WORX Tools WG305 Electric Chain Saw

Parts

PRODUCT SAFETY

WARNING: Some dust created by power sanding, sawing, grinding, drilling, and other construction activities contains chemicals known to the State of California to cause cancer, birth defects, or other reproductive harm. Some examples of these chemicals are:

- Lead from lead-based paints;

- Crystalline silica from bricks, cement, and other masonry products; and

- Arsenic and chromium from chemically-treated lumber.

- Your risk from these exposures varies depending on how often you do this type of work. To reduce your exposure to these chemicals:

- Work in a well-ventilated area, and

- Work with approved safety equipment, such as dust masks that are specially designed to filter out microscopic particles.

WARNING: This product can expose you to chemicals including lead, phthalates, or bisphenol A, which are known to the State of California to cause cancer, birth defects, or other reproductive harm. Wash your hands after use. For more information, go to www.P65Warnings.ca.gov

INSTRUCTIONS CONCERNING THE PROPER TECHNIQUES FOR BASIC FELLING, LIMBING, AND CROSSCUTTING

1. Felling a tree

When bucking and felling operations are being performed by two or more persons at the same time, the felling operations should be separated from the bucking operation by a distance of at least twice the height of the tree being felled. Trees should not be felled in a manner that would endanger any person, strike any utility line, or cause any property damage. If the tree does make contact with any utility line, the company should be notified immediately.

The chainsaw operator should keep on the uphill side of the terrain as the tree is likely to roll or slide downhill after it is felled. An escape path should be planned and cleared as necessary before cuts are started. The escape path should extend back and diagonally to the rear of the expected line of fall, as illustrated in Figure 1.

Before felling is started, consider the natural lean of the tree, the location of larger branches, and the wind direction to judge which way the tree will fall. Remove dirt, stones, loose bark, nails, staples, and wire from the tree.

2. Notching undercut

Make the notch 1/3 the diameter of the tree, perpendicular to the direction of fall, as illustrated in Figure 1. Make the lower horizontal notching cut (W) first. This will help to avoid pinching either the saw chain or the guide bar when the second notch (X) is being made.

3. Felling back cut

Make the felling back cut (Y) at least 50 mm higher than the horizontal notching cut, as illustrated in Figure 2. Keep the felling back cut parallel to the horizontal notching cut. Make the felling back cut so enough wood is left to act as a hinge. The hinge wood keeps the tree from twisting and falling in the wrong direction. Do not cut through the hinge.

As the felling gets close to the hinge, the tree should begin to fall. If there is any chance that the tree may not fall in the desired direction or it may rock back and bind the saw chain, stop cutting before the felling back cut is complete and use wedges of wood, plastic, or aluminium (Z) to open the cut and drop the tree along the desired line of fall.

When the tree begins to fall, remove the chainsaw from the cut, stop the motor, put the chainsaw down, then use the retreat path planned. Be alert for overhead limbs falling and watch your footing.

TECHNICAL DATA

ACCESSORIES

Only use the appropriate accessories intended for this tool. Accessory information can be found on the product packaging, at a WORX dealer, or on our website at www.worx.com.

ASSEMBLY

WARNING! Do not connect the chainsaw to the power supply before it is completely assembled. Always use gloves when handling the chain.

CHAIN AND GUIDE BAR ASSEMBLY

- Unpack all parts carefully.

- Place the chainsaw on a solid, level surface.

- Use only genuine WORX chains or those recommended for the Guide Bar.

- Slide the Chain (10) in the slot around the Guide Bar (9). Ensure the Chain is in the correct running direction by comparing it to the chain icon on the guide bar or referring to the Chain Direction Symbol (16) found on the saw body. Ensure the Bar Tensioning Plate (22) is facing outwards. (See Fig. A)

- Fit the Chain onto the Drive Sprocket (15), so that the Fastening Bar Hole (19) and the two Bar Locating Tabs (20) on the Bar Pad (18) fit into the keyway of the opening on the Guide Bar (9). (See Fig. B1, B2)

- Assure all parts are seated properly. Make sure the drive links are fully seated in the drive sprocket (See Fig. C1), avoiding a kink as shown in Fig. C2. If a kink occurs, pick up on the chain at the guide bar just ahead of the kink and then pull the kink out. NOTE: The Chain should rotate freely and be free of kinks.

