Remington RM2510 Rustler String Trimmer

SPECIFICATIONS

- Engine Type: Air-cooled, 2-Cycle

- Displacement:25 cc (1.52 cU. in.)

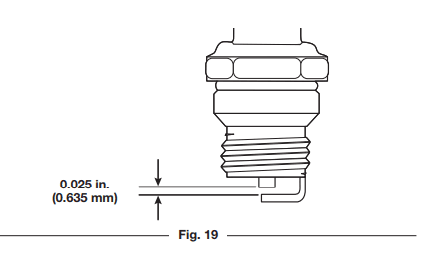

- Spark Plug Gap: 0.025 in. (0.635 mm)

- Spark Plug: Champion@ RDJ7J or equivalent plug

- Lubrication: Fuel/Oil Mixture

- Fuel/OilRatio: 40:1

- Fuel Tank Capacity: 10 oz. (296 ml)

- Approximate IJnit Weight (No fuel): 10- 11 lbs. (4.5 -5 kg)

- Trimmer Mechanism: Bump Head

- Trimming Line Diameter: 0.095 in. (2.41 mm)

- Cutting Path Diameter: 17 in. (43.18 cm)

ASSEMBLY

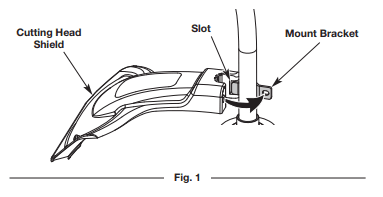

INSTALLING THE CUTTING HEAD SHIELD

- Remove the wing nut and washer from the cutting head shield.

- Insert the short tab (the one without a hole) on the mount bracket into the slot on the cutting head shield (Fig. 1).

- Rotate the cutting head shield counterclockwise to align the hole on the cutting head shield with the hole on the mount bracket (Fig. 1).

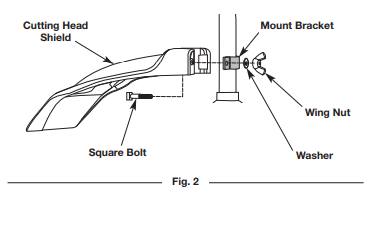

- Insert the square bolt into the hole underneath the cutting head shield (Fig. 2). Push the square bolt through the cutting head shield and mount the bracket.

- Put the washer onto the square bolt (Fig. 2).

- Screw the wing nut onto the square bolt until the cutting head shield is firmly in place (Fig. 2).

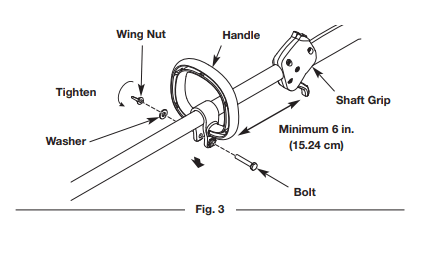

INSTALLING AND ADJUSTING THE HANDLE

Installing the Handle

- Push the handle down onto the shaft housing (Fig. 3). The hex bolt hole in the handle should be to the left.

- Insert the bolt into the hex bolt hole and push it through (Fig. 3). Place the washer onto the bolt. Screw the wing nut onto the bolt, but do not tighten the wing nut completely.

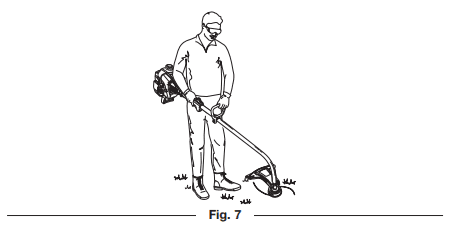

- While holding the unit in the operating position (Fig. 7), move the handle to the location that provides the best grip. Place it a minimum of 6 inches (15.24 cm) from the end of the shaft grip (Fig. 3).

- Tighten the wing nut until the handle is secure.

Adjusting the Handle

If the handle requires adjustment:

- Loosen the wing nut (Fig. 3).

- While holding the unit in the operating position (Fig. 7), move the handle to the location that provides the best grip. Place it a minimum of 6 inches (15.24 cm) from the end of the shaft grip (Fig. 3).

