VEVOR XRJF-21 Double Bowl Commercial Slushy Machine

Installation Instructions for The Whole Machine

Installation of Slushy Machine

- Remove all packaging components.

- Check if the machine is damaged during transportation, and then remove the attachments.

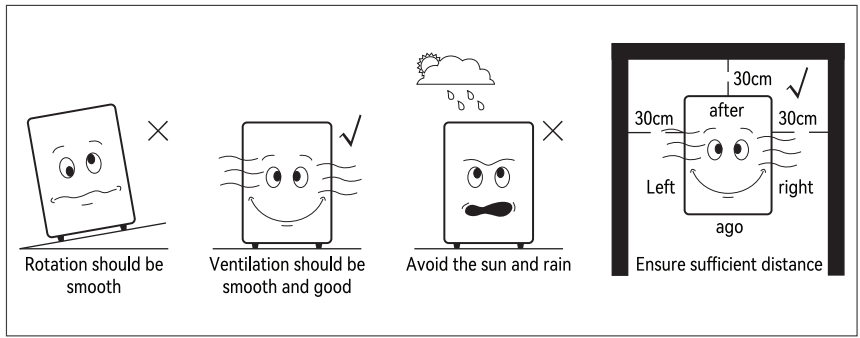

- This series of slushy machines should be placed in a clean place with air circulation, not suitable for open air, not suitable for direct sunlight and rain, nor can it be placed near a heat source.

- The ambient temperature around the series of machines should not be less than 3 °C/37.4°F, not higher than 38 °C/100.4°F, and the appropriate spacing should be retained around the four sides to maximize the efficiency of the slushy machine and the heat dissipation of the machine.

- When the slushy machine is installed, please place the slushy machine horizontally, and items cannot be placed on the top.

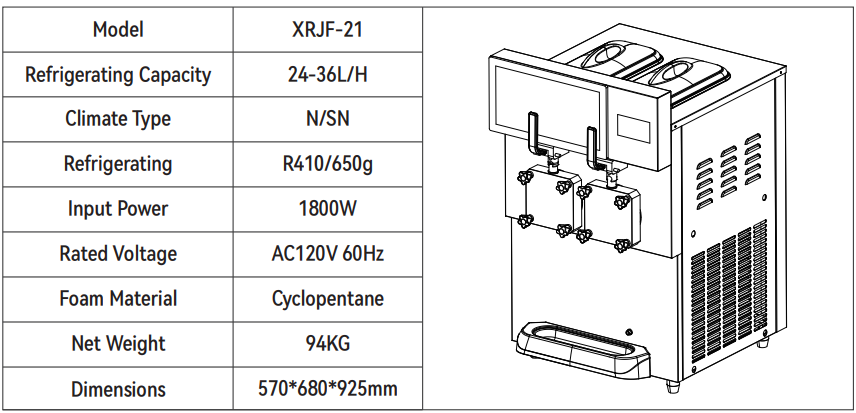

Installation of the Power Supply

- The power supply connected should be the same as the one indicated on the nameplate of the machine.

- Do not connect other electrical appliances to the same outlet.

- The Y-type connection must be replaced by the manufacturer, service agencies, or qualified personnel to connect the power cord.

- The power plug should be plugged directly into a power outlet with a ground wire, not into a temporary terminal block. All wiring must comply with national or regional standards.

- Voltage fluctuations shall not exceed ±10% of the rated voltage; otherwise, a voltage regulator shall be installed.

Pre-boot Inspection

- Is the slushy machine placed horizontally?

- Is there any problem with the power outlet?

- Whether the access to the power supply is consistent with the one marked on the machine nameplate.

Proper Operation When Using

- Do not place items on the top cover of this machine; otherwise, it will cause noise.

- The left, right, and rear sides of the machine must have sufficient heat dissipation space; otherwise, it will affect the heat dissipation, and the production capacity of the machine affected by the air-cooled circulation channel. And it is forbidden to place items around.

- The slushy machine should be kept away from the heat source; it is strictly forbidden to use it in a high or low temperature environment, and direct sunlight should be avoided as much as possible so as not to affect the heat dissipation of the machine.

- Sterilization should be carried out daily. Otherwise, bacterial multiplication can be detrimental to health.

- If the slushy machine is placed for a long time, please disassemble and wash it, turn off the power plug, please carefully dry the water of the material tank and the freezing tank; after they are dried and then cover the material basin cover for safekeeping.

