Trane SSC-APG002 Condensing Units Heat Pumps

Section I – Terms and Definitions

Three-phase products

All 2.5 to 5 ton three-phase split system cooling units and heat pumps are shipped from the factory with compressor crankcase heat. Three-phase compressors do not require start capacitors or start relays.

Definitions and information

- CCHT – Compressor Crankcase Heater, sometimes called a compressor sump heater. This device is designed to warm the compressor crankcase (or sump) to prevent or deter refrigerant migration during the compressor off cycle. Compressor crankcase heaters are required for low ambient cooling operation.

- TXV – Thermostatic Expansion Valve. This is a type of refrigerant flow control device designed to maintain constant superheat throughout the operating envelope. For low ambient cooling applications, a non-bleed TXV is required.

- Bleed TXV: This type of TXV will allow the refrigerant pressures between the high side and low side to equalize through the valve during the off cycle.

- Non-Bleed TXV: This type of TXV will not allow the refrigerant pressures between the high side and low side to equalize through the valve during the off cycle. When using this type of valve on single-phase units with reciprocating-style compressors, compressor start components are required. Check product data specifications for the most current information.

- Head pressure controller – A device that is field-installed on a condensing unit or heat pump, designed to maintain system head pressure that will allow safe system operation without indoor coil icing in colder outdoor ambients. The BAYLOAM will cycle the condenser fan motor to achieve adequate operating head pressure. The control is adjustable.

- Evaporator Defrost Control – A device that is field-installed on the system’s indoor coil to prevent the system from running during the cooling cycle when the indoor coil approaches or reaches a temperature at which frost will form on the coil surface. When the indoor coil approaches a safe temperature for cooling operation, the control will close and allow the outdoor unit to restart. This controller makes and breaks the control voltage to the condensing unit.

- Quick Start Component – This component may be factory-installed or offered as a field-installed accessory ( BAYKSKT). A quick start kit consists of a capacitor with a high microfarad rating and a potential relay. It is installed so that the start capacitor is wired in parallel with the compressor’s run capacitor. Before start-up, the potential relay contacts are closed, therefore placing the start capacitor in the compressor circuit. As the compressor motor reaches operating speed, electrical current flows through the potential relay’s coil, and the relay contacts are opened, thus taking the start capacitor out of the system until the next compressor start-up.

Section II – Off-Season Cooling Operation

Trane outdoor units may be operated in the cooling mode to 55°F outdoor ambient as shipped from the factory when applied with an indoor TXV. Where required, these units with appropriate accessories may be applied to operate at outdoor temperatures below 55°F.

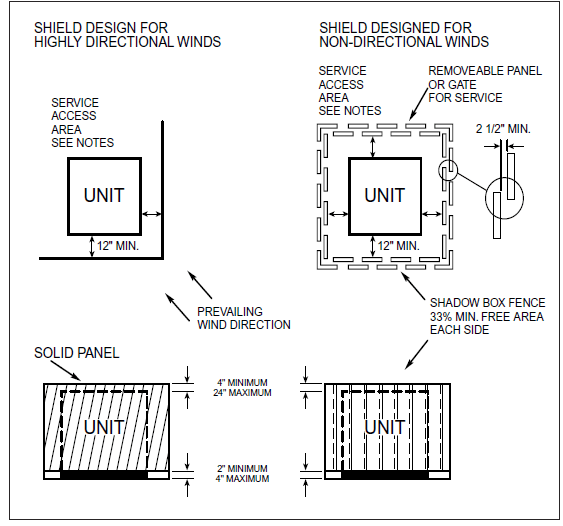

Windshields

If low ambient cooling operation is required, windshields are a must in order to block prevailing winds from impacting system performance at low outdoor temperatures. Reference Figure 1.

Figure 1 – Windshield Construction Information

Low ambient cooling utilizing the frost control in GAM5A and TAM4 indoor units

The TAM4 and TAM7 fan coil units utilize an electronic expansion valve (EEV). With this enhancement, the controls that monitor the EEV also allow us to take advantage of monitoring coil temperature.

How it works

The onboard electronic controls include a relay that will open when the indoor coil begins to frost. When this occurs, the contacts to the YO circuit will open and de-energize the outdoor unit, provided figures 2 and 3 are followed. When the YO circuit opens, the outdoor unit is taken offline; however, the indoor blower continues to operate, thus clearing the indoor coil of frost build-up.

Low ambient cooling utilizing thermostatic control was found in the AY28X079 and AY28X084.

