Troy-Bilt TBE515 4-Cycle Gasoline Lawn Edger

IMPORTANT SAFETY INSTRUCTIONS

- Read this operating instruction manual carefully. Be thoroughly familiar with the controls and the proper use of the equipment. Know how to stop the unit and disengage the controls quickly.

- Do not operate this unit when tired, ill, or under the influence of alcohol, drugs, or medication.

- Never allow children to operate the equipment. Never allow adults unfamiliar with the instructions to use the unit. Never allow adults to operate the equipment without proper instruction.

- All guards and safety attachments must be installed properly before operating the unit.

- Inspect the unit before use. Ensure the blade is installed correctly and secure.

- Clear the area to be edged before each use. Remove all objects such as rocks, broken glass, nails, wire, or string that can be thrown or become entangled in the edging attachment.

SPECIAL SAFETY WARNINGS FOR LAWN EDGERS

- Store fuel only in containers specifically designed and approved for the storage of such materials.

- Always stop the engine and allow it to cool before filling the fuel tank. Never remove the cap of the fuel tank or add fuel when the engine is hot. Never operate the unit without the fuel cap securely in place. Loosen the fuel tank cap slowly to relieve any pressure in the tank.

- Add fuel in a clean, well-ventilated area outdoors where there are no sparks or flames. Slowly remove the fuel cap only after stopping the engine. Do not smoke while fueling. Wipe up any spilled fuel from the unit immediately.

- Avoid creating a source of ignition for spilled fuel. Do not start the engine until fuel vapors dissipate.

- Move the unit at least 30 feet (9.1 m) from the fueling source and site before starting the engine. Do not smoke. Keep sparks and open flames away from the area while adding fuel or operating the unit.

- Never start or run the unit inside a closed room or building. Breathing exhaust fumes can kill. Operate this unit only in a well-ventilated area outdoors.

MAINTENANCE AND STORAGE

- Allow the unit to cool before storing or transporting. Be sure to secure the unit while transporting.

- Store the unit in a locked and dry or high and dry place to prevent unauthorized use or damage, out of the reach of children.

- Clean the blade with a hose and water. Wipe the blade with light machine oil to prevent rust.

- Never douse or squirt the unit with water or any other liquid. Keep handles dry, clean, and free from debris. Clean after each use.

- Keep these instructions. Refer to them often and use them to instruct other users. If you loan someone this unit, also loan them these instructions.

- Only qualified personnel should perform any repairs or maintenance procedures that are not described in this manual.

- Check shear bolts, engine mounting bolts, and other bolts at frequent intervals for proper tightness to be sure the equipment is in safe working condition.

- Inside a building, store the machine away from ignition sources. Allow the engine to cool before storing it in any enclosure.

- Always refer to the Operator’s Manual instructions for important details if the lawn edger is to be stored for an extended period.

- Do not attempt to repair the machine unless you have the proper tools and instructions for disassembly and repair of the machine.

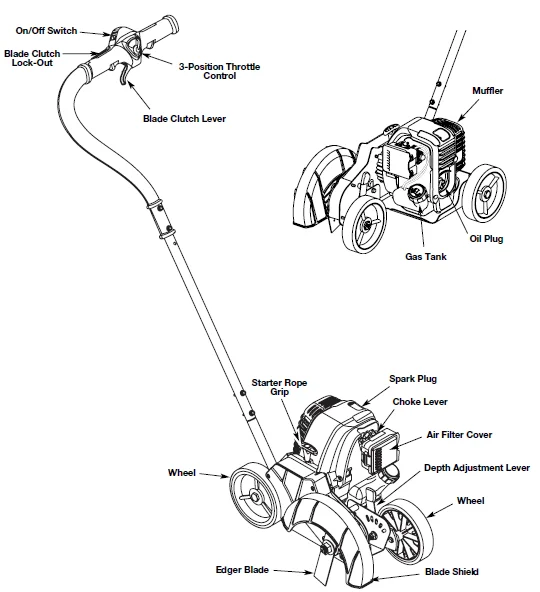

KNOW YOUR UNIT

APPLICATIONS

Edging along paths, driveways, rockeries, etc.