- Tighten the wing nut until the handle is secure.

OIL AND FUEL

OIL AND FUEL MIXING INSTRUCTIONS

The use of old and/or improperly mixed fuel is the most common cause of performance problems. use only fresh, clean unleaded gasoline. Follow the instructions carefully for the proper gasoline/oil mixture.

Definition Of Blended Fuels

Today’s fuels are often a blend of gasoline and oxygenate such as ethanol, methanol, or MTBE (ether). Alcohol blended fuel absorbs water. As little as 1% water in the fuel can make fuel and oil separate, forming acids when stored. ALWAYS use fresh fuel (less than 30 days old).

Using Blended Fuels

If using a blended fuel:

- Always use the fresh fuel mix explained in your operator’s manual

- Use the fuel additive STA-BIL@ or an equivalent.

- Always agitate the fuel mix before fueling the unit

- Drain the tank and run the engine dry before storing the unit

Using Fuel Additives

The bottle of 2-cycle oil provided with this unit contains a fuel additive to help inhibit corrosion and minimize gum deposits. Always use the brand of 2-cycle oil that comes with this unit. If this is unavailable, use a 2-cycle oil designed for air-cooled engines and mix it with a fuel additive, such as STA-BIL Fuel Stabilizer or an equivalent. Add 0.8 oz. (23 ml) of fuel additive per gallon of fuel, according to the instructions on the container. NEVER add fuel additives directly to the unit’s fuel tank.

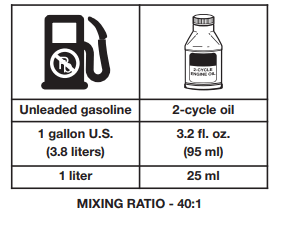

Mixing the Fuel

Thoroughly mix the proper ratio of unleaded gasoline with 2-cycle engine oil. Do not mix them directly in the unit’s fuel tank. use a separate fuel can. use a 40:1 gasoline/oil ratio. See the table below for specific gasoline and oil mixing ratios.

FUELING THE UNIT

- Position the unit with the fuel cap facing up.

- Remove the fuel cap.

- Place the fuel container spout into the fill hole on the fuel tank and fill the tank.

STARTING AND STOPPING

STARTING INSTRUCTIONS

- Mix gasoline with oil. Refer to Oil and Fuel Mixing Instructions.

- Fill the fuel tank. Refer to Fueling the Unit.

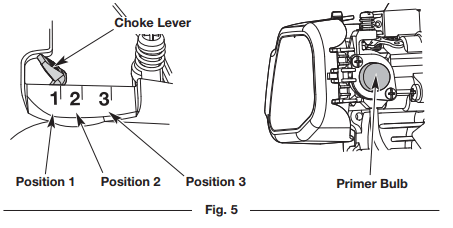

- Slowly press and release the primer bulb 10 times (Fig. 5). If fuel cannot be seen in the primer bulb, press and release the primer bulb until the fuel is visible.

- Move the choke lever to Position 1 (Fig. 5).

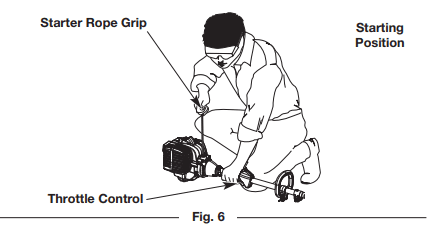

- Crouch in the starting position (Fig. 6).

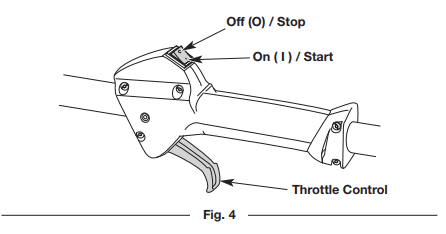

- Squeeze the throttle control (Fig. 4) and pull the starter rope with a controlled and steady motion 5 times (Fig. 6).

- Continue to squeeze the throttle control. Move the choke lever to position 2 (Fig. 5).