How it works

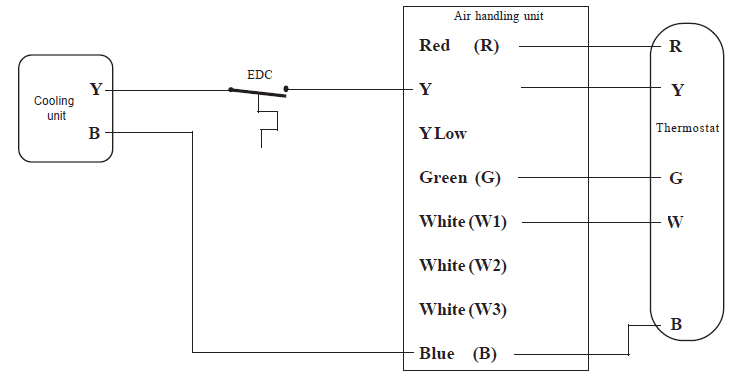

These controls are thermally controlled contacts with a capillary-style sensor. The capillary tube is inserted into the coil fins in between the tube rows. When the sensor detects 25F, the contacts open. The contacts close when the coil temperature reache60°F0F. When wired as shown in Figures 4 and 5, the outdoor unit is de-energized when the EDC contact opens and re-energized when the EDC contact closes.

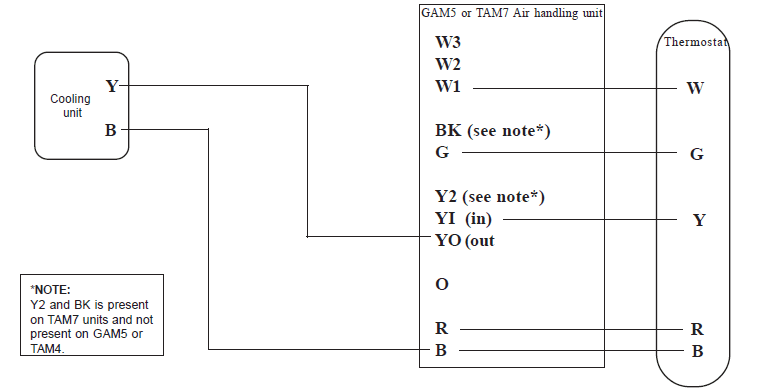

Typical wiring of the frost control located in the TAM4 or TAM7 fan coil unit

Figure 2: Cooling split system and TAMor TAM7M7 Fan Coil Un.  Figure 3: Heat pump split system and TAM4 or TAM7 fan coil unit

Figure 3: Heat pump split system and TAM4 or TAM7 fan coil unit

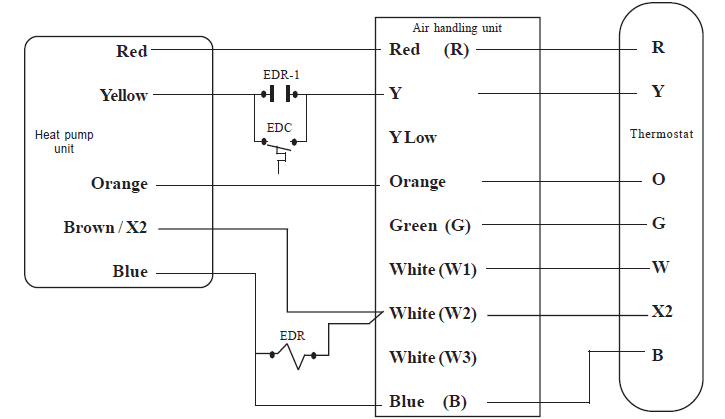

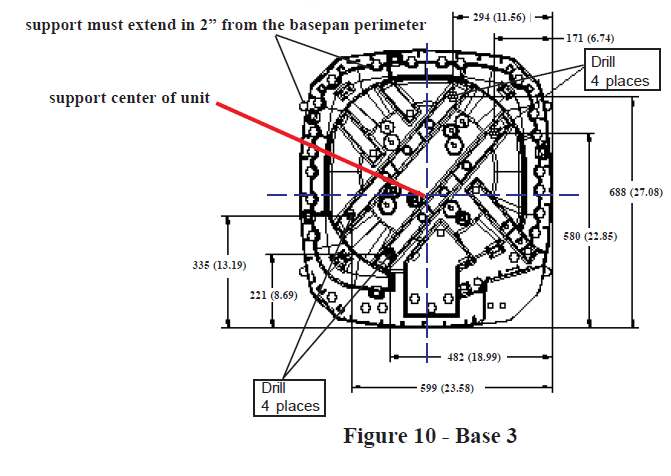

Typical wiring when using the evaporator defrost control (EDC)