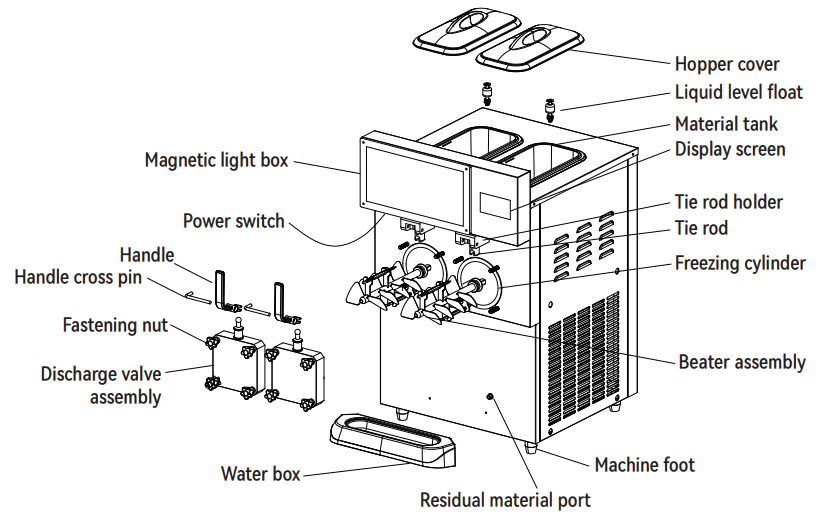

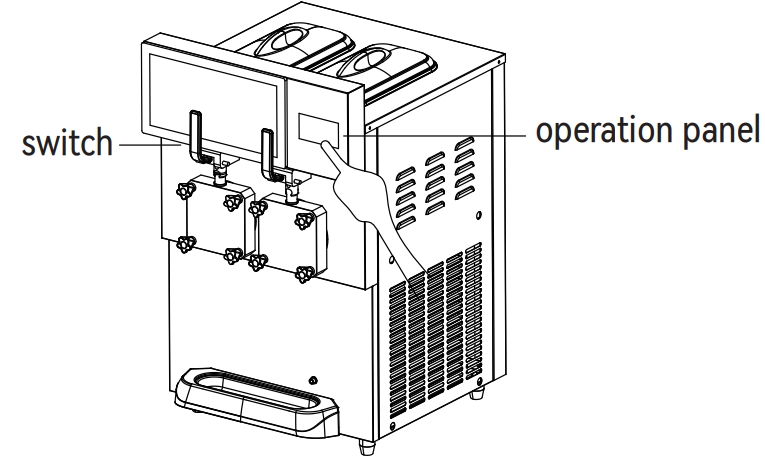

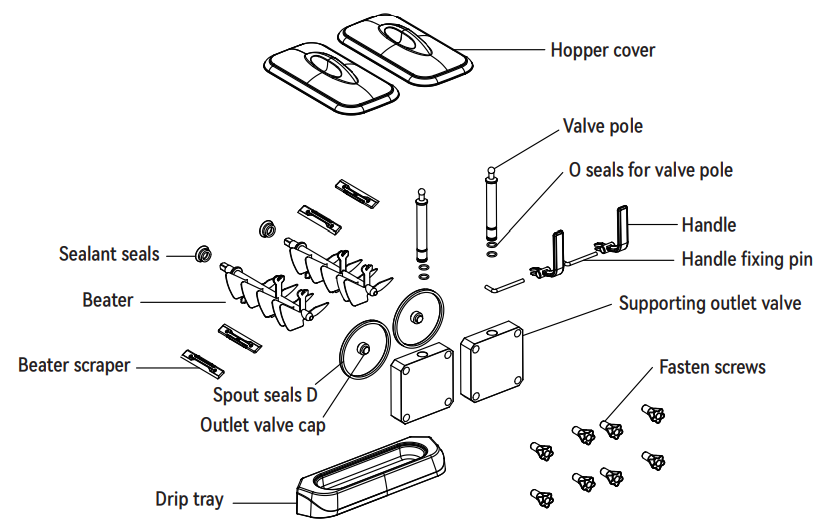

Names of Each Part

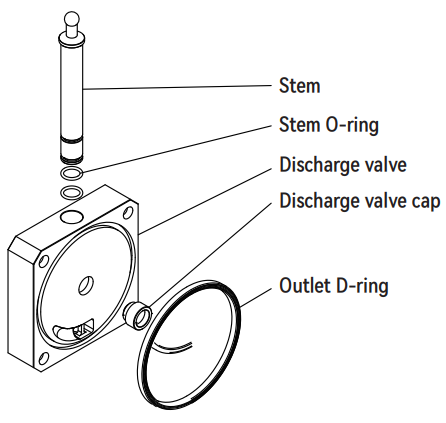

- Discharge Valve Assembly

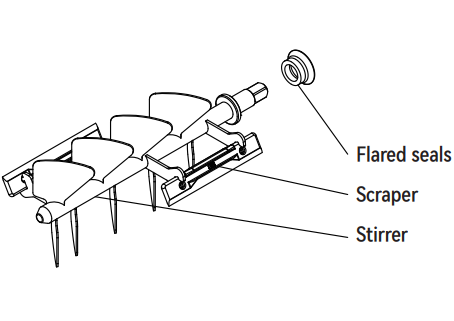

- Agitator Components

Product Specifications

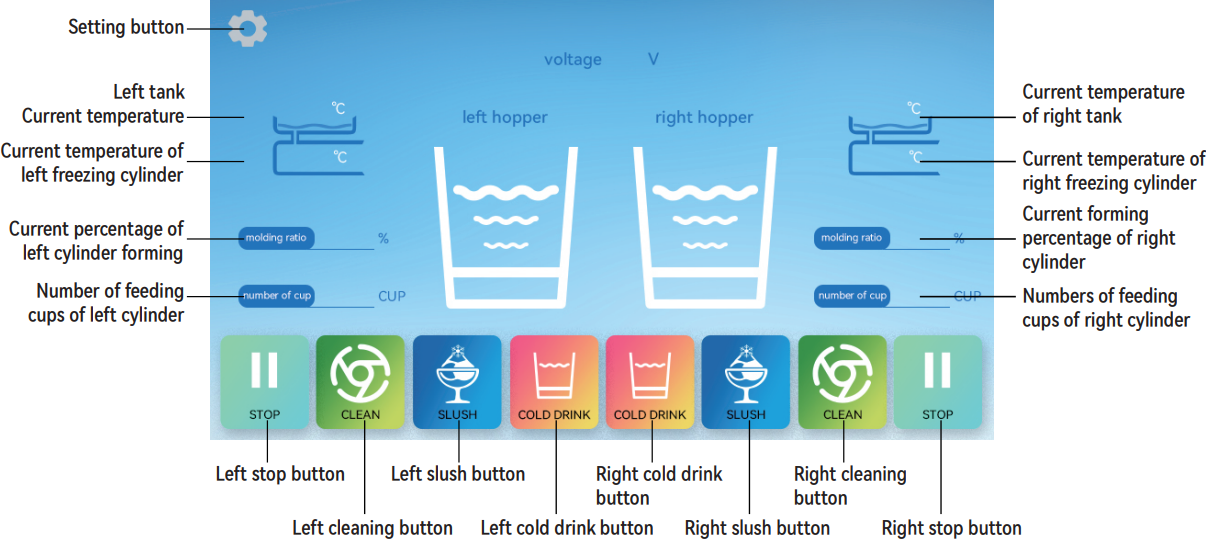

Operating Instructions

Notice: The left cylinder and the right cylinder correspond to the left system and the right system, respectively, and the two systems are independently controlled, and the independent displays do not affect each other.

