Delta 22-540 12-inch Portable Planer

SAFETY RULES

- FOR YOUR OWN SAFETY, READ THE INSTRUCTION MANUAL BEFORE OPERATING THE TOOL. Learn the tool’s application and limitations as well as the specific hazards peculiar to it.

- KEEP GUARDS IN PLACE and in working order.

- ALWAYS WEAR EYE PROTECTION.

- REMOVE ADJUSTING KEYS AND WRENCHES. Form the habit of checking to see that keys and adjusting wrenches are removed from tool before turning it “on”.

- KEEP WORK AREA CLEAN. Cluttered areas and benches invite accidents.

- DON’T USE IN DANGEROUS ENVIRONMENT. Don’t use power tools in damp or wet locations, or expose them to rain. Keep the work area well-lit.

- KEEP CHILDREN AND VISITORS AWAY. All children and visitors should be kept at a safe distance from the work area.

- MAKE WORKSHOP CHILDPROOF – with padlocks, master switches, or by removing starter keys.

- DON’T FORCE TOOL. It will do the job better and be safer at the rate for which it was designed.

- USE THE RIGHT TOOL. Don’t force a tool or attachment to do a job for which it was not designed.

- WEAR PROPER APPAREL. No loose clothing, gloves, neckties, rings, bracelets, or other jewelry to get caught in moving parts. Nonslip footwear is recommended. Wear a protective hair covering to contain long hair.

- ALWAYS USE SAFETY GLASSES. Wear safety glasses. Every day eyeglasses only have impact-resistant lenses; they are not safety glasses. Also, use a face or dust mask if the cutting operation is dusty. These safety glasses must conform to ANSI Z87.1 requirements. Note: Approved glasses have Z87 printed or stamped on them.

- SECURE WORK. Use clamps or a vise to hold work when practical. It’s safer than using your hand and frees both hands to operate the tool.

- DON’T OVERREACH. Keep proper footing and balance at all times.

- MAINTAIN TOOLS IN TOP CONDITION. Keep tools sharp and clean for the best and safest performance. Follow instructions for lubricating and changing accessories.

- DISCONNECT TOOLS before servicing and when changing accessories such as blades, bits, cutters, etc.

- USE RECOMMENDED ACCESSORIES. The use of accessories and attachments not recommended by Delta may cause hazards or risk of injury to persons.

- REDUCE THE RISK OF UNINTENTIONAL STARTING. Make sure the switch is in the “OFF” position before plugging in the power cord.

- NEVER STAND ON A TOOL. Serious injury could occur if the tool is tipped or if the cutting tool is accidentally contacted.

- CHECK DAMAGED PARTS. Before further use of the tool, a guard or other part that is damaged should be carefully checked to ensure that it will operate properly and perform its intended function – check for alignment of moving parts, binding of moving parts, breakage of parts, mounting, and any other conditions that may affect its operation. A guard or other part that is damaged should be properly repaired or replaced.

- DIRECTIONS OF FEED. Feed work into a blade or cutter against the direction of rotation of the blade or cutter only.

- NEVER LEAVE A TOOL RUNNING UNATTENDED. TURN POWER OFF. Don’t leave the tool until it comes to a complete stop.

- DRUGS, ALCOHOL, MEDICATION. Do not operate the tool while under the influence of drugs, alcohol, or any medication.

- MAKE SURE TOOL IS DISCONNECTED FROM POWER SUPPLY while motor is being mounted, connected, or re-connected.

- THE DUST GENERATED by certain woods and wood products can be injurious to your health. Always operate machinery in well-ventilated areas and provide for proper dust removal. Use wood dust collection systems whenever possible.

- WARNING: SOME DUST CREATED BY POWER SANDING, SAWING, GRINDING, DRILLING, AND OTHER CONSTRUCTION ACTIVITIES contains chemicals known to cause cancer, birth defects, or other reproductive harm. Some examples of these chemicals are:

- lead from lead-based paints,

- crystalline silica from bricks, cement, and other masonry products, and

- Arsenic and chromium from chemically-treated lumber.

Your risk from these exposures varies, depending on how often you do this type of work. To reduce your exposure to these chemicals: work in a well-ventilated area, and work with approved safety equipment, such as those dust masks that are specially designed to filter out microscopic particles.

SAVE THESE INSTRUCTIONS. Refer to them frequently and use them to instruct other users.

GROUNDING INSTRUCTIONS

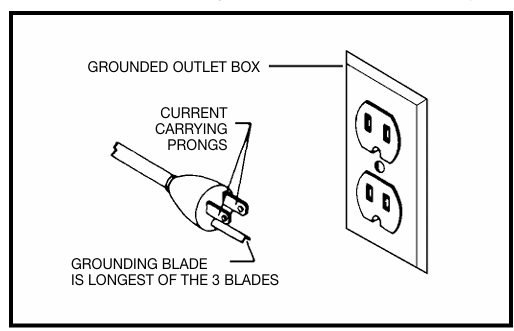

- All grounded, cord-connected machines: In the event of a malfunction or breakdown, grounding provides a path of least resistance for electric current to reduce the risk of electric shock. This machine is equipped with an electric cord having an equipment-grounding conductor and a grounding plug. The plug must be plugged into a matching outlet that is properly installed and grounded in accordance with all local codes and ordinances. Do not modify the plug provided – if it will not fit the outlet, have the proper outlet installed by a qualified electrician. Improper connection of the equipment-grounding conductor can result in the risk of electric shock. The conductor with insulation having an outer surface that is green with or without yellow stripes is the equipment grounding conductor. If repair or replacement of the electric cord or plug is necessary, do not connect the equipment-grounding conductor to a live terminal. Check with a qualified electrician or service personnel if the grounding instructions are not completely understood, or if in doubt as to whether the machine is properly grounded. Use only 3-wire extension cords that have 3-prong grounding type plugs and matching 3-conductor receptacles that accept the machine’s plug, as shown in Fig. A. Repair or replace damaged or worn cords immediately.