- Fit the Chain Cover (12) and tighten the Chain Cover by turning the Chain Tensioning Knob (11) clockwise until it is tight. (See Fig. D)

TENSIONING CHAIN (See Fig. E1, E2)

NOTE: New saw chains will stretch. Check the chain tension frequently when first used and tighten when the Chain (10) becomes loose around the Guide Bar (9).

WARNING:

- Unplug the chainsaw from the power source before adjusting the saw chain tension.

- Cutting edges on the chain are sharp. Use protective gloves when handling the chain.

- Maintain proper chain tension always. A loose chain will increase the risk of kickback. A loose chain may jump out of the guide bar groove. This may injure the operator and damage the chain. A loose chain will cause the chain, bar, and sprocket to wear rapidly.

- Place the chainsaw on any suitable flat surface.

- Turn the Chain Tensioning Knob (11) clockwise until it is hand-tight. NOTE: The tension is automatically increased while the Chain Tensioning Knob (11) is being turned in a clockwise direction. The built-in ratchet mechanism prevents the chain tension from loosening.

- Tilt the saw forward (See E1) where the Guide Bar (9) tip is pushed in an upward direction. This will remove slack from the chain.

- Fully tighten the Chain Tensioning Knob (11) by turning it clockwise. (See E1)

- Double-check the tension set by the automatic Chain Tensioning Knob. The correct chain tension is reached when the Chain (10) can be raised approximately. Half the drive link depth from the Guide Bar (9) in the center. This should be done by using one hand to raise the chain against the weight of the machine. (See Fig. E2)

LUBRICATION

- Set the chainsaw on any suitable surface with the Oil Filler Cap (5) facing upward.

- Clean the area around the Oil Filler Cap with a cloth and unscrew the cap by turning it counter-clockwise.

- Add bar and chain oil until the reservoir is full.

- Avoid dirt or debris from entering the oil tank, refit the Oil Filler Cap (5), and tighten by turning clockwise until hand-tight.

Oiling chain

Always check the oil level before using the saw. Do not attempt to operate the oil system while the saw is in operation. To the oil chain, press the Bulb (23). Oil will feed through the Oil Outlet (17) onto the Guide Bar (9) and chain. Press the Bulb (23) on the Oil Filler Cap at least once before each cut. (See Fig. F)

OPERATION

SWITCHING ON AND OFF (See Fig. G)

ATTENTION: Check the voltage and current supply. The voltage and current supply must comply with the ratings on the product plate. To switch on the tool, press the Lock-Out Button (3), then fully press the On/Off Switch (2) and hold it in this position. The Lock-Out Button can now be released. To switch off, release the On/Off Switch.

CUTTING

IMPORTANT: Is the oil reservoir filled? Check the Oil Level Window (4) prior to starting and regularly during operation. (See Fig. H1) Refill oil when the oil level is low. A full oil tank will last approximately. 12 minutes of cutting, depending on sawing intensity and stops. Check the recently replaced chain tension about every 10 minutes during operation.

- Connect the saw to the extension cord. Connect the extension cord to the power supply. (See Fig. H2)

- Make sure the section of the log to be cut is not lying on the ground. This will keep the chain (10) from touching the ground as it cuts through the log. Touching the ground while the Chain is moving is dangerous and will dull the Chain.

- Use both hands to grip the saw. Always use your left hand to grip the Front Handle (6) and your right hand to grip the Rear Handle (1). Use a firm grip. Thumbs and fingers must wrap around saw handles. (See Fig. H3)

- Make sure your footing is firm. Keep feet shoulder-width apart. Distribute your weight evenly on both feet.

- When ready to make a cut, push the Lock-Out Button (3) completely in with the right thumb and squeeze the trigger. This will turn the saw on. Releasing the trigger will turn the saw off. Make sure the saw is running at full speed before starting a cut.

- When starting a cut, slowly place the moving chain against the wood. The wood should be as close to the saw body as possible. Hold the saw firmly in place to avoid possible bouncing or skating (sideways movement) of the saw.