Press “Stop”, “Clean”, “Slush”, and “Cold Drink” on the touch screen to enter the corresponding working mode.

It is normal for the current temperature of the freezing cylinder to deviate from the actual temperature of the raw material in the cylinder. Freezing cylinder temperature is not involved in forming control when making slush.

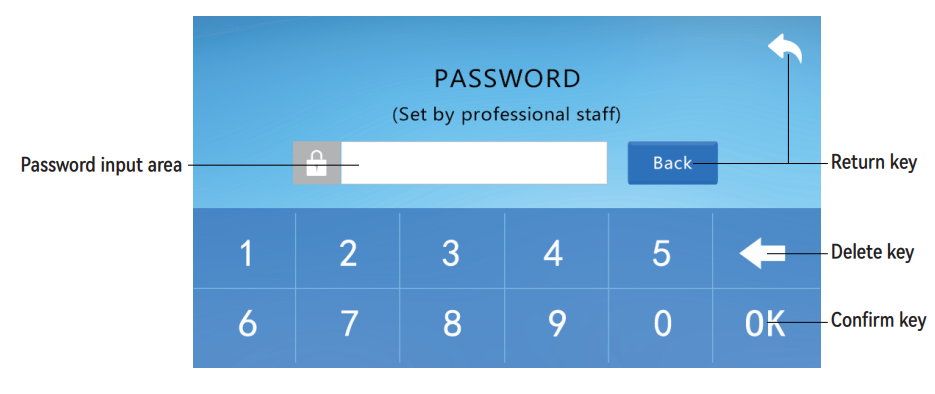

Password Input Interface

On the password input interface, click the password input area and enter the password “666666”, and then click “OK” to enter the parameter setting interface.