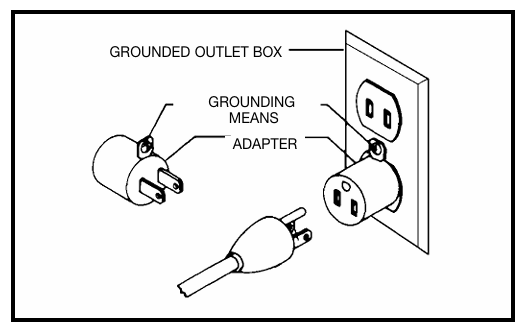

- Grounded, cord-connected machines intended for use on a supply circuit having a nominal rating less than 150 volts: If the machine is intended for use on a circuit that has an outlet that looks like the one illustrated in Fig. A, the machine will have a grounding plug that looks like the plug illustrated in Fig. A. A temporary adapter, which looks like the adapter illustrated in Fig. B, may be used to connect this plug to a matching 2-conductor receptacle as shown in Fig. B if a properly grounded outlet is not available. The temporary adapter should be used only until a properly grounded outlet can be installed by a qualified electrician. The green-colored rigid ear, lug, and the like, extending

from the adapter must be connected to a permanent ground such as a properly grounded outlet box. Whenever the adapter is used, it must be held in place with a metal screw.

NOTE: In Canada, the use of a temporary adapter is not permitted by the Canadian Electric Code. - 240 VOLT SINGLE PHASE OPERATION

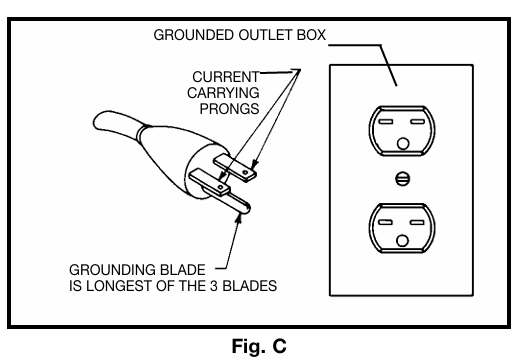

The motor supplied with your machine is a dual-voltage, 120/240-volt motor. It is shipped ready-to-run for 120-volt operation. However, it can be converted for 240-volt operation. A qualified electrician should do the conversion, or the machine can be taken to an Authorized Delta Service Center. When completed, the machine must conform to the National Electric Code and all local codes and ordinances. The machine is converted by re-wiring the motor for 240 volts, installing a 240-volt plug on the power supply cord, and replacing the switch with one that is rated for 240-volt operation. Be sure the 240-volt plug is only used in an outlet having the same configuration as the plug illustrated in Fig. C. No adapter should be used with the 240-volt plug.

EXTENSION CORDS

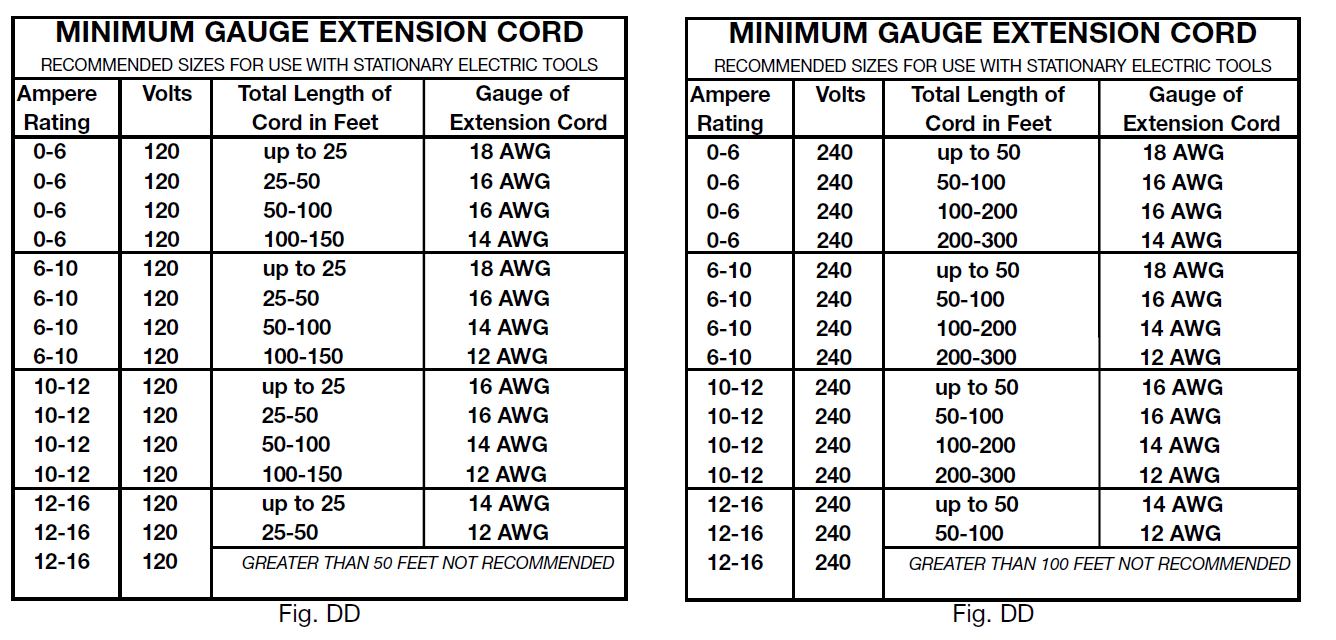

WARNING: Use proper extension cords. Make sure your extension cord is in good condition and is a 3-wire extension cord that has a 3-prong grounding type plug and a matching receptacle that will accept the machine’s plug. When using an extension cord, be sure to use one heavy enough to carry the current of the machine. An undersized cord will cause a drop in line voltage, resulting in loss of power and overheating. Fig. D-1 or D-2 shows the correct gauge to use depending on the cord length. If in doubt, use the next heavier gauge. The smaller the gauge number, the heavier the cord.

