VEVOR GL50 Cartridge Pool Filter

NEED HELP? CONTACT US!

Have product questions? Need technical support? Please feel free to contact us:

Technical Support and E-Warranty Certificate www.vevor.com/support

This is the original instruction. Please read all manual instructions carefully before operating. VEVOR reserves a clear interpretation of our user manual. The appearance of the product shall be subject to the product you received. Please forgive us for not informing you again if there are any technology or software updates on our product.

The installation of this product should be carried out by a person knowledgeable in swimming pool plumbing requirements, following the installation instructions provided in this manual. Please pass these instructions on to the owner of this equipment.

CARTRIDGE FILTER

Congratulations on your purchase of a quality product from the range of pool and spa equipment available from Pool Systems. You are assured of many years of reliable and efficient performance. Cartridge filters have been specifically designed for the filtration of spa and swimming pool water. They should not be used for any other purpose without first consulting your dealer or pool systems. Cartridge filters provide economy, high performance, and convenience in a well-designed pressure filter. The polyester element can be removed quickly for rinse cleaning without water loss.

Cartridge filters feature large filter areas, whichensuree even water distribution, peak filtration performance, and longer filter cycles. The corrosion-resistant construction of cartridge filters provides long life and durability. Cartridge filters are capacity matched with the range of pool and spa pumps available from pool systems, forming a total pool filtration system built to last. Take care to match the pump and filter capacities to gain maximum performance and efficiency.

CARTRIDGE FILTRATION PROCESS

Cartridge filtration is an effective, trouble-free, proven method of filtration. Pool water enters the filter and passes through a polyester single-element cartridge. Suspended particles are trapped, and the water is returned to the pool. As the build-up of dirt in the element increases, the water pressure rises and the flow decreases. When the pressure reaches an unacceptable level, the element must be removed and cleaned(spray washing with a common garden hose is generally sufficient)

INSTALLATION AND OPERATION INSTRUCTIONS

LOCATION

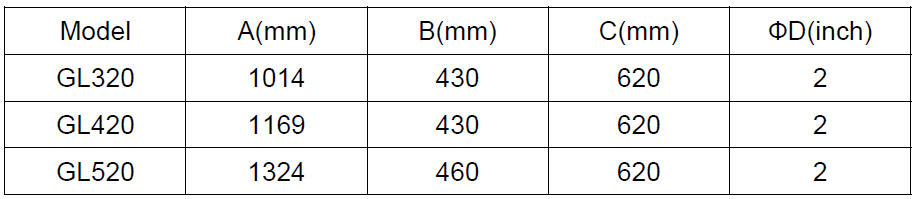

The filter should be placed in its permanent location, preferably as close to the pool or spa as practicable. Position the filter tank and pump on a level concrete slab or similar base. Allow sufficient space around the filter for routine maintenance and provide for adequate ventilation and drainage. Place the pump in position on the slab and locate the filter alongside the appropriate pump inlet connection, oriented towards the pump. Refer to the ‘Specifications’ section for the minimum clearance measurements required for each model.

WEATHER PROTECTION

Cartridge filters are constructed of corrosion-resistant materials. However, to ensure years of reliable performance, it is recommended that the filtration system be adequately protected from the weather.

ASSEMBLY

Assemble the pressure gauge to the filter lid using Teflon tape on the male thread. Do not over-tighten.

PIPE CONNECTIONS

Piping should be supported independently and not impose heavy loads on the filter or pump. Use 40mm or 50mm PVC pipe for pump and pool return lines. 50mm should always be used if the length of piping is over 15mm. Cartridge filters are supplied with quick-connect couplings suitable for 40mm L.D.PVC pipe or 50mm O.D. fittings. If the pump and filter are located below the pool water level, it is necessary to fit isolating valves in the pipe between the pump and the pool, and in the return line from the filter to the pool.

Pump to filter

Cartridge filters are equipped with two inlet ports marked ‘INLET’. Select the inlet port most suitable for the installation and plug the other inlet port with the blanking cap provided. Using quick connect couplings, connect the pool pump delivery piping to the selected inlet port couplings, connect the pool pump delivery piping to the selected inlet port. Tighten by hand only. Ensure the o-ring is lubricated and in the correct position.

Filter to pool return.

Using quick-connect couplings, connect the pool return piping to the filter fitting marked ‘OUTLET’. Tighten the fitting by hand only. Ensure the o’ring on the fitting is clean, lubricated with o’ring lubricant, and in the correct position. The filter base is provided with four mounting holes to enable it to be secured, if required.

FILTER OPERATION

- Make sure the pump is primed according to the manufacturer’s directions.

- Be sure all valves are open on suction and discharge lines. Ensure the air bleed valve on the filter lid is open and the lid lock ring is in place and secure.

- Start the pump. Close the air bleed valve when water is expelled.