- Guide the saw using light pressure and do not put excessive force on the saw, letting the saw do its work. The motor will overload and can burn out. It will do the job better and safer at the rate for which it was intended.

- Remove the saw from a cut with the saw running at full speed. Stop the saw by releasing the On/Off Switch (2). Make sure the chain has stopped before setting the saw down.

- Keep practicing on scrap logs in a secure working area until you are comfortable and can saw with ease, using a fluid motion and a steady cutting rate.

KICKBACK SAFETY DEVICES ON THIS SAW

This saw has a low-kickback chain and a reduced kickback Guide Bar. Both items reduce the chance of kickback. However, kickback can still occur with this saw. The following steps will reduce the risk of kickback:

- Use both hands to grip the saw while the saw is running. Use a firm grip. Thumbs and fingers must wrap around saw handles.

- Keep all safety items in place on the saw. Make sure they work properly.

- Do not overreach or cut above shoulder height.

- Keep a solid footing and balance at all times.

- Stand slightly to the left side of the saw. This keeps your body from being in direct line with the chain.

- Do not let the Guide Bar nose touch anything when the chain is moving.

- Never try cutting through two logs at the same time. Only cut one log at a time.

- Do not bury the Guide Bar nose or try a plunge cut (boring into wood using the Guide Bar nose).

- Watch for shifting of wood or other forces that may pinch the chain.

- Use extreme caution when reentering a previous cut.

- Use only the low-kickback chain and Guide Bar (9) that were supplied with this chainsaw or recommended.

- Never use a dull or loose chain. Keep the chain sharp with proper tension.

HOW TO USE SAW SAFELY

- Use the chainsaw only with a secure footing.

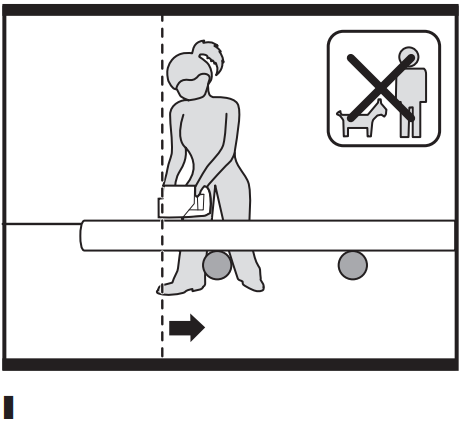

- Hold the chainsaw at the right-hand side of your body. (See Fig. I)

- The Chain (10) must be running at full speed before it makes contact with the wood.

- Use the Bumper Spikes (8) to secure the saw onto the wood before starting to cut.

- Use the Bumper Spikes as a leverage point while cutting. (See Fig. J)

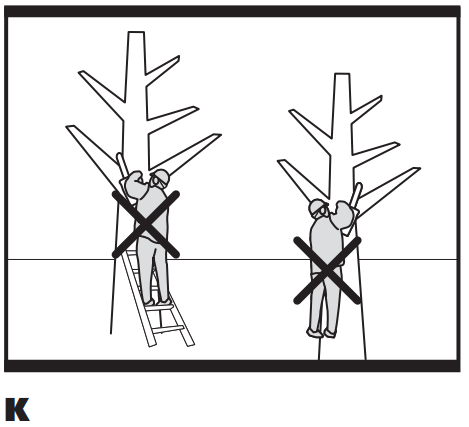

- Do not operate the chainsaw with arms fully extended, or attempt to saw areas which are difficult to reach, or stand on a ladder while sawing. (See Fig. K)

- Never use the chainsaw above shoulder height.

CUTTING WOOD UNDER TENSION (See Fig. L)

WARNING: When cutting a limb that is under tension, use extreme caution. Be alert for wood springing back. When wood tension is released, the limb could spring back and strike the operator, causing severe injury or death.

When sawing logs supported on both ends, start the cut from above (Y) (overbuck) about 1/3 of the diameter into the log, and then finish the cut (Z) from below, in order to avoid contact of the chainsaw with the ground.

When sawing logs supported on only one end, start the cut from below (Y) about 1/3 of the diameter into the log (underbuck) and finish the cut from above (Z) in order to avoid log splitting or jamming of the chainsaw.