UNPACKING AND CLEANING

Carefully unpack the tool and all loose items from the shipping container(s). Peel protective film from the table surface. Remove and clean the protective coating from the cutterhead. Remove the protective coating from all unpainted surfaces. This coating may be removed with a soft cloth moistened with kerosene (do not use acetone, gasoline, or lacquer thinner for this purpose). After cleaning, cover the unpainted surfaces with a good-quality paste wax.

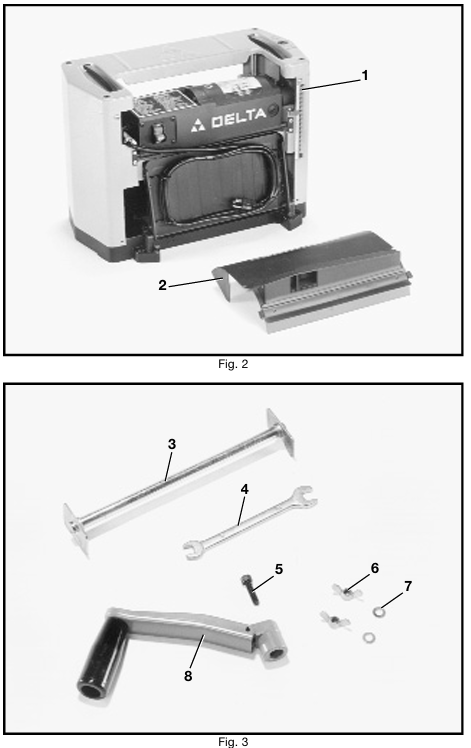

CAUTION: CARE MUST BE TAKEN WHEN CLEANING THE CUTTERHEAD, AS THE KNIVES ARE SHIPPED IN THE CUTTERHEAD AND THEY ARE VERY SHARP. Figs. 2 and 3, ILLUSTRATE THE PLANER AND ALL LOOSE ITEMS SUPPLIED WITH THE MACHINE.

- 12 Planer

- Chip Deflector

- Knife Setting Gauge

- 8mm and 10mm Open-End Wrench

- M5 x 20mm Hex Socket Head Screw

- M5 Wing Nut (2)

- M5 Flat Washer (2)

- Elevating Handle

ASSEMBLY INSTRUCTIONS

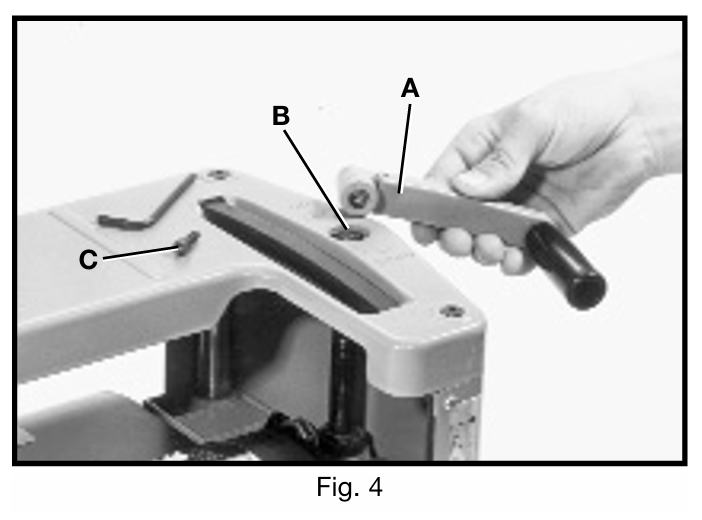

ASSEMBLING RAISING AND LOWERING HANDLE

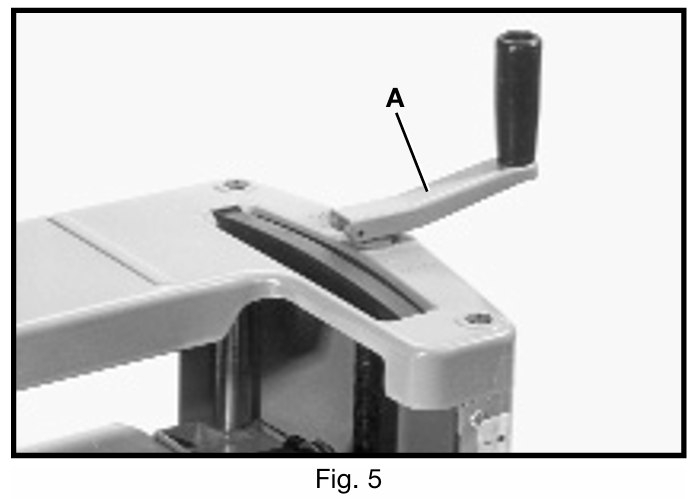

- Assemble the raising and lowering handle (A), Fig. 4, to the shaft (B) and fasten in place with the screw (C).