Fault Alarm Interface

On the setting interface, press “Fault Query” on the touch screen to enter the fault query mode. Displays an alarm interface when a fault occurs during machine operation.

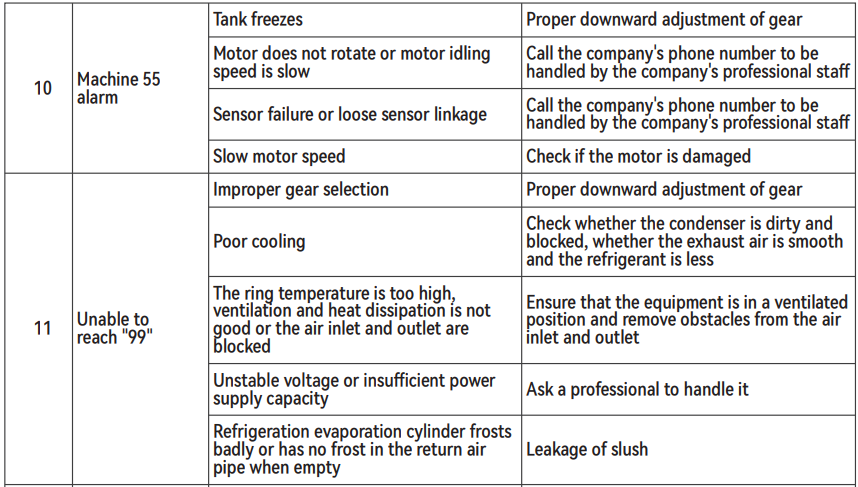

- 55 Low-speed alarm: 220V machine motor speed is lower than 130 rpm to stop the alarm to prevent the motor from being damaged by excessive force. (The motor speed of the 120V machine is lower than 165 rpm, and it will stop and alarm.)

- LL sensor is abnormal: When the motor is in working state but has no speed, it will stop and alarm to prevent the motor from being stuck and damaged, or the speed sensor from being abnormal.

88 Refrigeration poor alarm: if the longest forming time is exceeded, the poor refrigeration alarm will be reported. - UH high voltage: when the operating voltage of the machine is higher than the set value, it will stop and alarm. A 220V machine will alarm if it is higher than 255V, and a 120V machine will alarm if it is higher than 135V.

- UL low voltage: when the operating voltage of the machine is lower than the set value, the machine will stop and alarm, the 220V machine will alarm if it is lower than 182V, and the 120V machine will alarm if it is lower than 96V.

- AH return air temperature is abnormal: when the material cylinder temperature probe is damaged or abnormal, it will stop and alarm.

- Clear fault: clear all faults and re-test.

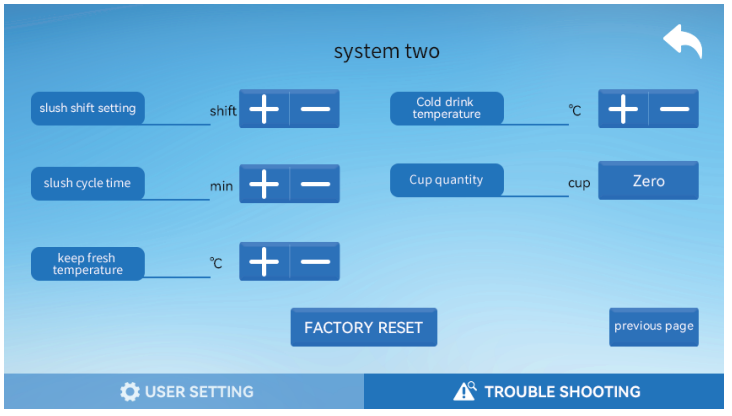

System 1 (left cylinder) parameter setting interface

- Slush gear: 1-8 gears are adjustable; press “plus” or “minus” to adjust the gear. The default is gear 3. The higher the gear, the harder the smoothie; and the lower the gear, the softer the smoothie.

