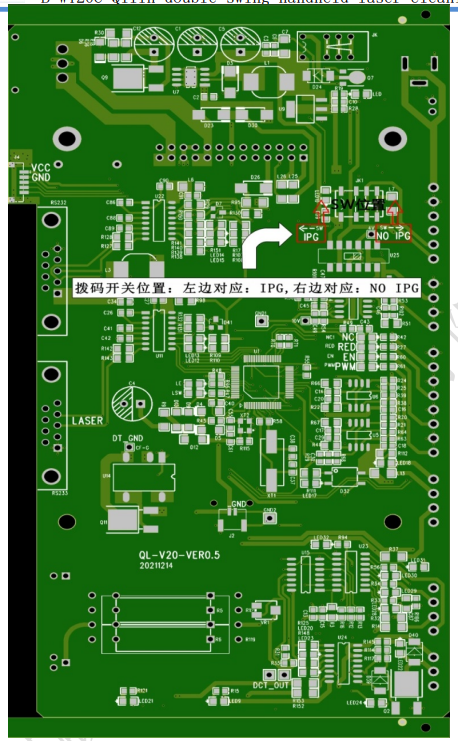

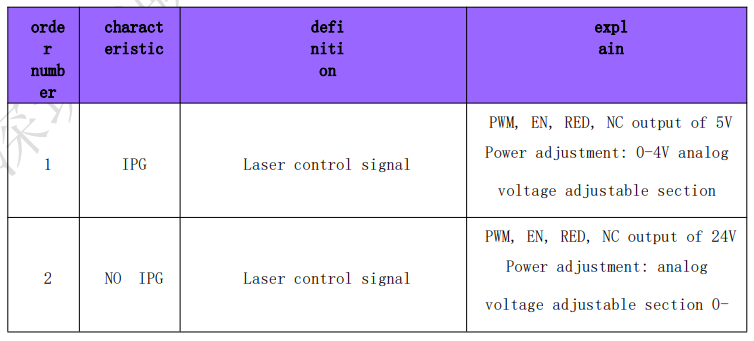

the dial-code switch

Figure 2.12, schematic diagram of the dial-code switch

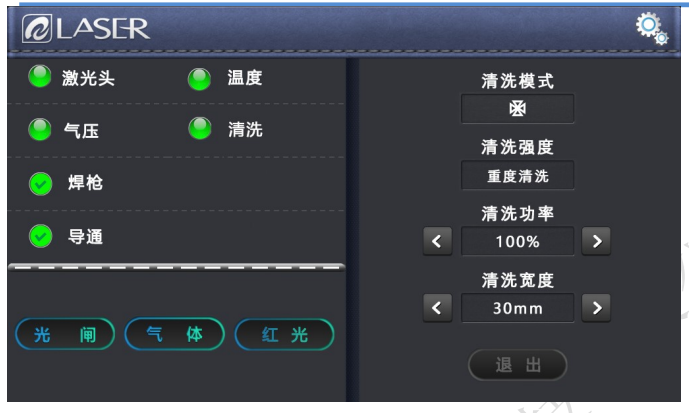

Man-machine interface function and operation introduction

The operation panel of the Qilin double swing handheld laser cleaning system adopts

7-inch configuration capacitive touch screen, which is dignified, generous, and easy to operate. It can be set up with laser, laser cleaning head-related parameters, but can also control the light mode. At the same time, it can control the energy strength during cleaning, and the highest can achieve laser no damage cleaning material surface.

Introduction of the function and operation of the main interface

This interface is the welding interface mode. Switch the welding interface and replace the handheld welding to start welding.

Set the interface function and operation introduction

Press the “” in the main interface to enter the setting interface, as shown in the figure below

Parameter setting, red light offset setting, S / N and language setting, and hardware configuration are all functions in welding mode. Please select cleaning mode. After selecting the cleaning mode, as shown in the figure below.

Important reminder: In the cleaning mode, it is necessary to continuously buckle the welding gun twice to continue the light for cleaning.

- Cleaning mode: line, ring, snowflake, cow head, Hot Wheels.

- Cleaning strength: including heavy cleaning, standard cleaning, and non-destructive cleaning. Click to change the cleaning mode.