NOTE: Make certain the flats of the handle and the flat on the shaft are aligned with each other. - Flip the handle (A) upward as shown in Fig. 5.

LOWERING EXTENSION TABLES

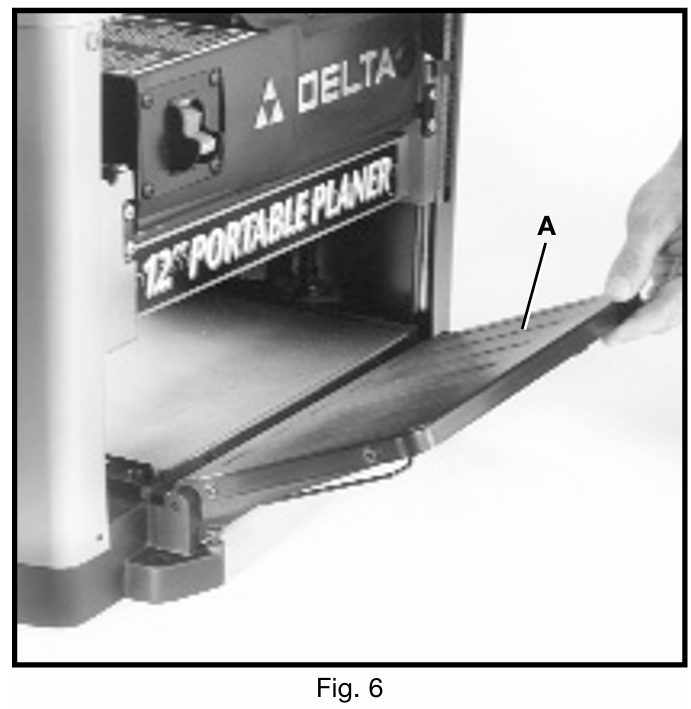

The infeed and outfeed extension tables (A) Fig. 6, are shipped attached to the machine in the raised position. Lower the tables (A) on both sides of the planer as shown in Fig. 6. The top surface of the extension tables should be level with the planer table. To check and adjust if necessary, refer to section “LEVELING EXTENSION TABLES” of this manual.

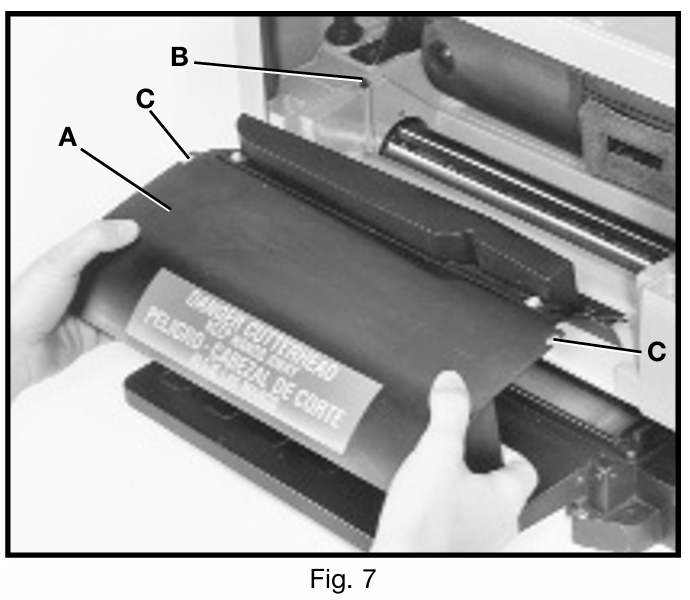

ASSEMBLING CHIP DEFLECTOR

- Assemble the chip deflector (A) Fig. 7, to the planer by inserting the end of the chip deflector over the top of the cutterhead. Make certain the two screws, one of which is shown at (B) are inserted upward through the two slots (C) in the chip deflector.

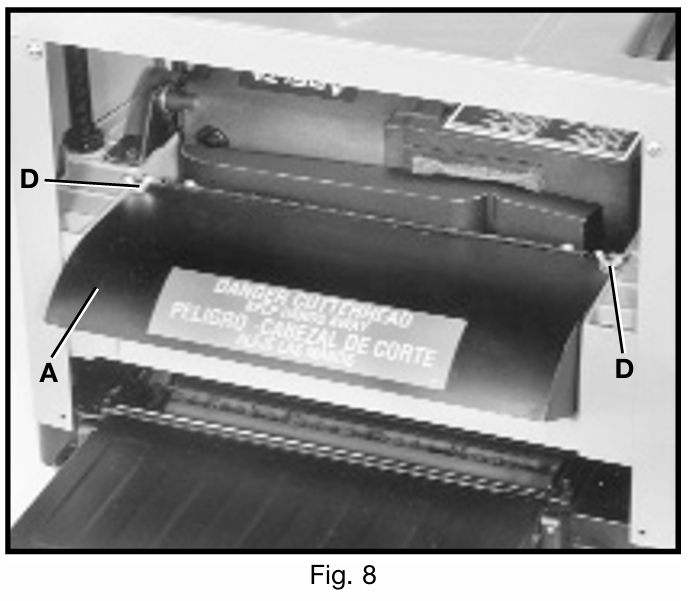

- Fasten the chip deflector (A) Fig. 8, to the planer using two flat washers and wing nuts (D).