- Slush cycle time: This time adjusts the cooling system after the slush is 100% formed. Stop time, adjustable from 5-20 minutes, press “plus” or “minus” to adjust the gear. The default is 10 minutes.

- Preservation temperature: Set the preservation temperature of the tray, adjustable from 5°C to 15°C, and the default is 10°C.

- Cold drink temperature: Set the cold drink refrigeration shutdown temperature, adjustable from 2°C to 10°C, and the default is 7°C.

- Number of cups delivered: Record the number of cups delivered by the machine for slush and cold drinks, and press “Clear” to subtract to clear the data.

- Restore factory settings: All data set by the user is cleared, and the parameters are restored to the factory settings.

- Next page: Enter system 2 (right cylinder system) user settings.

Note: All user-set parameters have a power-off save function, which will be automatically saved after the setting is completed and returned.

System 2 (right cylinder) parameter setting interface

The parameter setting method of system 2 (right cylinder) is the same as that of the left cylinder.

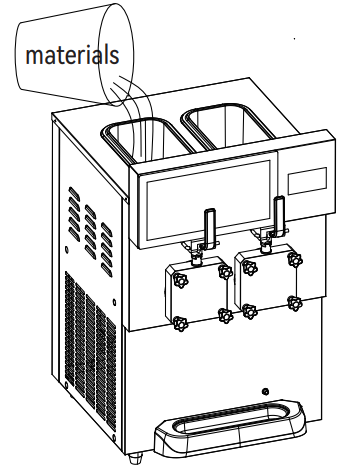

Slush Production

Raw Material Preparation

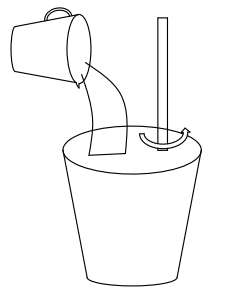

According to the manufacturer’s operating instructions, dilute the concentrate with water and stir in a suitable container. The mixture contains sugars, the amount of which should be kept between 13%-18%. Lower and higher concentrations can be destroyed by agitators and stirring motors.

Raw Material Filling

Before adding the raw materials, try to ensure that there is no residual moisture in the freezing tank during cleaning. Check the discharge valve assembly, whether it is installed in place, and whether the four fastening nuts are twisted. Inject about 6 liters of slush raw material into the material tank. (The single-tank slushy machine can pour up to about 10 liters of raw material into the material tank.) Each freezing tank of this machine is equipped with an independent stirring system, and the system can act independently on one side.

Start The Machine

Refer to the operating instructions. Note: When the machine is in working condition, do not put your fingers into the feed bowl or the raw material supply port. Failure to do so may result in finger injuries or machine malfunction.

Make Smoothies

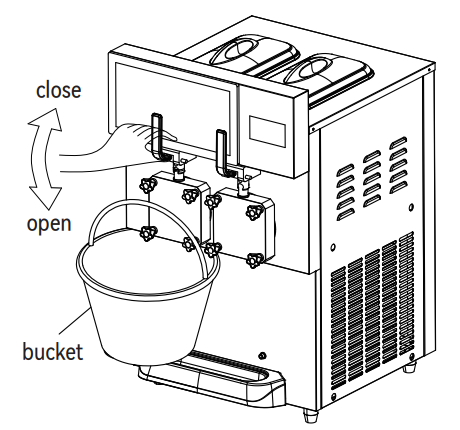

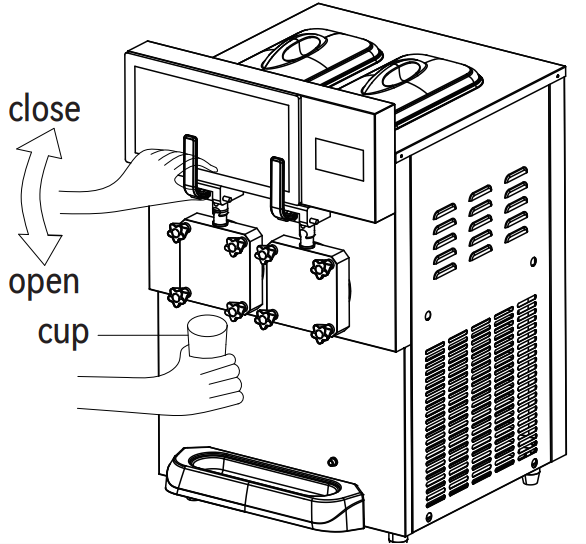

When the shape ratio reaches 99% and the machine is automatically stopped, it means that the smoothie is ready. Simply pull the handle down to punch out the smoothie.