Figure 4 -Single Speed Cooling Split System and AY28X079 Evaporator Defrost Control Figure 5 -Single Speed Heat Pump Split System and AY28X084 Evaporator Defrost Control

Figure 5 -Single Speed Heat Pump Split System and AY28X084 Evaporator Defrost Control

Section III – Compressor Crankcase Heat Requirements for Split Heat Pumps:

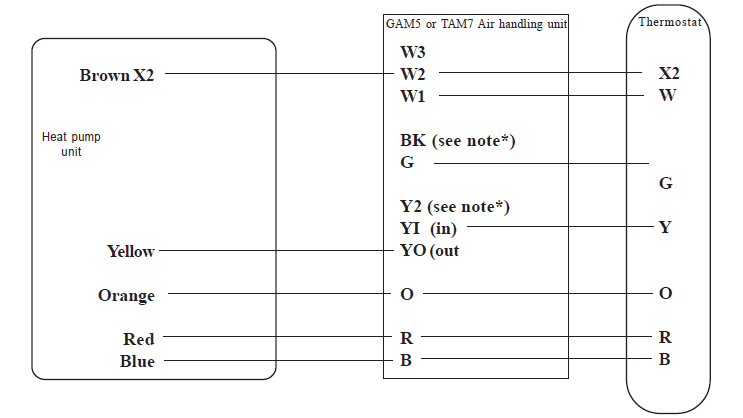

Figure 6 -Climatic Zones for United States Compressor crankcase heat is required in Climatic Zones 1, 2, and 3 for all heat pump applications. Refer to the unit product data catalog for crankcase heater selection.

Compressor crankcase heat is required in Climatic Zones 1, 2, and 3 for all heat pump applications. Refer to the unit product data catalog for crankcase heater selection.

Section IV- Unit Mounting

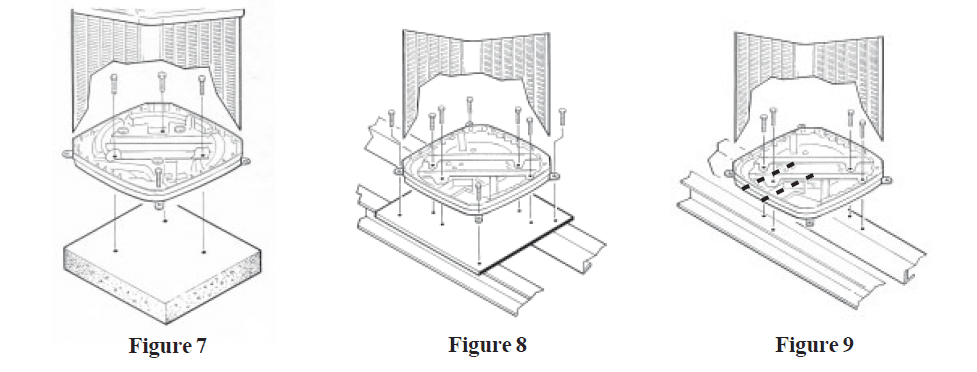

This section describes appropriate methods for mounting and securing the unit. However, if these units are to be mounted in a region where high winds are an issue, a Trane BAYECMT*** extreme conditions mounting kit.may be utilized. Otherwise, a local P.E. and restraining method approved by the authority having jurisdiction may be required.

In regions where seismic restraint is a requirement, approval from a local P.E. (professional engineer) may be required for the restraining method. (reference figures 7, 8, and 9 for possible mounting configuration examples)

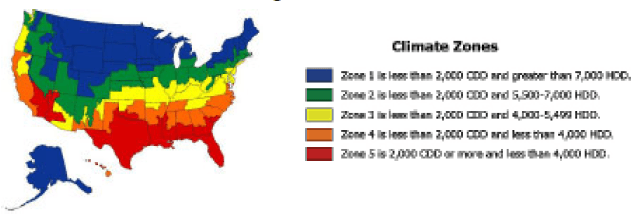

For mounting or securing the Trane condensing units and heat pumps, please observe the following:

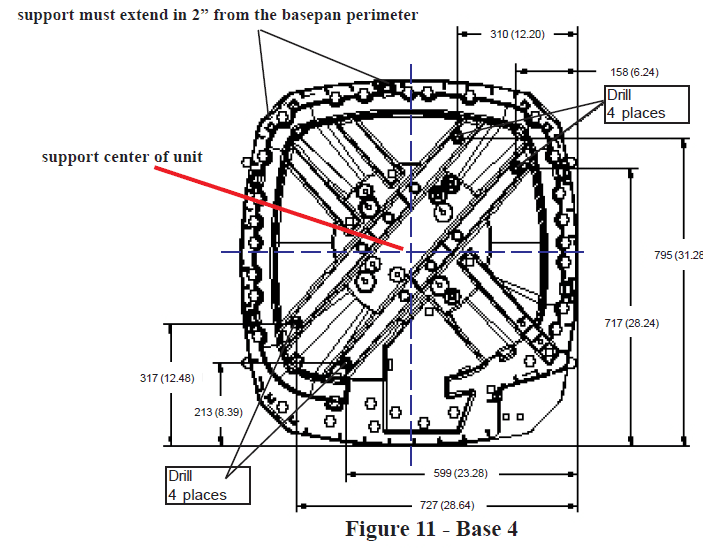

- If the unit is to be supported from the edge, the supporting material must extend two inches minimum under the perimeter of the unit’s base.

- The mounting hole locations are molded in the base pan; however, they must be drilled through.

- a) Hole locations are identified in Figures 10 and 11.

- Washers should be placed between the fastener head and the basepan.

- Trane recommends supporting the center of the unit as shown in Figures 9, 10, and 11.

- Base sizes 3 and 4 pans have four mounting holes – see Figures 10 and 11.

- For hurricane or high wind applications, if using the BAYECMT*** kit, the bolt hardness and diameter are specified in the BAYECMT installation guide.

- a) Bolt length is determined by the authority having jurisdiction and/or local P.E.

- b) Mounting surface composition and weight shall be determined by the authority having jurisdiction and/or local P.E.

- c) For non-ground installations, refer to a local P.E.

- d) A local P.E. may be required if the BAYECMT kit is used or not.

BASE PAN MOUNTING HOLE LOCATIONS ( location only, holes must be drilled )

Section V – Minimum Operating Clearances

This section discusses installing a condensing unit/heat pump where spacing is limited. When installing Trane outdoor units in a location where clearance to other units, walls, fences, etc., is limited, the concerns listed below must be addressed:

- System Operation – Adequate airflow must be provided to and away from the condensing unit/heat pump to enable appropriate heat transfer. If this is accomplished, head pressure will remain within an effective operating range.

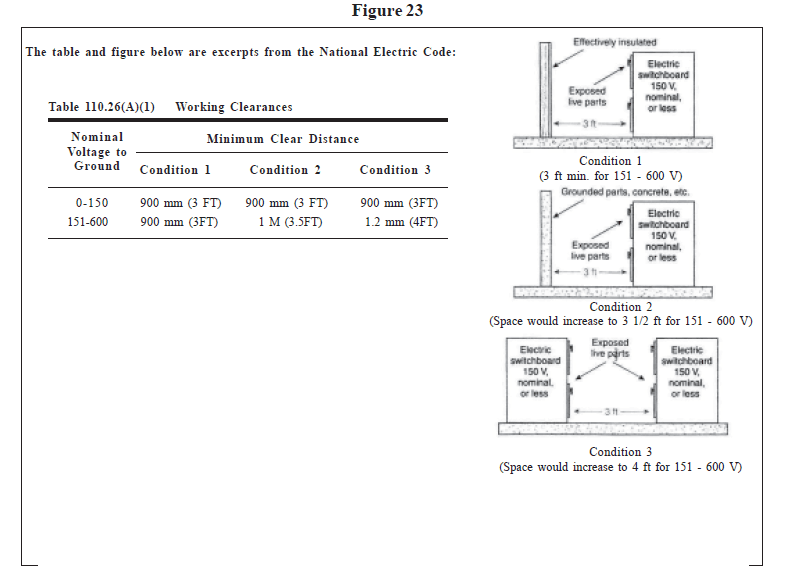

- System Servicability – Sufficient working space must be allowed for the HVAC service technician to properly maintain the condensing unit/heat pump. Furthermore, space must be allowed for a major component change in the event of a failure. Working space is determined by the Local, State, and National Codes. (See National Electric Code Table 110.26 for an explanation.)

- Space Maintenance – Appropriate space must be allowed for personnel to maintain the ground area where the units are positioned to prohibit foliage growth around the unit(s) and debris from collecting on the panels. State, Local Codes, and National Codes shall prevail. Check with the local jurisdiction before installation to ensure compliance.