FASTENING PLANER TO SUPPORTING SURFACE

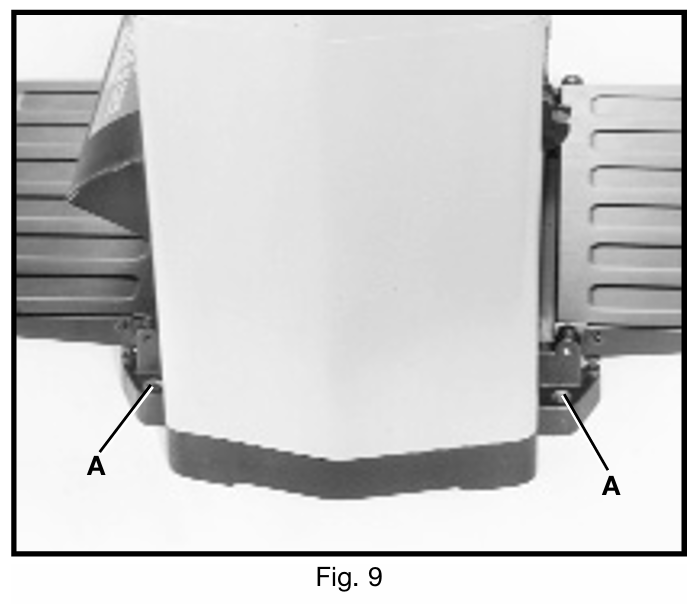

During operation, if there is any tendency for the planer to tip over, slide or “walk” across the supporting surface, the planer must be secured to the supporting surface through the four holes in the base, two of which are shown at (A) Fig. 9.

OPERATING CONTROLS AND ADJUSTMENTS

STARTING AND STOPPING PLANER

The “ON/OFF” switch (A), Fig. 13, is located on the front of the planer motor. To turn the machine “ON”, move the switch toggle (B) to the up position. To turn the switch “OFF”, move the switch toggle (B) to the down position.

LOCKING SWITCH IN THE “OFF” POSITION

IMPORTANT: When the tool is not in use, the switch should be locked in the “OFF” position to prevent unauthorized use. Grasp the switch toggle (B) and pull it out as shown in Fig. 14. With the switch toggle removed, the switch will not operate. However, should the switch toggle (B), Fig. 14, be removed while the machine is running, the switch (A) can be turned “OFF” once, but cannot be restarted without reinserting the switch toggle.

RAISING AND LOWERING HEAD ASSEMBLY

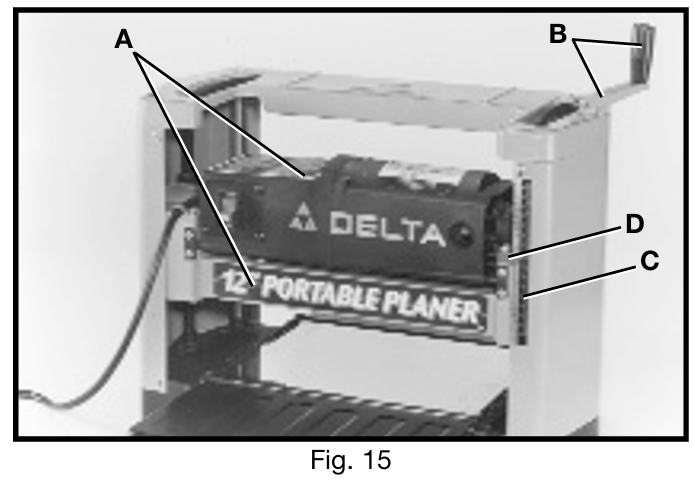

The head assembly (A), Fig. 15, contains the cutterhead feed rolls, chip deflector and motor. Raising and lowering the head assembly controls the depth of cut on your planer. To raise or lower the head assembly, rotate the raising and lowering handle (B).

NOTE: One revolution of the handle will move the cutterhead up or down approximately 5/64. An English/metric scale (C) and pointer (D) is located on the side of the planer for ease in setting the height of the cutterhead.

RECOMMENDED DEPTH-OF-CUT

A dual English/Metric scale and pointer, located at the right front of the machine, indicates the thickness of the workpiece.

NOTE: One revolution of the raising and lowering handle (B), Fig. 15, will move the cutterhead up or down 5/64 . A 3/32 depth-of-cut can be made in soft woods on stock 8 wide and in hard woods on stock up to 7 wide. See chart Fig. 16. For 10 and 12 wide soft wood, we recommend a maximum

depth-of-cut of 1/16. For 10 and 12-wide hardwood, a maximum depth-of-cut of 3/64 is recommended.

IMPORTANT: A 3/32 DEPTH-OF-CUT CAN BE MADE IN 10 AND 12-WIDE SOFT AND HARD WOODS. HOWEVER, CONTINUOUS OPERATION AT THIS CUTTING DEPTH CAN CAUSE PREMATURE MOTOR FAILURE.

LEVELING EXTENSION TABLES

For optimum performance, the extension tables, one of which is shown at (A) Fig. 17, must be level with the planer table. To check the extension tables and adjust if necessary, proceed as follows:

- Place a straight edge (B), Fig. 17, on the infeed extension table (A) with one end extending out over the extension table as shown. Check to see if the infeed table is level with the planer table on both ends of the extension table.

- If an adjustment is necessary, loosen locknut (C) Fig. 17, and adjust stop screw (D) on each side of the extension table (A) until the extension table is level with the planer table (E); then tighten locknut (C). Recheck and make certain the inside edge of the table extension is perfectly level with the planer table. If necessary, loosen two screws (F), adjust the extension table, and retighten two screws (F). Adjust the opposite side of the table in the same manner. Make certain the extension table is solidly supported when there is downward pressure on the table.

- Check and adjust the outfeed extension table in the same manner.