- Continue to squeeze the throttle control. Pull the starter rope with a controlled and steady motion 3 to 5 times to start the engine.

- Continue to squeeze the throttle control. Allow the engine to warm up for 30 to 60 seconds.

- Continue to squeeze the throttle control. Move the choke lever to Position 3 (Fig. 5) and continue warming the engine for an additional 60 seconds. The unit may be used during this time.

STOPPING INSTRUCTIONS

- Release the throttle control and allow the engine to idle.

- Press and hold the On/Off switch in the OFF (O) position until the engine comes to a complete stop (Fig. 4).

OPERATION

HOLDING THE UNIT

- Stand in the operating position (Fig. 7). Stand up straight. Do not bend over.

- Keep feet apart and firmly planted.

- Hold the shaft grip with the right hand. Keep the right arm slightly bent.

- Hold the handle with the left hand. Keep the left arm straight.

- Hold the unit at the waist level.

- Position the cutting head a few inches above the ground.

ADJUSTING THE TRIMMING LINE LENGTH

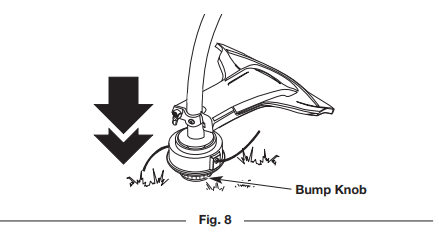

This unit is equipped with a bumphead. The trimming line can be released from the cutting head without stopping the engine. To release more lines, lightly tap the bump knob on the ground (Fig. 8) while operating the unit at high speed. For best results, tap the bump knob on bare ground or hard soil. Attempting to release the line in tall grass may stall the engine.

TIPS FOR BEST RESULTS

- To direct clippings away from the operator, tilt the cutting head slightly down to the left; cut from right to left whenever possible.

- Do not trim wet grass or weeds.

DECORATIVE TRIMMING

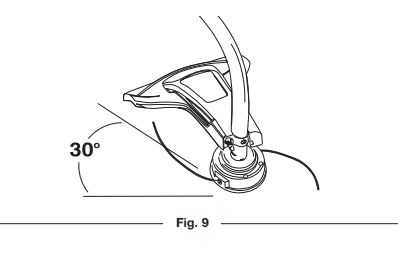

When trimming around trees, posts, fences, etc., rotate the whole unit so that the cutting head is at a 300 angle to the ground (Fig. 9).

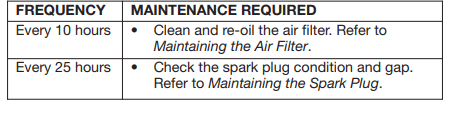

MAINTENANCE SCHEDULE

Perform these required maintenance procedures at the frequency stated in the table. These procedures should also be a part of any seasonal tune-up.

REPLACING THE TRIMMING LINE

Only use the trimming line described in the Specifications section. Other types of trimming line may cause the unit to overheat or fail.

Part 1 – Removing the Inner Reel

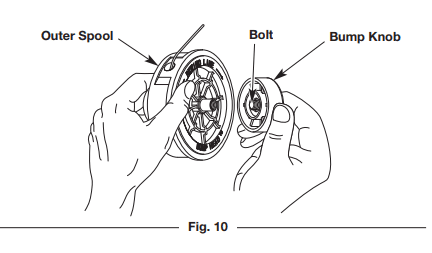

- Hold the outer spool with one hand and unscrew the bump knob counterclockwise (Fig. 10).

- Inspect the bolt inside the bump knob to make sure it moves freely. Replace the bump knob if it is damaged.

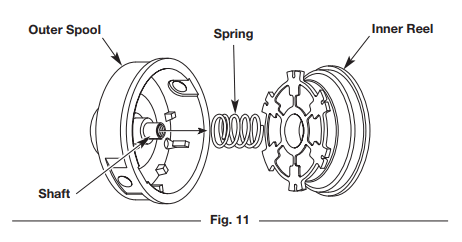

- Remove the inner reel from the outer spool (Fig. 11).