Simple Cleaning

- Release all the ingredients.

- Power off the machine.

- Fill the material tank with an appropriate amount of food detergent to prepare hot water that does not exceed 50°C, then open the tank cover and pour the hot water into the tank.

- Turn on the power of the machine, then press the wash button and let the agitator stir for 2-3 minutes.

- Release all the water from the tank, and then repeat the operation more than 2-4 times.

- Turn off stirring and power.

Cleaning & Maintenance

- Be sure to unplug and turn off the power supply before cleaning.

- Before any cleaning or maintenance, be sure to bring protective equipment (gloves, hand sleeves, protective glasses, etc.), which ensures your safety.

- Please do not rinse the slush with water spray, so as not to affect the insulation performance of the electrical appliances, and cause a leakage hazard.

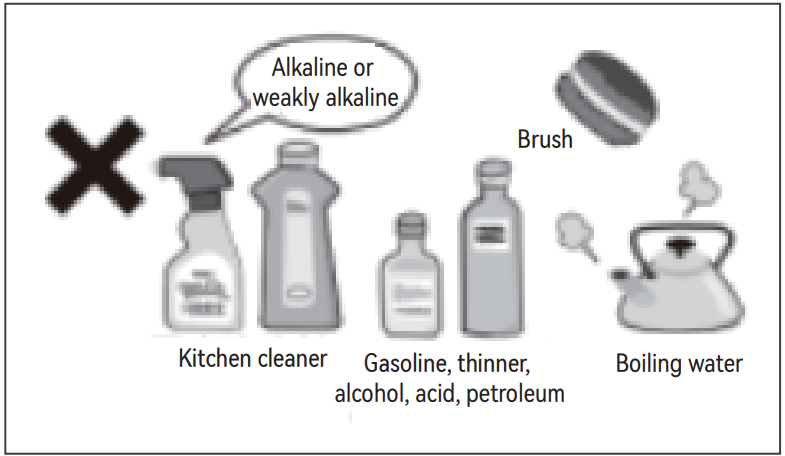

- Do not use hard-bristle brushes, wire brushes, or detergent powders, gasoline, bananas, water, acetone and other organic solvents, boiling water, or acids, alkalis, etc. to clean the slushy machine; improper use will cause damage to the slushy machine material and affect the service life.

- When cleaning a location with warning signs, be careful not to scratch your hands.

- Wash with disinfectant that meets food hygiene requirements.

- Use a suitable food-grade neutral cleaning agent to avoid damaging parts.

- The following items can damage the surface of the slush.

Cleaning Method of Parts

When using it for the first time or not using it for a long time, please clean the parts before use.

The Assembly Method of The Component

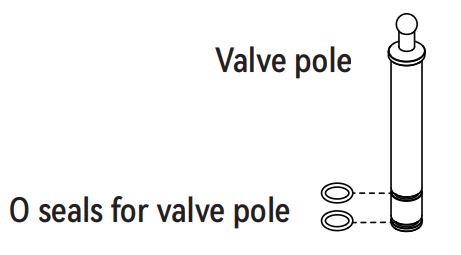

Assembly of The Valve Stem

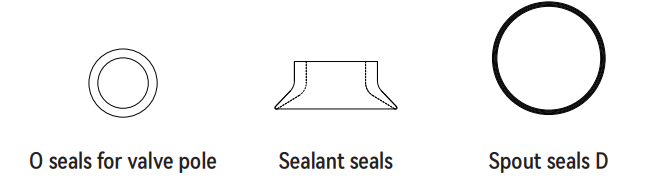

- Install the O-ring on the valve stem and assemble it according to the diagram.

- After the O-ring is installed, the surface is greased.

Assembly of Agitator Components

- The flared sealing ring is lubricated at both ends.

- Install the flared seal directly behind the agitator.

- Mount the scraper on the agitator. The spatula arrangement in the agitator is loose.

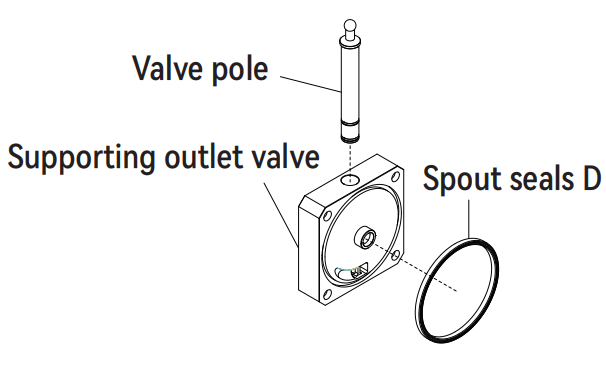

Assembly of Discharge Valves

- Insert the greased stem of the installed O-ring into the outlet hole of the discharge head.