- To determine the correct operating conditions with a clean filter, check that the pressure gauge reading is 180kPa or below.

- Record the pressure gauge reading or mark the needle position on the face of the pressure gauge.

- Operate the filter for a sufficient time to circulate the total pool water volume daily. The filter should also be operated at all times the pool is in use and for about one hour afterward. During winter, the running time may be reduced. Filter operating requirements will vary for spa applications. Depending on the system design, type, and size of the spa. Consult your builder or spa supplier.

- When the pressure gauge reading is 180-230kpa higher than the ‘clean filter’ reading, as in (4) above, it is time to clean the cartridge element(see’ Cartridge Cleaning Procedure).

CARTRIDGE CLEANING PROCEDURE

When the filter gauge reading is 50-70kpa above the clean filter gauge reading, cleaning the single-element cartridge is required. To perform the cleaning procedures

- Switch off the pump.

- Close isolating valves on suction and discharge lines where fitted.

- Open the air bleed valve on the filter lid. Unscrew the lock ring and remove the filter lid.

- Lift out the cartridge element.

- In most cases, the element can be easily cleaned with a garden hose, using a good velocity spray directly on the pleats.

NOTE

Algae, calcium, clay, suntan oil, and body oils can form a coating on the element which may not be easily removed with normal hosing. These materials can be removed by soaking the element in a de greaserand/orr descaler. Your local dealer will be able to recommend suitable products.

CARTRIDGE RE-ASSEMBLY INSTRUCTION

- Install the cartridge/s and center pipe so that it is located in the bottom spigot.

- Ensure the filter lid o’ring is clean, lubricated with o’ring lubricant, and located in the bottom groove.

- Replace the lid and press firmly in place. Screw down the lock ring; hand-tight is sufficient, NOT OVER TIGHTEN.

- Make sure the pump is primed according to the manufacturer’s directions.

- Ensure all valves are open on suction and discharge lines.

- Start the pump.

- Close the air bleed valve when all air has been expelled.

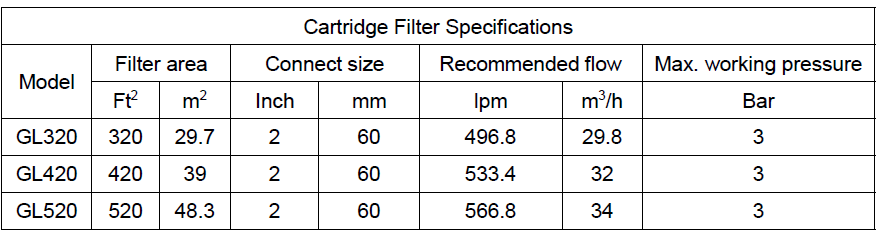

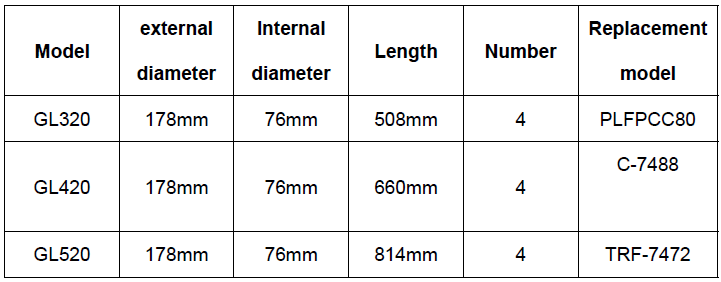

SPECIFICATIONS

Four cartridges in a compact design

GL320-520 cartridge filters contain four polyester cartridges that hold enormous amounts of dirt, yet are easy to clean. The fiberglass-reinforced tank halves are secured with an innovative clamp ring-just loosen the ring and remove the top half for easy cartridge access and rinsing. Filter maintenance made easier.

- Continuous internal air bleed prevents air build-up to keep the filter operating at peak performance.

- Single-piece base and body for strength, stability, and years of dependable service.