- Remove the spring from the inner reel (Fig. 11).

- Use a clean cloth to clean the inner reel, spring, shaft, and inner surface of the outer spool.

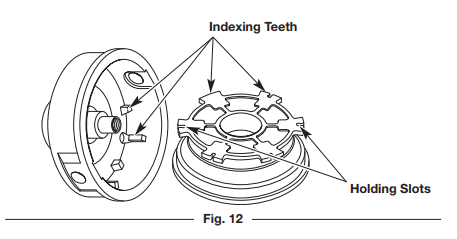

- Check the indexing teeth and holding slots for wear (Fig. 12). If necessary, remove burrs or replace the inner reel and outer spool.

Part 2 – Winding New Trimming Line onto the Inner Reel

- If using a single line, refer to Winding Single Line.

- If using a split line, refer to the Winding Split Line.

- If using a pre-wound inner reel, proceed to Part 3 – Installing the Inner Reel.

Winding Single Line

- Cut one 12-foot (3.7 m) length of new single trimming line. Fold the line in half to create a loop in the middle.

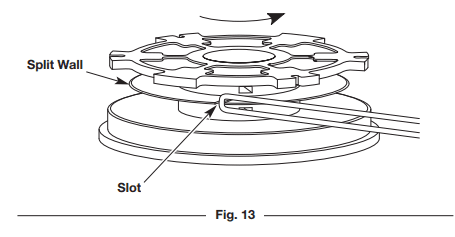

- Insert the loop into the slot in the split wall (Fig. 13). Wind the line tightly in the direction shown on the bottom of the inner reel until about 6 inches (150 mm) of the line remains. Keep the top half of the line above the split wall and the bottom half of the line below the split wall.

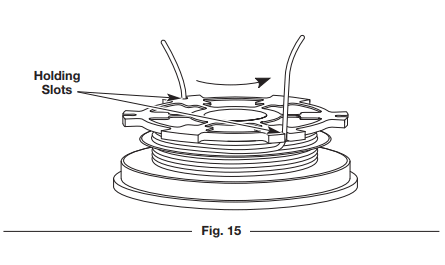

- Insert the two 6-inch sections into the two .095 holding slots (fig. 15).

Winding Split Line

- Cut one 6-foot (1.8 m) length of new split line trimming line. Split each end about 6 inches (150 mm).

- using one split end, insert one line into the top hole and the other line into the bottom hole in the inner reel (Fig. 14).

- Wind the line tightly in the direction shown on the bottom of the inner reel. The split wall will automatically divide the line. Wind the line until it is completely divided and about 6 inches (150 mm) of the line remains.

- Insert the two 6-inch sections into the two .095 holding slots (fig. 15).

Part 3 – Installing the Inner Reel

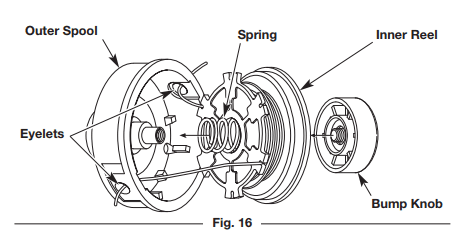

- Pass the two line ends through the eyelets in the outer spool. Place the spring inside the inner reel. Insert the inner reel into the outer spool. Push the inner reel and outer spool together (fig. 16).

- While holding the inner reel and outer spool together, firmly pull the two lines end to release them from the holding slots.

- While holding the inner reel and outer spool together, screw the bump knob clockwise. Tighten the bump knob securely.

MAINTAINING THE AIR FILTER

Failure to maintain the air filter can result in poor performance or can cause permanent damage to the engine. Engine failure due to improper air filter maintenance is not covered by the product warranty.

Cleaning the Air Filter

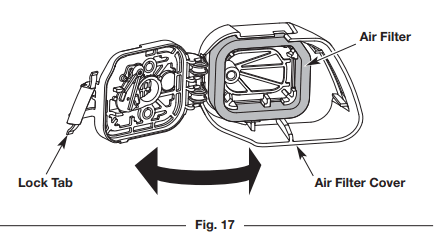

- Open the air filter cover: press the lock tab and swing the air filter cover to the right (Fig. 17).