Many projects require consideration of minimum clearances between outdoor units and adjacent walls, fences, and other units. The obstruction in question is usually one of the following:

- One or more walls of an adjacent building.

- Fences or barriers are provided to reduce sound transmission or visually screen the equipment.

- Other outdoor units in a multi-unit installation.

- A combination of the above.

- Overhangs

The prime considerations involved in establishing minimum clearances are:

- Adequate airflow to the outdoor coil with minimum recirculation.

- Service access to the equipment.

- Compliance with the National Electrical Code and other applicable codes.

- Design temperature – Design temperatures greater than 105°F require additional consideration.

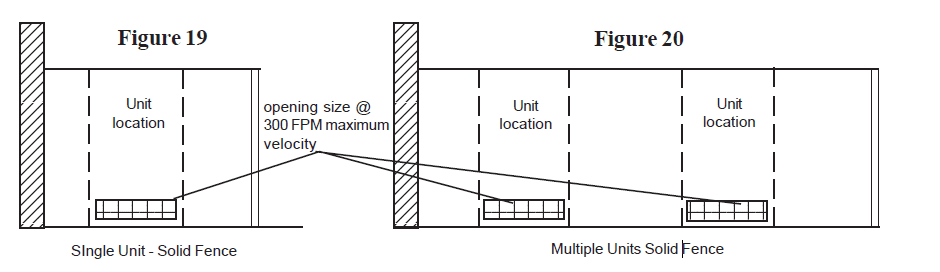

- I. To ensure adequate airflow reaches the condensing unit, size free air passages at 300 Feet Per Minute maximum velocity. See the condensing unit airflow performance on page 18 of this document.

- II. The importance of providing proper service access to equipment cannot be overemphasized. The HVAC service technician’s job may be performed with greater ease and lower cost if adequate service space is allowed.

- III. Knowledge of the National Electric Code and other applicable codes for the job site location is a necessity to satisfy local inspectors. These codes are in place for serviceability as well as safety.

- IV. Be sure to read all provisions and footnotes contained in this document.

- V. Where ASHRAE design temperatures exceed 105°F, minimum operating clearances may increase.

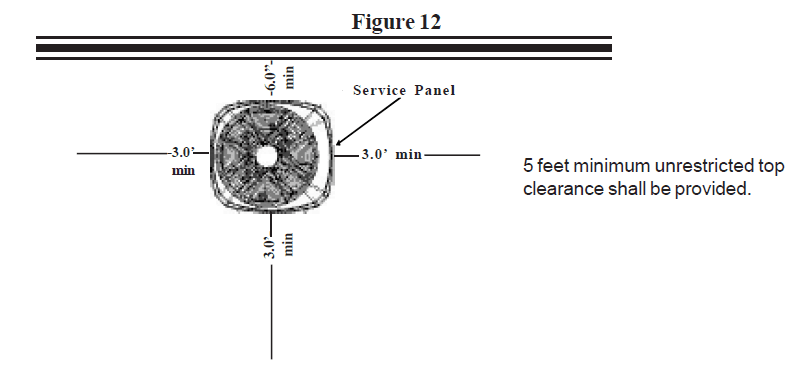

Installation of a single condensing unit/heat pump with one side facing a wall, fence, or other obstruction with free air space on top. (See Figure 12)

- A) For locations where the ASHRAE design ambient temperature is below 110°FF:

- 1) 6.0 inches clearance on 1 side. Three feet t minimum clearance is required from the other three sides from any obstructions.

- 2) Service access side – 3 feet minimum clearance required. Consult Local, State, and National Electric Codes for minimum service clearance.

- B) For locations where the ASHRAE design ambient temperature exceeds 1110°FF

- Do not restrict any side less than 1.0 feet. Refer to the unit’s installation manual or the following pages of this document for more information regarding unit clearances.

- Do not restrict any side less than 1.0 feet. Refer to the unit’s installation manual or the following pages of this document for more information regarding unit clearances.