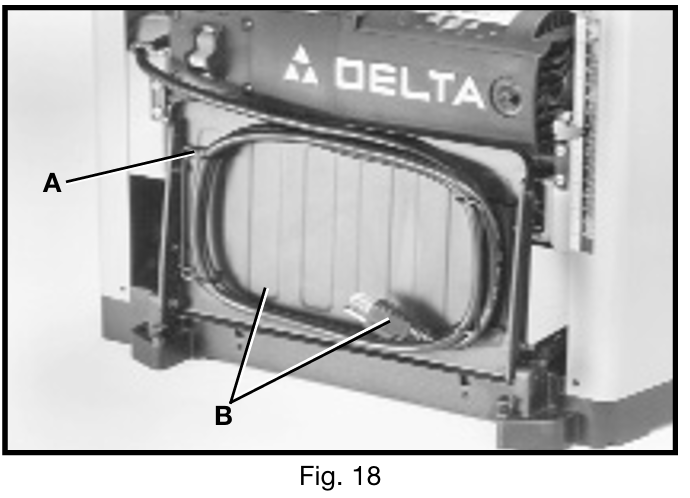

STORING THE POWER CORD

Wire hangers (A), Fig. 18, are provided on the underside of the outfeed extension table as shown, to store the power cord (B) when the planer is not in use and when transporting the machine.

ADJUSTING KNIVES

To check and adjust the knives, proceed as follows:

- DISCONNECT THE TOOL FROM THE POWER SOURCE.

- Lower the head assembly by turning the handle (B). Fig. 15.

- Remove chip deflector (A) Fig. 19.

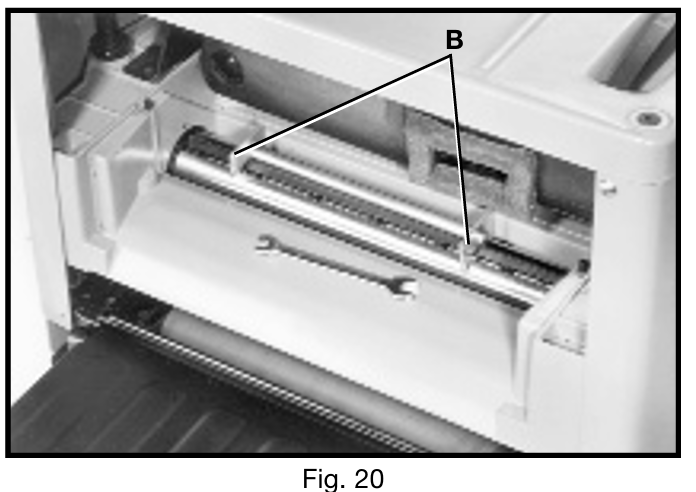

- Carefully place the knife setting gauge (B), Fig. 20, on the cutterhead so the rounded sections are directly over the knife as shown. When adjusted correctly, the knife should just contact the bottom of the center portion at each end of gauge (B). Check the other knife in the same manner.

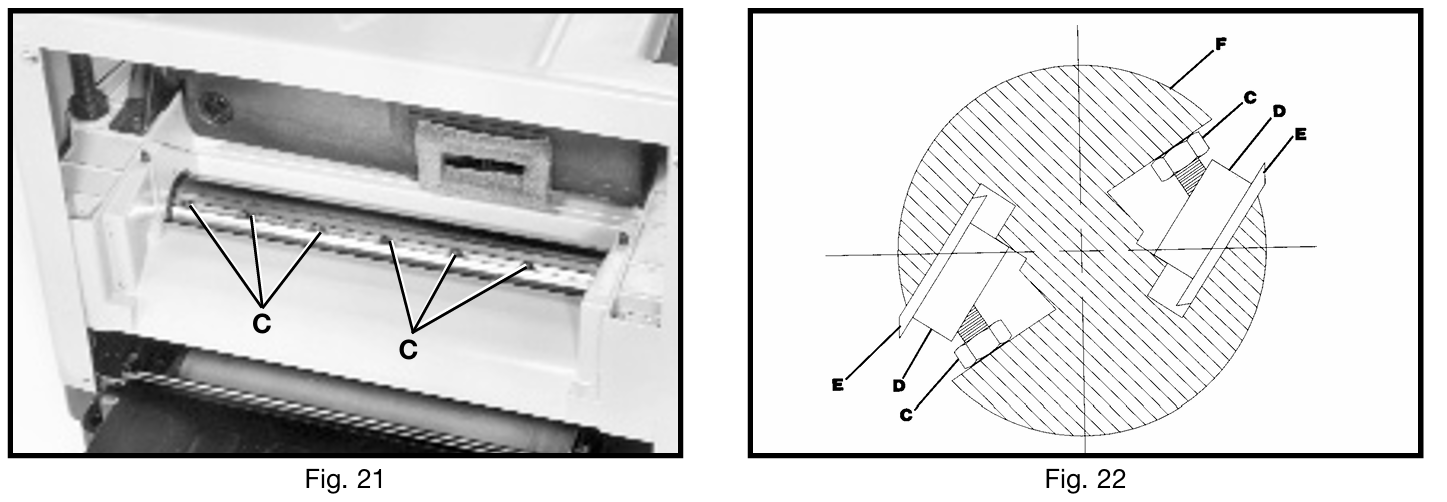

- If an adjustment to one or both knives is necessary, slightly loosen the seven locking screws, six of which are shown at (C) Fig. 21, by turning the screws CLOCKWISE into the knife locking bar just enough to relieve stress in the cutterhead and not disturb the knife setting.