- Install the D-ring on the discharge head mounting slot.

Methods for Installing on The Machine

Mounting of The Handle

- Insert the handle socket into the lever pin, then insert the handle pin into the lever holder, and then align the handle pin hole with the vel pin, and then the vel pin goes directly through the handle pin hole.

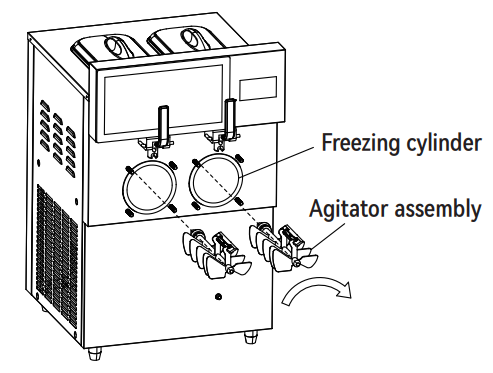

Installation of Agitators

- It is important to ensure that the control power switch is turned off. Confirm that the display is off. Insert the agitator into the freezer tank and slowly rotate the agitator with your hands to embed the quad head of the reducer into the quad connector of the reducer.

Installation of Discharge Manifolds

- The four mounting holes of the discharge valve are passed through the four discharge heads to fix the bolts, the stem head is stuck in the lever clamp position, and then the four fastening nuts are evenly fastened diagonally.

Cleaning And Maintenance of The Enclosure

Be sure to unplug the power supply and turn off the water source before cleaning. Do not plug the Power supply into wet hands, or there will be a risk of electric shock. Wipe the surface of the slushy machine shell by using a soft towel or sponge dipped in warm water (a diluted neutral detergent is available). After washing with detergent, wipe it off promptly with a soft cloth or sponge dipped in water. Wipe the water off the surface of the enclosure with a dry cloth.

Please never spill water directly on the machine. Failure to do so may result in a power leakage or accident. Check once or twice a month to confirm whether the power cord is damaged.

Cleaning of The Condenser

After working for a period of time, the condenser will be dusty and affect the heat dissipation, and the cooling effect will become worse (Manifested as: the output of the slush decreases or the slush is difficult to be formed), please clean once every three months (if the using environment is poor, please clean once a month), be sure to ask a professional cleaner to clean, turn off the power before cleaning, and pay attention not to damage condenser fins of the vessel.

Consumable Parts

Even if there are scars on the sealing ring that cannot be seen with the naked eye, it may cause problems such as “slush leakage”, so please replace the new product regularly with a rough replacement period of three months. Even within the replacement period, if there is a problem, such as scars, please replace it in time.