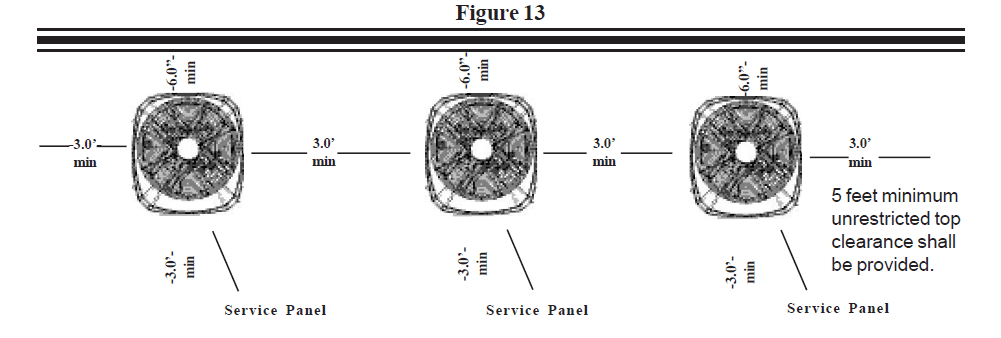

Installation of multiple condensing units/heat pump units with one side facing a wall, fence, or other obstruction, with free air space on top. (See Figure 13)

- A) For locations where the ASHRAE design ambient temperature is below 110°FF:

- 1) 6.0 inches clearance on 1 side. Three feet of minimum clearance is required from the other three sides from any obstructions.

- 2) Service access side – 3 feet minimum clearance required. Consult Local, State, and National Electric Codes for minimum service clearance.

- B) For locations where the ASHRAE design ambient temperature exceeds 1110°F

- Do not restrict any side less than 1.0 feet. Refer to the unit’s installation manual or the following pages of this document for more information regarding unit clearances.

- Do not restrict any side less than 1.0 feet. Refer to the unit’s installation manual or the following pages of this document for more information regarding unit clearances.

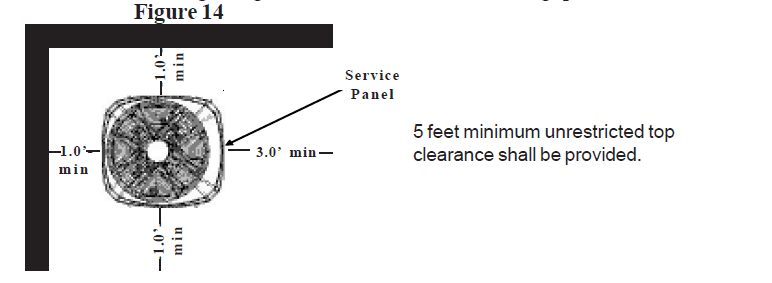

Installation of a single unit in a corner with free air space on top. (See Figure 14)

- A) For locations where the design ambient temperature is below 105°F:

- 1) 1.0 feet clearance on 2 sides – If foliage is to be placed by the unit’s other side, then allow 1.0 Feet minimum clearance from the unit

- 2) Service access side – 3 feet minimum clearance required. Consult Local, State, and National Electric Codes for minimum service clearance.

- B) For locations where the design ambient temperature exceeds 105°F:

- 1) 1.5 feet clearance on 2 walls. – If foliage is to be placed by the unit’s other side, then allow 1.0 Feet minimum clearance from the unit.

- 2) Service access side – 3 feet minimum clearance required.

- C) If the unit is located in such a way that the service panel is facing the wall

- 1) NEC requires 3 feet minimum clearance between the unit and the wall

- a) This space may be increased to 3 1/2 feet. Consult the National Electrical Code for more information regarding minimum clearances for working spaces.

- a) This space may be increased to 3 1/2 feet. Consult the National Electrical Code for more information regarding minimum clearances for working spaces.

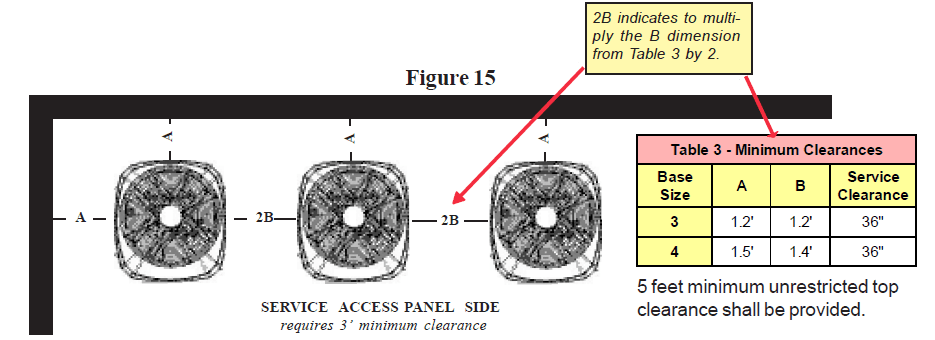

Installation of two or more units where two adjacent walls form a corner. (See Figure 15)

- A) For locations where the design ambient temperature is below 105°F:

- 1) Note the unit base size and obtain the minimum clearance values from the table below.