- Cleaning power: Set the peak power of the laser during cleaning.

- Wash width: Set the cleaning range of the laser during cleaning.

- Light lock: the light switch is open to the normal light.

- Gas: When the gas opens, the gas valve port will output 24V voltage, and the gas

will automatically blow without opening during welding. - Red light: Opening the red light preview swings out the set graph.

- Exit: Exit the cleaning mode and enter the welding mode.

Clean the red light offset setting:

- Red light offset setting: When the red light is not in the center position of the nozzle, it can be adjusted through the red light offset setting X coordinate position.

- Start correction: zero the X coordinates.

- Clear correction: clear the previous step.

Note for using the cleaning system

- The double swing handheld welding head includes lasers, a water cooler, a laser-welding system, and laser laser-welding head. In order to avoid interference, keep away from the argon arc welding machine and related equipment with large interference to ensure that the safe distance is kept at more than 5 meters. Ensure that the laser-welding machine has an independent space when conditions permit.

- To reduce equipment leakage or static electricity, ensure the use of a light double pendulum industrial welding head equipment.

- Please repeatedly confirm whether the cable joint is connected and locked normally. After locking, it can be wrapped with insulation tape.

- Check whether the laser head and the optical fiber are locked and connected. After confirming that it is normal, the beautiful strip tape can be sealed and wound to ensure that the dust does not enter the laser head cavity.

- Check whether there is water seepage in the cavity and many waterways in the cavity. Do not loosen screws without professional training to prevent water droplets from entering the cavity.

- Check whether the protective lens drawer is normal, and ensure that the sealing ring is normal and effective. When replacing the protective lens, ensure that the alcohol wipes the external stains of the laser head at least 5 times, and ensure that the lens environment is clean and clean before the lens is replaced.

- The laser head is so complex. To avoid a short circuit, stay away from the water source and make sure that no liquid can be sprayed on the laser head.

- The laser head refuses to use strong wind to blow and clean the laser head, and can only be wiped with alcohol and a dust-free cloth.

- The laser head is installed with a digital motor. When used, it must be put gently to prevent motor failure.

- When the laser head is not used, please use the system gas blowing air many times to discharge the dust, remove the copper nozzle, use the sealing tape to seal, and use the copper nozzle to blow the air for more than 2 times before using it.

- Continuous interruption of the power supply will cause damage to the welding /cleaning control system. If the external wire transmitter, 24V power supply should provide 200W (power voltage 24V, output current equal to or greater than 8A)!

- The external safety lock is 24V high level, do not short connect with the aviation plug GND shell of the system cable, or do not pay attention to collide with each other when installation, otherwise, the short circuit may burn the power supply or the main control board.

FOR MORE MANUALS BY BLOGS, VISIT MANUALSLIBRARYY

QILIN BWT20C Handheld Laser Cleaning System-FAQs

What is laser cleaning and how does it work?

Laser cleaning uses focused laser light to remove dirt, rust, paint, or contaminants by vaporizing or peeling them off without harming the base material.

What materials can be cleaned with this laser system?

It can clean metals like steel and aluminum, stone, plastics, glass, and some composites by removing surface rust, paint, or other residues.

What safety precautions should I follow when using the handheld laser cleaner?

Always wear certified laser safety glasses and protective clothing. Operate in a well-ventilated area, keep others away, remove flammable materials, and ensure proper grounding to prevent injuries.

How do I maintain and clean the laser cleaning machine?

Regularly clean lenses with alcohol, oil moving parts lightly, check water levels, clean mirrors if needed, and remove debris from the machine base.

Can laser cleaning damage the surface being cleaned?

If used correctly with proper calibration, laser cleaning safely removes contaminants without damaging the underlying material.

What power settings are typical for laser cleaning machines like this?

Power usually ranges from 100 to 3000 watts depending on the task, with higher power used for tougher cleaning like heavy rust or thick paint.

What hazards are associated with laser cleaning?

Potential hazards include eye and skin injuries from laser exposure, inhaling fumes, fire risks from sparks, and electrical hazards from equipment.

What training is recommended before using the laser cleaner?

Operators should get comprehensive training on machine operation, safety procedures, emergency responses, and correct use of protective gear.