- With setting gage (B) Fig. 20, in place, apply pressure to the knife being reset. Turn the seven knife locking screws (C) Fig. 21, CLOCKWISE until the knife locking bar becomes loose. Lift springs will automatically raise the knife until it comes in contact with gage (B) Fig. 20. Snug the knife locking bar by lightly turning the seven locking screws (C) Fig. 21, COUNTERCLOCKWISE. IMPORTANT: AT THIS TIME, ONLY TIGHTEN THE KNIFE LOCKING BAR JUST ENOUGH TO HOLD THE KNIFE IN POSITION INSIDE THE CUTTERHEAD SLOT.

- If the other knife needs adjustment, repeat STEP 6.

- After both knives are positioned in the cutterhead, turn each of the seven screws, six of which are shown at (C) Fig. 21, COUNTERCLOCKWISE until the knife is secure in the cutterhead.

NOTE: When tightening knife locking screws, tighten the end screws first, then inward toward the center of the cutterhead. - Replace chip deflector (A) Fig. 19.

OPERATIONS

When using your machine, you may want to follow these few simple steps for achieving the best results possible.

- Cross-cut to Length – Cross-cut rough lumber to length.

- True Up One Face – Feed one face of the board over a Jointer, making thin cuts with each pass, until the entire surface is flat.

- Plane to Thickness – Place the side you just surfaced in STEP 2 face down and feed the board through the Planer, as shown in Figs. 24 and 25. Plane both sides of the board until you are satisfied with the thickness, making thin cuts with each pass. If during the planning operation you notice the board twisting, warping or bowing, repeat STEP 2 and true up one face.

- When planning long stock, provide auxiliary tables or rollers to support the infeed and outfeed ends of the workpiece.

- For best results, plane with the wood grain only, and keep the planer table clean. Occasionally, wax the table surface to reduce friction during the planing operation.

MAINTENANCE

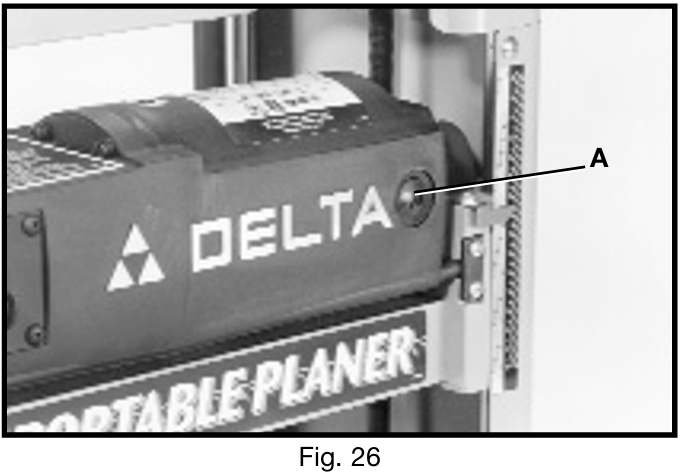

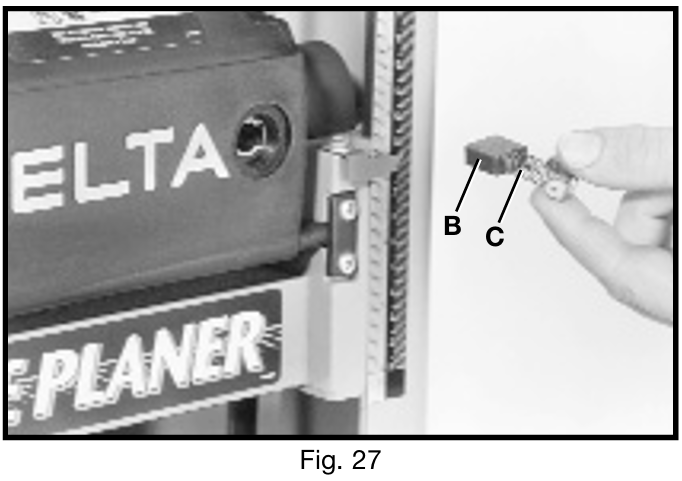

BRUSH INSPECTION AND REPLACEMENT

CAUTION: BEFORE INSPECTING THE BRUSHES, DISCONNECT THE TOOL FROM THE POWER SOURCE.

Brush life varies. It depends on the load on the motor. Check the brushes after the first 50 hours of use for a new machine or after a new set of brushes has been installed. After the first check, examine them after about 10 hours of use until such time that replacement is necessary. The brush holders, one of which is shown at (A) Fig. 26, are located on the motor housing opposite each other. Fig. 27 illustrates one of the brushes removed for inspection. When the carbon (B) on either brush is worn to 3/16 in length or if either spring (C) or shunt wire is burned or damaged in any way, replace both brushes. If the brushes are found serviceable after removal, reinstall them in the same position as removed.

LUBRICATION

The gears in the gearbox and the feed roller bushings should be lubricated periodically, as follows:

- DISCONNECT THE TOOL FROM THE POWER SOURCE.

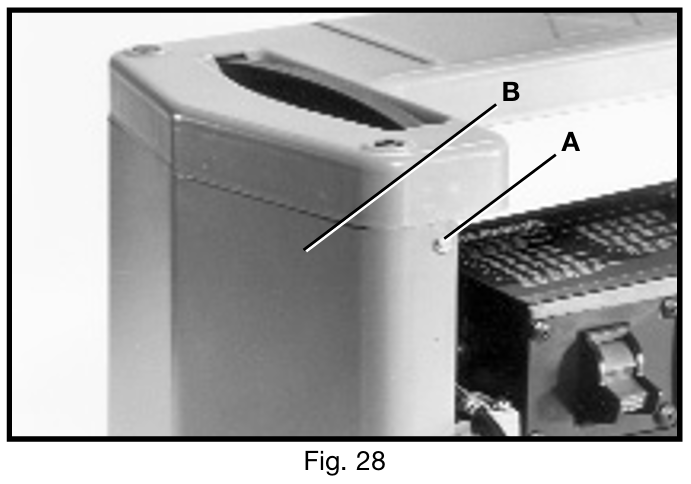

- Remove screw (A), Fig. 28, and the nut located on the other end of the screw. Remove the side cover (B) from the left side of the planer.