- B) For locations where the design ambient temperature exceeds105°FFF:

- 1) 2.0 feet clearance from both walls.

- 2) 3.0 feet clearance in between units, unless service panels face each other. If service panels face each other, this clearance may be increased to 4 feet per NEC.)

- C) If units are located with the service panels facing the wall

- 1) NEC requires a minimum of 3 feet between the unit and the wall

- a) This space may be increased to 3 1/2 feet. Consult the most current edition of the National Electrical Code for more information regarding minimum clearances for working spaces.

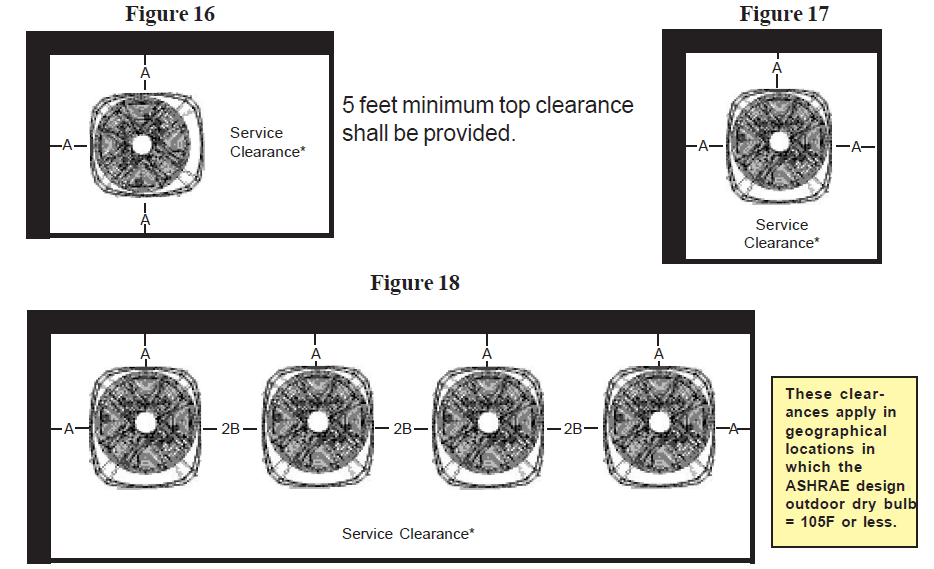

Units surrounded on all four sides: (See Figures 16, 17, 18, 1,9, and 20)

- A. If installed unit(s) is/are surrounded by 2 walls and a solid fence, the fence height on two sides shall be no higher than the height of the unit. In this application, knockouts or louvers shall be provided on two sides, minimum, with free area to provide a maximum 300 FPM velocity. Cutting a portion of the lower fence on two sides to accomplish 300 FPM maximum velocity is acceptable, provided debris, dirt, and grass are prohibited from accumulating or growing to obstruct the opening. Refer to page 19 of this document for outdoor unit airflow. Please refer to the table below for minimum clearances.

| Table 3 – Minimum Clearances | |||

| BaseSizee | A | B | Service clearance |

| 3 | 1.2′ | 1.2′ | 36″ |

| 4 | 1.5′ | 1.4′ | 36″ |

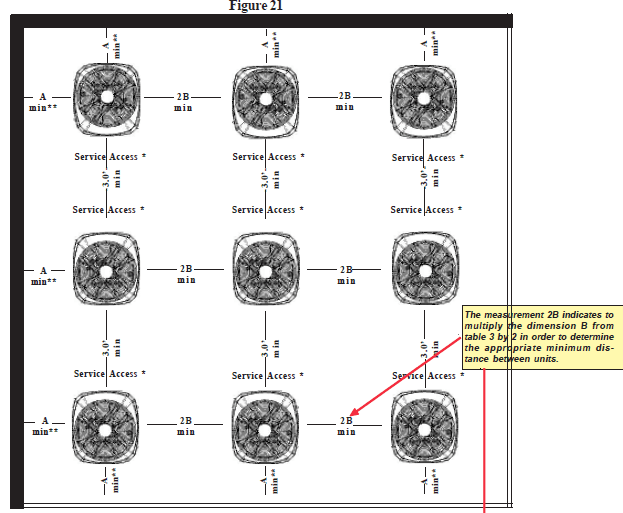

Installation of multiple units on a pad /rooftop where the top clearance is open. (See Figure 21)

- A) Refer to the minimum clearance table in the lower corner of this page for clearances

- B) The National Electric Code requires 3 feet (4 feet if certain conditions are present) clearance between the service access panel and the adjacent unit. If the service access panel faces the wall, the required space between the wall and the unit shall be a minimum of 3 feet. (May require as much as 3 1/2 feet)

- C) Walls shall not be higher than the top of units.