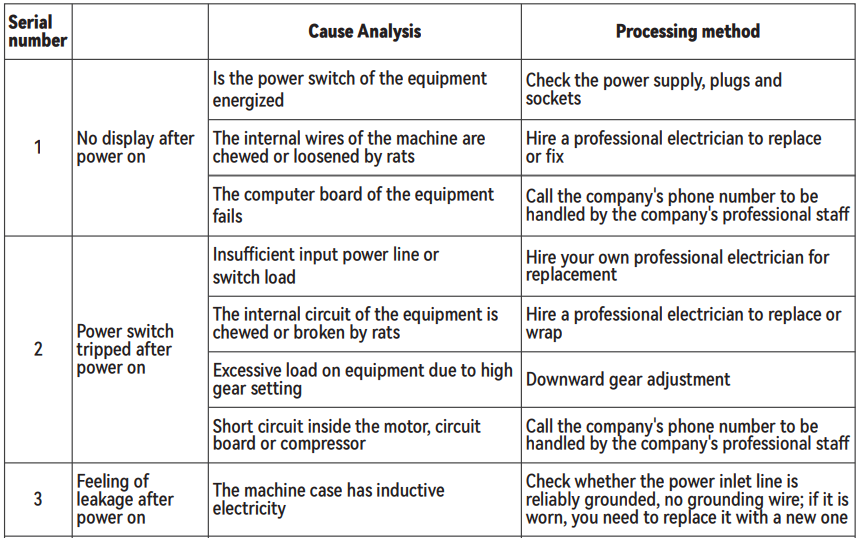

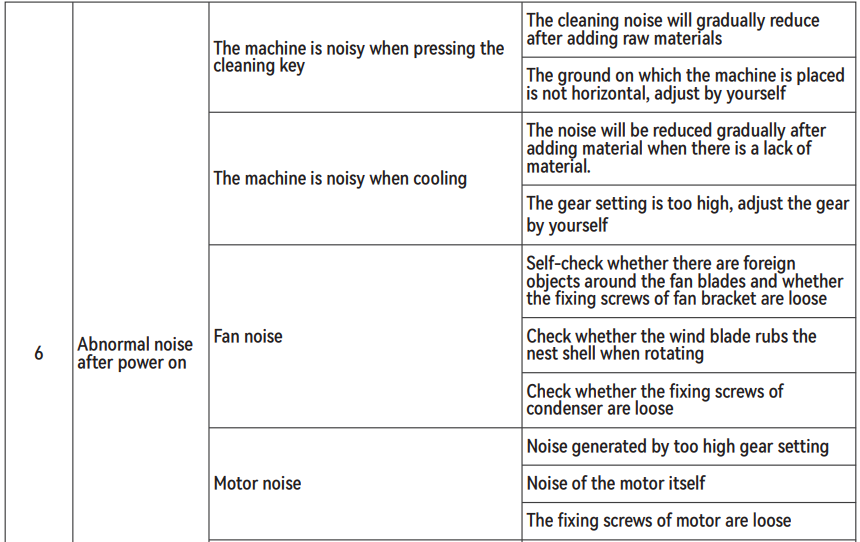

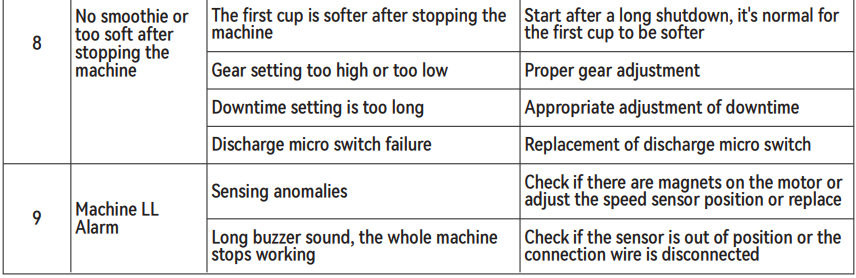

Troubleshooting Instructions

The slushy machine you receive is a mechatronic professional equipment that integrates computer program control, mechanical transmission, and an efficient refrigeration system! You must arrange for your own personnel to be responsible for the operation and maintenance of this equipment. At the same time, please understand the installation and maintenance requirements of this equipment in detail when purchasing the machine, and receive professional training before use!!! (Very important) The violation of the installation, use, and maintenance requirements of the machine caused by equipment failure is not within the scope of the company’s warranty! At the same time, for the problems encountered in the process of use, please strictly follow the following precautions

For More Manuals By VEVOR, Visit ManualsLibraryy.

VEVOR XRJF-21 Double Bowl Commercial Slushy Machine-FAQs

Q1: How long until the slush is ready?

It takes about 60 minutes for a full batch to freeze from a liquid to a proper slush consistency.

Q2: Why won’t my mixture freeze?

The most common reasons are:

Using the wrong water-to-syrup ratio (use 6:1).

A dirty condenser (clean it regularly).

The machine is not level.

Q3: What temperature should it be set to?

Non-alcoholic slush: -3°C to -1°C (27°F to 30°F)

Alcoholic slush: -12°C to -6°C (10°F to 21°F)

Cold drinks: 3°C to 5°C (37°F to 41°F)

Q4: Can I leave it running overnight?

You can use the “Night Mode” to hold the mixture at 3-4°C (38°F) without freezing it solid, which is ideal for saving product overnight.

Q5: Why is my slush watery?

The mixture needs more time to freeze, or the syrup ratio is incorrect. Ensure the “Mixing” function is on to create the right texture.

Q6: What kind of syrup should I use?

Always use commercial-grade slush syrup. Using the wrong type can damage the machine and will not freeze correctly.

Q7: How do I clean it?

Drain the basins daily and wash with warm, soapy water.

Regularly wipe down the exterior and clean the condenser coils to maintain cooling performance.

Q8: What is the voltage?

This commercial unit operates on standard 110-120V power. Ensure it is plugged into a dedicated outlet.