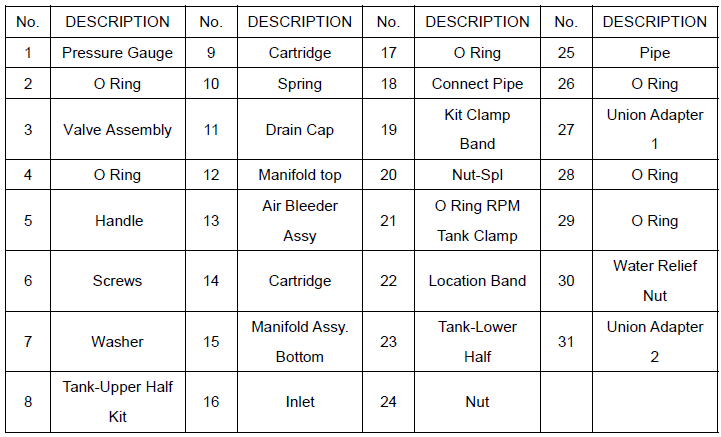

Expanded Diagram

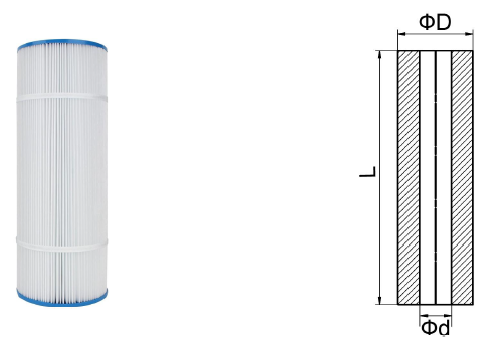

Filter Cartridge

Easy-to-clean & Reusable Cartridge Elements

Cartridges have extra dirt-holding capacity and are engineered of durable, high-quality materials for longer service life with minimal care. Simply remove the cartridge element and flush the cartridge with hose water or clean the cartridge with a Filter Cleaner.

NOTICE

After the service life of the filter Cartridges expires or is damaged, the user can purchase other filter elements of the same size for installation.

WARNING

![]() This filter operates under high pressure. When any part of the circulating system (e.g., clamp, pump, filter, valves, etc.) is serviced, air can enter the System and become pressurized. Pressurized air can cause the lid or valve to be blown off, which can result in severe injury, death, or property damage.

This filter operates under high pressure. When any part of the circulating system (e.g., clamp, pump, filter, valves, etc.) is serviced, air can enter the System and become pressurized. Pressurized air can cause the lid or valve to be blown off, which can result in severe injury, death, or property damage.

![]() Turn the pump off before changing the valve position.

Turn the pump off before changing the valve position.

![]() To prevent damage to the pump and for proper operation of the system, Clean pump strainer and skimmer baskets regularly.

To prevent damage to the pump and for proper operation of the system, Clean pump strainer and skimmer baskets regularly.

Address: Baoshanqu Shuangchenglu 803long 11hao 1602A-1609shi Shanghai

Imported to AUS: SIHAO PTY LTD. 1 ROKEVA STREET EASTWOOD NSW 2122 Australia

Imported to the USA: SanvenTechnology. Suite 250, 9166 Anaheim Place, Rancho Cucamonga, CA 91730

SHUNSHUN GmbH

Römeräcker 9 Z2021,76351

Linkenheim-Hochstetten,Germany

Pooledas Group Ltd

Unit 5 Albert Edward House, The Pavilions

Preston, United Kingdom

For more manuals by VEVOR, visit ManualsLibraryy

VEVOR GL50 Cartridge Pool Filter- FAQs

Do you backwash a cartridge filter?

No. Cartridge filters are not designed for backwashing. Cleaning is done by manually removing and hosing off the cartridge as described above.

How often should the cartridge be replaced?

With proper care, a cartridge can last 2 to 3 years. However, replace it immediately if you notice visible damage, tears in the fabric, broken end caps, or if cleaning no longer restores water flow and pressure.

Can I run the pump without a filter cartridge?

You can temporarily run the pump without a cartridge for tasks like circulating chemicals or vacuuming to waste (if your system allows it). Never run it for extended periods without a filter, as this can allow debris to circulate and potentially damage the pump.

Why is my filter pressure too high?

High pressure is almost always caused by a clogged or dirty cartridge. The pleats are blocked with debris, restricting water flow. Clean the cartridge to resolve the issue.

Why is my filter pressure too low?

Low pressure usually indicates a problem before the filter. Check for a clogged pump basket, a blocked skimmer, or a closed valve. It could also signal an air leak on the suction side of the pump.

What setting should the filter be on to vacuum?

Set the multiport valve (if equipped) to “FILTER” mode for normal vacuuming. This ensures debris is caught by the cartridge. If there is a large amount of debris, you may need to vacuum directly to “WASTE” to bypass the filter and prevent it from clogging immediately.

How long should I run my pool filter each day?

For adequate circulation and filtration, you should run your pool pump and filter for at least 8 hours per day during the swimming season. This may need to be increased during very hot weather or with high pool usage.

How do I know if my pool filter is working properly?

A properly working filter will maintain clear water and stable pressure. You can perform a simple test: add a small amount of dirt near the skimmer. If the filter is working, the dirt should be sucked into the skimmer and not return through the pool jets.

How does a cartridge pool filter work?

Water is pumped from the pool into the filter tank, where it is forced through the pleated fabric of the cartridge. The fabric traps dirt, debris, and contaminants, allowing only clean water to pass through and return to the pool.

What is the normal operating pressure for my filter?

A clean VEVOR GL50 filter should typically run at a pressure between 8 and 15 PSI on the pressure gauge. This is your “clean” baseline pressure.