- D) National, State, and Local Codes must be observed.

- E) If the design outdoor dry bulb exceeds 105°F 40.6 °C), add 1.0 Ft to all dimensions.

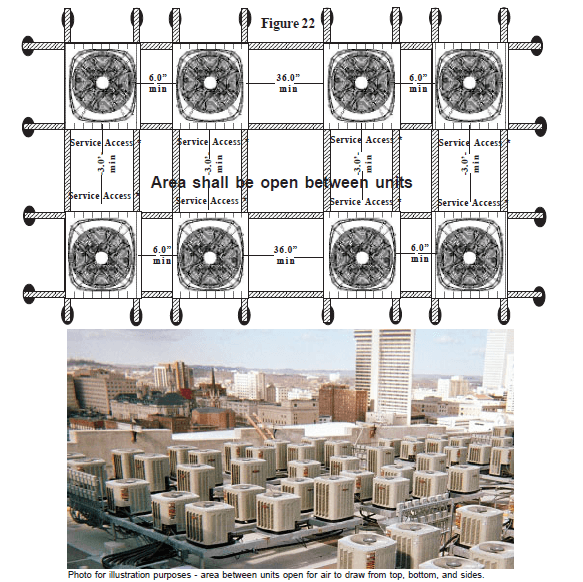

Installation of multiple units on a raised rooftop rail where the top clearance and side clearance are open. (See Figure 22)

- A) The area between outdoor units shall be open so that air may be drawn from the top, bottom, and sides.

- B) Decorative walls shall be at a minimum of 10 feet away from the outdoor units.

- C) Decorative walls shall not extend above the unit tops.

- A) The National Electric Code requires 3 feet (4 feet if certain conditions are present) clearance between the service access panel and the adjacent unit.

- D) National, State, and Local Codes shall be observed.

- E) If the design outdoor dry bulb exceeds 95°F 35.0 °C), add 1.0 Ft to all dimensions.

- Condition 1 – Exposed live parts on one side and no live or grounded parts on the other side of the working space, or exposed live parts on both sides effectively guarded by suitable wood or other insulating materials. Insulated wire or insulated busbars operating at not over 300 volts to ground shall not be considered live parts.

- Condition 2 – Exposed live parts on one side and grounded parts on the other side. Concrete, brick, or tile walls shall be considered grounded.

- Condition 3 – Exposed live parts on both sides of the workspace (not guarded as provided in Condition 1) with the operator between.

For more manuals by Tran, visit ManualsLibraryy

Trane SSC-APG002 Condensing Units Heat Pumps-FAQs

What is the minimum temperature for a Trane heat pump to operate?

Trane heat pumps, such as those with the Climatuff™ Variable Speed Compressor, can efficiently operate in temperatures as low as 0°F, making them suitable for average-sized homes even in colder climates.

How can I tell if my Trane unit is a heat pump?

You can identify a heat pump by checking for the Energy Guide label or the HSPF (Heating Seasonal Performance Factor) or HSPF2 rating. If listed, this indicates you have a heat pump.

How does a Trane dual fuel heat pump work?

A dual fuel heat pump combines an electric heat pump and a gas furnace, switching between the two depending on the temperature and need. This hybrid system maximizes energy efficiency while effectively heating and cooling your home year-round.

Where do heat pumps work best?

Heat pumps are most effective in moderate climates but are particularly popular in the South or Southwest, where temperatures rarely drop below freezing.

What is the heating limit for a heat pump?

Air source heat pumps typically operate efficiently between -4°F (-20°C) and 68°F (20°C). For air-to-water systems, heating output can reach up to 140°F (60°C), while cooling temperatures can go down to 41°F (5°C).

Can a heat pump run without the fan?

No, a heat pump should never be used without the fan running. The fan is crucial for proper airflow and heat distribution.

Where is a heat pump located?

A heat pump can either be a split system, with one unit inside and one outside your house, or a packaged system, which is an all-in-one unit typically placed outside.

Does Trane offer geothermal heat pumps?

Yes, Trane offers a variety of geothermal heat pumps, including packaged systems, water-to-water systems, and split systems, to meet diverse heating and cooling needs.

Figure 5 -Single Speed Heat Pump Split System and AY28X084 Evaporator Defrost Control

Figure 5 -Single Speed Heat Pump Split System and AY28X084 Evaporator Defrost Control