ASSEMBLY INSTRUCTIONS

HANDLE ASSEMBLY

- Remove the unit from the box.

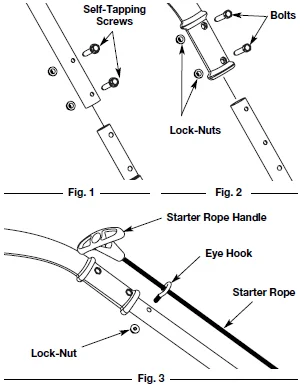

- Place the 2-holed end of the straight metal shaft over the shaft base on the unit and align the holes (Fig. 1).

- Insert the two self-tapping screws (1/4” x 1-1/4”) into these holes (Fig. 1).

- Using a 3/8” wrench, screw each self-tapping screw into the shaft until firm. DO NOT OVERTIGHTEN.

- Insert the control handle onto the 3-holed end of the straight metal shaft and align the control handle’s holes with the two end holes of the straight metal shaft (Fig. 2). NOTE: Because the control cables are pre-installed, care must be taken when installing the control handle to not pinch or bend the cables. This can damage them and cause them to function improperly.

- Insert the two screws (1/4” x 1-1/2”) into the recessed hex holes on the handle (Fig. 2) and hold in place.

- Hand-start the lock-nuts onto these bolts.

- Using a 7/16” wrench, tighten each nut onto each bolt until firm.

- Pull out the starter rope and run it into the eye hook (Fig. 3).

- Insert the eye hook into the remaining hole on the straight metal shaft (Fig. 3).

- Screw the nut onto the eye hook (Fig. 3) and use a 7/16” wrench to tighten. DO NOT OVERTIGHTEN.

- Using the zip tie in the hardware bag, secure the handle cables to the straight metal shaft midway between the eye hook and the motor housing.

OIL AND FUEL INFORMATION

RECOMMENDED OIL TYPE

Using the proper type and weight of oil in the crankcase is extremely important. Check the oil before each use and change the oil regularly.

Failure to use the correct oil or using dirty oil can cause premature engine wear and failure. Use a high-quality SAE 30 weight oil of API (American Petroleum Institute) service class SF, SG, or SH.

ADDING OIL TO CRANKCASE: INITIAL USE

NOTE: This unit is shipped without oil. In order to avoid damage to the unit, put oil in the crankcase before you attempt to start the unit.

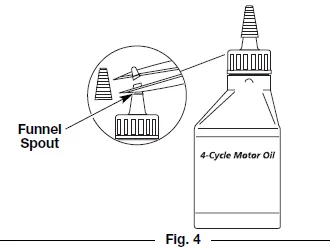

Your unit is supplied with one 3.04 fluid oz. (90 ml.) bottle of SAE 30 SF, SG, SH oil (Fig. 4).

NOTE: Save the empty oil bottle. It can be used to measure the correct amount during future oil changes. See Changing the Oil.

- Unscrew the top of the bottle of oil and remove the paper seal covering the opening. Replace the top. Next, cut the tip off the funnel spout (Fig. 4).

- Tip the unit so that the back of the engine is facing up in a vertical position.

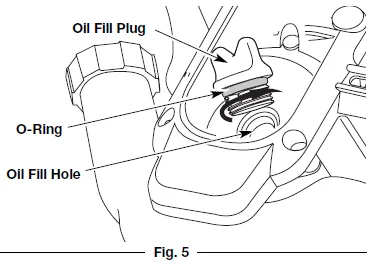

- Remove the oil fill plug from the crankcase (Fig. 5).

- Pour the entire bottle of oil into the oil fill hole. NOTE: Never add oil to the gas or gas tank.

- Wipe up any oil that may have spilled and reinstall the oil fill plug.

Check oil before each use and change as needed. Refer to Checking the Oil Level.

RECOMMENDED FUEL TYPE

Old gasoline is the primary reason for improper unit performance. Be sure to use fresh, clean, unleaded gasoline.

NOTE: This is a four-cycle engine. In order to avoid damage to the unit, do not mix oil with the gasoline.