- Remove the air filter from inside the air filter cover (Fig. 17).

- Wash the air filter with detergent and water. Rinse the air filter thoroughly and allow it to dry.

- Lightly coat the air filter with clean SAE 30 oil.

- Squeeze the air filter to spread and remove excess oil.

- Reinstall the air filter inside the air filter cover (Fig. 17).

- Close the air filter cover: swing the air filter cover to the left and press it closed until the lock tab snaps into place (Fig. 17).

ADJUSTING THE IDLE SPEED

If, after checking the fuel and cleaning the air filter, the engine still will not idle, adjust the idle speed screw as follows:

- Start the engine. Refer to Starting and Stopping.

- Release the throttle control and let the engine idle.

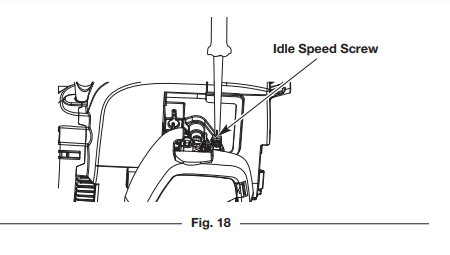

- If the engine stops, use a small Phillips screwdriver to turn the idle speed screw clockwise, 1/8 of a turn at a time (as needed) until the engine idles smoothly (Fig. 18).

- If the engine idles too quickly, turn the idle speed screw counterclockwise, 1/8 of a turn at a time (as needed) to reduce the idle speed (Fig. 18).

MAINTAINING THE SPARK PLUG

- Stop the engine and allow it to cool. Grasp the spark plug boot firmly and pull it from the spark plug.

- Clean around the spark plug. Remove the spark plug from the cylinder head with a 5/8-inch socket, turning counterclockwise.

- Inspect the spark plug. If the spark plug is cracked, fouled, or dirty, replace it with a replacement part #753 06193, a Champion RDJ7J, or an equivalent spark plug.

- Use a feeler gauge to set the air gap at 0.025 in. (0.635 mm) (fig. 19).

- Install the spark plug in the cylinder head. Tighten the spark plug with a 5/8-inch socket, turning it clockwise until snug.

- Reattach the spark plug boot.

CLEANING AND STORAGE

CLEANING

Use a small brush to clean the outside of the unit. Do not use strong detergents. Household cleaners that contain aromatic oils such as pine and lemon, and solvents such as kerosene, can damage plastic. Wipe Off any moisture with a soft cloth.

STORAGE

- Never store a fueled unit where fumes may reach an open flarne or spark.

- Allow the engine to cool before storing.

- Lock up the unit to prevent unauthorized use or damage.

- Store the unit in a dry, well-ventilated area.

- Store the unit out Of the reach Of children.

Short-term Storage (1-2 weeks)

- Store the unit in a horizontal position. If this is not possible, store the unit vertically with the engine at the top.

Long-term Storage

- Remove the fuel cap, tip the unit, and drain the fuel into an approved container. Reinstall the fuel cap.

- Start the engine and allow it to run until it stalls. This ensures that all fuel has been drained from the carburetor.

- Allow the engine to cool. Remove the spark plug and put 5 drops of any high-quality motor oil or 2-cycle oil into the cylinder. Pull the starter rope slowly to distribute the Oil. Reinstall the spark plug.

- Thoroughly clean the unit and inspect it for any loose or damaged parts. Repair or replace damaged parts and tighten loose screws, nuts, or bolts.

Preparing the Unit for Use after Long-term Storage

- Remove the spark plug and drain all of the oil from the cylinder.