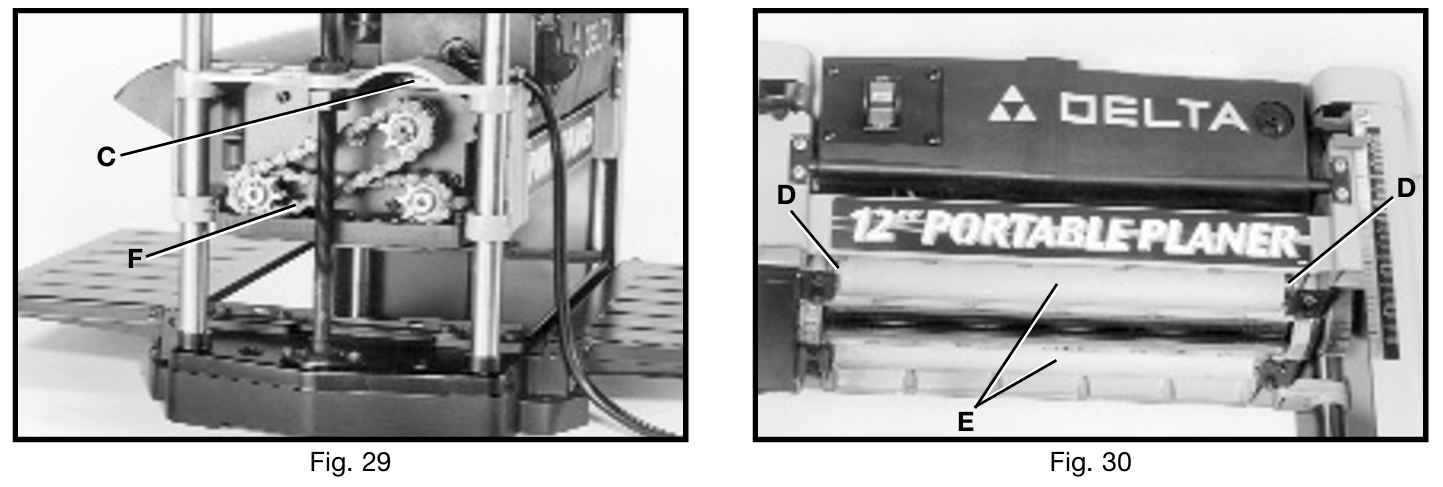

- Place a light coat of E.P. multi-purpose grease on the teeth of the large gear (C), Fig. 29, and a light coat of spray lubricant on the chains (F). Replace the side cover.

- Lay the planer on its back and squirt oil on the feed roller bushings (D) Fig. 30, at each end of the feed rolls (E).

ACCESSORIES

A complete line of accessories is available from your Delta Supplier, Porter-Cable · Delta Factory Service Centers, and Delta Authorized Service Stations. Please visit our website www.deltamachinery.com for a catalog or for the name of your nearest supplier.

WARRANTY

Two-Year Limited New Product Warranty

Delta will repair or replace, at its expense and at its option, any new Delta machine, machine part, or machine accessory which in normal use has proven to be defective in workmanship or material, provided that the customer returns the product prepaid to a Delta factory service center or authorized service station with proof of purchase of the product within two years and provides Delta with reasonable opportunity to verify the alleged defect by inspection. For all refurbished Delta products, the warranty period is 180 days. Delta may require that electric motors be returned prepaid to a motor manufacturer’s authorized station for inspection and repair or replacement. Delta will not be responsible for any asserted defect which has resulted from normal wear, misuse, abuse or repair or alteration made or specifically authorized by anyone other than an authorized Delta service facility or representative. Under no circumstances will Delta be liable for incidental or consequential damages resulting from defective products. This warranty is Delta’s sole warranty and sets forth the customer’s exclusive remedy with respect to defective products; all other warranties, express or implied, whether of merchantability, fitness for purpose, or otherwise, are expressly disclaimed by Delta.

For more manuals by Delta, visit ManualsLibraryy

Delta 22-540 12-inch Portable Planer-FAQs

How big is the Delta 22-540 planer?

It has a 12-inch cutting width, 6-inch thickness capacity, and up to 3/16-inch depth of cut per pass.

What is the minimum thickness it can handle?

The planer can cut boards down to about 1/8 inch (3.2 mm).

How do I change the cutting blades?

Unplug the planer, remove the blade cover, loosen the screws, replace the blades, and tighten securely before use.

What type of blades does it use?

It uses high-speed steel (HSS) knives, designed for durability and smooth cutting.

What is snipe on a planer?

Snipe is a deeper cut at the start or end of a board caused by uneven roller pressure. Proper support helps reduce it.

How thin can a planer cut wood?

Most planers, including this one, are safe down to about 1/4 inch thickness without special jigs.

Can I run a 2×4 through the Delta 22-540?

Yes, but make sure it is properly supported to avoid twisting or uneven cuts.

How much wood can it remove in one pass?

It can remove up to 3/16 inch, but multiple shallow passes are recommended for smoother results.

How do I maintain the planer?

Clean dust regularly, keep blades sharp, lubricate moving parts, and check rollers for wear.