Definition of Blended Fuels

Today’s fuels are often a blend of gasoline and oxygenates such as ethanol, methanol, or MTBE (ether). Alcohol-blended fuel absorbs water. As little as 1% water in the fuel can form acids when stored. Use fresh fuel (less than 60 days old) when using alcohol-blended fuel.

Using Blended Fuels

If you choose to use a blended fuel, or its use is unavoidable, follow recommended precautions:

- Always use fresh unleaded gasoline.

- Use a gas stabilizer fuel additive

- Drain the tank and run the engine dry before storing unit

Using Fuel Additives

The use of a gas stabilizer will inhibit corrosion and minimize the formation of gum deposits. Using a fuel additive can keep fuel from forming harmful deposits in the carburetor for up to six (6) months. Add 0.8 oz. (23 ml.) of fuel additive per gallon of fuel according to the instructions on the container. NEVER add fuel additives directly to the unit’s gas tank.

OIL AND FUEL INFORMATION

FUELING THE UNIT

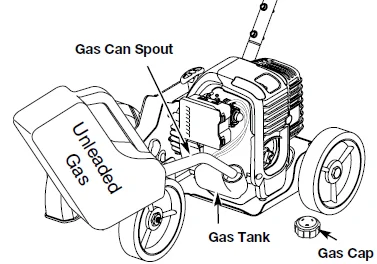

- Remove the gas cap.

- Place the gas container’s spout into the fill hole on the fuel tank and fill the tank. NOTE: Fill or add gas to the tank only when the edger is in the horizontal position. Do not overfill the tank.

- Wipe up any gasoline that may have spilled.

- Reinstall the gas cap.

- Move the unit at least 30 ft. (9.1 m) from the fueling source and site before starting the engine. NOTE: Dispose of the old gasoline in accordance with Federal, State, and Local regulations.

STARTING/STOPPING INSTRUCTIONS

STARTING INSTRUCTIONS

- Check the oil level in the crankcase. Refer to Checking the Oil Level.

- Fill the fuel tank with fresh, clean unleaded gasoline. Refer to Fueling the Unit. NOTE: There is no need to turn the unit on. The On/Off Stop Control is in the ON ( I ) position at all times.

- Fully press and release the primer bulb 10 times, slowly. Some amount of fuel should be visible in the primer bulb and fuel lines. If you can’t see fuel in the bulb, press and release the bulb as many times as it takes before you can see fuel in it.

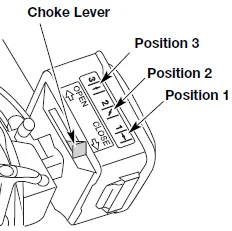

- Place the choke lever in Position 1.

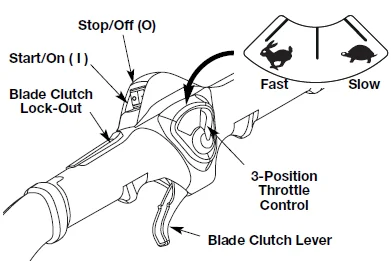

- Stand in the starting position. Place the Throttle Control Lever in the Fast position and pull the starter rope briskly 5 times.

- Place the choke lever in Position 2.

- Pull the starter rope briskly 1 to 4 times to start the engine.

- Allow the engine to warm up for 15 to 30 seconds.

- Place the choke lever in Position 3. The unit is ready for use.

- IF… the engine does not start, go back to step 3.

- IF… the engine fails to start after a few attempts, place the choke lever in Position 3, move the throttle control lever to the fast position. Pull the starter rope briskly 3 to 8 times. The engine should start. If not, repeat.

STOPPING INSTRUCTIONS

- Release your hand from the blade clutch lock-out and the blade clutch lever, and move the throttle control lever to the slow position. Allow the engine to cool down by idling.

- Press and hold On/Off Stop Control in the OFF (O) position until the engine comes to a complete stop.

OPERATING INSTRUCTIONS

HOLDING THE UNIT

Before operating the unit, stand in the operating position. Check for the following:

- The operator is wearing eye protection and proper clothing.

- Both hands are holding the handlebars firmly.