SAW MAINTENANCE

Follow maintenance instructions in this manual. Proper cleaning of the saw and chain, and Guide Bar maintenance can reduce the chances of kickback. Inspect and maintain the saw after each use. This will increase the service life of your saw.

NOTE: Even with proper sharpening, the risk of kickback can increase with each sharpening.

MAINTENANCE AND STORAGE OF CHAIN SAW

If the replacement of the supply cord is necessary, this has to be done by the manufacturer or their agent in order to avoid a safety hazard.

- Unplug the chainsaw from the power source

- When not in use

- Before moving from one place to another

- Before servicing

- Before changing accessories or attachments, such as the saw chain and guard

- Inspect chainsaw before and after each use. Check carefully if the guard or other part has been damaged. Check for any damage that may affect operator safety or the operation of the saw. Check for alignment or binding of moving parts. Check for broken or damaged parts. Do not use a chainsaw if damage affects safety or operation. Have the damage repaired by an authorized service center. To locate an authorized service center, visit www.worx.com

- Maintain the chainsaw with care.

- Never expose the saw to rain or direct moisture.

- Keep the chain sharp, clean, and lubricated for better and safer performance.

- Follow the steps outlined in this manual to sharpen the chain.

- Keep handles dry, clean, and free of oil and grease.

- Keep all screws and nuts tight.

- Inspect the power cord often. If damaged, have it repaired by an authorized service center.

- Never carry a chainsaw by its power cord.

- Never yank the power cord to unplug it.

- Keep the power cord away from heat, oil, and sharp edges.

- Inspect extension cords often and replace them if damaged.

- When servicing, use only identical replacement parts.

- When not in use, always store the chainsaw

- In a high or locked place, out of children’s reach

- In a dry place

- With the Bar and Chain Storage Cover (21) in place

Bar Maintenance

To maximize bar life, the following bar maintenance is recommended. The bar rails that carry the chain should be cleaned before storing the tool, or if the bar or chain appears to be dirty. The rails should be cleaned every time the chain is removed.

To clean the Bar rails:

- Remove the chain cover and bar, and chain. (See section ASSEMBLY)

- Using a wire brush, screwdriver, or similar tool, clear the residue from the inner groove of the bar. (See Fig. M)

- Make sure to clean oil passages thoroughly.

Conditions which require Chain (10) and Guide Bar (9) maintenance:

- Saw cuts to one side or at an angle.

- The saw has to be forced through the cut.

- Inadequate supply of oil to the bar and chain.

Check the condition of the Guide Bar each time the chain is sharpened. A worn Guide Bar will damage the chain and make cutting difficult. After each use, with the unit disconnected from the power source, clean all sawdust from the Guide Bar and sprocket hole. When the rail top is uneven, use a flat file to restore square edges and sides.

Replace the Guide Bar when the groove is worn, the Guide Bar is bent or cracked, or when excess heating or burring of the rails occurs. If replacement is necessary, use only the Guide Bar specified for your saw in the repair parts list or on the decal located on the chainsaw.

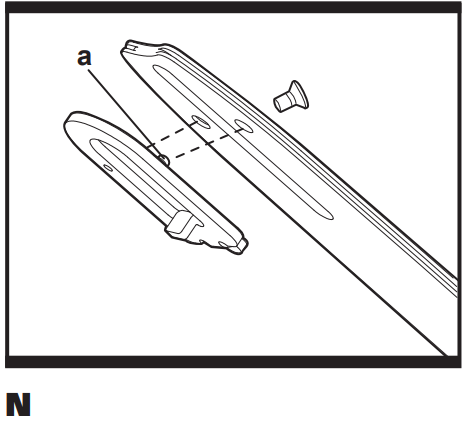

Replacing Bar & Chain

Replace the chain when the cutters are too worn to sharpen or when the chain stops. Only use the replacement chain noted in this manual. Inspect the Guide Bar before sharpening the chain. A worn or damaged Guide Bar is unsafe. A worn or damaged Guide Bar will damage the chain. It will also make cutting harder. Turn the bar over, top rail becoming bottom and bottom rail becoming top, around every 5 hours of use. Fit the Bar Tensioning Plate (22) Tab into the new bar by tightening the screw clockwise. The tab protrusion (a) must be fitted into the bar hole. (See Fig. N)

Sharpening Saw Chain

WARNING: Unplug chainsaw from the power source before servicing. Severe injury or death could occur from electrical shock or body contact with the moving chain. Cutting edges on the chain are sharp. Use protective gloves when handling the chain.