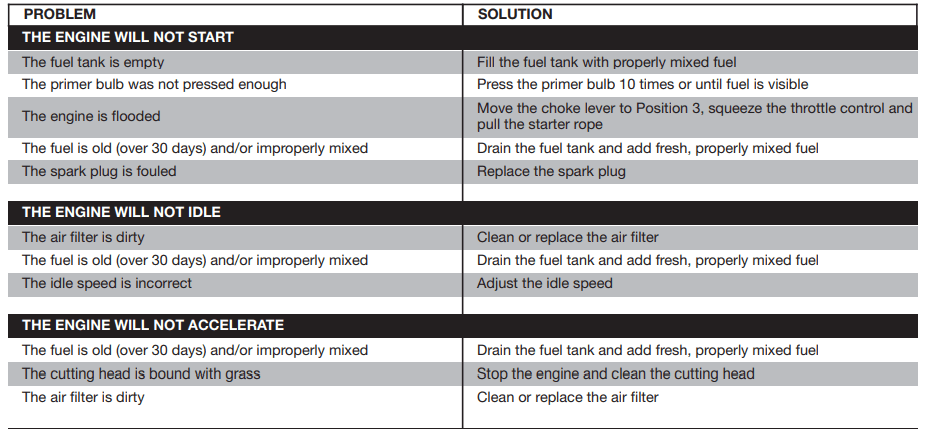

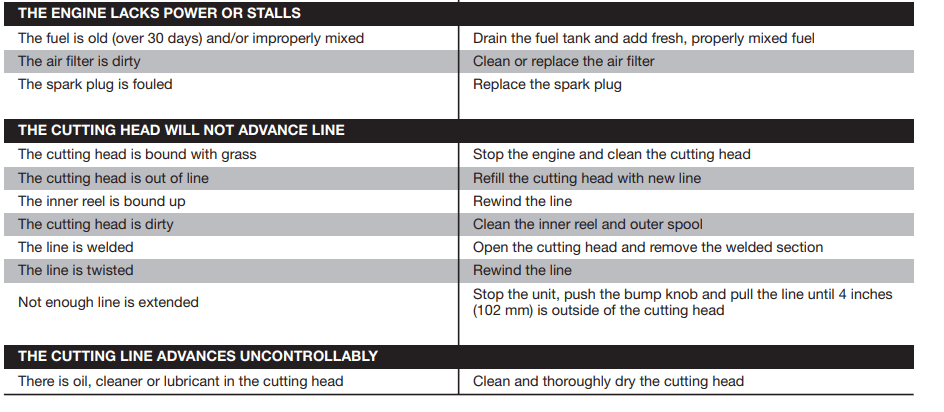

TROUBLESHOOTING

For more manuals by Remington visit, ManualsLibraryy

For more manuals by Remington visit, ManualsLibraryy

Remington RM2510 Rustler String Trimmer-FAQs

What is the fuel mixture for the Remington RM2510?

The Remington RM2510 is a 2-cycle machine, requiring a 40:1 mixture of gas and oil. It’s recommended to use non-ethanol, high-octane gasoline along with high-quality 2-cycle engine oil.

What is the correct gas and oil ratio for a trimmer?

Most trimmers, including the Remington RM2510, require a 40:1 ratio of gasoline to 2-cycle engine oil.

What is the strongest string for a trimmer?

For heavy-duty work, Oregon Magnum Gatorline (0.115-inch) is considered the best option for trimmers. It’s durable, with a weld-resistant top coat and strong core, ideal for commercial use.

What is the pitch of a Remington thread?

Remington 700 receivers typically have a thread pitch of either 16 TPI (1.588 mm), 18 TPI (1.411 mm), or 20 TPI (1.270 mm) depending on the model and application.

What is 2-cycle fuel?

A 2-cycle engine requires a mixture of gas and oil for both combustion and lubrication. Operating without oil can cause engine failure.

Why should I soak trimmer string?

Soaking trimmer line in water for 24 hours helps maintain flexibility and extend its lifespan. This is particularly important for newly purchased or stored trimmer lines.

What does TPI mean in thread terminology?

TPI stands for “Threads Per Inch,” indicating the number of threads within an inch of a fastener. It’s used with American fasteners, while metric fasteners use thread pitch.

Is a 4-stroke engine just petrol?

Unlike 2-stroke engines, 4-stroke engines run solely on gasoline with no oil mixed in. They operate through a four-step cycle, making them more complex but more fuel-efficient.