- The edger wheel is adjusted for proper cut depth, and the edger is positioned.

ADJUSTING EDGER CUTTING DEPTH

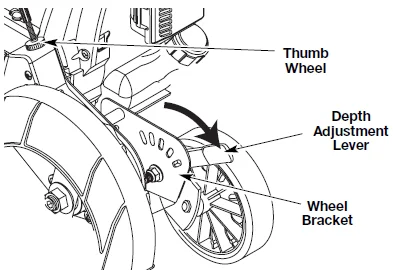

- Grasp the depth adjustment lever located beside the front wheel.

- To raise the cutting blade, move the lever toward the front of the wheel bracket. Lowering the wheel decreases the cutting depth.

- To lower the cutting blade, move the lever toward the rear of the wheel bracket. Raising the wheel increases the cutting depth.

TIPS FOR BEST EDGING RESULTS

- Do not force the edger. Edge the first time at a lesser depth (No more than 1/2” depth cut per pass), then do the area again with a deeper setting.

- Walk the edger at a slow, even pace.

- Check the blade condition. As it wears, it becomes smaller, thus reducing the cutting depth performance. Replace with a new blade when the blade has worn to the blade’s wear limit holes.

ADJUST BELT TENSION

If the blade fails to turn when the blade clutch lock-out and the blade clutch lever are pressed, then:

- Locate the small thumb wheel on top of the belt housing.

- Turn the wheel clockwise 1 revolution to increase the tension on the belt.

- Try depressing the blade clutch lock-out and the blade clutch lever, and see if the blade turns. If not, repeat step 2 until the blade turns.

MAINTENANCE AND REPAIR INSTRUCTIONS

MAINTENANCE SCHEDULE

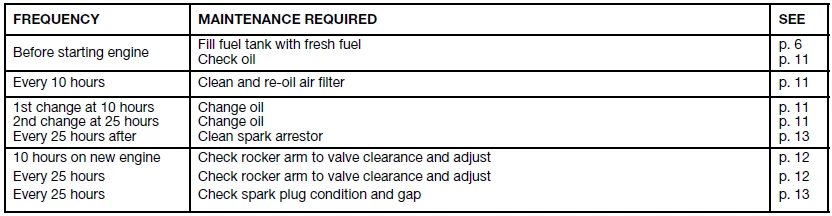

Perform these required maintenance procedures at the frequency stated in the table. These procedures should also be a part of any seasonal tune-up.

NOTE: Some maintenance procedures may require special tools or skills. If you are unsure about these procedures, take your unit to a Troy-Bilt or other qualified service dealer.

NOTE: Maintenance, replacement, or repair of the emission control devices and system may be performed by a Troy-Bilt or other qualified service dealer.

In order to assure peak performance of your engine, inspection of the engine exhaust port may be necessary after 50 hours of operation. If you notice lost RPM, poor performance, or a general lack of acceleration, this service may be required. If you feel your engine is in need of this inspection, refer service to a Troy-Bilt or other qualified service dealer for repair. DO NOT attempt to perform this process yourself, as engine damage may result from contaminants involved in the cleaning process for the port.

BLADE REPLACEMENT

WARNING: To avoid serious personal injury, always wear gloves while handling, removing, or installing the blade.

- Place the 5/16” Allen wrench in the spindle hole.

- While holding the Allen wrench in place, loosen the nut with a 15/16” wrench by turning it counterclockwise.

- Remove the nut and blade. Keep the nut for new blade installation.

- Install the new blade and nut.

- While holding the Allen wrench in the spindle hole, tighten the nut by turning the wrench clockwise until tight.

NOTE: Make sure that the blade stays flat and centered against the output shaft throughout installation.

WARNING: Verify the blade is flat against the output shaft after the nut is tightened. If the blade is off-center, the unit will be damaged by vibration, and the blade may fly off, which can cause serious personal injury.

CHECKING THE OIL LEVEL

The importance of checking and maintaining the proper oil level in the crankcase cannot be overemphasized. Check oil before each use:

- Stop the engine and allow oil to drain into the crankcase.

- Place the unit on a level surface to get a proper oil level reading.