Keep the chain sharp. Your saw will cut faster and more safely. A dull chain will cause undue sprocket, Guide Bar, chain, and motor wear. If you must force the chain into wood and cutting creates only sawdust with a few large chips, the chain is dull.

Lubricate Sprocket

WARNING: Wear heavy-duty gloves when performing any maintenance or service to this tool. Always unplug the tool before performing any service or maintenance on this tool.

NOTE: It is not necessary to remove the chain or bar when lubricating the guide bar sprocket.

- Clean the bar and sprocket.

- Using a grease gun, insert the tip of the gun into the lubrication hole and inject grease until it appears at the outside edge of the sprocket tip. (See Fig. O)

- To rotate the sprocket, pull the chain by hand until the ungreased side of the sprocket is in line with the grease hole. Repeat the lubrication procedure.

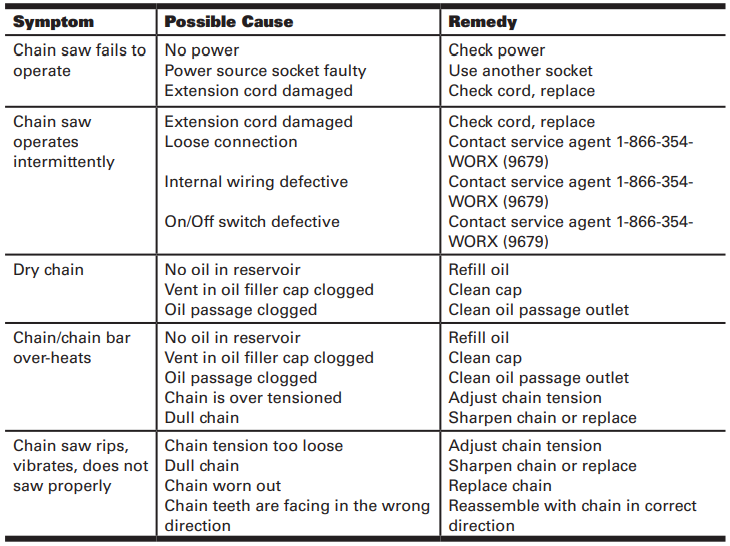

TROUBLESHOOTING TABLE

The following table gives checks and actions that you can perform if your machine does not operate correctly. If these do not identify/remedy the problem, contact your service agent.

WARNING: Switch off and remove plug from power source before investigating fault.

For More Manuals By WORX, Visit ManualsLibraryy.

WORX Tools WG305 Electric Chain Saw-FAQs

What is an electric chainsaw used for?

An electric chainsaw is ideal for trimming branches, cutting firewood, or handling fallen trees. It delivers consistent power with less maintenance compared to gas models.

How do I operate the WORX WG305 chainsaw safely?

Plug the saw into a power source, hold it with both hands, disengage the chain brake, and press the trigger to start cutting. Always maintain a firm stance and use protective gear.

How should I maintain my electric chainsaw?

Keep the chain sharp, clean the guide bar, check chain tension regularly, and refill the bar oil before each use for smooth operation.

What oil should I use for my WORX WG305?

Always use bar and chain oil. It is specially designed to lubricate and protect the chain and guide bar, preventing wear and overheating.

How often does the chain need sharpening?

Sharpen the chain whenever you notice fine sawdust instead of wood chips, or if cutting feels slow. Typically, a chain can be sharpened up to 10 times before replacement.

Why is my chainsaw not cutting properly?

A dull chain, lack of lubrication, or incorrect chain tension are common reasons. Re-sharpen the chain, check oil flow, and adjust the tension as needed.

How do I adjust the chain tension?

Loosen the bar nuts slightly, turn the tensioning screw until the chain is snug but still moves freely, then re-tighten the nuts securely.

What safety tips should I follow when using the WG305?

Always wear gloves, eye and ear protection, keep both feet firmly planted, and never operate the chainsaw above shoulder height or when the chain is moving at idle.