- Keep dirt, grass clippings, and other debris out of the engine. Clean the area around the oil fill plug before removing it.

- Remove the oil fill plug.

- Look into the oil fill hole, use a flashlight if needed. The oil should be just touching the innermost thread.

- If the oil level is not touching the innermost thread on the oil fill hole, add a small amount of oil to the oil fill hole and recheck. Repeat this procedure until the oil level reaches the innermost thread on the oil fill hole.

NOTE: Do not overfill the unit.

NOTE: Make sure the O-ring is in place on the oil fill plug when checking and changing the oil

CHANGING THE OIL

For a new engine, change the oil after the first 10 hours of operation. Change the oil while the engine is still warm. The oil will flow freely and carry away more impurities.

WARNING: Wear gloves to prevent injury when handling the unit.

- Unplug the spark plug boot to prevent accidental starting.

- Remove the oil fill plug.

- Pour the oil out of the oil fill hole and into a container by tipping the unit to a vertical position. Allow ample time for complete drainage.

- Wipe up any oil residue on the unit and clean up any oil that may have spilled. Dispose of the oil according to Federal, State, and local regulations.

- Refill the crankcase with 3.04 fluid ounces (90 ml) of SAE 30 SF, SG, SH oil. NOTE: Use the bottle and spout saved from initial use to measure the correct amount of oil. The top of the label on the bottle measures approximately 3.04 ounces (90 ml). Check the level, see Checking the Oil Level. If the level is low, add a small amount of oil and recheck. Do not overfill.

- Replace the oil fill plug.

- Reconnect the spark plug boot.

AIR FILTER MAINTENANCE

WARNING: To avoid serious personal injury, always turn the unit off and allow it to cool before you clean or service it.

Cleaning the Air Filter

Clean and re-oil the air filter every 10 hours of operation. It is an important item to maintain. Failure to maintain your air filter properly can result in poor performance or cause permanent damage to your engine.

- Open the air filter cover. Push the tab on the left side of the cover in, swing the air filter cover out, and off the air filter housing.

- Remove the air filter and the screen that sits behind it.

- Wash the filter in detergent and water. Rinse the filter thoroughly and allow it to dry.

- Apply enough clean SAE 30 motor oil to lightly coat the filter.

- Squeeze the filter to spread and remove excess oil.

- Replace the filter.

For more Manuals by Troy-Bilt, visit ManualsLibraryy

Are Troy-Bilt edgers reliable?

Yes. Troy-Bilt edgers are known for their durability, lightweight design, and consistent performance. Users appreciate their easy start-up and ability to create clean, professional-looking lawn edges.

What is the Troy-Bilt TBE515 4-Cycle Edger?

The TBE515 is a 4-cycle gasoline-powered lawn edger designed for clean driveway and sidewalk edges. It delivers strong torque, quiet operation, and doesn’t require mixing gas and oil.

Is the Troy-Bilt engine a 4-cycle?

Yes. The TBE515 features a 4-cycle engine, which runs on straight gasoline and has a separate oil reservoir—no fuel mixing needed.

What’s the difference between 2-cycle and 4-cycle engines?

A 2-cycle engine is lighter and faster, while a 4-cycle engine is more fuel-efficient, produces less noise, and generally lasts longer.

What kind of gas does the Troy-Bilt TBE515 use?

Use unleaded gasoline with an octane rating of 84–90 and less than 10% ethanol. Avoid using E15 or higher ethanol blends.

Where are Troy-Bilt edgers made?

Most Troy-Bilt lawn equipment, including edgers, is designed, built, and tested in the United States across facilities in Ohio, Mississippi, Tennessee, and Arizona.

Who manufactures Troy-Bilt equipment?

Troy-Bilt is a brand owned by MTD Holdings, which is part of Stanley Black & Decker, headquartered in Valley City, Ohio.

What does “4-cycle” mean in an engine?

A 4-cycle engine completes four stages—intake, compression, power, and exhaust—during operation, resulting in smoother performance and greater efficiency.

Do I need to mix gas and oil in a 4-cycle engine?

No. The 4-cycle engine has separate compartments for gasoline and oil, eliminating the need for mixing.